Contents

1General ................................... 3

2Safety .................................... 4

2.1 Used symbols ............................... 4

2.2 Hazard potential of profile rail slides .............. 5

2.3 Designateduse ............................. 5

2.4 Authorized personnel ......................... 6

2.5 General safety advise ......................... 6

2.6 Transport and interim storage . . . . . . . . . . . . . . . . . . 8

2.7 Electricalsafety ............................. 9

2.8 Exclusion of liability . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3Accuracies ................................. 10

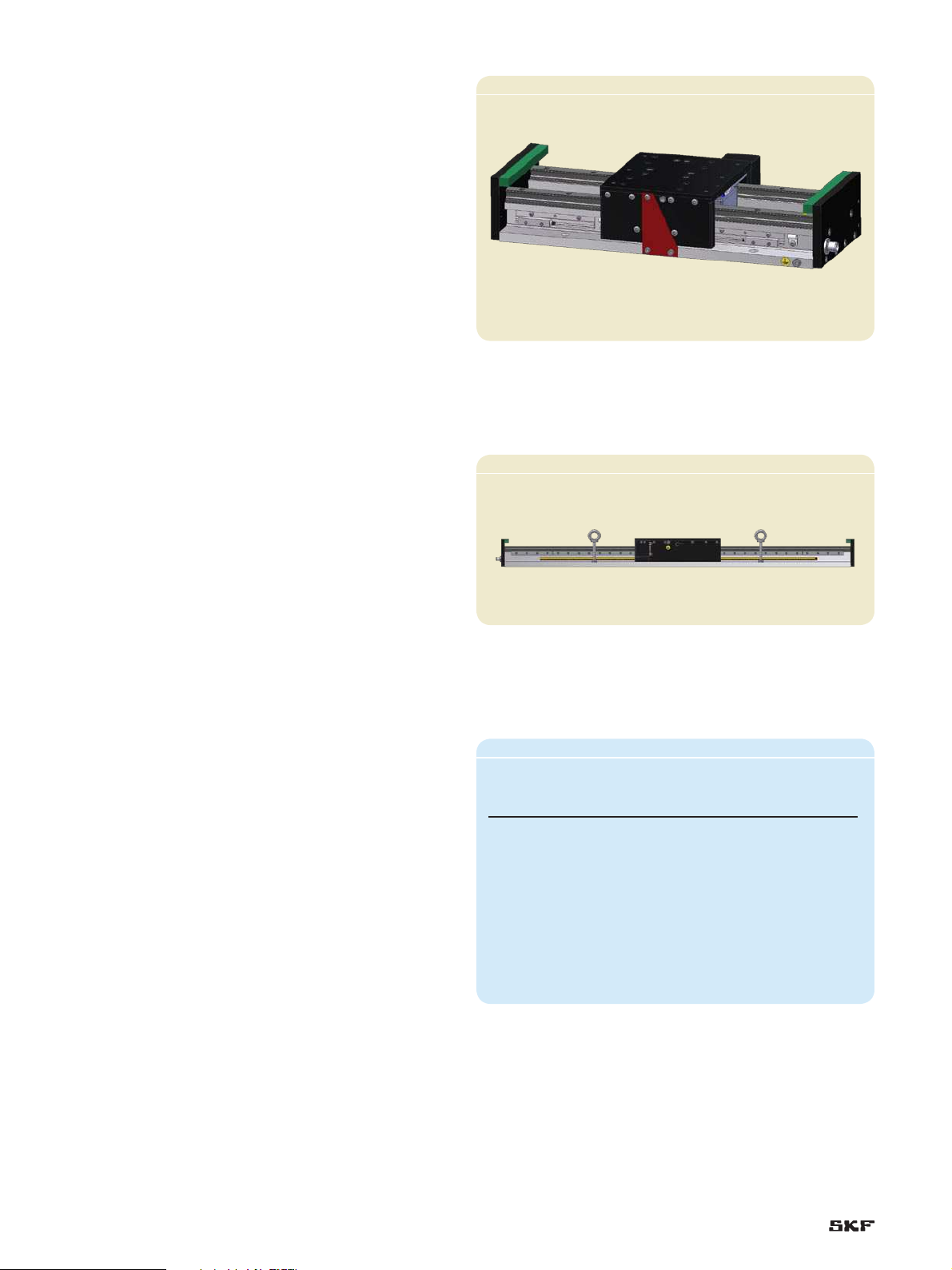

4Product description . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.1 Design (exploded drawing) ..................... 11

4.2 Dimension tables ............................ 12

4.3 Load carrying capacity of slide tops . . . . . . . . . . . . . . 15

5Technical data .............................. 16

5.1 Motor ..................................... 16

5.2 DC link voltage 515 V DC . . . . . . . . . . . . . . . . . . . . . . 18

5.3 DC link voltage 600 V DC . . . . . . . . . . . . . . . . . . . . . . 21

5.4 Motor temperature sensor ..................... 24

5.5 Linear encoder .............................. 25

5.6 Limitswitches .............................. 26

6Accessories ................................ 27

6.1 Bellows ................................... 27

6.2 Energy chain with mounting bracket . . . . . . . . . . . . . 27

6.3 Cables .................................... 29

7Mounting instructions according to

directive 2006/42/EC, appendix VI ................ 30

7.1 Mechanical interfaces ......................... 30

7.2 Electrical interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.2.1 Pin configuration . . . . . . . . . . . . . . . . . . . . . . . . 33

7.2.2 Connection of protective conductors.......... 34

7.3 Start up ................................... 35

7.3.1 Preconditions ........................... 35

7.3.2 Commissioning with a servo amplifier . . . . . . . . 35

8Maintenance and repairs . . . . . . . . . . . . . . . . . . . . . . 36

8.1 Preventive maintenance ....................... 36

8.2 Lubrication ................................. 36

8.3 Relubrication................................ 37

8.4 Cleaning the measuring scale ................... 37

8.5 Repairs .................................... 37

9Ordercode ................................ 38

10 Declaration of incorporation .................... 39

The SKF brand now stands for more

than ever before, and means more

to you as a valued customer.

While SKF maintains its leadership as a

high-quality bearing manufacturer

throughout the world, new dimensions

in technical advances, product support

and services have evolved SKF into a

truly solutions-oriented supplier,

creating greater value for customers.

These solutions enable customers to

improve productivity, not only with

breakthrough application-specific prod-

ucts, but also through leading-edge

design simulation tools and consultancy

services, plant asset efficiency mainte-

nance programmes, and the industry’s

most advanced supply management

techniques.

The SKF brand still stands for the very

best in rolling bearings, but it now

stands for much more.

SKF – the knowledge engineering

company