Battenfeld UNIROB R10S User manual

User´s Manual

UNIROB R10S - UNILOG B4

Version: R104GBV00 04/04

Read this manual before using the control system

and keep it in a place near the control system

Battenfeld GmbH

Scherl 10 • D-58527 Meinerzhagen

Tel. ++49 2354/72-0 • Fax ++49 2354/72-234

Battenfeld Kunststoffmaschinen Ges.m.b.H.

Wr.Neustädter Straße 81 • A - 2542 Kottingbrunn

Tel. ++43 2252/404-0 • Fax ++43 2252/404-261

www.battenfeld.com

DIN EN ISO 9001

Spritzgießtechnik

R104GBD2B.PMD

Contents

A: R104GBI3C.PMD

B: R104DEI3C.PMD

E: 140404 / TCS

G: 150404 / T. Wenger

Section - I

Page 1

0 Forward

UNILOG B4 control system

Operation and Control System

Screen functions

Menus

Screen functions

1 Menu pages - General

General menu pages - General

Language / Date and Time

Job data

Print

Data Manager

2 Status pages

Robot status

Position variable status page

User Variable Status page

Pneumatic axes status

Gripper status

IMM status

Periphery status

PAL status

3 Program editor

Program editor

4 Inserting a token command

(Axis command)

Inserting a

token command

Robot (ROB) token

commands

3D commands

Selecting axis movements with

position variables

Position variable selection list

Using position variables

Commands for pneumatic axis

movements

5 Gripper and IMM commands

Gripper (GRP) token

commands

Activate gripper function

Monitoring

IMM interface token commands

Signals from the IMM to the

robot system

6 PCS - Commands

Description of SPS commands

Creating a User variable

A: R104GBI3C.PMD

B: R104DEI3C.PMD

E: 140404 / TCS

G: 150404 / T. Wenger

Section - I

Page 2

Contents

7 Periphery

Description of peripheral

commands

Peripheral commands

Conveyor commands

8 Palletising program

Palletising program

Palletising program

commands

Entering palletising program

data

9 Programs

Programs

Subprogram selection

Parprogram selection

CNC selection

10 Examples of programs

Examples of programs

11 Service pages

Lock areas

Entering a lock area

Protection AREA

Auxiliary axis configuration

(pneumatic axes)

Gripper configuration

Peripheral interface

configuration

12 Troubleshooting

Alarm list

Logbook

Alarm protocol

Controller error

Peripheral commands

Operation and Control System

A: R104GB00A.PMD

B: R104DE00A.PMD

E: 290304 / TCS

G: 290304 / TCS

Section 0

Page 1

Forward

Who is this manual for?

This manual is intended for all persons involved

in the operation and monitoring of the robot

system.

They are responsible for ensuring that the robot

system runs smoothly. If a fault occurs they

should be able to search for signs of the cause

of the fault and call up key program sequences.

In order to do this it is necessary to be learn how

to use the control system. This manual explains

how to operate the control system safely.

What does the manual consist of?

In order to keep the manual as short and as

clear as possible it only deals with those

activities which you are able to do and are

authorised to carry out. Functions and

information relating to start-up procedures and

specific service activities can be found in a

separate service manual. The service manual is

only available to Battenfeld employees who are

trained for this work.

We start by looking at the various operating

features of the control system. The typical

operating sequence is presented using an

example. This is followed by a description of

each of the display menus.

As a rule the description always follows the

same pattern: After a brief introduction you are

given further explanations of the individual

parameters.

Intended use

The UNILOG B4 control system is designed for

operating and controlling robot systems. The

control system may only be operated by trained

specialists (e.g. set-up persons, service

technicians). The control system may not be

used for any other purpose.

Safety measures

This manual is a part of the technical

documentation relating to the robot system.

Before operating the control system you should

familiarise yourself with all the required safety

measures which are relevant to the operation of

the robot system.

A: R104GB00A.PMD

B:R104DE00A.PMD

E: 290304 / TCS

G: 130404 / T. Wenger

Section 0

Page 2

Operation and Control System

UNILOG B4 control system

Functions

The UNILOG B4 digital control system is a

newly developed UNILOG 9000. All the robot

system functions can be controlled using the

display menus, touch screen and keyboard. The

functions are divided into modules and activities.

Each menu can be directly selected by simply

pressing a key. The symbols provide quick

access the desired functions.

In Manual mode the control system uses

specific keys to activate the machine’s main

functions (drive and operating mode). Other key

and touch functions have other uses depending

upon the machine.

The control system is equipped with a

dustproof, easy-to-clean membrane keyboard.

The operator senses a special pressure point

each time a key is pressed.

Operation and Control System

A: R104GB00A.PMD

B: R104DE00A.PMD

E: 290304 / TCS

G: 290304 / TCS

Section 0

Page 3

Operating features

Manual Control Device (MCD) – Key

functions

1 – ON/OFF and START/STOP buttons

Press one of the two buttons to start/stop

the Automatic program. The START

button is also used to move the servo

axes in Manual mode after entering a

numerical value. Press STOP to interrupt

the movement. The red LED in the

STOP button lights up when the power is

deactivated or when the robot has been stopped

in Automatic mode.

2 - INIT button

Press the INIT button to switch to the

Start-up display. The orange LED

indicates that the Start-up display is

activated.

7

6

5

4

3

2

1

89

14

13

12

1110

R10B4_010.BMP

A: R104GB00A.PMD

B:R104DE00A.PMD

E: 290304 / TCS

G: 130404 / T. Wenger

Section 0

Page 4

Operation and Control System

3 - PROG button

Press the PROG button to switch to the

Program editor (from User level ”30”).

The orange LED indicates that the

Program editor is activated.

4 - ROB button

Press the ROB button to switch to the

Axis status page showing the status of

the main and auxiliary axes.

The orange LED belonging to this button lights

up when these pages are selected.

5 - SERVICE button

Press the SERVICE button to switch to

the corresponding Service page

depending upon which page has been

selected. (refer to ”Menus” in the handbook)

User level 30

6 - PERIPHERY button

Press the PERIPHERY button to switch

to the Periphery interface status page. It

displays all the input and output statuses

of this interface.

The orange LED belonging to this button lights

up when these pages are selected.

7 - Move buttons

These four buttons are

used for moving the

servo and auxiliary

axes. The two outer buttons (snail, hare) adjust

the servo axis overrides. The orange snail LED

lights up at 5% override and the orange hare

LED at 100%.

The arrow keys are only used for moving the

main and auxiliary axes. These buttons have

different functions on some of the other pages.

The LEDs light up wherever the arrow buttons

are in use.

8 - PAL button

Press the PAL button to switch to the

Palletising programs status page. The

orange LED for this button lights up when

the page is selected.

Operation and Control System

A: R104GB00A.PMD

B: R104DE00A.PMD

E: 290304 / TCS

G: 290304 / TCS

Section 0

Page 5

9 - Previous menus button

Press this button to scroll through the last

10 menus in reverse order.

10 - ERROR button

Press this button to switch to the Error

list. The red LED belonging to this button

lights up when an error occurs.

11 - Gripper button

Press this button to switch to the Gripper

status page. The orange LED for this

button lights up when the page is

selected.

12 - IMM button

Press the IMM button to display the IMM

interface status page in Manual mode.

The orange LED for this button lights up

when the page is selected.

13 - BLOCK/MAN button

Press this button to switch back and

forth between Manual mode (MAN) and

Blocks (BLOCK). It automatically

switches to MAN mode when the system is

switched ON/OFF. The right orange LED lights

up in MAN mode and the left orange LED in

BLOCK mode.

14 - AUTO/SINGLE

Press this button to switch from Manual

(MAN) to Automatic (AUTO) or Single

(SINGLE) mode. The left orange LED

indicates Single mode and the right LED

indicates Fully Automatic mode.

A: R104GB00A.PMD

B:R104DE00A.PMD

E: 290304 / TCS

G: 130404 / T. Wenger

Section 0

Page 6

Operation and Control System

Green START BUTTON on MCD

Press the START BUTTON to

activate the power supply (main

contactor).

EMERGENCY STOP BUTTON on MCD

The red Emergency Stop button is

intended to protect both the

machine and the machine

operators.

DEADMAN’S BUTTON

The DEADMAN’S button

must be pressed for every

movement.

Slam button

If it is pressed too hard the current movement is

stopped.

Use the arrow buttons to move

the selected axes.

Operation and Control System

A: R104GB00A.PMD

B: R104DE00A.PMD

E: 290304 / TCS

G: 290304 / TCS

Section 0

Page 7

Screen functions

1 User level

The current User level is displayed. The

key symbol changes to yellow when a

user is logged on.

2 Page number

Enter the desired page number to switch

to another display.

3 Page indicator

123 4 567 8 9

R10B4_017.BMP

The individual functions of the UNILOG B4

control system are activated with the aid of the

touch screen and the buttons on the manual

control device.

Screen display

A: R104GB00A.PMD

B:R104DE00A.PMD

E: 290304 / TCS

G: 130404 / T. Wenger

Section 0

Page 8

Operation and Control System

4 Status bar

The status according to the selected

page is displayed here. This bar is used

differently on each page.

5 PIC to DISK

Touch this symbol to create a *.bmp file

from the current page and store it on a

data carrier in the control system. (refer

to Section 5 Assembly and Operation)

6 ERROR symbol

This symbol flashes if an error has been

detected. Select this symbol to cancel all

current errors. (refer to Alarms)

7 Date and Time display

8 Operating mode

The robot system’s current operating

mode (AUTO, SINGLE, MAN, REF,

BLOCK) is displayed here. This section

of the screen is also used to indicate

whether or not the deadman’s button

has been pressed. A green background

indicates that the deadman’s button has

been activated.

9 Function keys

These six softkeys are used differently

on each page. They can be used to

switch between screens or for other

functions such as Delete, Load or Add.

The screen elements described in 1 – 10

(headings and function keys) are displayed in

the same way on all UNILOG B4 menu pages.

Operation and Control System

A: R104GB00A.PMD

B: R104DE00A.PMD

E: 290304 / TCS

G: 290304 / TCS

Section 0

Page 9

Password system (start-up display)

Menus

The manual control device has 10 screen

change buttons. Each of these buttons is

assigned to a fixed function / screen change.

FUNCTION: Save data

FUNCTION: Load data

FUNCTION: Save data to disk

FUNCTION: Delete

FUNCTION: Enter

FUNCTION: Cancel

List of users

Language / Date / Time

Notepad

Job data

Print

Data sets

Password system

Language / Date / Time

Notepad

Job data

Print

Data sets

List of users

Password system

Notepad

Job data

Print

Data sets

List of users

Language / Date / Time

Notepad

Password system

Print

Data sets

List of users

Language / Date / Time

Notepad

Job data

Password system

Data sets

A: R104GB00A.PMD

B:R104DE00A.PMD

E: 290304 / TCS

G: 130404 / T. Wenger

Section 0

Page 10

Operation and Control System

Sequential programming

Robot status

Auxiliary axes

Axis group 1

Axis group 2 (optional)

Axis group 3 (optional)

Axis group 4 (optional)

..

ROB status

Axis group 1

Axis group 2 (optional)

Axis group 3 (optional)

Axis group 4 (optional)

Axis group 5 (optional)

FUNCTION: Save data

FUNCTION: Load data

FUNCTION: Save data to disk

FUNCTION: Delete

FUNCTION: Enter

FUNCTION: Cancel

FUNCTION: Delete

..

..

FUNCTION: Insert

FUNCTION: Teach/Edit

Data sets

Operation and Control System

A: R104GB00A.PMD

B: R104DE00A.PMD

E: 290304 / TCS

G: 290304 / TCS

Section 0

Page 11

PalProg 1

PalProg 2

PalProg 3

PalProg 4

PalProg 5

PalProg . . .

Palletis. statistics (PalProg 1)

Gripper group 1

Gripper group 2 (optional)

Gripper group 3 (optional)

Gripper group 4 (optional)

Gripper group 5 (optional)

Gripper group 6 (optional)

Gripper status

FUNCTION: Quit

FUNCTION: Scroll +

FUNCTION: Scroll -

Logbook

Alarm protocol

Controller error

Alarm list

FUNCTION: Scroll +

FUNCTION: Scroll -

..

..

Alarm list

..

FUNCTION: Quit

..

..

..

..

Next NC-axis

A: R104GB00A.PMD

B:R104DE00A.PMD

E: 290304 / TCS

G: 130404 / T. Wenger

Section 0

Page 12

Operation and Control System

1

2

3

R10B4_019.BMP

Description of

screen elements

Touch screen operation provides various screen

elements which make it easier to enter data and

settings.

Entering values

A numeric keypad appears whenever a

numerical value is entered.

1 Cancel

Inputted value is cancelled and the

current value remains unchanged.

2 Delete

Press this key to delete a character.

3 Enter key

Press the Enter button to confirm the

alphanumeric entry.

Values can be entered wherever a blue/white

input box is displayed provided it is

not linked to a specific User level or Operating

mode. This applies to both numeric and

alphanumeric entries.

Desired values are shown in blue/white.

Actual values are shown in grey/green.

These values cannot be changed.

Operation and Control System

A: R104GB00A.PMD

B: R104DE00A.PMD

E: 290304 / TCS

G: 290304 / TCS

Section 0

Page 13

Entering alphanumeric data

An alphanumeric keypad appears whenever

alphanumeric data is entered.

1 TAB key

2 CAPS LOCK key

This key is used to enter only upper/

lower case characters (first or second

row).

3 Shift key

This key is used to switch to upper/lower

case (first or second row) for the next

character.

4 TAB key

This key is used to enter a space.

5 Enter key

Press to confirm entry.

6 Cursor - Left

7 Cursor - Right

The two cursor keys are used to move

the cursor to the left and right inside the

data input box.

8 Cancel

Inputted value is cancelled and the

current value remains unchanged

9 Delete

Press this button to delete a character.

12345

6 7 8 9

R10B4_022.BMP

A: R104GB00A.PMD

B:R104DE00A.PMD

E: 290304 / TCS

G: 130404 / T. Wenger

Section 0

Page 14

Operation and Control System

Alphanumeric entries for various editors

(e.g. CNC editor)

This keypad appears when several lines of data

can be entered such as in the CNC editor or

notepad.

This keypad has basically the same functions

as the previously described alphanumeric

keypad.

1

R10B4_024.BMP

It has an additional navigation pad on the right

(1) which is used to position the Editor cursor as

required. (left, right, up, down, start, end)

Select DEL to delete the entry.

Select INS to select either ”Insert” or

”Overwrite”.

Operation and Control System

A: R104GB00A.PMD

B: R104DE00A.PMD

E: 290304 / TCS

G: 290304 / TCS

Section 0

Page 15

Other operating features

In addition to entering numeric and

alphanumeric data it is possible to change

values/objects using the following symbols.

Object deactivated

Object activated

Object selected and deactivated

Object selected and activated

The value can be changed depending upon the

menu item.

The current status of each object is highlighted

in green/grey.

Object deactivated

Object activated

These symbols are used especially where there

are only two statuses.

(ON/OFF, SET/RESET etc.)

Touch keys

Each page of the UNILOG B4 control system

contains various touch keys. Each of these keys

activates different functions depending upon the

label and how it is displayed.

Examples include:

Confirm key

Log in

Selected axis

A: R104GB00A.PMD

B:R104DE00A.PMD

E: 290304 / TCS

G: 130404 / T. Wenger

Section 0

Page 16

Operation and Control System

This manual suits for next models

2

Table of contents

Popular Controllers manuals by other brands

Allen-Bradley

Allen-Bradley 2080-LC20-20QBB user manual

Niles

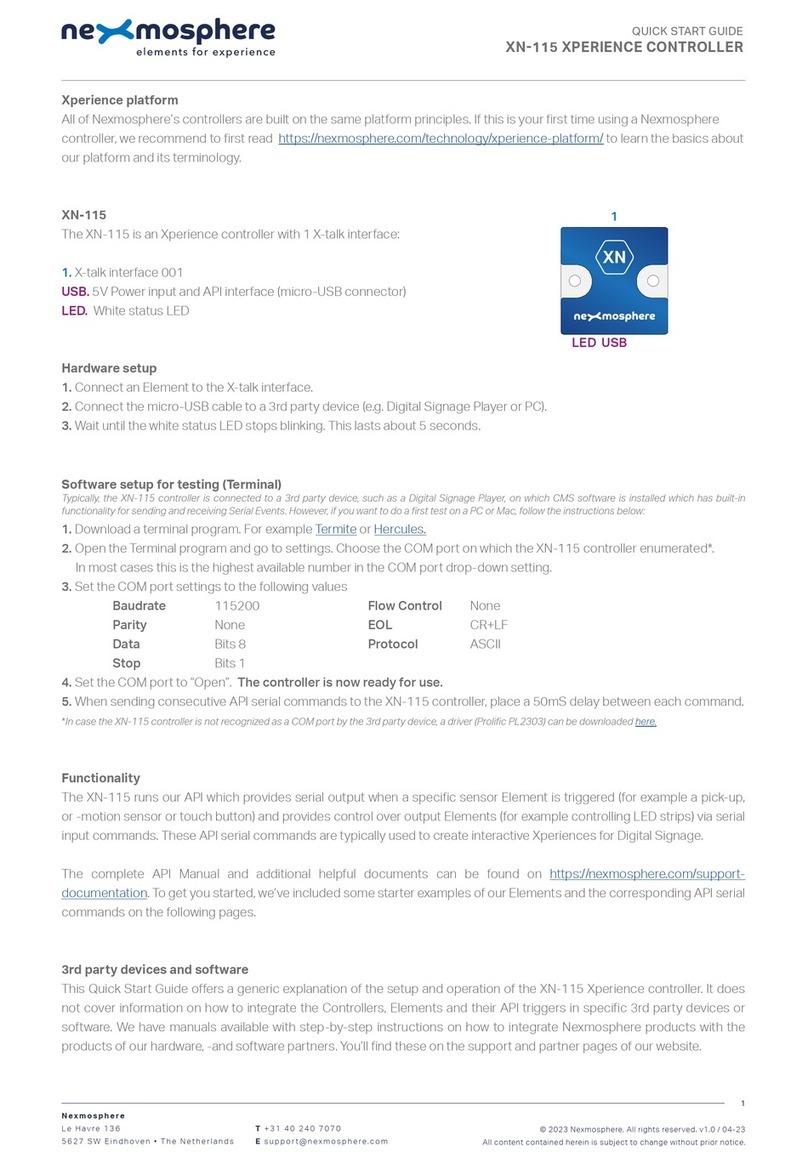

Niles MVC100 installation guide

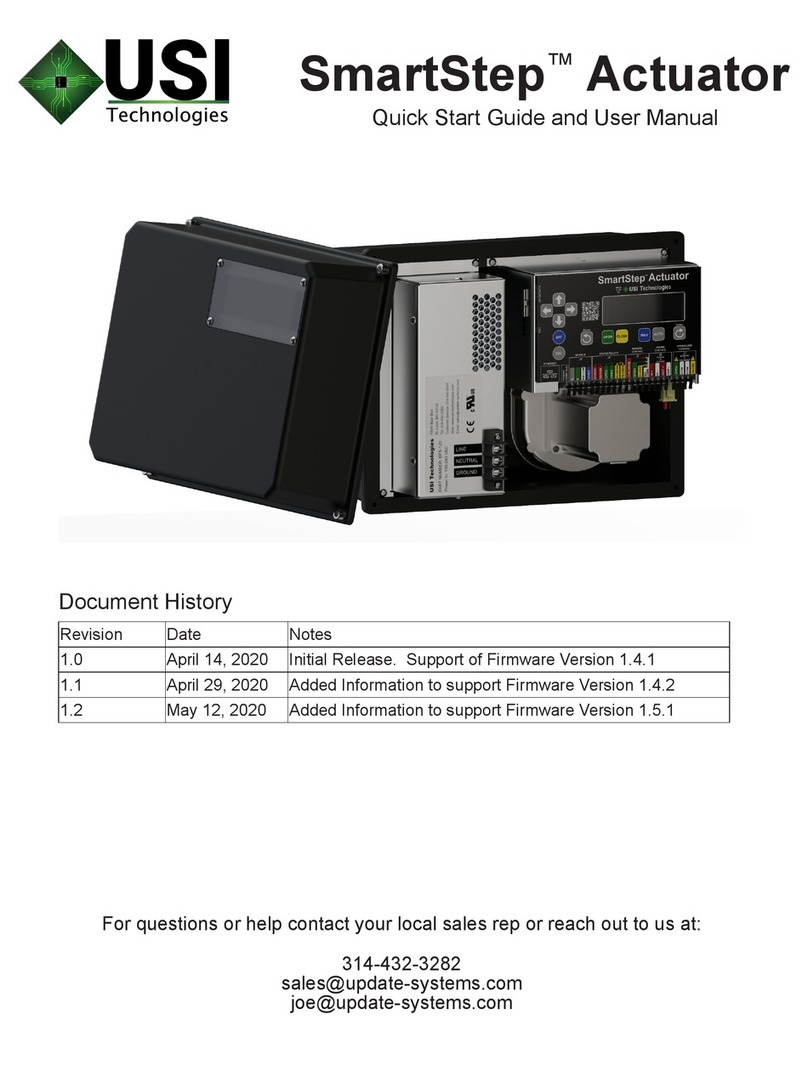

usi

usi SmartStep Quick start guide and user manual

Mitsubishi Electric

Mitsubishi Electric MELSEC FX3U-485ADP-MB Hardware manual

Zamel

Zamel GRM-10 Manual instruction

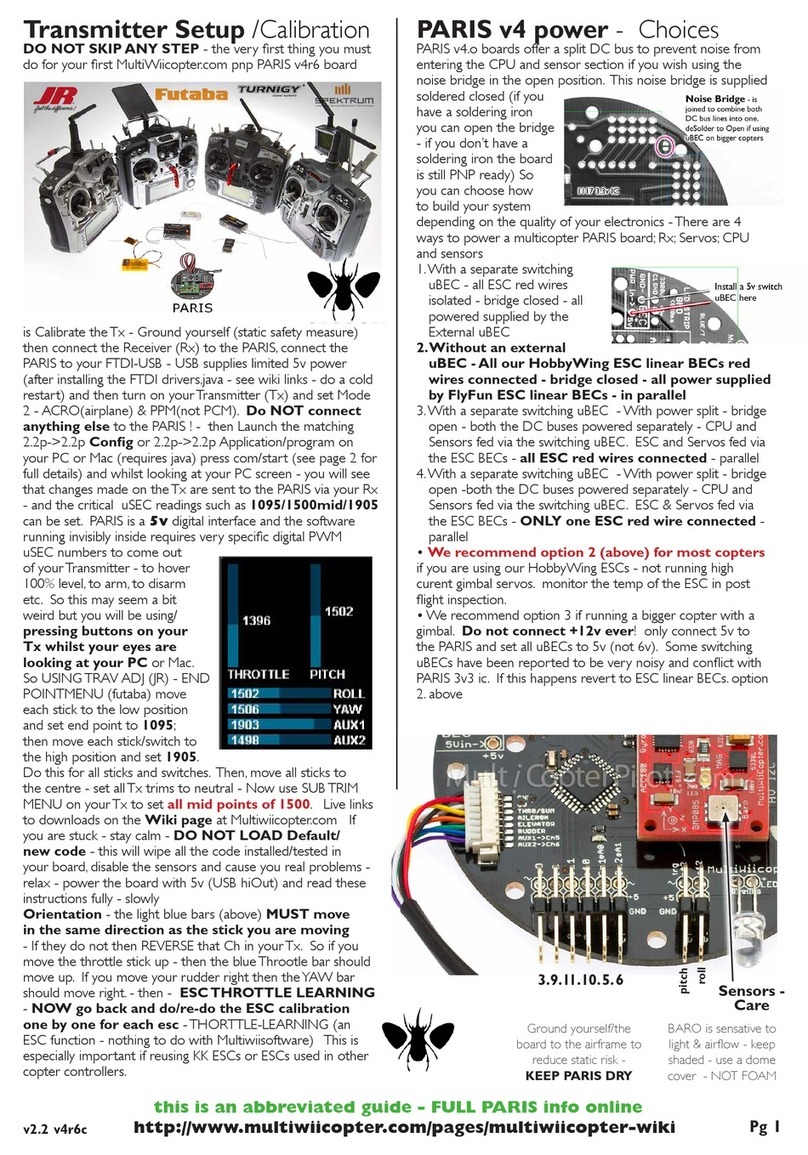

MultiWii

MultiWii PARIS Setup and Calibration Instructions

Calian

Calian SatService sat-nms ACU-19V user manual

Omron

Omron E5ARER user manual

HGLRC

HGLRC Zeus F722 manual

Emerson

Emerson TESCOM 04 Series Safety, Installation, Operations & Service

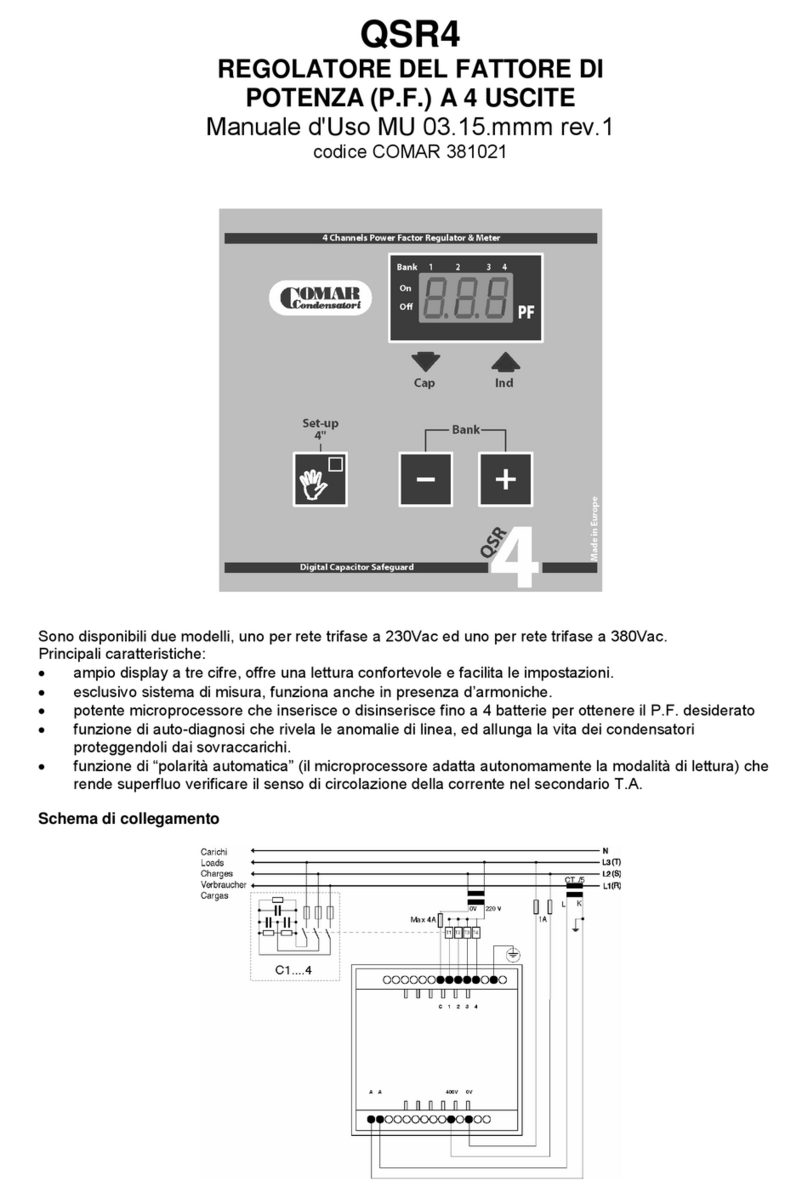

Comar Condensatori

Comar Condensatori QSR4 user manual

Mitsubishi Electric

Mitsubishi Electric MELSERVO MR-JET-G-N1 user manual