Operating Instructions Temperature Indicating Controller CS4R

V1.2 •05/2006 - 3 -

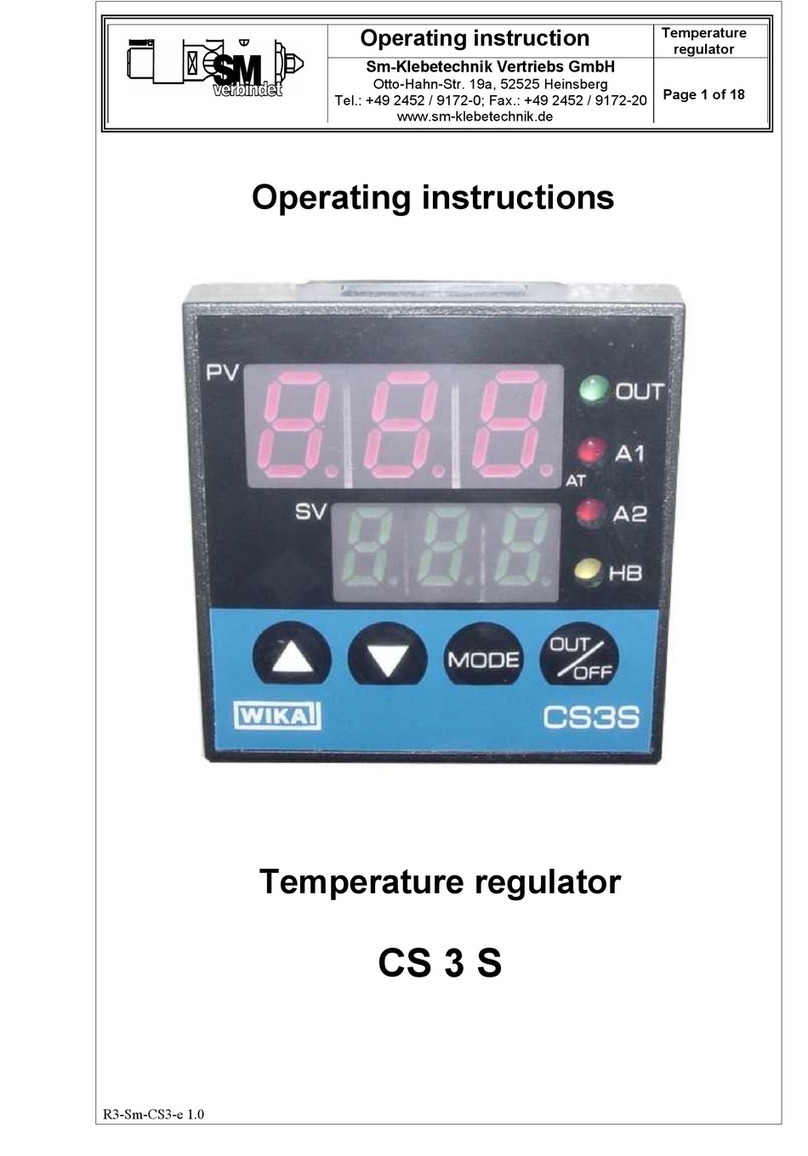

List of contents

1. Model name and order code......................................................................................................... 4

2. Name and functions of the sections............................................................................................ 5

3. Mounting to the control panel ...................................................................................................... 5

3.1 Site selection............................................................................................................................. 5

3.2 External dimension ................................................................................................................... 6

3.3 CT (current transformer) external dimension............................................................................ 6

3.4 Mounting to DIN rail .................................................................................................................. 6

4. Wiring connection.......................................................................................................................... 7

5. Setup............................................................................................................................................... 9

5.1 Operation flow chart.................................................................................................................. 10

5.2 Main setting mode..................................................................................................................... 11

5.3 Sub setting mode ...................................................................................................................... 11

5.4 Auxiliary function setting mode 1 .............................................................................................. 12

5.5 Auxiliary function setting mode 2 .............................................................................................. 14

5.6 Control output manipulated variable indication......................................................................... 17

6. Converter function......................................................................................................................... 18

7. Running........................................................................................................................................... 19

8. Action explanations....................................................................................................................... 19

8.1 OUT action................................................................................................................................ 19

8.2 OUT ON/OFF action ................................................................................................................. 20

8.3 Event (Alarm) action ................................................................................................................. 21

8.4 Event (Heater burnout Alarm) action ........................................................................................ 21

9. PID auto-tuning of the CS4R......................................................................................................... 22

10. Specifications................................................................................................................................. 23

10.1 Standard specifications........................................................................................................... 23

10.2 Optional specifications ............................................................................................................ 27

11. Troubleshooting............................................................................................................................. 28

11.1 Indication................................................................................................................................. 28

11.2 Key operation.......................................................................................................................... 29

11.3 Control..................................................................................................................................... 29

12. Character table............................................................................................................................... 30