BATTERYBOX SmartAim Supreme Series User manual

version: EN001/2019

SUPREME

PRODUCT RANGE

FIRE SAFETY - Do not place the device near flammable materials such as fabric, paper, straw

or plastic film. Flammable materials should be placed at a minimum distance of 500mm from

the top.

Do not place any electronic equipment sensitive to radio frequency and electromagnetic

interference near the device.

Wiring preparation:

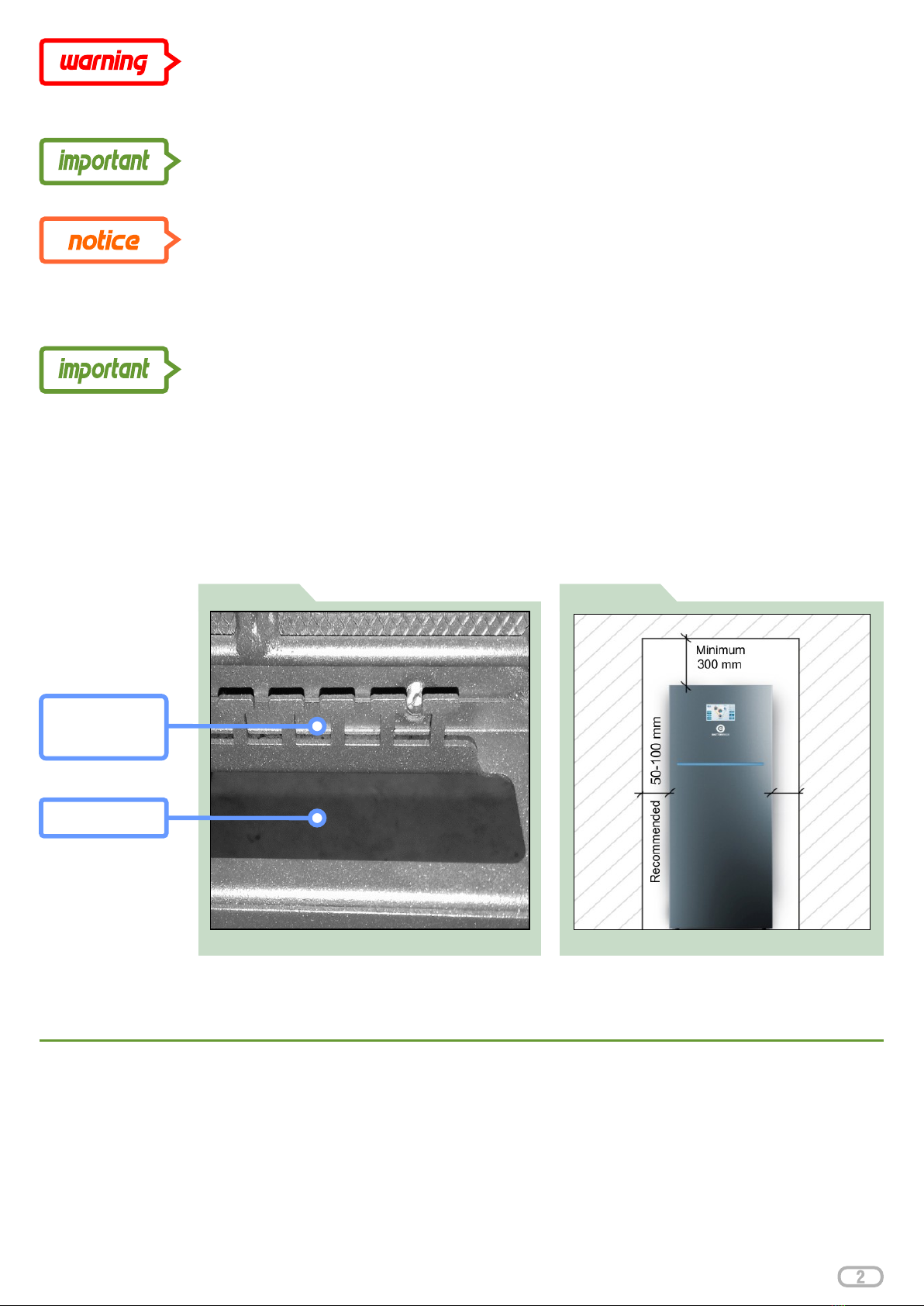

All electrical connections must be in accordance with local and national standards and

regulations. The cable compartment is at the back of the device, including cable entries to

facilitate the installation of wires / cables.

Do not drill, cut openings into the device. Use only the cable entries provided for the wiring and

cables. (Figure: 1)

Photo of SmartAim cable compartment Minimum space requirements for iinstallation.

FIGURE 2

Minimum space requirements

Recommended minimum clearance on each side is 100mm. Provide a minimum clearance of

300 mm around the top to provide adequate ventilation. Ventilation openings must not be

covered by foreign objects. The premises in which the device is located must have adequate

ventilation. (Figure: 2)

Installation of SmartAim

The device is designed for vertical mounting. The surface must be strong enough to carry the

weight of the device.

Recommended configuration of PV panels:

SmartAim is designed to use polycrystalline or monocrystalline panels. Poles of the PV panels

must NOT be grounded and leakage currents must NOT leak from the panels into earthed

structures. The OIGP configuration program is used to design the number of panels per MPPT

controller.

FIGURE 1

Cable ridge for

fastening cables

with cable ties

Cable opening

Please consider the environment before printing this document

Detail of DC photovoltaic panel connection to

FIGURE 3

device – DC terminal block.

String1:

XMPP: + / -

String 2:

XMPP: + / -

DC Connection

This section describes how to connect DC

photovoltaic panels to the device. DC

cables must be installed by a qualified

installer. (Figure: 3)

DC terminal block includes 4 terminals:

String 1: XMPP1: + / -

system voltage 350V - 800V

String 2: XMPP2: + / -

system voltage 350V - 800V

Recommended cable type:

solar conductor with PU insulation 2.5- 6

mm. The device has string 1&2 DC current

protection (see device datasheet),

including auxiliary contact and category II

surge protection, including auxiliary

contact.

For safe and efficient operation, it is very important to use suitably rated conductors to connect

photovoltaic panels. Risk of electric shock: Make sure that all DC circuit breakers are in the

OFF position. Never touch the terminals of the device. This will cause a fatal electric shock. To

avoid electric shock, do not touch the device when the photovoltaic panels are exposed to

sunlight.

FIGURE 4

Detail of DC Photovoltaic Panel Connection to device — DC String protection.

String 2 protection

String 1 protection

Please consider the environment before printing this document

Before continuing, check that the cables are in the correct polarity: the positive

cable on the device is connected to the positive terminal and the negative cable is

connected to the negative terminal. (Figure: 5)

Device is not isolated, only the following types of photovoltaic panels (hereafter "PV

modules") can be used - monocrystalline and polycrystalline class A only. To prevent

malfunctions, it is necessary that PV panels with the option of leakage current to the inverter,

are not connected. For example, grounded PV panels cause leakage current to transmit to the

device. Maximum open field voltage: 900 V (900 V is the absolute maximum at low

temperatures, we recommend a maximum of 800 V during normal operation).

Follow the steps below to connect the PV panels:

1

2

5

6

7

8

3

4

Input Voltage / Polarity check Removing of cable insulation

FIGURE 6

FIGURE 5

CHECK BEFORE CONNECTING

SmartAim system !!!

Exceeding the maximum input voltage

may cause damage to the device.

Remove 8mm of the

insulation from the end of

the solar conductor.

Lead the DC wires to XMPP1 and XMPP2 strings.

Remove 8mm of the insulation from the end of the solar conductor. (Figure: 6)

Insert the end of the solar conductor into the end sleeve and fit it with crimping pliers.

Check the photovoltaic input voltage. Acceptable voltage at low temperatures: in normal

operation we recommend a voltage range of 350-800V and maximum current flowing to

the input terminals is 18.6 A

Turn off the FADC1 and FADC2 DC circuit breakers.

Connect one end of the photovoltaic panel cable to the positive (+) terminal XMPP1: +,

XMPP2: +. Observe correct voltage polarity.

Connect one end of the photovoltaic panel cable to the negative (-) terminal XMPP1: -,

XMPP2: -. Observe correct voltage polarity.

Please consider the environment before printing this document

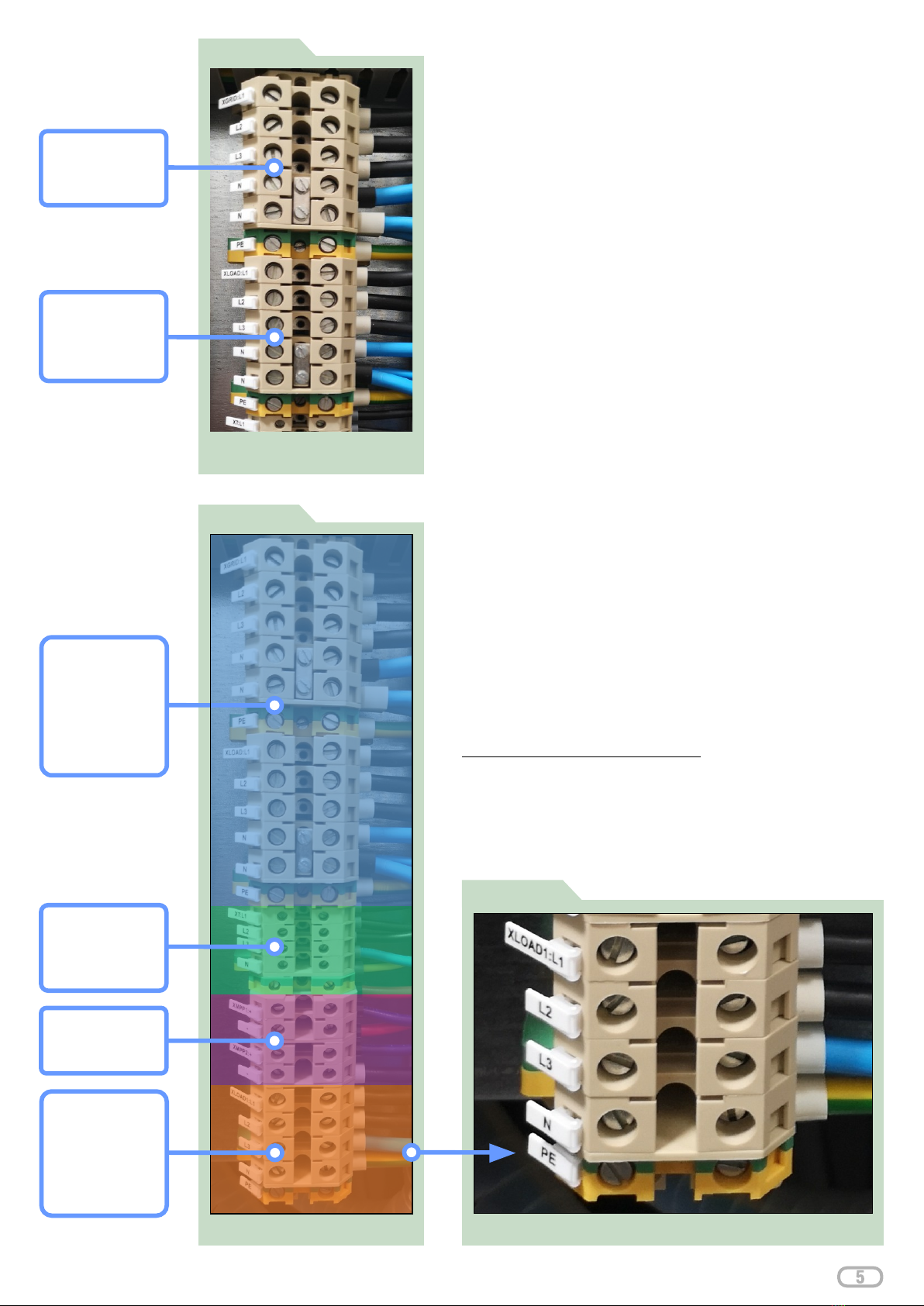

FIGURE 8

FIGURE 7

OUTPUT:

L1, L2, L3, N, PE

AC EPS/BACKUP connection

to device – AC terminal block

XLOAD:

AC GRID INPUT:

L1, L2, L3, N, PE

XGRID:

Overview of AC connection to device

AC INPUT /

up to 15 kW, with

EPS / BACKUP

OUTPUT

LOAD

input circuit

breaker up to 50A

breaker up to 50A

Detail of AC connection of NON-CRITICAL LOAD to device

FIGURE 9

AC Connection

This section describes how to connect the AC part to the

device. AC wires / cables must be fitted by a qualified

installer.

AC terminal block - contains 6 terminals: AC input (from

utility grid): XGRID: L1, L2, L3 N, PE

AC Terminal block EPS/BACKUP LOAD - contains 6

terminals: AC output to load (Load - max. 15kW with

available utility grid): XLOAD: L1, L2, L3, N, PE

(Figure: 9)

The AC terminal block NON-CRITICAL LOAD:

contains 5 terminals: AC output to load (Load – above

15kW, max. 50A supply): XLOAD1: L1, L2, L3, N, PE up to

10 kW in OFF GRID). (Figure: 7)

The EPS/BACKUP LOAD is connected to a load of up to

15 kW, including supply from the utility grid (up to 10 kW in

OFF GRID).

A measurable load above 15 kW can be connected to

the NON-CRITICAL LOAD. AC connection with

maximum input circuit breaker up to 50A.

The NON-CRITICAL LOAD is fed from PV production in

case of PV energy production surplus. (Figure: 9)

Recommended Cable Type:

Flexible 5x10mm CMSM Cable, minimum requirement

5x10mm Fixed Cable. The device has AC side

protection, including auxiliary contacts.

AC OUTPUT

over 15 kW, with

NON-CRITICAL

input circuit

LOAD

AC OUTPUT:

L1, L2, L3

XT:

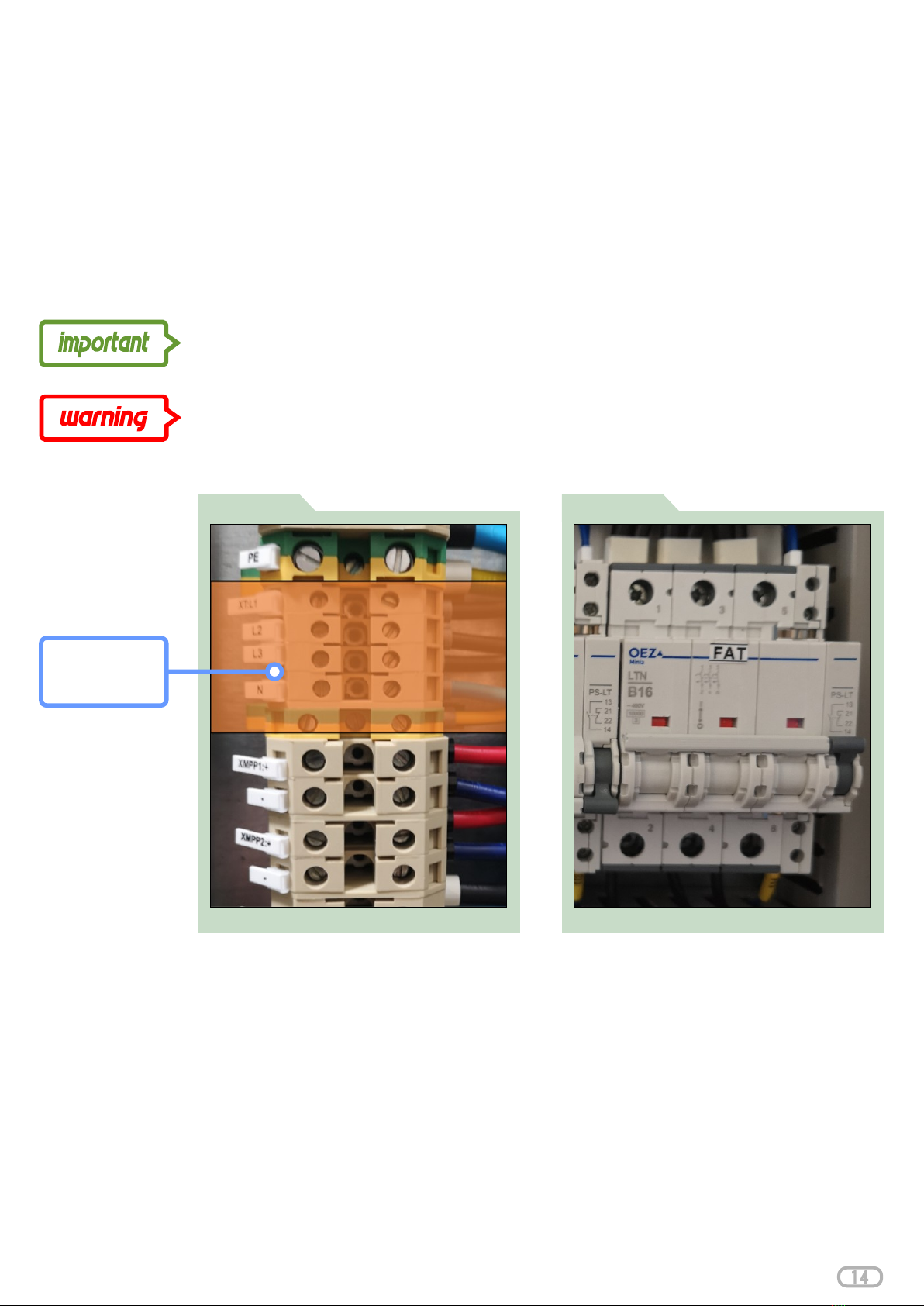

DC Connection

String 2

String 1 &

(See page 14)

AC EPS/BACKUP

Please consider the environment before printing this document

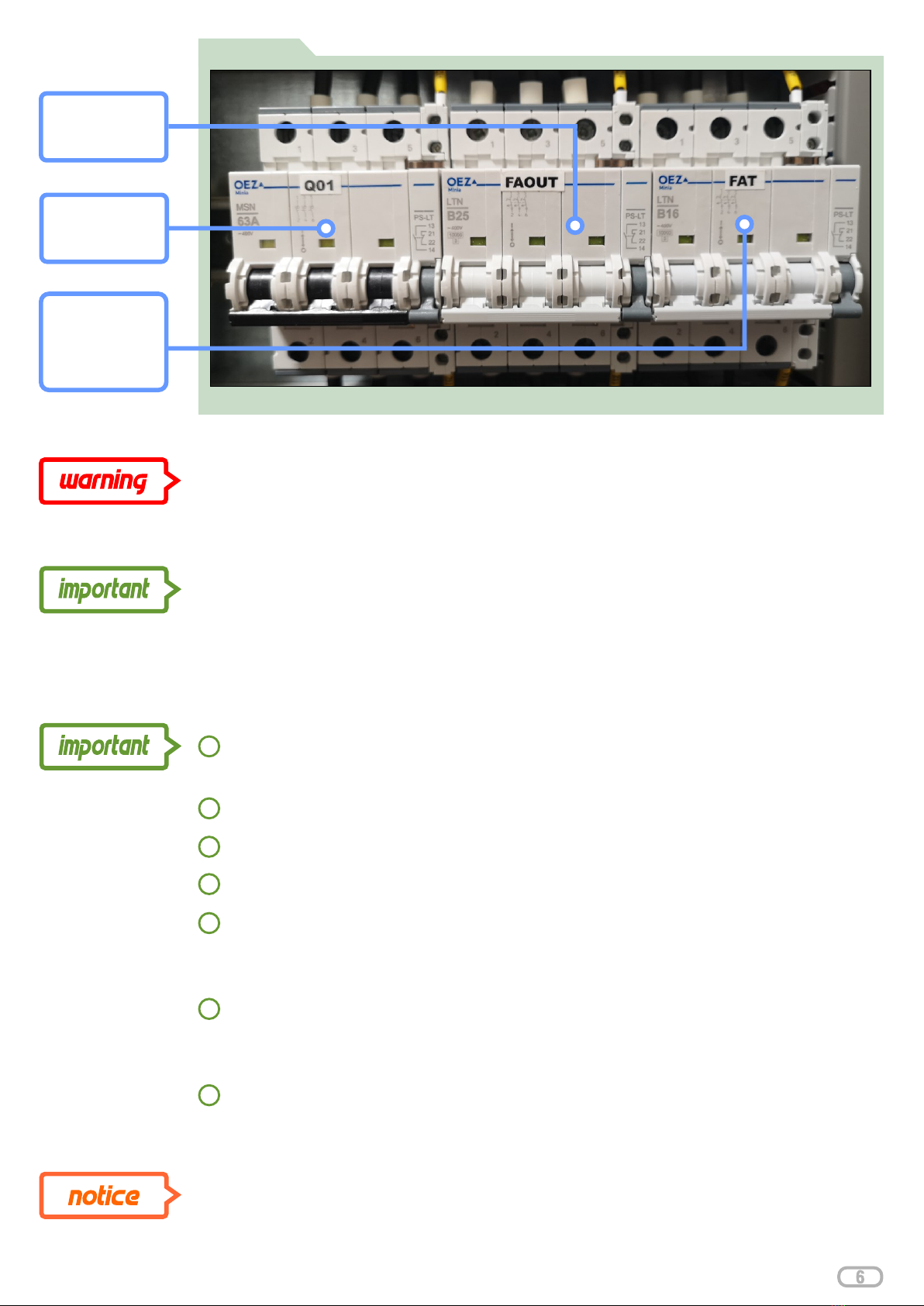

Risk of electric shock: Make sure that all AC breakers are in the OFF position. For safe and

efficient operation, it is very important to use suitably rated cables for utility grid and load

connections. Use the double-insulated cables recommended above to reduce the risk of

injury . (See page 3)

FIGURE 10

Detail of AC connection to device - AC protection

To reduce the risk of electric shock, ensure that the earth wire is properly grounded before the

device is operated on. This safety precaution should be followed, regardless of whether the

device is connected to the utility grid.

Q01:

main switch from

the utility grid

FAOUT:

load input

protection

FAT:

load input

protection - hot

water / auxiliary

output

Follow the steps below to connect the AC connection:

Check the mains voltage and frequency with a test meter. The data must match the

voltage on the label of the device.

Connect the AC power cables to XGRIG, XLOAD, XLOAD1.

Remove 10mm of the insulation from the end of the AC cable.

Switch off the AC circuit breakers Q01, FAOUT and FAT. (Figure: 10)

Connect the input power cable from the utility grid to the XGRID terminal block: L1, L2, L3 -

phase terminals – brown(L1), black(L2), grey(L3), N (neutral terminal - blue), PE terminal

(green and yellow). Observe correct polarity.

Connect the output power cable to the load / load unit XLOAD, XLOAD1: L (phase

terminals - brown(L1), black(L2), grey(L3), N (neutral terminal- blue), PE (terminal –

green and yellow). Observe correct polarity.

Before continuing, check that the cables have the correct polarity.

1

2

5

6

7

3

4

If the phase sequence and the clockwise field on the input of the device is not

adhered to, all loads will be covered by the device and the utility grid will be

unavailable.

Please consider the environment before printing this document

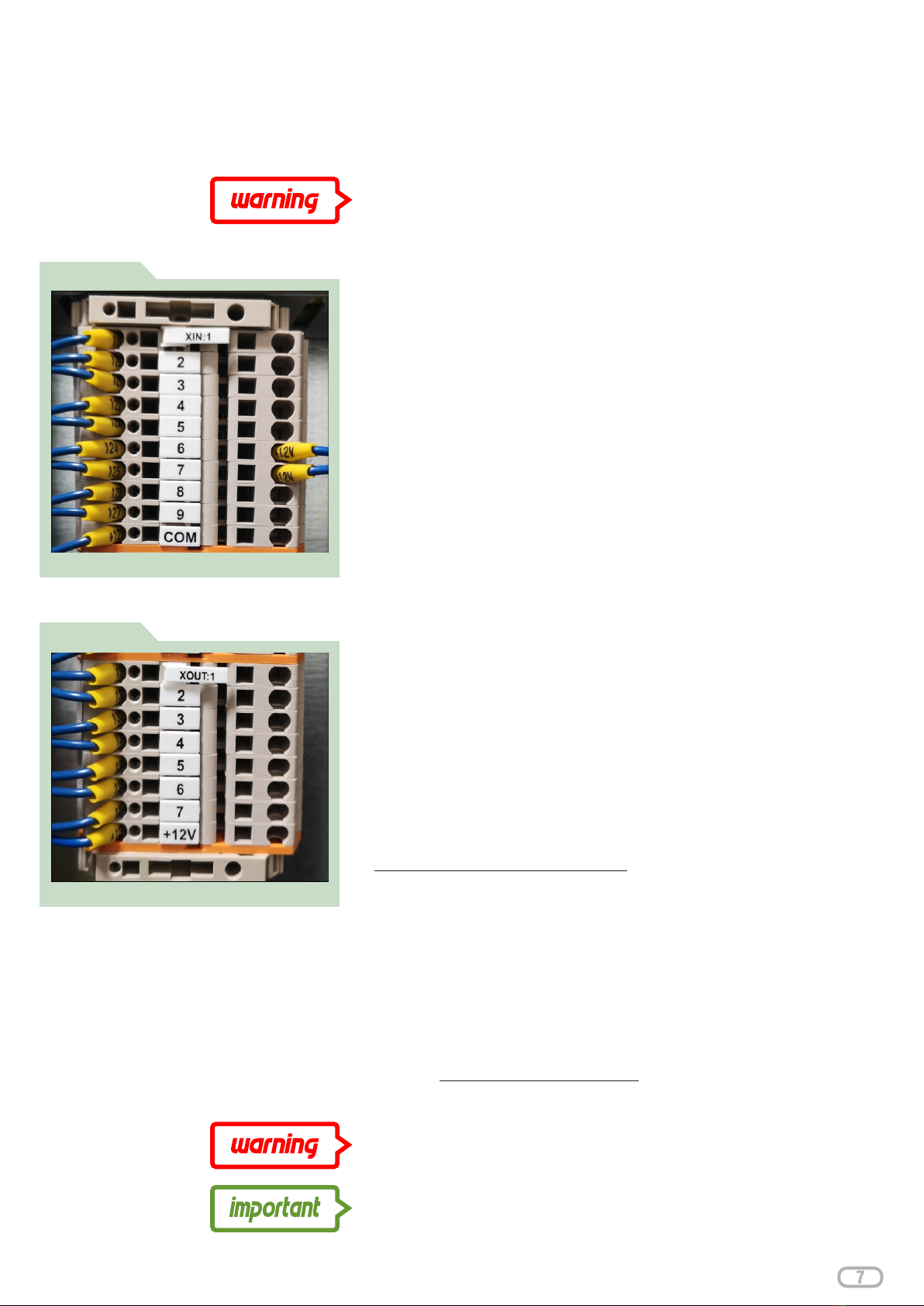

Control cables connection

This section describes how to connect a portion of the control part to

the device. Control cables must be installed by a qualified installer.

Overview of control input terminals

FIGURE 11

Overview of control output terminals

FIGURE 12

Control input terminals: XIN: 1, 2, 3, 4, 5, 6, 7, 8, 9 (Figure: 11)

XIN: COM - common terminal

XIN: 1 - signal (heat up water from grid - smart electricity tariff)

XIN: 2 - signal (charge the device from the grid – smart electricity

tariff)

XIN: 3 - safety stop. Device Safety Shutdown - After activating the

safety stop, the device switches the load off, utility grid and

photovoltaic panels. Under safe voltage remains: LCD, battery

bank and monitoring. After deactivating the safety stop, the device

will restart operation within 2 to 5 minutes.

XIN: 4 - power export control to utility grid in the range 0 - 100%

XIN: 5 - water heater - thermostat control

XIN: 6 - Manual unit bypass switch

XIN: 7 - Automatic unit bypass switch

XIN: 8 - spare 1

Control output terminals: XOUT: GND, 1, 2, 3, 4, 5, 6, 7 (Figure: 12)

XOUT: + 12V

XOUT: 1 - AUX 1 (programmable contactor)

XOUT: 2 - AUX 2 (programmable contactor)

XOUT: 3 - AUX 3 (programmable contactor)

XOUT: 4 - spare 1

XOUT: 5 - spare 2

XOUT: 6 - spare 3

XOUT: 7 - spare 4

Recommended control cable type: JYTY- ..x1

Risk of electric shock: Make sure all DC, AC circuit breakers and

fuse switch disconnectors are in the OFF position.

Connecting the batteries

This section describes how to connect a battery bank to the device.

DC cables and communication cables must be fitted by a qualified

installer. Recommended cable type: included

Risk of electric shock: Make sure all DC, AC circuit breakers and

fuse switch disconnectors are in the OFF position.

Incorrect DC and communication cable connections may

damage the unit.

Please consider the environment before printing this document

Battery Bank Wiring Example - Point 4-5

FIGURE 14

When connecting the battery bank, follow these steps:

Place the individual battery modules in the designated slots

in the device. (Figure: 13)

Install the battery modules with the supplied screws.

(Figure: 13)

Connect the individual battery modules with supplied CYA 6

green/yellow cables. (Figure: 13)

Connect the red wire to the positive terminal (+) and the

black wire to the negative terminal (-). (Figure: 14)

1

2

3

4

Connect the Link PORT 1 (first battery) communication

cable to Link PORT 0 (second battery). Then connect Link

PORT 1 (second battery) to Link PORT 0 (third battery), etc.

(Figure: 14)

5

Connect the CAN cable to the CAN PORT connector of the

top battery.

6

Make sure the wires are firmly connected. (Figure: 15)

7

6

Turn the power switch of each battery module to position 1

(ON position). (Figure: 16)

8

Battery Bank Wiring - Point 6-7

FIGURE 15

Press the SW button (on the top battery only) (Figure: 17)

9

Check the battery voltage at the DC fuse switch-

disconnector. The rated voltage is 48 V DC. (Figure: 17)

10

Battery Bank Wiring Example - Point 1-3

FIGURE 13

Battery Bank Wiring - Point 8

FIGURE 16

Battery Bank Wiring - Point 9-10

FIGURE 17

Risk of electric shock: Make sure all DC,

AC circuit breakers and fuse switch

disconnectors are in the OFF position.

CAN

Communication

Please consider the environment before printing this document

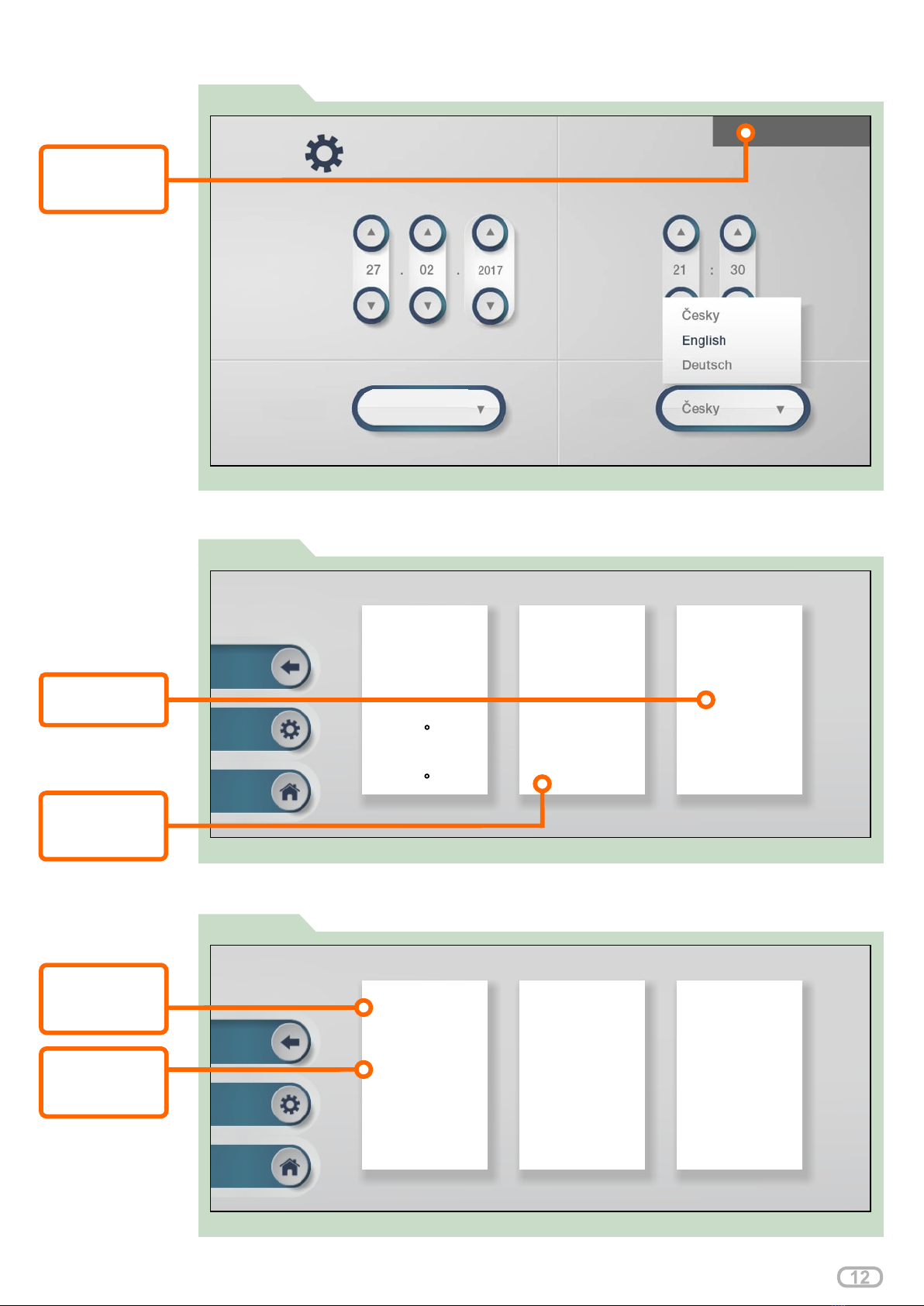

Detail of grounding terminals

FIGURE 19

Overview of connection of communication

FIGURE 18

cable to device

Connection of communication cables

For cable communication between the device and a third party, it

is recommended to use a Cat 5e shielded communication cable.

It is because of the higher risk of interference, overlapping, etc.

The shielded communication cable is to be connected only on

one side of the connection for protective earthing.

It is not permitted to place communication cables near power

lines. If unable to keep the minimum distance of 0.15m, for

example use additional shielding in plastic channels.

These channels must have good conductivity throughout the

distribution and connected to the earth cable of the power lines.

Communication cables must be within 50mm of any part of the

low voltage circuit (230V AC).

When installing cables, avoid sharp bends, never break the

cable (e.g. in corners). For each cable type, the manufacturer

specifies the minimum bending radius - typically bending radius

min. 6 x cable diameter, do not bend the cable more than 90 °.

The cables must not be subjected to mechanical pressure. Do

not exceed the permissible tensile limit when handling the

cables (through holes, channels). Stretching the cable with a

force greater than about 10 kg will cause damage by means of

pulling or twisting.

Cables should be laid so that they are mechanically protected.

Do not stretch the cables but rather leave them loose. Also,

frequent movements damage the cables.

Failure to observe the cable laying rules may result in slow data

transmission and interruption of the cable route. Due to the high

frequencies, a mere change in the geometrical arrangement of

the veins in the cable may cause obstruction of data

transmission. This can be the case despite the cable looking

operational to look at. Particularly sensitive to mechanical

damage are the points of the cable leading up to the connector.

In these places it is necessary to protect the cable from both

bending and axial pulling.

Device grounding/earthing

CY (CYA) 16 green / yellow cable must be connected from the

main PE earthing/grounding point, and it needs to be connected

to the main PE bus in the device. (Figure: 19)

All metal frames of the entire PV solar plant must be

interconnected, using CYA 10 green / yellow cables. In addition,

all Class I electrical equipment that is connected with the main

PE grounding point must be interconnected.

Please consider the environment before printing this document

Device wiring before the first parallel connection

1.1 Battery bank connection, power section (+/-), CAN communication (grey

communication cable from the device to the first battery and black communication

cables Link Port 1 to 0) (Figure: 20)

1.2 Grounding / Earthing after connection check (Figure: 20)

2.1 Turn power switches on the batteries to position 1 (ON position) (Figure: 20)

2.2 Press SW button to activate the batteries (always the top battery where the CAN

communication cable is connected). (Figure: 20)

A total overview of battery bank wiring according to initial commissioning

FIGURE 20

1.1

2.2

1.1

2.1

connection check

1.2

leave these CAN

ground / earthing

communication

ports empty

Please consider the environment before printing this document

Battery bank wiring

SmartAim unit connection, LAN cable connection (switch or router)

Measure voltage on XMPP1 terminals

Measure voltage on XMPP2 terminals

Switch on the 1FADC circuit breaker

Switch on the 2FADC circuit breaker (keep the circuit breaker switched on if

string ll not connected: otherwise it signals alarm and indicates a fault in the

Service Portal

Measure voltage per phase 1 to 3 on terminals XGRID

Switch on the main switch

Check the right connections using the Bypass function

Turn on the main output circuit breaker FAOUT

Measure voltage on terminals XLOAD

Overview of cabinet wiring

08

05

04

09

07

06

10

03

02

01

01

02

03

04

05

06

07

08

09

10

Overview of cabinet wiring - Wiring Diagram

Please consider the environment before printing this document

Wiring Diagram

FIGURE 21

DIAGRAM

FIGURE 22

FIGURE 23

FIGURE 24

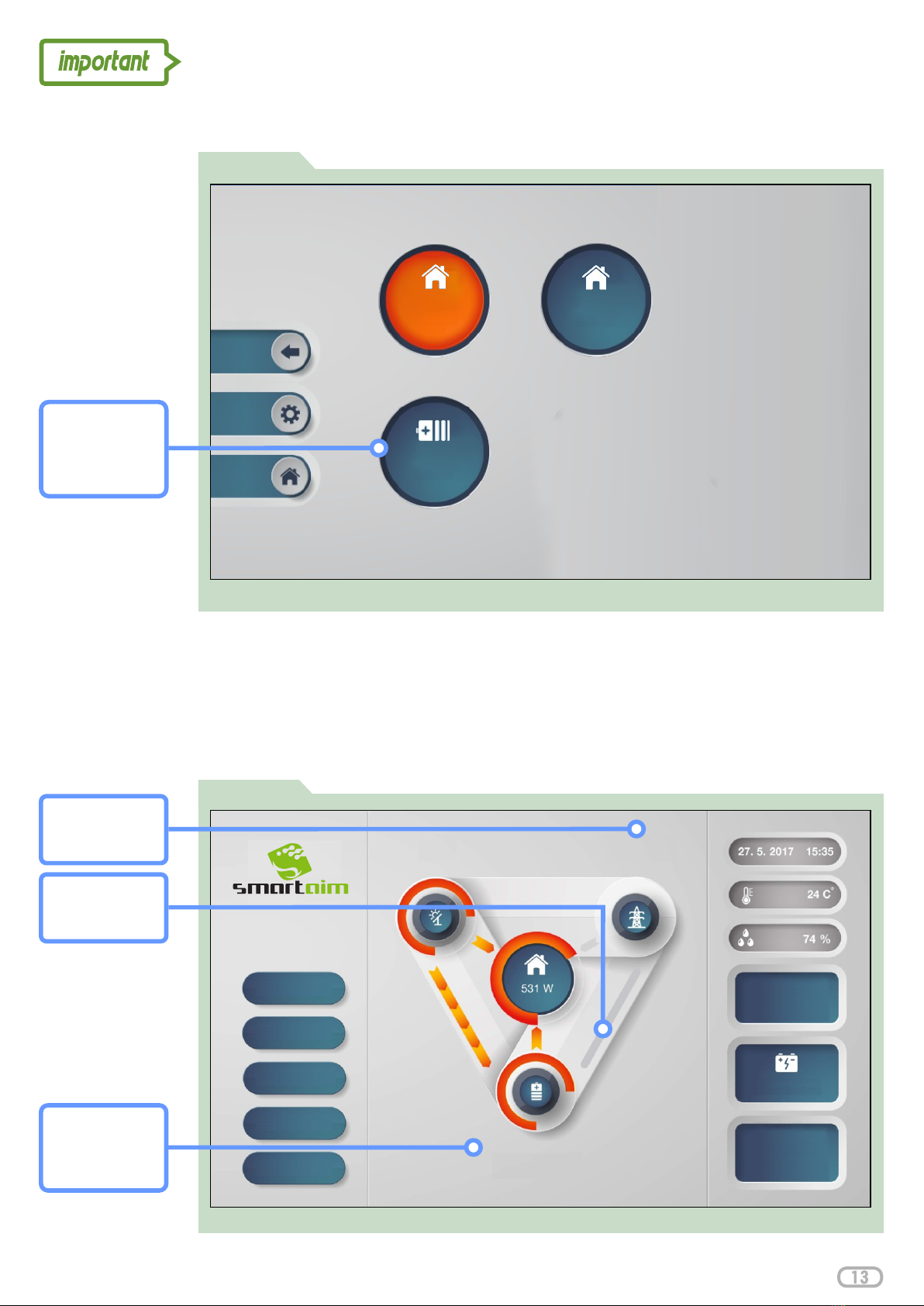

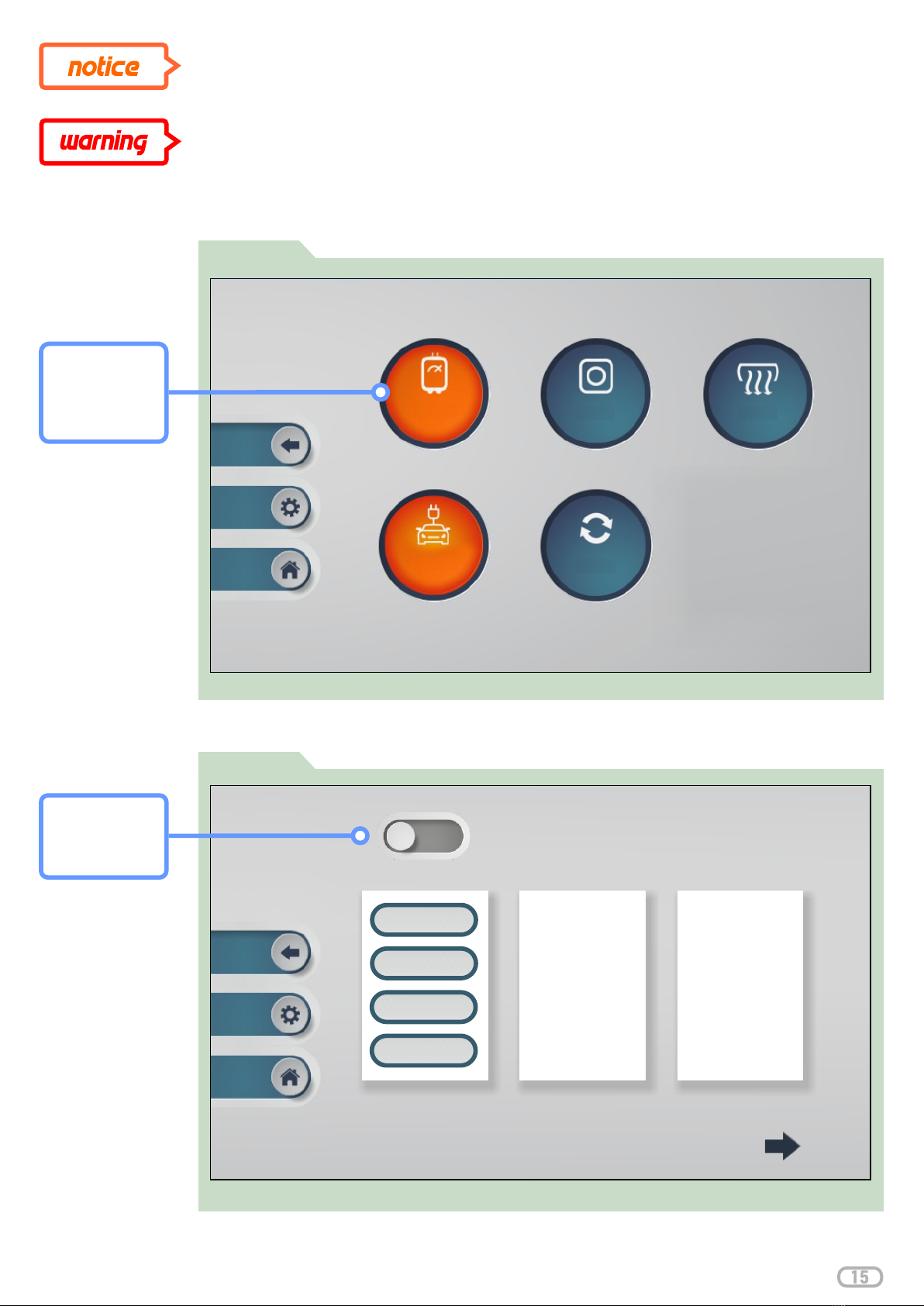

CONTROL PANEL SETUP

Firmware version check

IP address / batteries state of charge check

PV Power and Battery Power adjustment

Please consider the environment before printing this document

IP ADDRESS

check

AC CHARGE

THRESHOLD

check

SOLAR PV

ajustment

CAPACITY

ajustment

STORAGE

FIRMWARE

check

VERSION

User interface: Firmware version check

SETTINGS

Date Time

Ethernet Language

v.3.0.41

SIZE

User Interface: PV Power and Battery Power adjustment

Inverter ON/OFF

Active

Password

0

LCD Reset

Inactive

Solar PV size

9800W

Grid Capacity

10000W

Charge Capacity

10000W

Storage Capacity

7200Wh

Battery Shutdown

20%

Grid > Battery

15%

Generator > Battery

AC Charge

Unit ID

717013002

Port

5710

Domain

0

IP Address

90.183.11.205

LED Brightness

20%

LCD Brightness

80%

Ventilator 1

Ventilator 2

40 C

37 C

charge threshold

safe threshold

15%

start threshold

60%

threshold

User Interface: IP address check

Formating of the batteries

Pressing the "Formatting" button will start formatting. The initial screen will (Figure: 25)

take up to 2 minutes to take effect. An animation in the form of arrows (from grid to

batteries) shows up, meaning the batteries are being charged from the utility grid

(Figure: 26). The number of Watts (below the battery icon) start to increase and the total

storage capacity value changes.

Check the charge status of the batteries vs. "AC Charge threshold". To start (Figure: 25)

formatting, the charge status of the batteries must be less than the "AC Charge

threshold" value. The charge status of the batteries is displayed on the right-hand side

of the screen.

FIGURE 25 Formating of the batteries

89%

78 %

contribution

67 %

Solar PV

Statistics

Weather

Settings

Mode

Alerts

Self-Sufficiency

Power Grid

Solar PV

1468 W 0 W

Battery Storage

15063 W

FIGURE 26

ARROW

arrow animation

from grid to battery

User interface - Home screen: Battery formatting

STORAGE

Watts increase

to battery

POWER GRID

Watts increase

from utility grid

Please consider the environment before printing this document

FORMATING

press the button

to initiate

formating of the

batteries

User Interface: Battery formating

Home Grid

Formating

1

Home Grid

2

BATTERY

Connection on XT power terminals

FIGURE 27

FAT circuit breaker set to one position

FIGURE 28

AC OUTPUT:

L1, L2, L3

XT:

Load selection, wiring and hot water settings

PV solar power primarily covers the load and recharges the batteries. In case of electricity

surplus to the utility grid, the auxiliary devices will activate according to your selected priority

settings.

It is possible to connect a single-phase or three-phase immersion heater. However, the

maximum power per phase is 2 kW. If a single-phase heater is used, 6kW value must be

entered in the Power Output settings. The system always divides into thirds. In case a 2kW

value is entered, then the maximum output per phase is 666W.

If a three-phase electrical immersion heater is connected, it must be star-wired, i.e. 3x230V

(not in a triangle at 400V).

If no immersion heater is not connected, leave the FAT circuit breaker switched on. (Figure: 28)

(otherwise it indicates a fault in the ).Service Portal

From the Home Screen select SETTINGS . Select the immersion heater (Figure: 26)

icon and another screen will be displayed. Immersion heater (Figure: 29) (Figure: 30)

activation is performed by touching the On / Off icon . The immersion (See Table 1)

heater icon turns when switched on. orange (Figure: 30)

Refer to for the function of each button. Priority 0 is the factory default Table 1

setting (0 = first priority). In order for the immersion heater function to operate, it

is necessary to have a power set and the On/Off icon on . If you want to use orange

a smart electricity tariff to heat your water, this can also be performed from the

screen. Once your smart periods have been selected, the system will become

active.

Please consider the environment before printing this document

Immersion heater load settings

Immersion heater settings and status

DO NOT FORGET TO TURN OFF MANUAL MODE, OTHERWISE SMART

ELECTRICITY TARIFF SETTINGS WILL NOT WORK

Immersion heater can be switched manually to test its functionality. (Figure: 29, 31)

Please consider the environment before printing this document

HEATER

select Immersion

heater button to

access settings

FIGURE 30

SETTINGS:

ON / OFF

activation of

immersion heater

Priority

IMMERSION HEATER

Power Output

Time Band 1

Time Band 2

Power Output

8W

Priority

0

Time Band 1

01:00 - 08:00

Time Band 2

18:30 - 23:30

Required Power

100 W

Smart Tariff

Active

Thermostat

ON

Consumption

0 Wh

Individual functions for immersion heater settings

Immersion

Heater

Heat Pump

Air Con

EV charger

MHRV

Ventilation

Overview of individual functions in the load settings

IMMERSION

FIGURE 29

Immersion heater settings and status

TABLE: 1: IMMERSION HEATER SETTINGS

Please consider the environment before printing this document

TABLE 1

Priority

Power output

Time Band 1

Time Band 2

Required Power

Consumption

Thermostat

Manual Mode

Priority management settings. A lesser priority (eg: 1) will be regulated when an

energy surplus is detected in the utility grid and the immersion heater control is

activated. Upon termination of priority 1 and other overflows to the grid, priority 2 will

be regulated.

Power output setup of the immersion heater. Max. 3x2kW / 3x230V in three-phase

and 6kW in single-phase.

Select a specific time to heat water. This is particularly useful in combination with

smart electricity tariffs. When a time period is set, water is heated regardless of PV

solar production. To activate this function, it is necessary to enable XIN 1 on the

control input terminals.

Amount of energy (kW) the user wishes to send to the immersion heater (6kW

max.)

Amount of daily energy (kW) being provided.

Water temperature. Enable XIN 5 on the control input terminals to activate.

Manual ON/OFF control: when selected manually, it activates the immersion

heater.

Set your surplus energy threshold for the immersion heater to activate.

ON/OFF button for the immersion heater

Select another specific time to heat water. This is particularly useful in combination

with smart electricity tariffs. When a time period is set, water is heated regardless of

PV solar production. To activate this function, it is necessary to enable XIN 1 on the

control input terminals.

Start energy

Settings and status display for immersion heater

Manual Mode

IMMERSION HEATER

Start Energy

Manual Mode

Active

Start Energy

200 W

FIGURE 31

SETTINGS:

ON / OFF

activation of

immersion heater

In order to be able to manage SmartAim via the APP, you need to establish

connection with your internet network.

SmartAim allows dynamic and static IP address allocation.

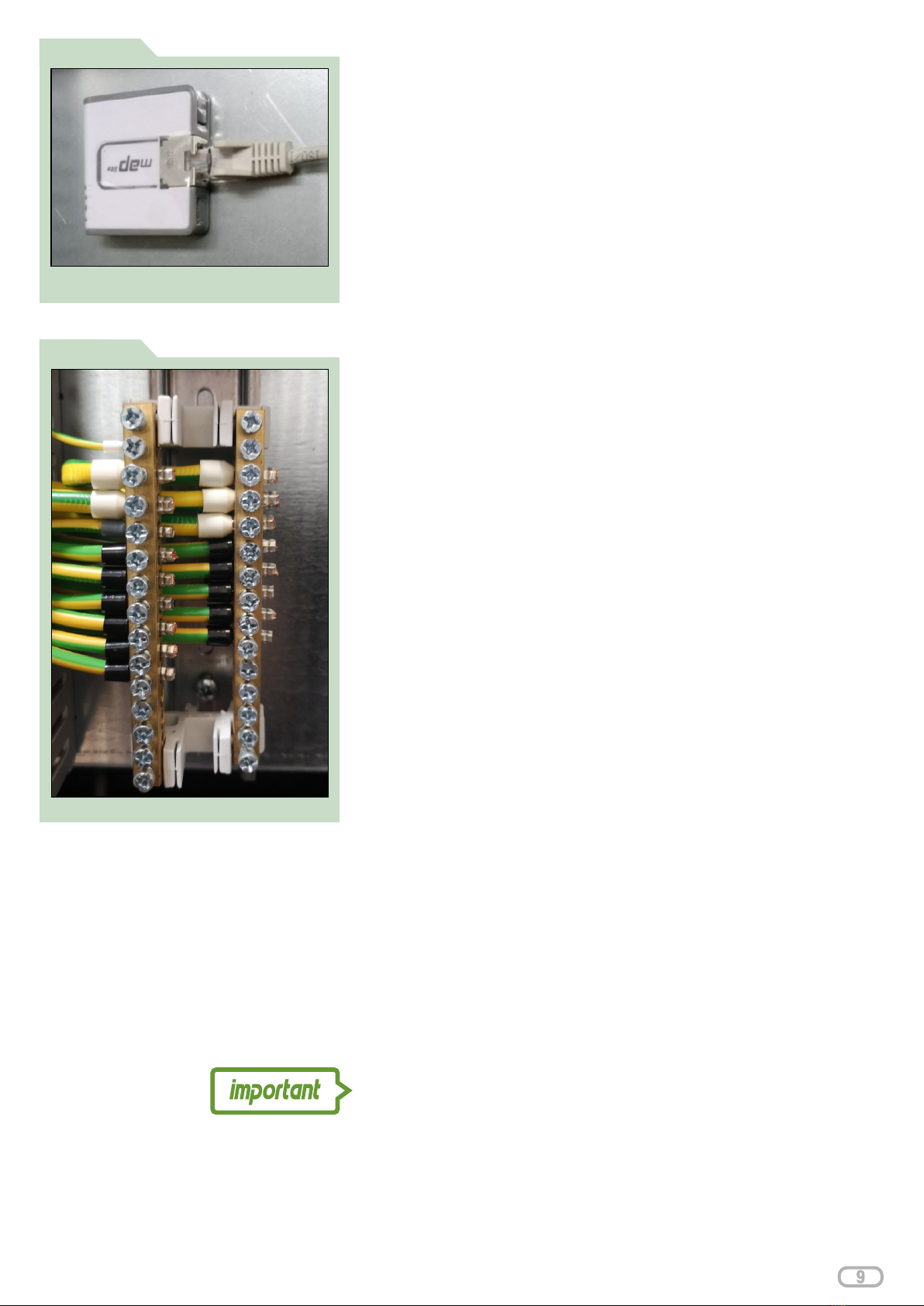

Connection

The network cable from your local network is connected to a pre-

configured Ethernet switch or RJ connector in the router. After (Figure: 32)

connecting the network cable, the device automatically actives.

Internet connection

When the access point is activated, it will be automatically paired with the

data box. All device data including remote control data will be sent to the

data box. The data box setup is part of the factory settings.

IP address of the data box: Port: 90.183.11.205 5710

SmartAim - AVAILABLE WITH ACCESS POINT MIKROTIK

The Internet connects directly to the power cube to a free LAN connector.

(Figure: 32)

Please consider the environment before printing this document

FIGURE 32 Internet connection

Photo of internet connection

CONNECTOR:

use the free LAN

connector

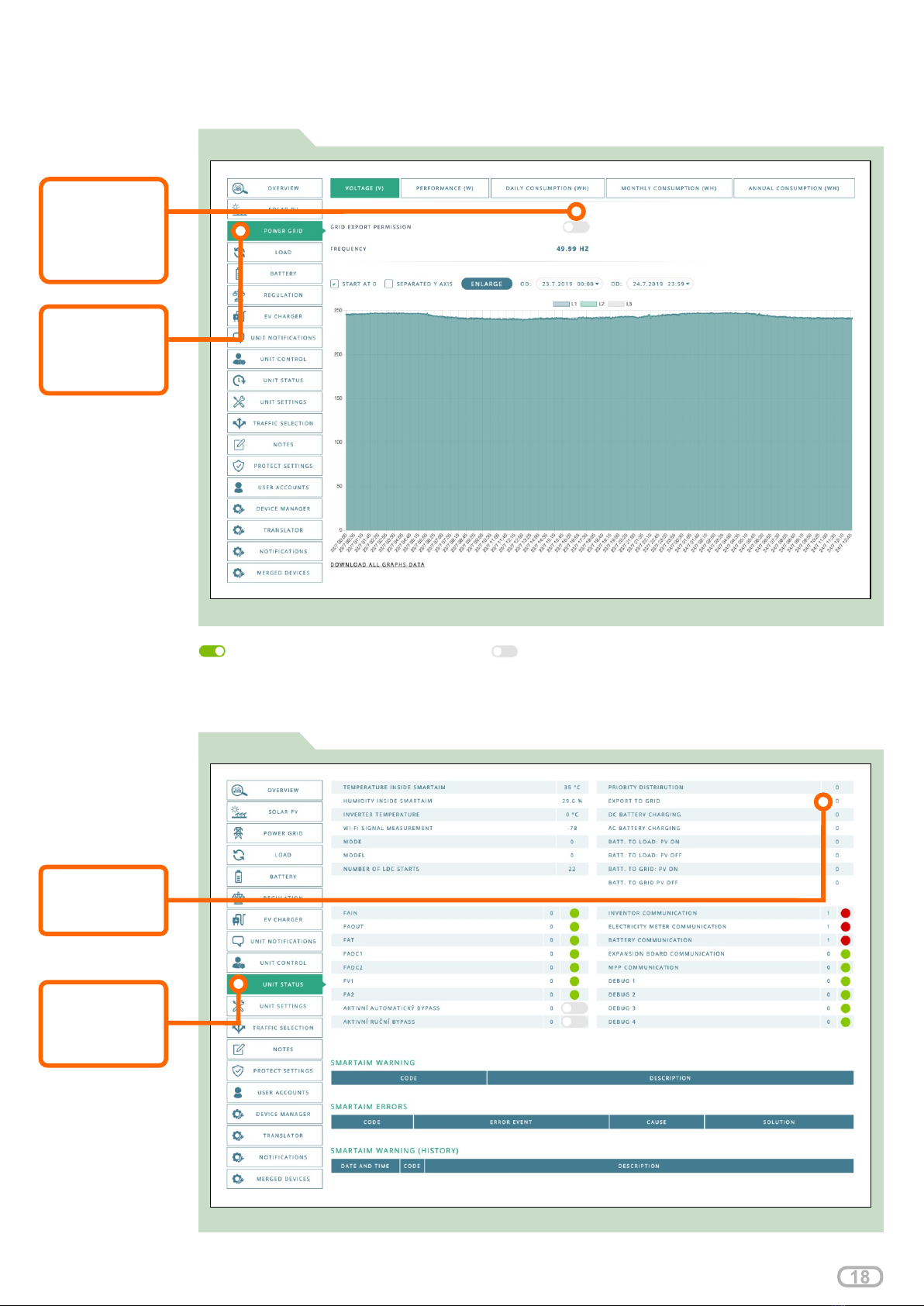

Export limitation

FIGURE 34

Allowing surplus energy to grid Preventing energy surplus to the grid

Surplus to grid is displayed on the "STATUS" tab on

Please consider the environment before printing this document

Adjust your settings on the Service Portal in section

Displaying status of surplus energy to grid using the service portal

VALUE:

value: 0 = OFF

value: 1 = ON

MENU:

“UNIT STATUS”

tab

select

FIGURE 33

Settings for surplus energy to grid using the service portal

BUTTON:

turn ON / OFF

to Allow / Prevent

MENU:

“POWER GRID”

tab

select

export electricity

to utility grid

FIGURE 35

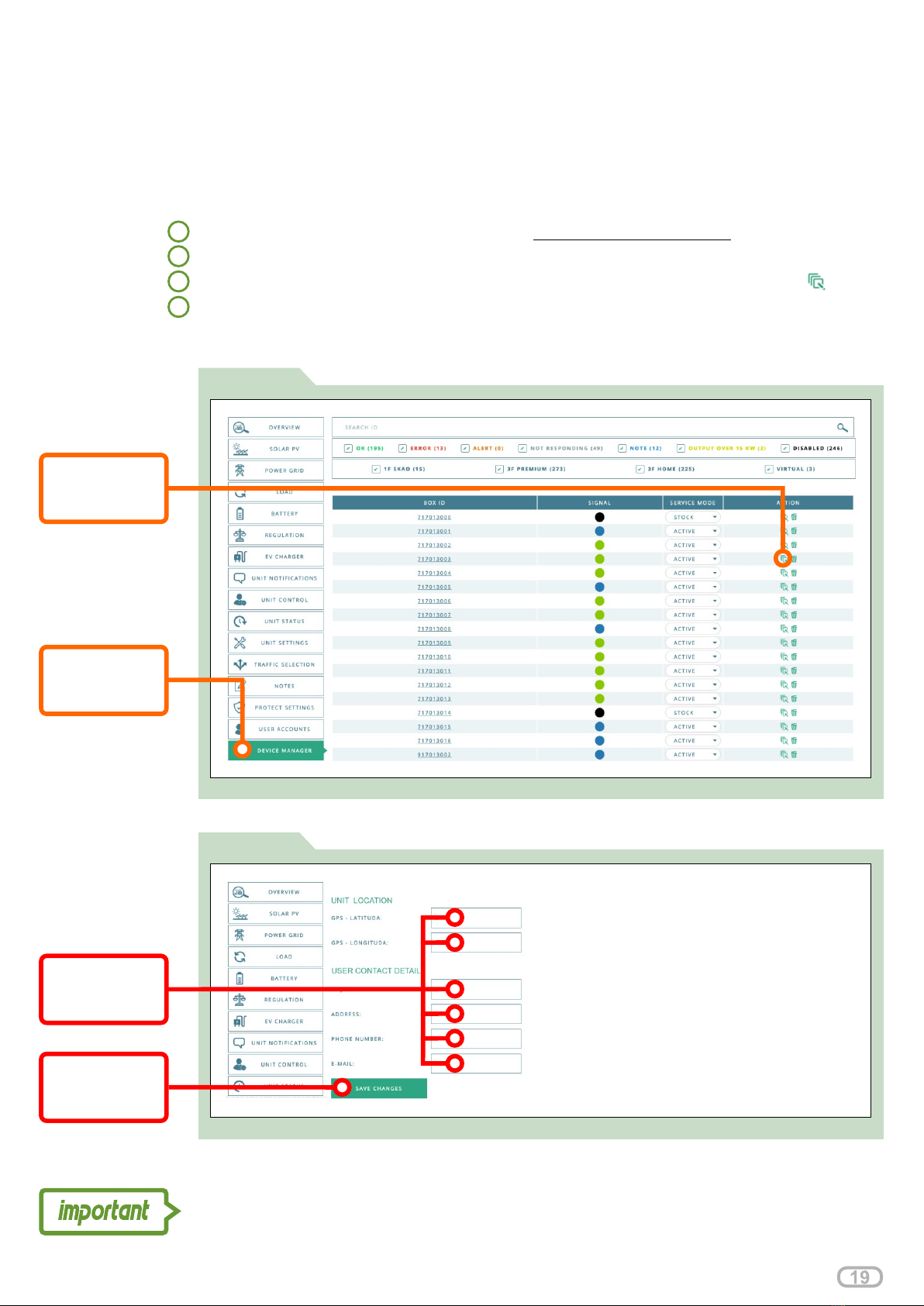

Device Manager tab

Register the device following the steps: (Figure: 35, 36)

Log in to your Service Portal account on servis.oigpower.cz/en/

1

2

3

4

Select DEVICE MANAGER tab from the main menu

Click the line tab or action icon on device you wish to register (Figure: 35)

Fill the registration form and click SAVE CHANGES button to apply changes

(Figure: 36)

SMARTAIM UNIT REGISTRATION

If the user does not want to use the application on a mobile device (does not register as a

user), the installer can perform the registration in the service portal. This step identifies the

device and does not prevent a future user registration.

Register SmartAim if the user refuses to register to assure free 24/7 unit monitoring,

maintenance and repair via manufacturers CMO (Central Monitoring Office) .

Please consider the environment before printing this document

BUTTON:

turn ON / OFF

to Allow / Prevent

MENU:

select “DEVICE

MANAGER” tab

FIGURE 36

Screenshot of device registration form

FIELDS:

fill in the blank

fields

BUTTON:

Save to apply

changes

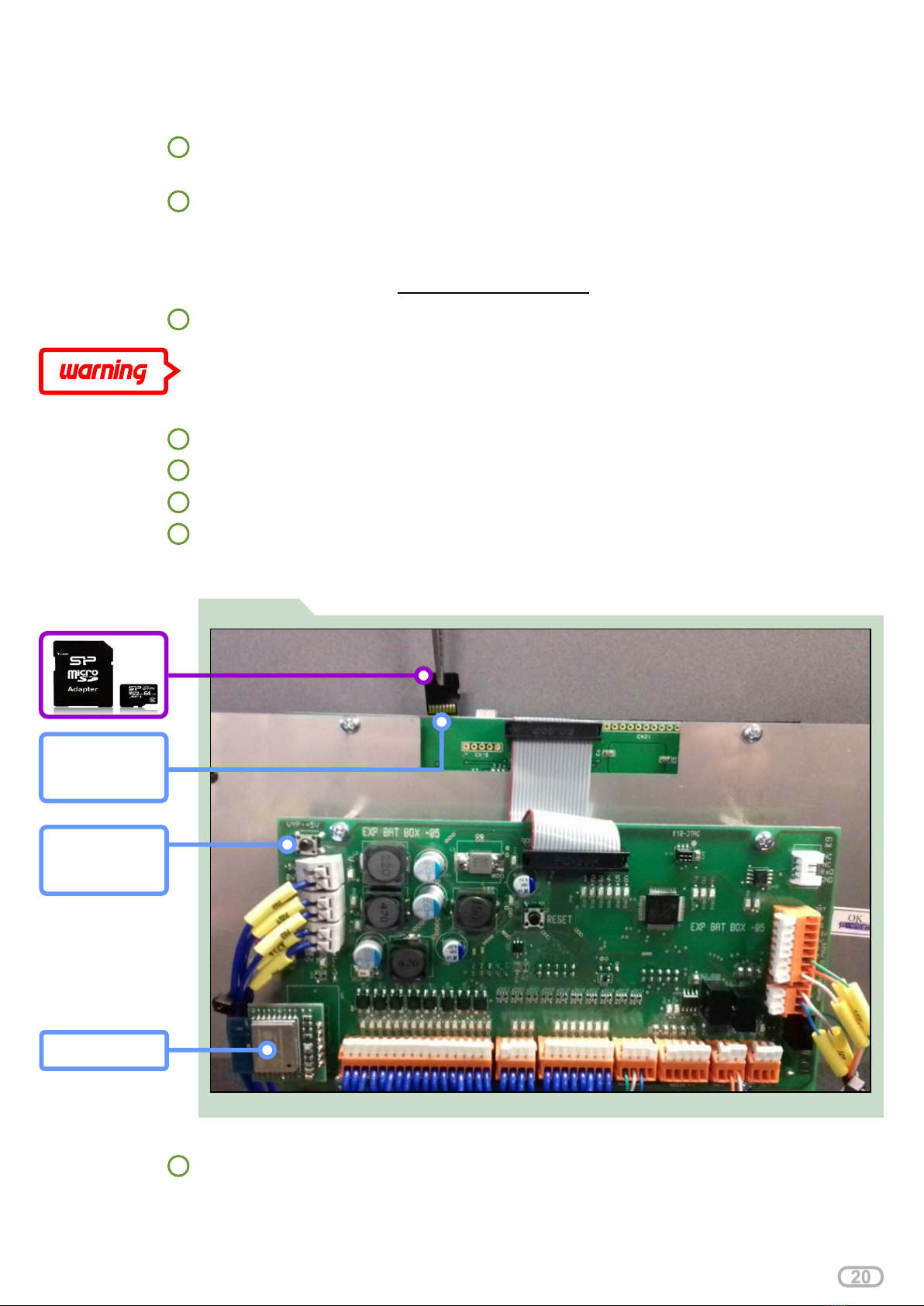

FIGURE 37 Demonstration of insertion of microSD card

Demonstration of insertion of microSD card

1

2

3

4

Ensuring the availability of the OIGpower or OIGpower Wi-Fi network. The name

of the internal Wi-Fi network in the device can be found using a smartphone or

personal PC. The name of the OIG power or OIGpower network is given by the

type of the router inside the device. The access point name must be found to enter

the SSID in the system. Password for access: . 10401947

Upload a file to the micro SD card that is designed for your device type.

ATTENTION! YOUR INTERNET CONNECTION MAY BE LOST AFTER THE

UPDATE IF THE ACCESS POINT NAME IS INCORRECT.

Open the door and remove the cover (unscrew 8 nuts)

SOFTWARE UPDATE

If the installer is updating the device, it is necessary to follow the steps below.

Component needed for updating - Micro SD card (recommended capacity up to

4GB, type – transcend)

Wi-Fi module

LCD SLOT

for micro SD

card

5Remove the Wi-Fi module from the expansion board slot (Figure: 37)

6Insert the micro SD card into the LCD slot (Figure: 37)

7Insert the Micro SD card in the LCD slot and press the reset button (Figure: 37)

8After the reset, the update package will be updated. The LCD must display an

update - "PPF Processing". If PPF-Processing is not displayed, the problem is in

the micro SDcard.

RESET

press the reset

button

Please consider the environment before printing this document

Table of contents