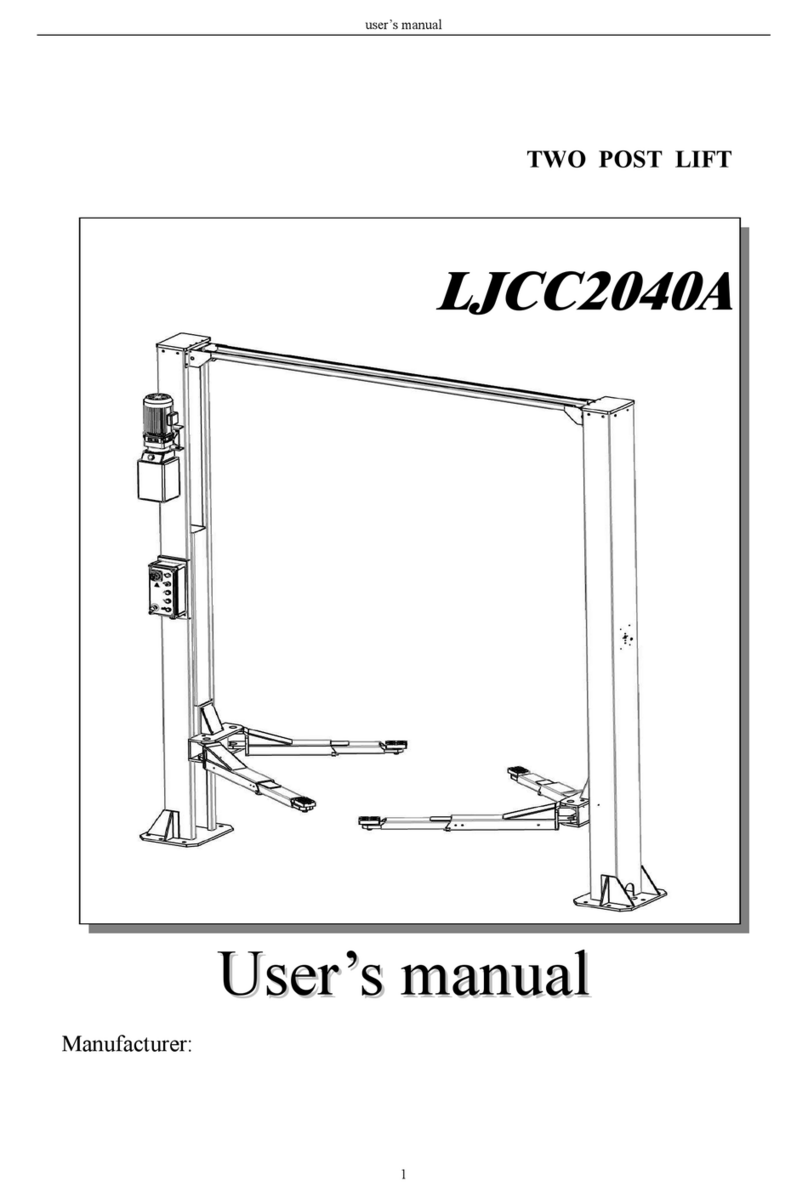

Operation Manual

Contents

1、Applications and Features3

1.1 Applications:............................................................................................................................... 3

1.2 Structure Features:..................................................................................................................3

2、Main Specifications................................................................................................................................. 4

2.1 Dimension:.................................................................................................................................. 4

2.2 Specification Chart:..................................................................................................................4

3、Installation and Test...............................................................................................................................5

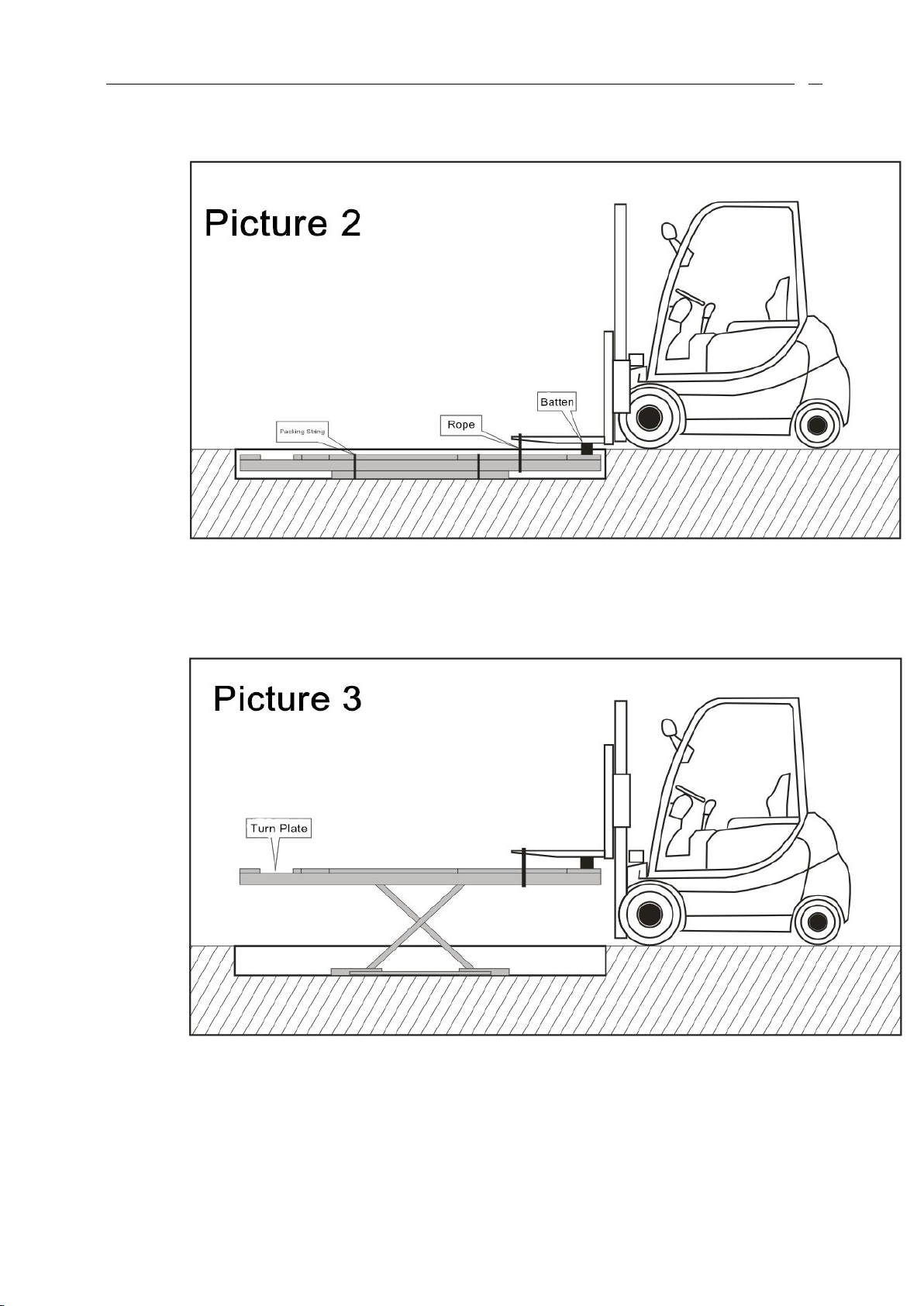

3.1 Foundation Preparation:.........................................................................................................5

3.2 Hydraulic Oil Filling:.................................................................................................................7

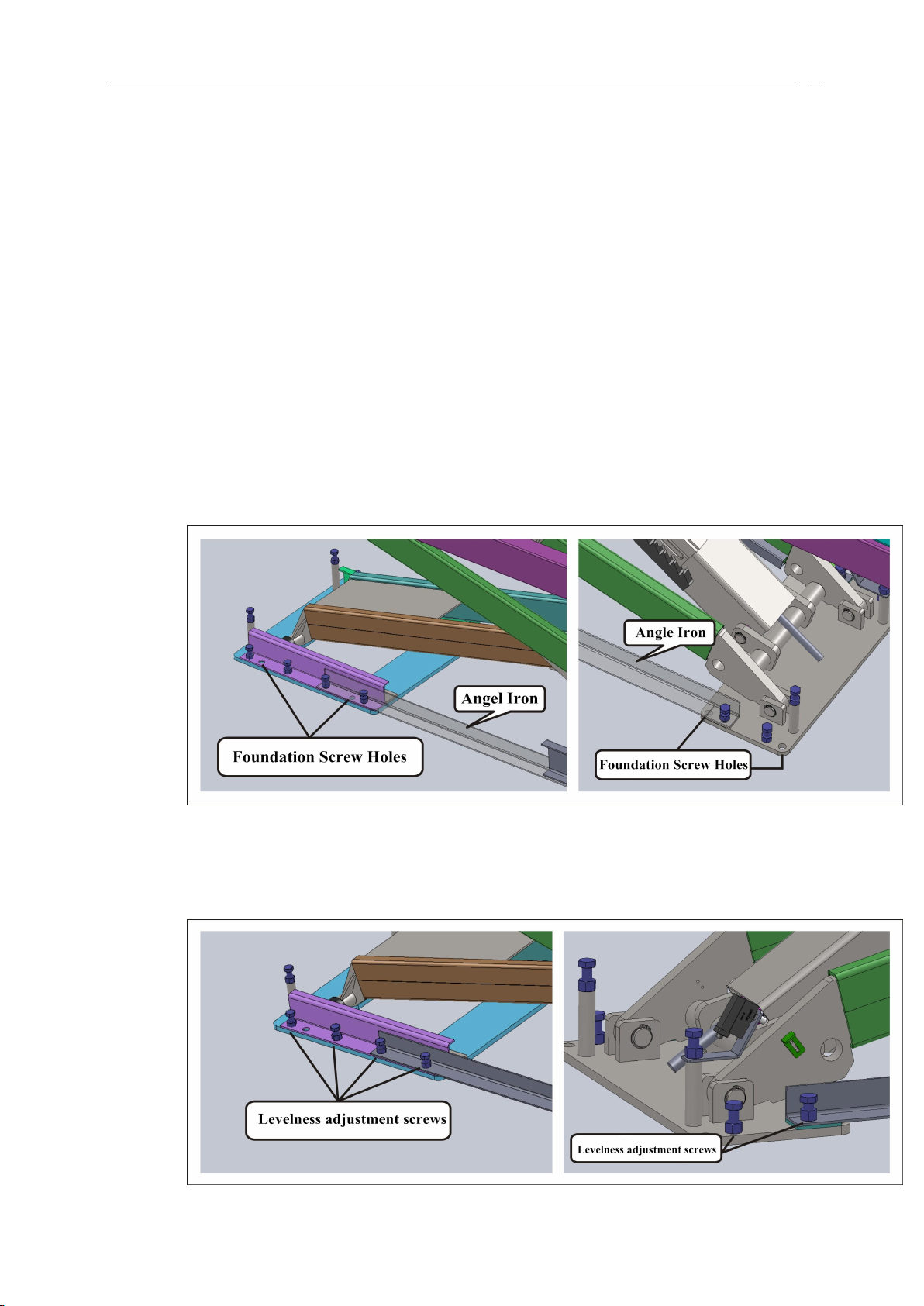

3.3 Connection of Power Supply and Air Supply:................................................................7

3.4 Installation Procedures of the Oli Pipe between Lift and Control Cabinet:.......8

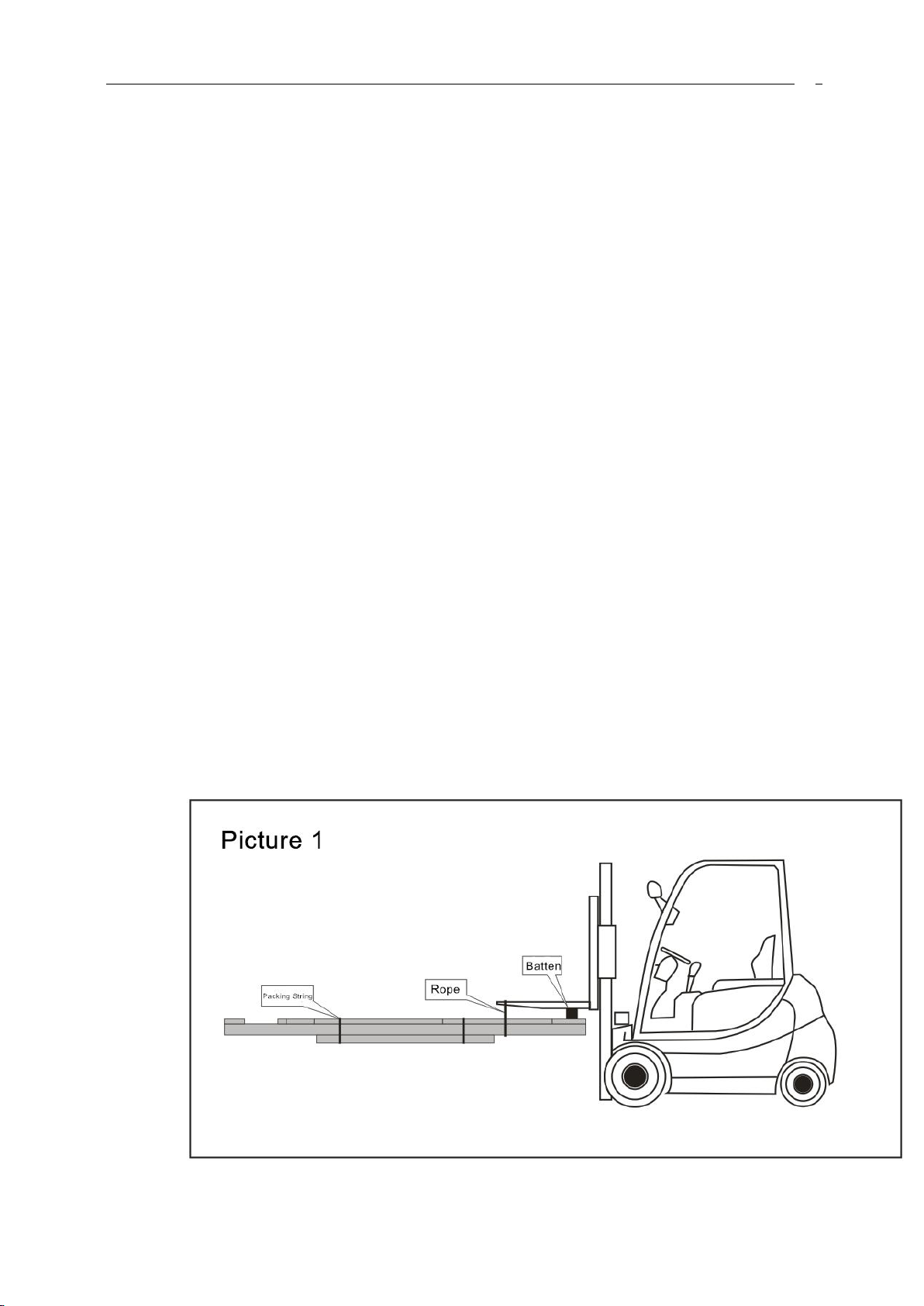

3.5 Placing the Lift in the Pit:...................................................................................................... 9

3.6 Oil filling, Exhaust and Levelling of the Platfrom:.................................................... 12

3.7 Oil filling, Exhaust and Levelling of the Secondary Lift............................................ 15

3.8 Installation and Adjustment of Limit Switch:............................................................. 15

3.9 Loading Test:......................................................................................................................... 156

4、Care and Maintence............................................................................................................................. 16

5、Matters need attention during operation.................................................................................... 16

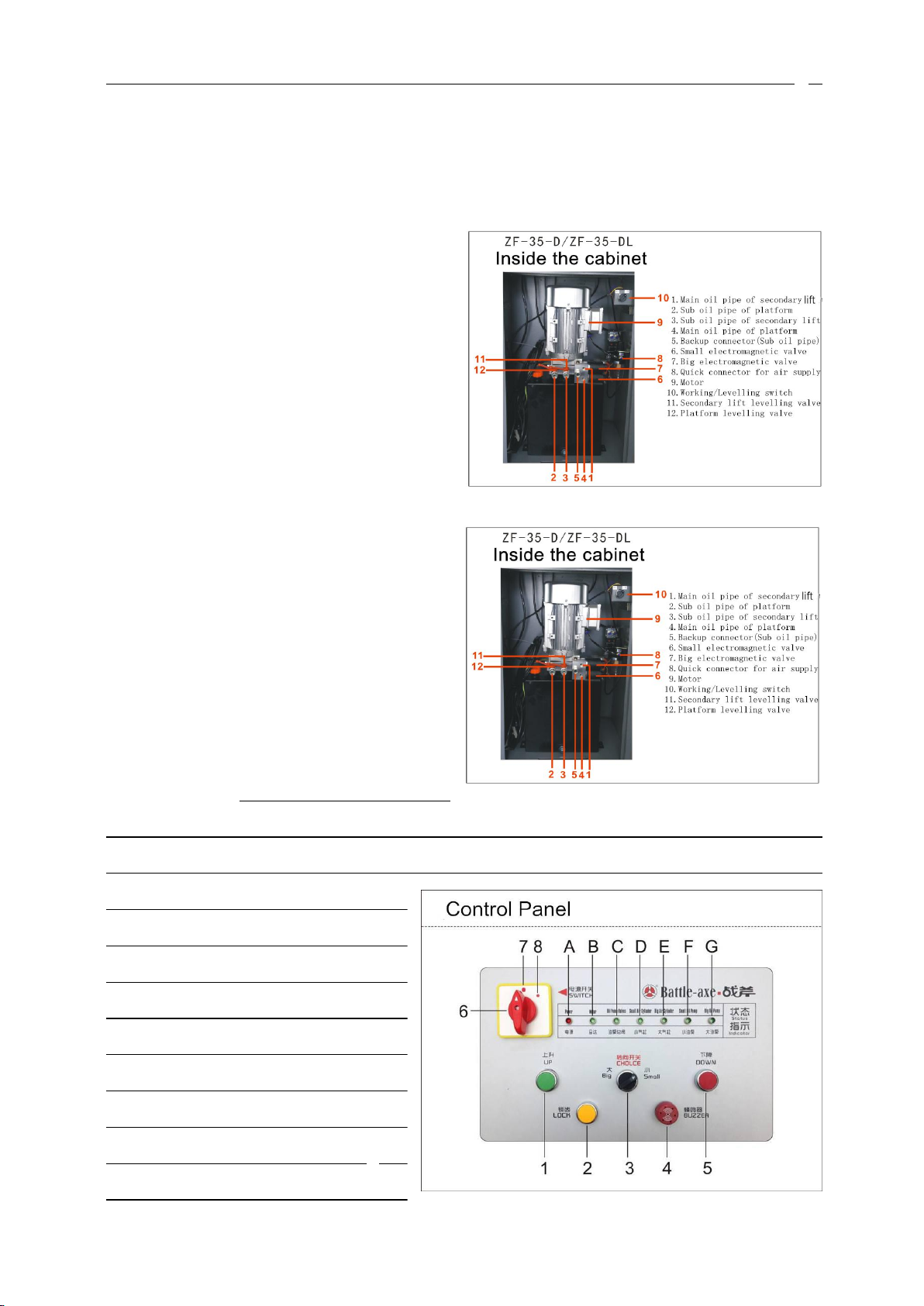

6、Operation Instruction..........................................................................................................................17

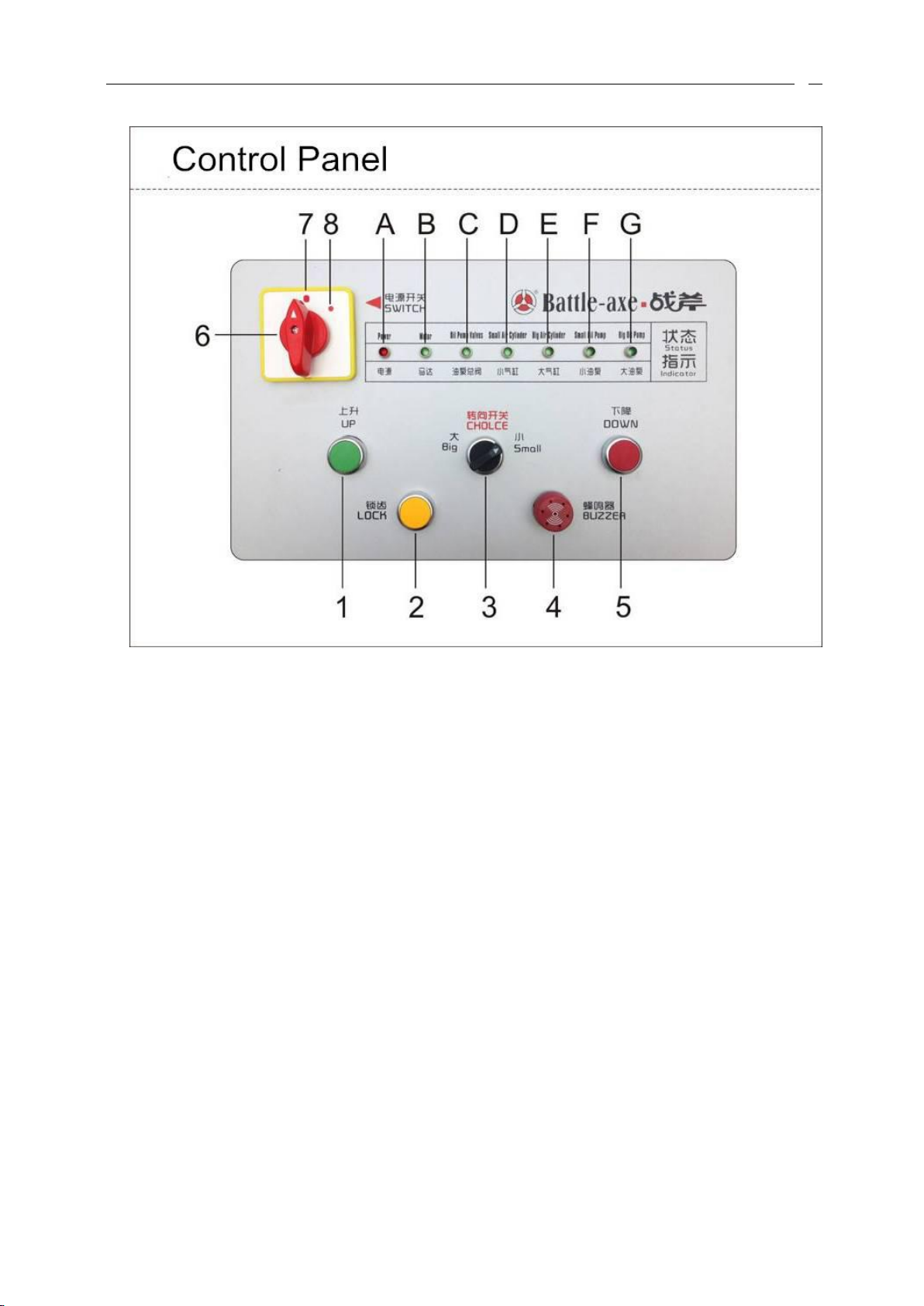

1、UP:....................................................................................................................................................18

2、LOCK:.............................................................................................................................................. 18

3、CHOICE............................................................................................................................................. 18

4、BUZZER.............................................................................................................................................19

5、DOWN................................................................................................................................................19

6、SWTCH.............................................................................................................................................. 19

7、INDICATORS A-G.......................................................................................................................... 19

7、Oil Refilling:.......................................................................................................................................... 19

8、Manual descend in case of power failure:................................................................................20

9、Failure Recovery Operation:...........................................................................................................21

10、Foundation drawing:.......................................................................................................................23

11、Oil pipe conneciton drawing:.......................................................................................................25

12、Control Panel:....................................................................................................................................26