Basic Supply Unit BUG 622, 623 3

Baumüller Nürnberg GmbH 5.94034.07a

TABLE OF CONTENTS

Table of Contents

1 Safety Notes ........................................................................................................ 5

2 Technical data ..................................................................................................... 9

2.1 General ................................................................................................................................... 9

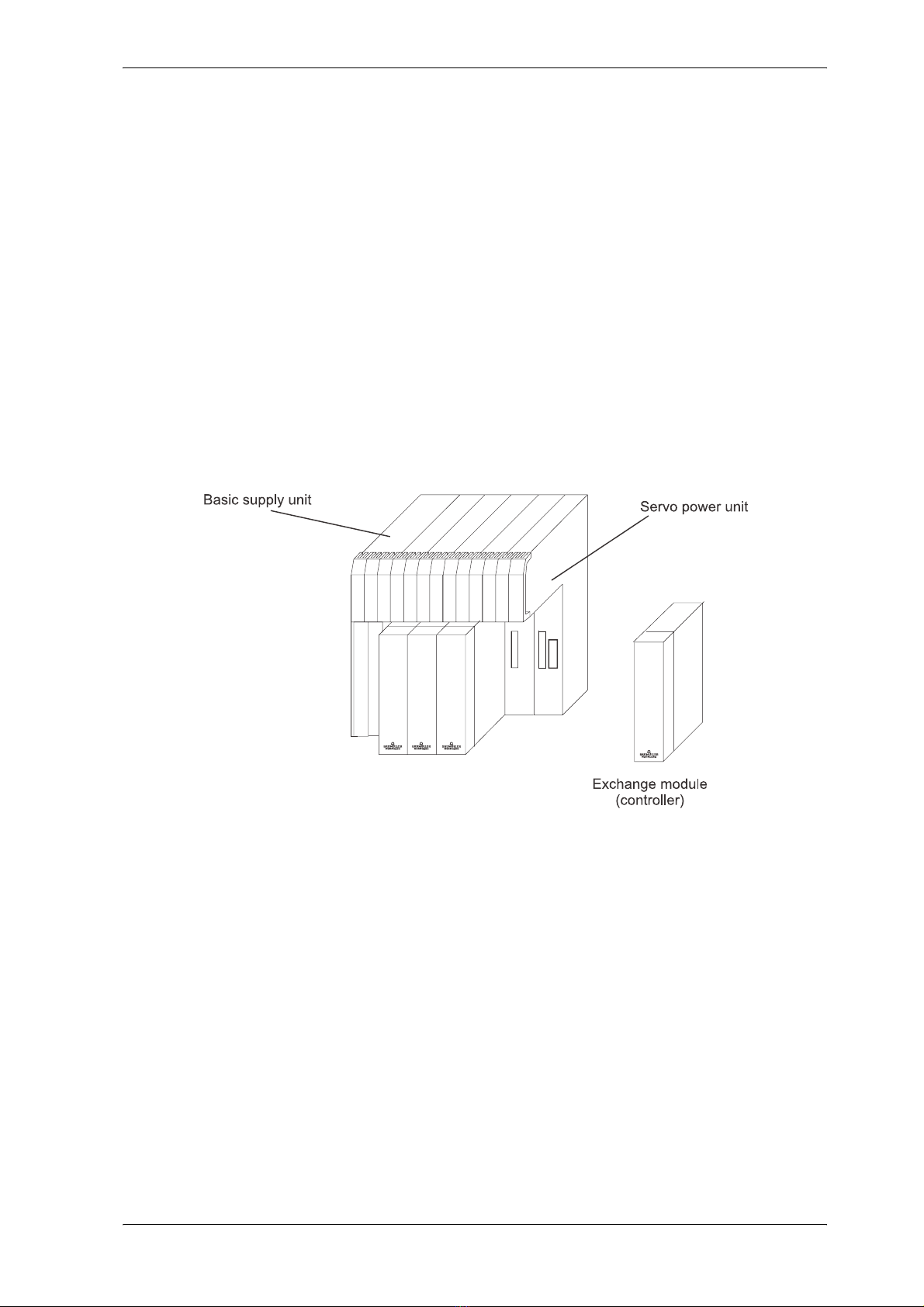

2.1.1 Function description ..................................................................................................................... 10

2.1.2 Block diagram .............................................................................................................................. 11

2.2 Electrical Data ...................................................................................................................... 12

2.3 Type code ............................................................................................................................. 15

3 Transport, Removal of Packaging .................................................................. 17

4 Assembly ........................................................................................................... 19

4.1 Dimensions ........................................................................................................................... 20

4.2 Assembly notes .................................................................................................................... 21

4.3 Attachment ........................................................................................................................... 22

5 Installation ......................................................................................................... 23

5.1 Hazard notes ........................................................................................................................ 23

5.2 Applicable standards ............................................................................................................ 24

5.3 EMC notes ............................................................................................................................ 26

5.4 Terminal diagram .................................................................................................................. 34

5.5 Connector pin assignment .................................................................................................... 37

5.5.1 Power terminals ........................................................................................................................... 37

5.5.2 Control terminals .......................................................................................................................... 39

5.6 Accessories .......................................................................................................................... 40

6 Commissioning ................................................................................................. 41

6.1 Danger information ............................................................................................................... 41

6.2 Operation .............................................................................................................................. 43

6.3 Mains failure ......................................................................................................................... 43

6.4 Messages and warnings ....................................................................................................... 44

6.5 Flow chart ............................................................................................................................. 46

7 Maintenance ...................................................................................................... 47

7.1 Maintenance information ...................................................................................................... 47

7.2 Environmental conditions ..................................................................................................... 48

7.3 Recommissioning ................................................................................................................. 48

7.4 Disposal ................................................................................................................................ 49

8 Appendix ........................................................................................................... 51

8.1 Manufacturer´s declaration ................................................................................................... 51

8.2 Declaration of Conformity ..................................................................................................... 52

8.3 General Conditions of Sale and Delivery .............................................................................. 53

8.4 Index ..................................................................................................................................... 56