bautek Fluggeräte Pico User guide

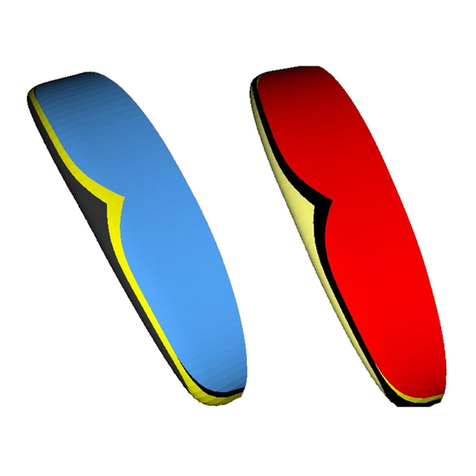

Pico/Pico S

Two-seater-wing

Pico L

Single-seater-wing

Owners Hand Book (Revision 02.2006)

bautek, Fluggeräte GmbH, Im Gewerbegebiet, 54344 Kenn, Germany

Tel. 06502-3060, Fax 06502-7436

E-mail: [email protected]

Pico Serie Operating Procedures

General

20 years of experience in hang glider design and manufacture enabled us to aim our

objectives high during the design of our Dual Microlight Wing. We wanted to set new

standards in Trike Wing handling, performance and design quality,

The construction was purposely based on the best wings available but incorporating

tried and proven innovations from our hang gliding development. Thus the Pico

became the patented Speed Valves, which are small openings in the undersurface

towards the wing tips, which gives an improved directional stability and performance

at higher air speeds. The Wing Tips have fairings fitted providing an optimal flow for

the wing tip vortices and improves the aesthetics of the wing as well.

The structure of the two-seater-wings was tested for a maximum certified take off

weight of 450 kg (992 lbs), the single-seater-wing for more than 230 kg.

During the initial design of the Pico Wing, particular attention was paid to attaining a

wide speed range. The wing has together with low bar pressures also light handling,

a fantastic performance and very balanced and safe flight characteristics.

The Pico is perfectly suitable for training, cruising and aero towing. We are certain

that the Pico will completely fulfil your expectations in every way and wish you

pleasant and adventurous flights.

Before rigging the wing for the first time, it is imperative that the Hand Book is

thoroughly read through.

The attached Aircraft Type Data Sheet is a part of this Hand Book.

Rigging from the short or long packed condition.

Open the zip of the short packed transport bag, remove the batten container and

wing tip fairings and lay them to one side. Spread the uprights apart, taking the free

end of the base bar and attaching it to the opposite upright knuckle, locking it with the

quick pin. Turn the complete wing over laying it on the base bar, open the remaining

Velcro straps. If the wing is short packed, unfold the outer leading edge tubes. Push

the outer tubes into the inner leading edge tubing ensuring that the spring loaded

snapper pins locate correctly. This can be seen when the black swivel tip spigots

point left and right towards the end of the keel tube. Finally, from a short packed wing

the sail tips now have to be pulled over both leading edge end caps. There is a thin

black webbing strap sewn to the main black sail tip webbing loop to aid this task. Pay

particular attention to the position of the main webbing loop, it must fit precisely in the

cap groove and be secured in place with the Velcro attached to the leading edge

tubing.

-2-

Spreading the sail, fitting the battens

Now spread both wing halves out and place the king post between the two cross tube

tensioning cables onto the spigot attached to the keel tube. Make sure the tensioning

cables are not twisted. Finally insert the upper surface battens into the batten

pockets, starting from the wing tips working inwards (left hand side Red, right Green)

and secure them with the batten strings doubled over. The sail can be tensioned

once all the upper surface battens have been fitted.

To tension the wing, the doubled cross tube cable must be pulled rearwards to hook

the front part of the tensioning lever onto the bolt in the attachment rail. Quite a

reasonable amount of pressure is required to achieve this. Finally, the tensioning

lever must be laid back rearwards and secured with the quick pin.

Setting up the Wing

Unless you have ordered the keel tube extension as an optional extra, you will need

a second person to assist with setting the wing up on its control frame. Together with

your helper, one of you at the front the other at the rear, lift the keel tube and unfold

the control frame forwards. The person standing at the front now takes the front lower

rigging wires and attaches the triangular screw gate link onto the retention hook on

the underside of the nose plate. The press button snapper secures the connection

and must be depressed to release the front rigging wires. Finally lower the wing onto

its nose.

Attachment of the additional cross tube retention strop

The Pico can be fitted with an additional cross tube safety strop. For this purpose,

pass the black webbing strap around the back of the control frame head piece, left

and right next to the keel tube towards the nose, and connect it with the webbing

loops above and below the cross tube centre joint, using a screw link karabiner.

Before derigging the wing, this strop must be removed first.

Tensioning the tip struts

The tip struts have a folding mechanism, with which the higher tensioning pressure of

these struts can be easily applied. Always tension the wing before tensioning the tip

struts. To tension the tip struts, unfold the shorter end of the strut towards the end of

the keel tube, placing the end of the strut into the webbing loop on the rear most sail

tip. Finally with an open hand in the sail (be careful not to trap your fingers or palm)

and the other hand on the sail tip, push the hinge of the strut towards the keel tube

until it locks after just going over being straight (geometric lock). The reverse

procedure is required to remove the tip struts.

-3-

Inserting the undersurface battens and swivel tips

Insert the straight battens through the oval openings in the undersurface until the sail

batten is completely enclosed in the batten pocket. Using the attached cord, pull the

batten back out a few millimetres until it is secured from sliding out further by the

small reverse pocket. The straight battens at not purposely marked as they easily

identified by their length. Push the swivel tips fully onto the plastic spigots, left and

right, on the outer leading edge tubes. Zips have been fitted to this area of the lower

surface to ease this task.

Install the wing tip fairings

The Pico has plastic fairings to optimise the flow of the wing tip vortices leaving the

wing. Before fitting the fairings, check once again the correct position of the sail

retention webbing loop in the leading edge end cap groove, then fit the fairing with

the winglet pointing upwards, using the attached Velcro.

Fitting the nose fairing

Place the nose of the centre sail batten onto the foremost bolt in the nose plate (if it is

not already correctly installed). Press the Velcro of the nose fairing firmly into place

on the upper and lower surfaces.

The wing is now completely rigged.

Derigging the wing is performed with the above steps in the reverse procedure.

The pre-flight checks

Make it a habit, before take off or assembly of the wing to the trike, to perform a

thorough pre-flight check. Serviceable equipment, the correct appreciation of the

flying field and weather reduce the risk of flying appreciably.

1. Holding the wing in front of you and looking along the leading edges from the

nose plate, check both leading edges for a symmetrical, smooth and an even

bend to the wing tips, check also for a symmetrical rigging of the wing. Is the

spring loaded button, to secure the lower front rigging wires, protruding

completely?

2. Is the cross tube safety strop fitted correctly and the screw link karabiner closed

tightly?

3. Are all zips in the under surface closed?

4. Are both outer swivel tips pushed fully onto the spigots?

-4-

5. Are both, the right and left hand, tip struts tensioned and are the plastic tip fairings

correctly fitted?

6. Are the lower rigging wire swages twisted, have the cables, left and right the

same tension and is the cable damaged in any way?

7. Is the quick pin securing the base bar fully inserted and safetied?

8. Are the uprights straight and is the keel tube, in the area of the mast attachment

and control frame head piece, damaged at all?

9. Are all the under surface battens installed and secured?

10.Are all the luff lines undamaged and correctly fitted?

11.Is the tensioning lever for the cross tube tensioning cables, correctly positioned

and secured with a quick pin?

12.Are all top surface battens installed and secured with the attached cords?

Occasionally check for the following

1. The tubing for bends and dents, as described in the section concerning

maintenance and repair procedures.

2. The steel cables left and right within the sail double surface, for possible damage.

3. The sail batten camber using the batten plan.

General Information and limitations

The Pico was type certified by the German Microlight Association, DULV, to a MTOW

of 450 kg (992lbs). Flight envelope +30 to -30 degrees pitch and 60 degrees roll, in

excess of which is classed as aerobatics and not permitted.

The Pico was tested in January 2000, in accordance with the in Germany, then valid

aviation standards for microlight wings. They represent the standard of technology at

the present time. As the understanding of this technology progresses, it is possible

that to date unknown physical conditions have not yet been taken into account!

We therefore recommend to include a safety reserve when choosing the weather

conditions in which you intend to fly, as well as the flight manoeuvres you intend to

perform.

Trim instructions

The Pico sail is trimmed very accurately in the works production using special

measuring instruments. It is, never the less, possible that the wing pulls to one side in

flight after a duration of time. In case it is necessary to search for the cause of such a

condition, before a trim correction is made, it must be certain that everything is

correctly rigged and no damage is present. After which, it must noted if in flight the

wing pulls to one side constantly, that is, at all speeds and at idle. If this is the case

then two correction possibilities are available:

-5-

The wing pulls to the right: Increase the camber of the sail battens No. 10 and 11

on the right hand side by approx. 5 mm, or screw the left hand leading edge end cap

tightly together with the plastic wing tip fairing in the lower hole.

If the wing pulls to one side only at high speeds then the swivel tip must be checked

for distortion/bends. Give us a call if the problem persists, and you require advice.

Maintenance und Repair procedures

For long durations of transport on a car roof rack, we recommend the use of a

specialised restraint system (e.g. Toli Carrier) or an aluminium ladder. Do not roll the

area of the Mylar insert too tight and also do not pull the Velcro straps too tight so as

not to cause wrinkles in the leading edge surface. If the sail is wet, spread the wings

slightly to allow it to dry out, otherwise mildew will develop.

When the sail or frame is found to be damaged, check all involved parts very

thoroughly, the best method is to remove the frame from the sail.

When a tube has been overloaded, it firstly becomes permanently distorted (is bent),

after which it will actually break. Therefore any bent tubing found, has already

received an overloading and must be immediately replaced, as the material structure

has already been damaged. Due to repetitive rigging and derigging, the steel cables

can suffer from accelerated wear, especially in the area close to the edges of the

swages. These areas should be regularly checked. The upper surface sail battens

should be occasionally checked for correct camber using the sail batten plan.

The length of the leading edge end caps and the tip struts are adjusted for each

individual wing. Should one of these parts require replacement, it must be adjusted to

the originals length.

All zips should be sprayed occasionally with cockpit spray (vehicle accessory shop).

Dirt and soil marks on the sail can be removed using normal washing agents.

Thoroughly rinse the sail material with clean water afterwards. Stains on the Mylar

sail or adhesive remains from registration numbers can be removed using acetone.

The Mylar sail is best preserved and protected with the use of a synthetic material

spray (such as Amour or similar, also vehicle accessory shop). If the chance of a

flight in rain cannot be completely discounted, the leading edge should rubbed with a

light film of washing liquid, so that the risk of rain drops clinging to the leading edge

and disturbing the normal airflow, thus causing an increase in the sink rate, is

reduced to a minimum. For this reason areas of rain should be avoided if at all

possible.

Attention!

In accordance with the regulations of the German Microlight Association,

DULV, the Pico must be checked once every year.

-6-

Technical specifications

Type name Pico Pico S Pico L

Wing area 14.8 m² (159 sqft) 12.2 m² (131 sqft) 12,2 m² (131 sqft)

Wing span 9,92 m (30,2 ft) 9.52 m (29 ft.) 9,52 m (29 ft.)

Qty of upper battens 22 + Centre batten 20 + Centre batten 20 + Centre batt.

Qty of lower battens 8 + 2 tip struts 8 + 2 tip struts 8 + 2 tip struts

Qty of Luff Lines each side 3 each side 3 each side 3

Swivel Tips 1 per side 1 per side 1 per side

Weight 49 kg (108 lbs) 47 kg (104 lbs) 39 kg (86 lbs)

Nose angle 132 ° 132° 132°

MTO 450 kg (992 lbs) 450 kg (992 lbs) 230 kg (507 lbs)

Sail material leading edge GTS-UV-Trilam-Surf,

Top surface NCV-Grille-UV-protection,

Lower surface Polyester 180g (4.0 oz), various sail colours

available without addition cost,

Stitching V69 with UV resistance.

Performance Data

Type name Pico Pico S Pico L

V min. 45-48 km/h 57-60 km/h 44 km/h

28-30 mph 35-37 mph 27 mph

V cruise 80-100 km/h 100-130 km/h 70-90 km/h

50-62 mph 62-81 mph 43-56 mph

V max. 140 km/h 160 km/h 120 km/h

87 mph 99 mph 74 mph

bautek Fluggeräte GmbH

Gewerbegebiet

54344 Kenn

Germany

Tel. 0049 6502 3060, FAX 7436

www.bautek.com

This manual suits for next models

2

Other bautek Fluggeräte Aircraft manuals