bautek Fluggeräte FIZZ User manual

Bautek:

FIZZ

Manual

Bautek :

FIZZ

Owner Manual March 2012

Translation by Konrad Kurp for:

Bautek Fluggreraete Gmbh

Gwerbegebiet, 54344 Kenn, Germany

Table of contents page 1

General Introduction 2

Package contents 3

Set-up from short-pack 3

Leading edge assembly 4

Sail spreading and top battens 5

Spreader bar tensioning 6

Folding tip battens and sail end winglets 7

Bottom battens and swivel tips 8

Nosecone 9

Pre-flight check and start 10

Flight 11

Landing 12

Towing 12

General information 12

Optimum trim 13

Trim: center of gravity and straight flight 13

Break down 14

Maintenance and repair instructions 15

Storage and care 15

Technical data 16

Inspection regulations and protocol 17-23

Specifications _

Fizz Manual [as of 27. March 2012]

General Information

The “Fizz” evolved out of a two year development for a new, light, topless,

high performance glider, which produced after a year a flight ready prototype;

but the weight did not satisfy the high expectations. Therefore a change in

concept was made, before the extensive flight tests were started.

Most pilots, especially longtime and experienced ones, today prefer light,

uncomplicated, but high performance and affordable gliders. The heavy,

topless, high-performance, competition gliders are too demanding to fly and

take the fun out of hang glider flying!

For this reason we developed five years ago the kingposted high performance

“Kite”, which excites many pilots by it’s easy handling and very good

thermaling characteristics today and will do so in the future.

The planned topless was to become a top class glider with kingpost, that sets

new standards in faster glide mode and in X-country flying.

The engine of any hang-glider is the sail. With best sail fabrics the cut for a flat

wing profile was fitted to the flexibility of the leading edge tubes and the sail

battens. In frame and cables we can trust our safe and tested components.

Everything is light and simple to inspect; damage can be repaired

economically.

At the end of a development each glider has a personality, representing

launch-, flight- and landing-characteristics, which are marked by the goal and

capabilities of the designer. With the “Fizz” our top model became reality! We

are convinced, the “Fizz” matches exactly the expectations of the demanding

recreational- and X-country pilot.

Best thermaling and climbing characteristics

Very good glide ratio in wind penetration or fast

flight

Easy launch- and landing characteristics

Safety tested for DHV-airworthiness requirements

Bautek maintenance and repair service

The “Fizz”:

Full Mylar sail of high quality ODL 04/06 (Technora Black)

90% double surface sail

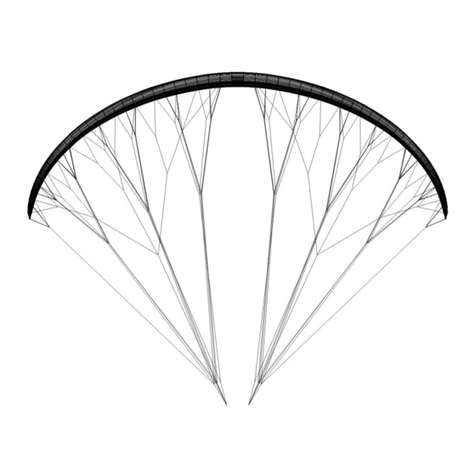

Thin wing profile with 24 top and 6 bottom battens

Narrow wing projection of 152 sft.

VG extended travel with a 24to1 advantage, for easy operation

Radial wingtips with winglets

Spring loaded side wires

Optional profiled Alu-Speedbar with split wheels

Thanks to many clever construction details the set up and break down of this

glider is exemplary simple, and without effort.

We wish you many beautiful flights and always “happy landings”!

Delivery package:

1 Batten plan; 1 Batten-quiver; 3 Padding [kingpost, keel center and end]; 2

yellow Velcro ties; 1 red Velcro tie; 2 Batten plugs front and rear; 2 Wing tip

bags; 1 Cover bag.

Before the first time set-up, it is necessary to read this manual

thoroughly. For additional questions or when uncertain the

manufacturer should be consulted.

The enclosed “Air sport equipment certificate” is part of this manual.

Assembly from the short pack of 13.5 ft [4.15 m]

(Combination cover bag long/short)

Lay down the short pack with the control bar area pointing up. Open the

zipper and put the batten bundle [quiver] and both rear leading edge [wing

tubes] to the side. If you are flying with non-split wheels, slide these on the

speed bar now, before mounting it.

The bow of the speed bar is pointing up, when assembling. Alternatively the

use of a profiled bautek- Alu-speedbar [with or without wheels] is an option.

Attach the speed bar right and left with the push-pins at the control bar

corners.

Now turn the wing over so it lies on the control bar and open the Velcro ties.

Unfold the rear sail-halves to the rear and the swivel-tip of the right and left

outside [= rear] leading edge tube towards the front in the direction of the

keel.

Push the rear sections of the leading edge tubes from the rear into the sail. Let

the swivel tip exit the double sail at the zipper opening and push the tube into

the front leading edge tube with the swivel tip cable pointing up. The swivel

tip will swing to the rear. Press both snaps in and see that both snap out again

through the holes in the front tube.

Then pull the wide, black, inside loop at the end of the sail leading edge over

the end-cap of the rear leading-edge tube. There is an auxiliary loop, which

helps to do this. Pay attention to the proper seating of the loop webbing in the

grove of the plastic end-cap. Close the Velcro loop inside the sail to keep the

black loop from moving out of its grove during transport.

Spreading the sail and inserting the top battens:

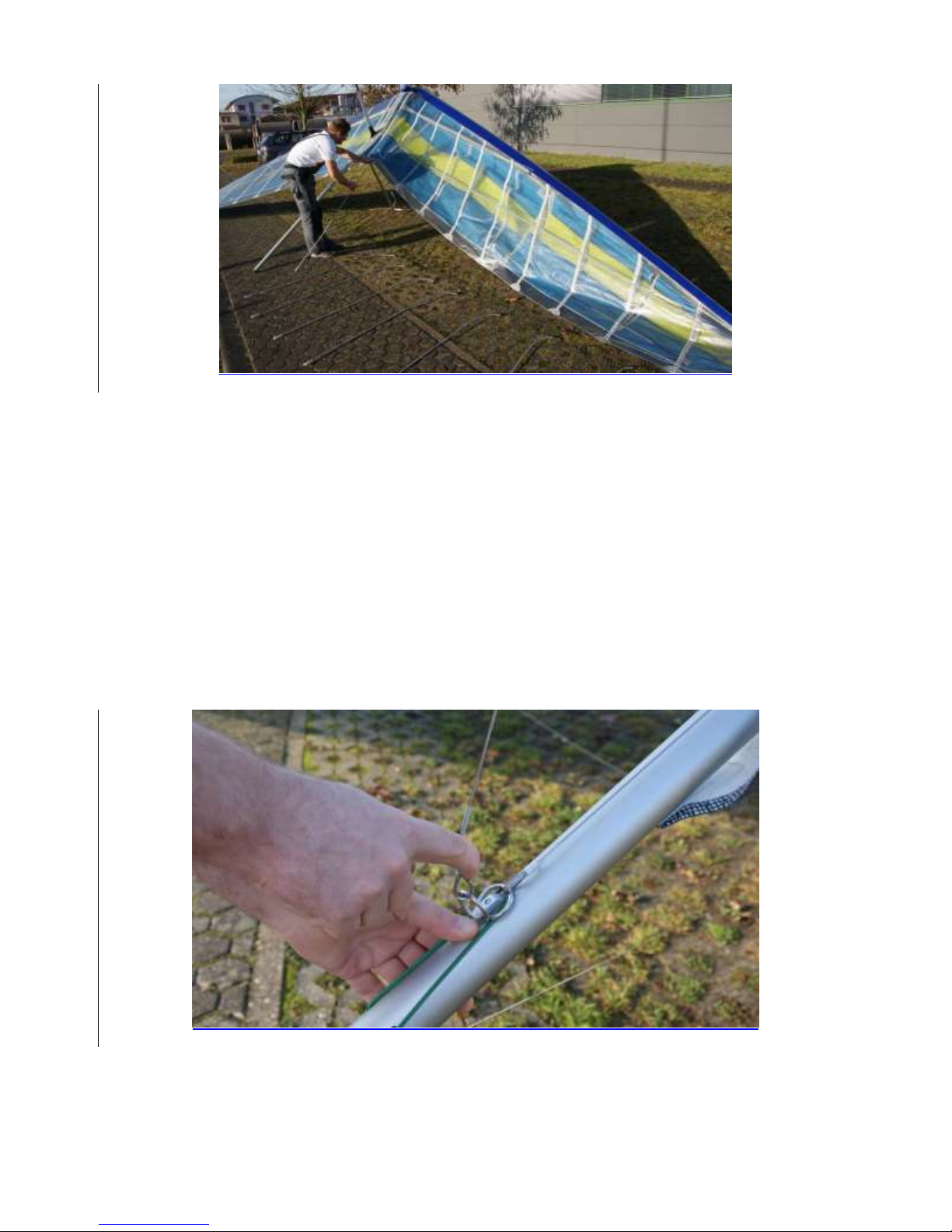

Stand the glider on the control bar and raise the kingpost.

Spread the wings in steps, since the spreader bar has limited float.

In strong winds keep the glider flat on the ground for the next steps.

Push the top battens 1-10, starting at the center with Batten 1, into their sail

pockets and secure them with the spring-loaded end plug, by pushing the plug

forward against the spring and releasing the flat tang into the open space in

the trailing edge seam of the sail.

Red batten numbers = left side, green batten numbers = right side, looking in

flight direction. [Portside and Starboard for the mariners] The batten quiver

has separate pockets for the right and left wing. After the top battens are

inserted, you can stand the glider up, if not done earlier, and tension it.

Before tensioning the glider, standing on the control bar, the wings should be

spread as far as possible. Out of the keel-pocket leads a tensioning line to an

elongated hole in the keel tube. Pull the spreader bar with this line to the rear

and hang the steel ring in the notch of the tension line receptacle.

Then the steel ring of the rear upper rigging placed in the same notch. Check if

the snap behind both rings is out and secures them.

In the front the two nose wires of the lower rigging are combined with a small

screw closed triangle. Hang the triangle into the receptacle under the nose

plate and again confirm that the snap secures it.

After this attach the snap hook of the spreader-bar safety cable from below =

upwards into the tensioning line eye at the spreader bar; the zipper of the

double sail is closed after this.

Folding tip battens tensioning; sail end caps = winglets attachment:

The folding mechanism of the tip battens allows their tensioning with ease.

Tension the tip batten always after the spreader bar is tensioned. With de-

tensioned mainframe [=spreader bar] the tip battens carry substantial higher

loads! For tensioning unfold the short end of the batten tube in the direction

of the end of the keel and insert its end plug into the web loop at the rear sail

corner. Now with the open hand [Warning: danger of pinching] inside the

double sail and the other hand at the sail corner, push the hinge of the batten

past its balance point in the direction of the end of the keel.

Fit the two sail end caps [winglets] outside, exactly at the front of the sail and

close the Velcro at the edge of the upper sail first and then the one at the edge

of the lower sail.

Inserting lower sail battens and folding out the Swivel-tips:

Push the straight battens into their pockets in the lower sail; they are not

specifically marked, but clearly of different length; the elongated holes in the

lower sail mark their pockets. Insert them fully and secure them against the

rear seam.

The swivel tips are now folded out and automatically secured in their rear

pocket and the closure of the zipper.

Nose plate cover:

The center battens rest each on a rivet case in the upper nose plate. In the

leading edge right and left in the nose plate area are two short zippers, which

prevent folding of the leading edge in the cover / transport bag. Before you

place the nose plate cover as the last step of the set-up, take a look through the

opening of the upper sail at the nose plate area; make sure all parts are

operational. Close the two zippers in the leading edge and press the Velcro

strips of the cover in the proper position at the upper and lower sail on.

The glider is now flight-ready assembled.

Pre-flight check:

Make it a habit, to do a careful pre-flight check before each start.

Functioning equipment and proper judgment of conditions and the

weather reduce the risk in hang gliding significantly.

1. Check from the nose plate the even bend of both leading edge tubes,

the symmetrical assembly of the glider and the “out” position of safety

snap for the nose wires.

2. Check for easy operation of the VG pulley system and proper

functioning of the VG jam cleat.

3. Base tube installed correctly and no cables kinked and tangs or eyes

twisted?

4. Down tubes straight? Keel tube undamaged at control bar apex?

5. Check all lower rig cables, especially at eyes and press fittings.

6. Lift the glider at the rear end of the keel and check with tensioned VG

for symmetry of the glider, the swivel tips right and left and installation

of the straight battens and their secure seat in the double sail seam.

7. Tensioning line/cable ring seated correct in its seat?

8. Is the keel pocket screwed securely to the keel tube?

9. Are both pilot Hang strap and Safety strap correctly fastened and

undamaged?

Periodically and after a crash inspect in addition:

All tubes for dents and bends as described in the maintenance and

repair protocol.

Upper and lower rigging right and left and the lines and cables inside

the double sail as well as the swivel tip cables.

Batten curves according to the batten chart.

Start:

Always make a hang check before the start or always get in your harness after

it is hooked to the glider and the karabiner is locked. One standard routine

needs to be adopted. A hook-in check is essential immediately before any

start.

The “Fizz” is neutral on the shoulders and easy to guide on launch. The

integral spring system keeps the side wires tensioned, even when the VG is

off; so there is no problem to set proper attitudes and balance for the start.

Pilots, who like “tight” side wires for launching, can do so with ca. 3 ft pulled

out on the VG. Start with a slow jog and accelerate continuously till lift-off.

Close your harness after you are a safe distance from the ground and the

glider flies self-stabilizing.

Flight:

The Fizz has a variable geometry = nose angle [VG], with which the sail

tension can be increased in flight. With loose VG the wing has more twist, is

neutral in turns and easy to handle. For the first flight half tensioned VG is

recommended to avoid over controlling. Even with full tensioned VG can

the Fizz be controlled around the vertical axle; in this configuration the

wing has little twist and its best glide ratio. The Fizz should be steered with

short control impulses, especially at higher speeds under tow, e.g. winch- or

UL aero-tow. Airstream separation [stall] occurs late with loose VG setting and

is easily controlled; after a short dip of the wing the airstream reattaches right

away. With full tensioned VG the stall is more sudden and the wing dips more

pronounced. In very slow turning mode, with tensioned VG the Fizz can be

made to spin, by weight transfer to the rear [“pushing out”]. To exit a spin

bring your weight forward [“pull in”] first then steer against the turn to

the outside of it. [Roll input is after pitch input] For fast altitude loss, e.g. in

“cloud suck”, pull in the base tube and put your weight in one corner. In steep

spirals a lot of altitude is destroyed this way. To exit such a maneuver, center

your weight and level out gradually.

Landing:

Landing starts at altitude with repeated checks of the wind direction. Only

after you are sure of the wind direction, should one decide on the approach

and then stick to it.

The Fizz is easy to land; but an exact landing pattern is important. Too much

altitude is hard to get rid of. Fly the final approach in a straight glide with

some extra speed against the wind and let the glider lose its energy in ground

effect. Change hand position when the glider flies level and at trim speed.

Keep your legs bent and behind you till flair time; arch your back. Your

upper body is thus closer to the down tubes and you have a longer way for the

flair. The Fizz glides long in ground effect and stalls soft and easy, with 1/3 VG

harder, but more definitive. The nose comes up by itself during the flair,

increases angle of attack and drag, and stand up landings are already possible

in a light head wind.

Towing:

The Fizz is licensed for winch- and UL- tow. Requirements for this per DHV

are:

A certified hand glider tow winch

Tow training of the pilot

Training of the winch operator and the UL-Pilot

A certified tow hook up / latch system

For the UL-tow the VG should be ca. 70-100 % tensioned. Then the glider has

less control bar pressure, but is still very controllable. Give at disturbances

only short, strong steering impulses with the hip [body center of gravity]

and keep the tow latch in the middle of the base tube. Weight shift into a

corner and waiting for a course correction leads as a rule to PIO [pilot induced

oscillations] of the glider. Do not support yourself on the base tube. Tip: Pull in

on the base tube with open hands.

General information and limitations:

The Fizz is in Germany type tested by the DHV and certified as a class 3 model.

The Fizz is licensed to be flown only:

by pilots with a correspondent license and training

solo

with an angle of +30deg to -30deg to the horizon

with a roll angle up to 60deg, and

with a top speed of max. 56 mph

The Fizz is not to be used for aerobatics. It can be motorized with

different motor systems [take notice of the license].

In Germany hang gliders can only be started and landed I approved/official

fields. Is after a X-country flight an out landing is necessary, a timely search

for a suitable landing field is advisable. If damage is caused in the landing,

owner and personal liability insurance company are to be informed.

Maximum flight enjoyment through optimal trim:

The sails of modern High Performance [HP] gliders are more tensioned and

therefore more sensitive to their configuration = trim. Sail fabric and sail-

construction tolerances are with special measuring devices taken into account

and individually corrected for. Despite these in depth measuring techniques it

might be necessary after some time, to correct the basic trim.

Test the glider always in light thermal conditions, because changes in flight

characteristics are easier detected in moving air. It is certainly not the case

that more tension also brings about better performance. The sail tension in

the direction of the wingspan can be changed with the position of the leading

edge end pieces and the folding batten length. The end pieces are in standard

production screwed through the middle hole to the tube end.

In case you make any changes, we recommend, marking first the old

position, so that in case the change is unsuccessful, the original position

can be found again.

Center of gravity:

The Fizz should fly ca. 18.5-22 mph [30-35kmh] with hands of = at trim. By

repositioning the kingpost in its base [case-nut, for six point insert] the center

of gravity can be adjusted. Moving forward = nose heavy = faster, to the rear =

tail heavy = slower!

Straight flight:

Glider draws slightly to the right: left end piece higher, i.e. screwed through

the lower hole, or/and reducing right folding batten length by ca. two

revolutions.

Glider draws slightly to the left: right end piece higher, i.e. screw in lower

hole, or/and batten length on left side reduced by ca. 2 revolutions.

If these changes are not sufficient, can on the better carrying side the bend of

batten no. 10 at the high point be reduced by ca. 3/16 to 3/8 inch [5-10mm];

or on other side be increased.

If the leading edge end piece tension is increased on one side, then the folding

batten of the same side has to be lengthened by ca. 5/32 inch [4mm]. The

folding batten has a threaded adjustment at the front, turning the nut changes

the length of the batten. Check the curve of the battens from time to time.

Call us, if flight characteristics and performance of your glider do not

meet your expectations and you are not totally enthusiastic about your

wing. We love to advise you in finding the optimal adjustment / trim for

your weight.

Warnings:

Open zippers and / or no nose cone result in a dangerous flying tendency with

negative bar pressures, especially in fast flight. In this case fly rather slow to

the closest landing area!

Raindrops on the leading edge disturb the airflow! In this case fly faster, to

blow them partially off, do not fly tight turns and anticipate an early and

sudden stall at the landing. Tip: Apply a dishwashing soap to the leading edge

before the start. This prevents for a time the forming of droplets and assures

normal flight characteristics even in rain!

Glider breakdown:

The breakdown of the glider is done in reverse order of the assembly, with

attention to the following details:

Remove the nose cone and open both zippers at the leading edge, before you

place the glider down on the nose. Open the zippers of the four swivel tips and

swing the swivel tips outward.

Loosen the underside of the sail end caps [winglets] first with a finger, before

removing the caps sideways from the Velcro on the upper sail edge.

Pull the lower battens and detention the folding battens. Set the glider on the

end of the keel and detach the spreader bar safety cable and the triangle of the

nose wires. This triangle can be hooked into the snap hook of the spreader bar

safety cable, so it is close at hand at the next assembly.

Pull the upper battens 10 –1 right and left out of the sail and fold the wing in

increments together. Roll up each side of the sail and secure each side,

separately at the middle swivel tip with a flour yellow Velcro tie. The red tie is

longer and is placed in front of the control frame apex. Each rolled up sail end

is put together with the folded swivel tip in the long cover bag.

Close the ties loosely to avoid permanent folds. Pull the cover bag over the

standing glider and close it’s zipper from the front up to the control frame

apex. Now turn the glider over, lay it on it’s back and remove the speed bar.

Put the protective pouch, sown to the cover bag, over both down tube ends.

Lay the batten bag and the sail end caps in the rear of the cover bag. Close the

zipper all the way.

Maintenance and Repair protocol:

For car transport a special support system or a ladder are advantageous. Do

not roll the sail to tight at the Mylar insert. The Velcro ties should also not be

too tight, to avoid folds in the leading edge. A wet glider needs to be spread

out for drying after transport, to prevent mildew spots in the sail. Undo the

Velcro ties for this! Carefully inspect the glider after a crash!

In the lower sail at the keel and the swivel tips are zippers, which facilitate a

thorough inspection. After a hard crash the disassembly ob the tubes is

recommended. In an overload situation a tube is first permanently bent and

then breaks subsequently. Therefore bent tubes where already overstressed

and need to be promptly replaced, because the metal structure is damaged.

Call us, if in doubt. Because of repeated set up and break down most cables are

subject to added (ab-) use, especially in the area of the press fittings and eyes;

Check this area regularly!

From time to time the sail battens need to be checked for correct form

according to the batten plan. The length of the leading edge tube end piece is

for each glider individually adjusted. If such a part is replaced, the original

length must be ordered or adjusted to.

Damaged down tubes can be removed by pushing in the snap safety at the top

and unscrewing the M5 Allen bolt at the bottom. All bolt connections without

nylon locknuts are to be secured with Loctite 243. Instructions are on the

Loctite container.

Inspections:

After 60 month the Fizz needs to be inspected by the manufacturer or

self inspected according to the attached inspection protocol. This

inspection is to be repeated and documented every 24 month thereafter.

Storage, maintenance and disposal:

Spray all zippers from time to time with Cockpit spray [silicon spray].

Standard gentle washing soaps will clean the sail. Rinse with clear water.

Spots on the Mylar leading edge, e.g. adhesives from markings can be removed

with acetone. For maintenance of the Mylar upper sail and the leading

edge a plastic deep care solution [automotive shop] can be used. This

keeps the Mylar flexible and protects it better from sunlight [UV-

radiation]. Store the glider in a dry room on wall brackets.

For transport on the car roof support a PVC cover bag over the light

standard bag is recommended. This will protect the sail from rain and

flapping.

For final disposal of the glider cut up the sail with a new box knife and bundle

it. The sail fabric is polyester and goes to a waste disposal site. The aluminum

tubes get disassembled and go with the SS cables and bolts to the metal

recycler.

Technical specifications:

Bautek model: Fizz

[type tested DHV 01-0462-12]

HG class: DHV

3, solo

Sail area: 152

sft [14.1 qm]

Span: 34 ft

[10.41 m]

Nose angle: 130

degr.

Aspect ratio: 7.7

Double surface: 90 %

Length packed-: long

18.7 ft; short 13.5 ft [5.7m, 4.1m]

Battens: 24

top; 6 bottom

Stall speed: ca. 16

mph [25 km/h]

Other bautek Fluggeräte Aircraft manuals