Supplied By www.heating spares.co Tel. 0161 620 6677

1.0 Introduction – Page 4

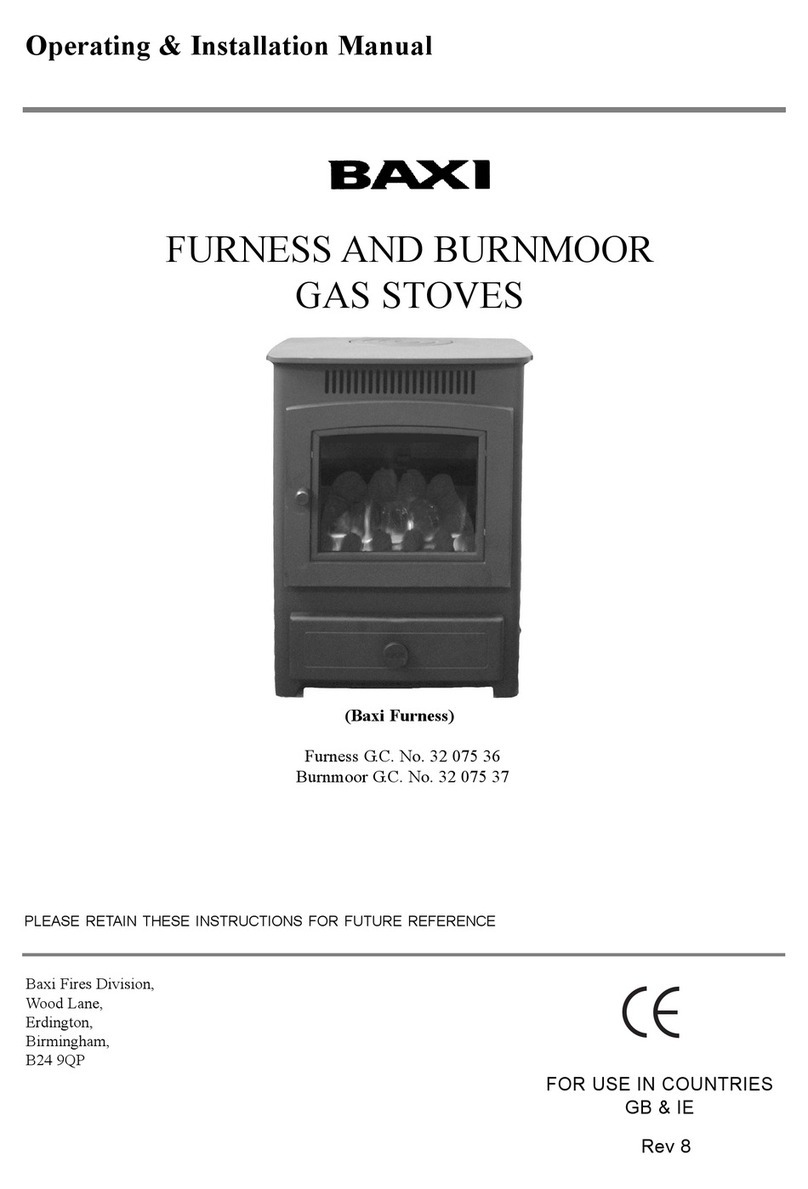

1.1 Description

1. The Baxi Windermere RF and TF and Grasmere RF and

TF are gas fired stove - style appliances with heat inputs of

8.17 kW (27,876 Btu/h) and 6.5 kW (22,178 Btu/h)

respectively at maximum setting. They are designed to be

used on Natural Gas only at a setting pressure of 20mbar

on an installation with a governed meter. The appliances

are intended for heating and decorative purposes.

2. For details of Propane appliances see section 13.0

Propane Models.

3. They incorporate a safety feature in the form of a spillage

monitoring system which must not be adjusted or

bypassed.

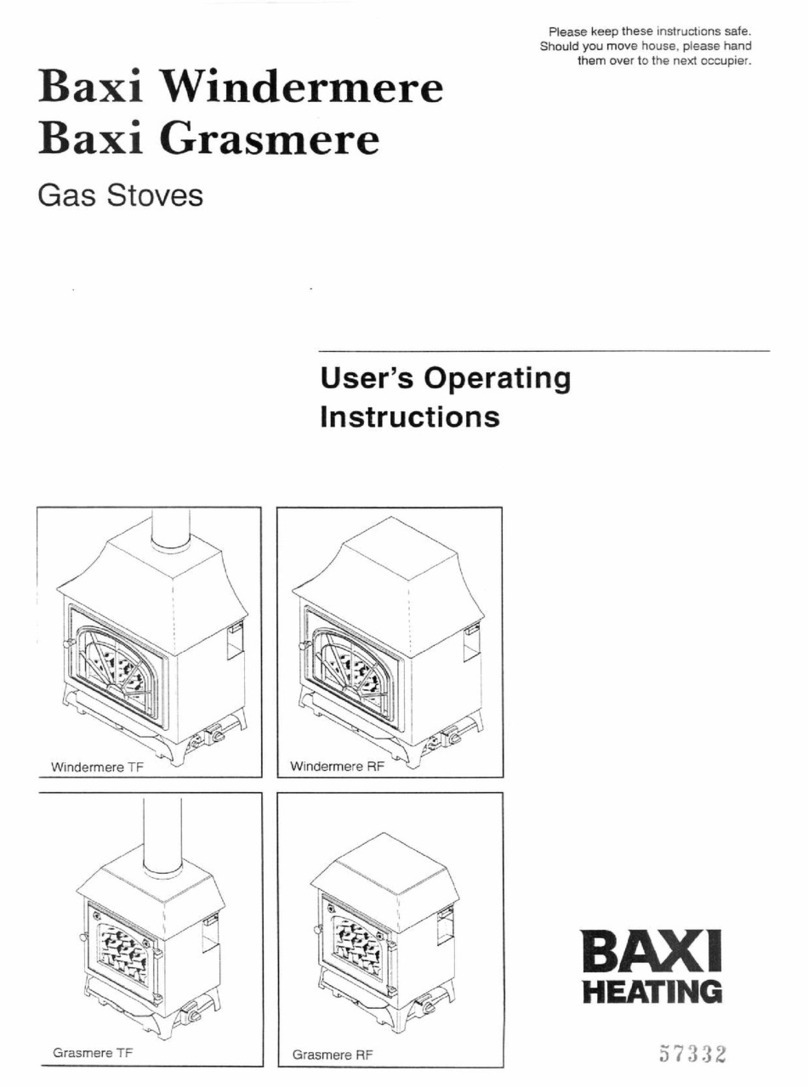

4. The stove is controlled by a knob which is positioned at the

lower right hand side of the appliance (Fig1). The knob has

four positions:

OFF IGN LOW HIGH

5. The pilot will be lit at IGN.

1.2 Installation

1. Prior to installation, ensure that the local distribution

condition (identification of the type of gas and pressure)

and the adjustment of the appliance are compatible.

2. The appliance is suitable for installation only in GB. and

I.E. and should be installed in accordance with the rules in

force. For Ireland install in accordance with l.S.813

“INSTALLATION OF GAS APPLIANCES”. The

installation must be carried out by a CORGI Registered

Installer or other competent person and be in accordance

with the relevant requirements of the current GAS

SAFETY (Installation and Use) REGULATIONS (as

amended), the BUILDING REGULATIONS issued by the

Department of the Environment, BUILDING STANDARDS

(Scotland) (Consolidation) REGULATIONS issued by the

Scottish Development Department and the LOCAL

BUILDING REGULATIONS. Where no specific

instructions are given, reference should be made to the

relevant BRITISH STANDARD CODES OF PRACTICE.

2. This appliance must be installed in accordance with

the manufacturers instructions and the rules in force

and only used in a suitably ventilated location.

3. Read the instructions before installing or using this

appliance.

Notice

Discolouration of wall surfaces

Most heating appliances generate warm air convection currents

and transfer heat to any wall surface against which they are

situated.

Some soft furnishings (such as blown vinyl wallpapers) may not

be suitable for use where they are subject to temperatures

above normal room levels and the manufacturer’s advice should

be sought before using this type of wall covering adjacent to any

heating appliance.

The likelihood of wall staining from convected air currents will be

increased in environments where high levels of tobacco smoke

or other contaminants exist.

1.3 Important Information

This product contains Refractory Ceramic Fibres (R.C.F.) which

are man-made vitreous silicate fibres. Excessive exposure to

these materials may cause temporary irritation to eyes, skin and

respiratory tract. Care must be taken when handling these

articles to ensure the release of dust or fibres is kept to a

minimum.

To ensure that the release of fibres from these articles is kept to

a minimum, during installation and servicing it is recommended

that a H.E.P.A. filtered vacuum is used to remove any dust, soot

or other debris accumulated in and around the appliance. This

should be performed before and after working on the

installation.

It is recommended that any replaced item(s) are not broken up

but sealed within heavy duty polythene bags and clearly labelled

“R.C.F. waste”. This is not classified as ‘hazardous waste” and

may be disposed of at a tipping site licensed for the disposal of

industrial waste.

Protective clothing is not required when handling these articles

but it is recommended that gloves are worn and the normal

hygiene rules of not smoking, eating or drinking in the work area

are followed and always wash hands before eating or drinking.