BAYKON BX11 User manual

BX11

Smart Process Indicator

Technical Manual

BX11 Smart Process Indicator, Technical Manual, Rev. 1.2, May 2013

Pa e 1 of 92

Contents:

1.

Safety Instructions ................................................................................... 4

2.

Introduction ............................................................................................. 6

2.1

Overview ....................................................................................................................................... 6

2.2

Key features and specifications ..................................................................................................... 6

3.

The Front View and Key Functions ........................................................... 9

3.1

Display .......................................................................................................................................... 9

3.2

Key Pad ....................................................................................................................................... 10

3.3

Key Lock ..................................................................................................................................... 10

3.4

Housin ....................................................................................................................................... 10

3.5

Accessories ................................................................................................................................. 12

3.5.1

Accessories supplied with the instrument .................................................................................... 12

3.5.2

Accessories sold separately ........................................................................................................ 12

4.

Installation ............................................................................................. 13

4.1

Recommendations ...................................................................................................................... 13

4.1.1

Control Cabinet Desi n ................................................................................................................ 13

4.1.2

Cablin ....................................................................................................................................... 13

4.2

Mechanical Installation ................................................................................................................ 13

4.3

Electrical Connections ................................................................................................................. 13

4.3.1

Power Supply Connection and Groundin .................................................................................... 14

4.3.2

Load Cell Connection ................................................................................................................... 15

4.3.3

RS 232C Connection ................................................................................................................... 15

4.3.4

RS 485 and Modbus-RTU Connection .......................................................................................... 16

4.3.5

Analo ue Connection (only BX11 AN ) .......................................................................................... 16

4.3.6

Profibus Connection (only BX11 PB ) ............................................................................................ 17

4.3.7

Profinet Connection (only BX11 PN ) ............................................................................................ 17

4.3.8

Ethernet Connection (only BX11 EN ) ........................................................................................... 18

4.3.9

CANopen Connection (only BX11 CO ) .......................................................................................... 19

4.3.10

Di ital Inputs and Outputs Connection ......................................................................................... 20

4.4

Commissionin ........................................................................................................................... 22

5.

Serial Data Outputs ................................................................................ 23

5.1

Continuous Data Output .............................................................................................................. 23

5.2

Fast Continuous Data Output ....................................................................................................... 24

5.3

Print Mode .................................................................................................................................. 24

5.4

BSI Data Structure ....................................................................................................................... 25

6.

Pro rammin and Calibration ................................................................. 33

6.1

Enterin the Pro rammin and Calibration .................................................................................. 33

6.2

Fast Access to the Calibration ..................................................................................................... 34

6.3

Exitin the Pro rammin and Calibration ..................................................................................... 34

6.4

Pro rammin .............................................................................................................................. 36

7.

Analo ue ( only BX11 AN ) ..................................................................... 52

8.

Modbus RTU ( only BX11 MB ) ............................................................... 53

8.1

Modbus RTU Data Structure ........................................................................................................ 53

BX11 Smart Process Indicator, Technical Manual, Rev. 1.2, May 2013

Pa e 2 of 92

9.

Profibus ( only BX11 PB ) ....................................................................... 59

9.1

GSD Confi uration ....................................................................................................................... 60

9.2

Profibus DP Data Structure .......................................................................................................... 61

10.

Profinet ( only BX11 PN ) ........................................................................ 66

10.1

Profinet Parameters .................................................................................................................... 67

10.2

GSDML Confi uration .................................................................................................................. 68

10.3

Profinet Data Structure ................................................................................................................ 69

11.

Ethernet TCP/IP ( only BX11 EN ) ............................................................ 74

11.1

Ethernet Setup ............................................................................................................................ 74

11.2

Modbus TCP Data Structure ........................................................................................................ 76

12.

CANopen ( only BX11 CO )...................................................................... 81

12.1

EDS Confi uration ....................................................................................................................... 82

12.2

CANopen Data Structure .............................................................................................................. 83

13.

Trouble Shootin .................................................................................... 88

14.

Parametre’s Default Table ...................................................................... 89

15.

Calibration Table .................................................................................... 90

16.

Frequently Asked Questions ................................................................... 91

BX11 Smart Process Indicator, Technical Manual, Rev. 1.2, May 2013

Pa e 3 of 92

RIGHTS AND LIABILITIES

All ri hts reserved.

No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or

by any means, mechanical, photocopyin , recordin , or otherwise, without the prior written permission

of BAYKON A.S.

No patent liability is assumed with respect to the use of the information contained herein. While every

precaution has been taken in the preparation of this book, BAYKON assumes no responsibility for errors

or omissions. Neither is any liability assumed for dama es resultin from the use of the information

contained herein.

The information herein is believed to be both accurate and reliable. BAYKON, however, would be obli ed

to be informed if any errors occur. BAYKON cannot accept any liability for direct or indirect dama es

resultin from the use of this manual.

BAYKON reserves the ri ht to revise this manual and alter its content without notification at any time.

Neither BAYKON nor its affiliates shall be liable to the purchaser of this product or third parties for

dama es, losses, costs, or expenses incurred by purchaser or third parties as a result of: accident,

misuse, or abuse of this product or unauthorized modifications, repairs, or alterations to this product, or

failure to strictly comply with BAYKON operatin and maintenance instructions.

BAYKON shall not be liable a ainst any dama es or problems arisin from the use of any options or any

consumable products other than those desi nated as Ori inal BAYKON Products.

NOTICE: The contents of this manual are subject to chan e without notice.

Copyri ht © 2012 by BAYKON A.S. Istanbul, Turkey

BX11 Smart Process Indicator, Technical Manual, Rev. 1.2, May 2013

Pa e 4 of 92

1. S

AFETY

I

NSTRUCTIONS

CAUTION! READ THIS MANUAL BEFORE OPERATING OR SERVICING THIS EQUIPMENT.

FOLLOW THESE INSTRUCTIONS CAREFULLY. SAVE THIS MANUAL FOR FUTURE

REFERENCE. DO NOT ALLOW UNTRAINED PERSONNEL TO OPERATE, CLEAN, INSPECT,

MAINTAIN, SERVICE, OR TAMPER WITH THIS EQUIPMENT. ALWAYS DISCONNECT THIS

EQUIPMENT FROM THE POWER SOURCE BEFORE CLEANING OR PERFORMING

MAINTENANCE. CALL BAYKON ENGINEERING FOR PARTS, INFORMATION, AND SERVICE.

WARNING! ONLY PERMIT QUALIFIED PERSONNEL TO SERVICE THIS EQUIPMENT.

EXERCISE CARE WHEN MAKING CHECKS, TESTS AND ADJUSTMENTS THAT MUST BE

MADE WITH POWER ON. FAILING TO OBSERVE THESE PRECAUTIONS CAN RESULT IN

BODILY HARM.

WARNING! FOR CONTINUED PROTECTION AGAINST SHOCK HAZARD CONNECT TO

PROPERLY GROUNDED OUTLET ONLY. DO NOT REMOVE THE GROUND PRONG.

WARNING! DISCONNECT ALL POWER TO THIS UNIT BEFORE REMOVING ANY

CONNECTION, OPENING THE ENCLOSURE OR SERVICING.

WARNING! BEFORE CONNECTING/DISCONNECTING ANY INTERNAL ELECTRONIC

COMPONENTS OR INTERCONNECTING WIRING BETWEEN ELECTRONIC EQUIPMENT

ALWAYS REMOVE POWER AND WAIT AT LEAST THIRTY (30) SECONDS BEFORE ANY

CONNECTIONS OR DISCONNECTIONS ARE MADE. FAILURE TO OBSERVE THESE

PRECAUTIONS COULD RESULT IN DAMAGE TO OR DESTRUCTION OF THE EQUIPMENT OR

BODILY HARM.

CAUTION! OBSERVE PRECAUTIONS FOR HANDLING ELECTROSTATIC SENSITIVE DEVICES.

BX11 Smart Process Indicator, Technical Manual, Rev. 1.2, May 2013

Pa e 5 of 92

Declaration o Con ormity

We;

BAYKON ENDÜSTRİYEL KONTROL SİSTEMLERİ SAN. VE TİC. A.Ş.

Kimya Sanayicileri Or anize Sanayi Böl esi Or anik Cad. No:31

34956 Tepeören Tuzla/İSTANBUL

to which this declaration relates, is in conformity with the followin standard(s) or other normative

document(s).

EC Directive: Applicable Standards:

Low Volta e Directive (LVD): (2006/95/EC) EN 60950-1

Electroma netic Compatibility (EMC): (2004/108/EC) EN 61326-1

Baykon, March 2013

Muhammed YALÇINKAYA

Sedat AYDEMİR

General Mana er Quality Assurance Mana er

BX11 Smart Process Indicator, Technical Manual, Rev. 1.2, May 2013

Pa e 6 of 92

2. I

NTRODUCTION

2.1 Overview

BX11 family instruments are economic and powerful state-of-the-art technolo y indicators for wei hin and

force measurements. These instruments convert the low level strain a e load cell analo si nal to di ital

si nal in hi h resolution and accuracy to transmit di ital data to PLC or PC. With a wide variety of interface,

BX11 instruments are used for any type of wei hin processes and force measurement includin tank and

silo wei hin , dynamic wei hin , check wei hin , fillin , tension /compression force measurement etc.

2.2 Key eatures and speci ications

Features:

BX11

BX11 AN

BX11 MB

BX11 PB

BX11 PN

BX11 EN

BX11 CO

1 000 to 999 999 display resolution Yes Yes Yes Yes Yes Yes Yes

Hi h internal resolution up to 16

000 000 c

ounts

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Up to 16

00 conversion per second

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Serial interface RS 232C

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Serial interface RS 485

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Analo ue output

-

Yes

-

-

-

-

-

Profibus DPV1 inte

rface

-

-

-

Yes

-

-

-

Profinet interface

-

-

-

-

Yes

-

-

Ethernet interface

-

-

-

-

-

Yes

-

CANopen interface

-

-

-

-

-

-

Yes

Continuous data output

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Fast Continuous data output

Yes

Yes

Yes

Yes

Yes

Yes

Yes

BSI data interfac

e

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Modbus RTU

-

Yes

Yes

Yes

Yes

Yes

Yes

Modbus TCP

-

-

-

-

-

Yes

-

1 di ital input and 3 relay contact output

-

-

-

Yes

Yes

-

Yes

2 di ital input and 4 relay contact output

Yes

Yes

Yes

-

-

Yes

-

Peak function

Yes

Yes

Ye

s

Yes

Yes

Yes

Yes

Hold function

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Auto

-

zero trackin and auto

-

zero at power

-

up

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Motion detection

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Zeroin and Tarin by field bus command

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Adap

tive di ital filter for fast and stable readin

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Electronic calibration (eCal) without test wei hts

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Electronic calibration (eCal) over field bus

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Zero and Span calibration

s over field bus

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Zero adjustment

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Span adjustment with test wei hts

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Span adjustment for filled

tanks

Yes

Yes

Yes

Yes

Yes

Yes

Yes

3 point calibration ( linearity correc

tion )

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Pro rammin by BAYKON

IndFace1X

PC software

Yes

Yes

Yes

Yes

Yes

Yes

Yes

8

load cells 350

Ω or 18 load cells 1100 Ω

Yes

Yes

Yes

Yes

Yes

Yes

Yes

12

to

28 VDC power supply ran e

Yes

Yes

Yes

Yes

Yes

Yes

Yes

BX11 Smart Process Indicator, Technical Manual, Rev. 1.2, May 2013

Pa e 7 of 92

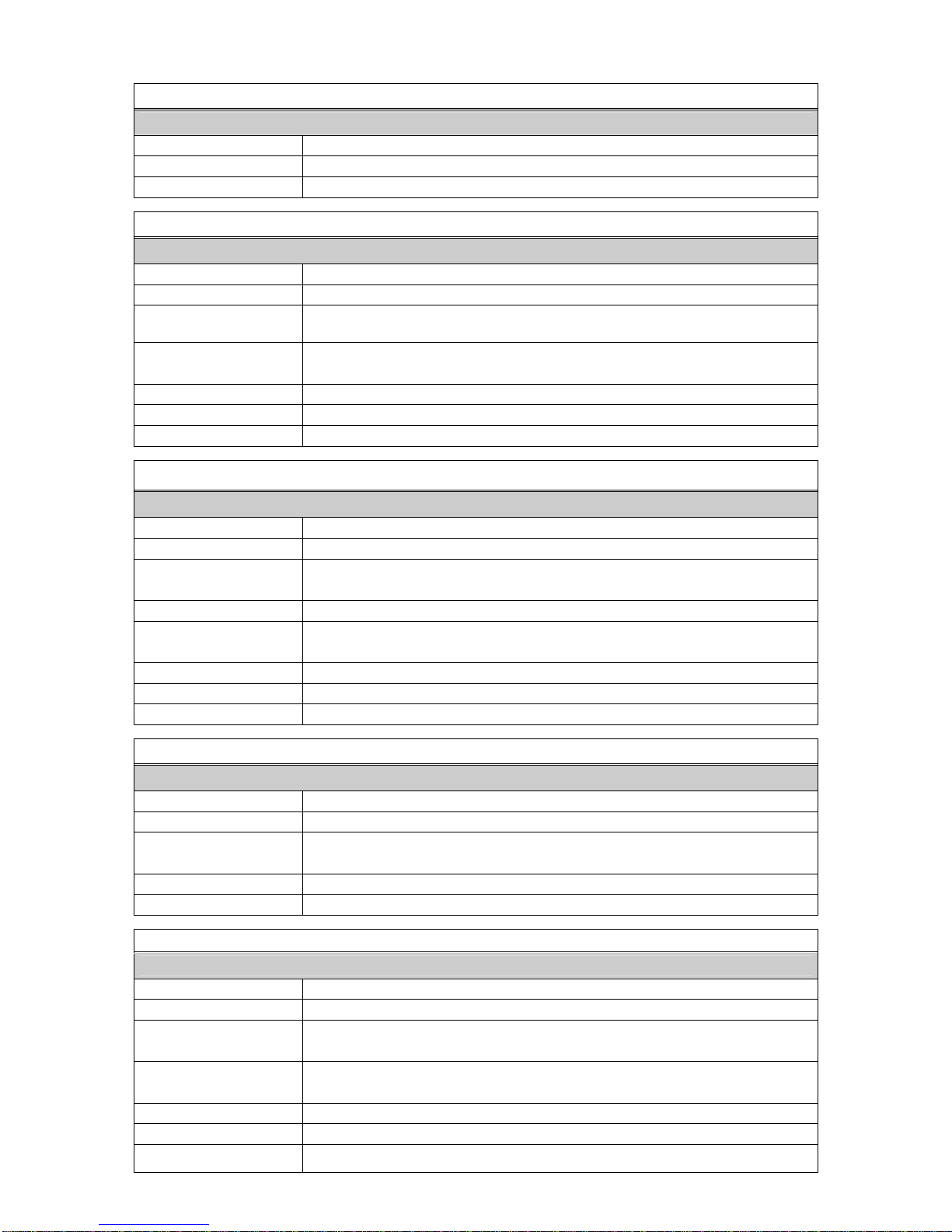

Speci ications:

Common Speci ications

A/D Converter:

A/D converter type: 24 bit Delta-Si ma radiometric with inte ral analo and di ital filters

Conversion rate: Up to 1600 measurement values per second

Input sensitivity: 0.1 μV/e (non approved)

Analo input ran e: 0 mV to +18 mV ( unipolar ) ; - 18 mV to +18 mV ( bipolar )

Internal resolution: up to 16 000 000

External Resolution:

Display resolution up to 999 999 increment

Scale Calibration and Functions:

Calibration: Calibration is performed with or without test wei hts ( eCal )

Di ital filter: 10 steps pro rammable adaptive filter

Wei hin functions: Tarin , zeroin , auto zero trackin , motion detection, auto zero at power up, net

indication at power on, increased resolution

Linearity:

Within 0.0015% FS, ≤ 2 ppm/°C

Load cells:

Excitation: 5 VDC max. 300 mA

Number of load cells: Up to 8 load cells 350 Ω or 18 load cells 1100 Ω in parallel

Connection: 4- or 6-wire technique.

Cable len th: maximum 250 m/mm² for 6-wire connection

Di ital Inputs and Outputs:

Di ital Inputs

1 optoisolated di ital input at BX11 PB, BX11 PN, BX11 CO,

2 optoisolated di ital inputs at BX11, BX11 AN, BX11 MB, BX11 EN,

12 to 28 VDC, 10mA

Di ital Outputs

3 free relay contact at BX11 PB, BX11 PN, BX11 CO,

4 free relay contact at BX11, BX11 AN, BX11 MB, BX11 EN,

250 VAC or 30 VDC , 1A

DC Power supply:

12 to 28 VDC max. 300 mA

Environment and Enclosure:

Operation temp.: -10 °C to +40 °C; 85% RH max, non-condensin

Enclosure Panel type, front panel and rear panel are stainless steel;

Aluminum body.

Protection Front panel IP67

BX11 AN Analogue

Communication:

Volta e output: 0-5 VDC, 0-10 VDC

Current output: 4-20mA, 0-20mA

D/A Converter: 16 bit

Max. cable len th: 300 meter

Max. load resistance:

(current output ) 500 Ω

BX11 Smart Process Indicator, Technical Manual, Rev. 1.2, May 2013

Pa e 8 of 92

BX11 MB Modbus-RTU

Communication:

RS-485: 1200 to 115200 baudrate, 8N1 / 7E1 / 7O1

Response speed: Up to 4 ms response delay after read/write commands

Max Stations: Up to 31 stations per se ment

BX11 PB Pro ibus DPV1

Communication:

Data rate: Up to 12000 kbit/s with automatic baud rate detection

GSD file Generic GSD-file provided

Topolo y:

Dependin on physical media

RS-485: se mented line topolo y without stubs

Installations: Shielded twisted pair cable

Line len th dependin on physical media and transmission speed

Max. Stations: Up to 32 stations per se ment, up to 126 stations per network

Isolation: Galvonically isolated bus electronics

Response speed: Up to 4 ms response delay after read/write commands

BX11 PN Pro inet

Communication:

Data rate: 100 Mbit/s, full duplex

GSDML file: Generic GSDML-file provided

TCP/IP settin s: DHCP or manual IP assi n over EtherX PC Software.

Device identity customization

Topolo y: Line, Bus, Star or Tree topolo y dependin on physical media

Installation: Switched Ethernet transmission with shielded twisted pair cables and RJ-45

connectors.

Web client: Available

Isolation: Galvonically isolated bus electronics

Response speed: Up to 4 ms response delay after read/write commands

BX11 EN Ethernet

Communication:

Transmission rate: 10 Mbit/s, half duplex

TCP/IP settin s: Manual IP assi n over EtherX PC Software

Installation: Switched Ethernet transmission with shielded twisted pair cables and RJ-45

connectors.

Web client: Available

Response speed: Up to 4 ms response delay after read/write commands

BX11 CO CANopen

Communication:

Data rate: 10 kbit/s – 1 Mbit/s (selectable) kbit/s

ESD file Generic EDS-file provided

Topolo y: Line with Trunkline, Dropline structure and Termination at both Ends

Line len th dependin on baudrate 25 – 500 meter.

Installation: 2 wire shielded twisted pair cable

Alternatively 4 wire with 24 Volt power over the bus

Max. Stations: Up to 127 stations per network

Isolation Galvonically isolated bus electronics

Response speed: Up to 4 ms response delay after read/write commands

BX11 Smart Process Indicator, Technical Manual, Rev. 1.2, May 2013

Pa e 9 of 92

3. T

HE

F

RONT

V

IEW AND

K

EY

F

UNCTIONS

Figure 3.1 - Front panel view of BX11

3.1 Display

The wei ht display of BX11 is seven se ments LED. At the ri ht side of the display there are two LED’s for

indicatin the net and the unit ( standard k ), also the left side of the display for indicatin the ross, center

of zero and unstable.

The meanin s of the announcement LED’s on the display are:

Gross Announces the indicated value is the ross wei ht.

Net

Announces the indicated value is the net wei ht.

Announces the wei ht is in the center of zero.

Announces the wei ht value on the display is unstable.

Units , k , t, lb, klb, N, kN units are located on the ri ht of the display.

BX11 Smart Process Indicator, Technical Manual, Rev. 1.2, May 2013

Pa e 10 of 92

3.2 Key Pad

The keys and the key functions of BX11 are:

Function : Key function is pro rammable to Increased Indication, Total, Tare value

indication, CN value indication, Peak function and Hold function at parameter [ 116 ]

(Page 41).

GN / Set Point : Pressin this key indicates the Gross wei ht temporarily. To enter the set

point menu, lon press this key.

Tare / Clear : Pressin this key tares the scale and et into the Net mode.

Zeroing: In Gross mode, if the scale doesn’t show zero while there is no load on the pan,

you can zero the scale by pressin this key.

Print: By pressin this key wei ht data and other information dependin on the setup

parameters sent to a printer or a PC via serial port.

3.3 Key Lock

BX11 has ability to lock the keys to avoid unauthorized person’s interfere. The key(s) which would be locked

are pro rammed at parameter [ 115 ] (Page 41 ).

You can activate or deactivate this function by lon pressin <F> key, press <Tare/Clear> and <Print>

keys sequentially. [ Lock ] prompt appear for a short while to indicate the pressed key is locked.

3.4 Housing

BX11 housin s are panel type with stainless steel front and back parts, and aluminum body.

The hole dimensions for mountin BX11 on the panel

92 mm ( 3,62" )

47 mm

( 1,85" )

BX11 Smart Process Indicator, Technical Manual, Rev. 1.2, May 2013

Pa e 11 of 92

BX11 front and side view

BX11 AN Panel type rear view BX11 & BX11 MB Panel type rear view

BX11 PB Panel type rear view BX11 PN Panel type rear view

BX11 EN Panel type rear view BX11 CO Panel type rear view

95

mm ( 3.75" )

46 mm

( 1.81" )

100

mm ( 3.94" )

55 mm

( 2.16" )

BX11 Smart Process Indicator, Technical Manual, Rev. 1.2, May 2013

Pa e 12 of 92

3.5 Accessories

The followin accessories are supplied with the instrument or can be purchased separately.

3.5.1 Accessories supplied with the instrument

The followin accessories are supplied to ether with the BX11 instruments. If any part is missed, please

contact to your supplier.

BX11

BX11

AN

BX11

MB

BX11

EN

BX11

PB

BX11

PN

BX11

CO

3-pos and 3,81 mm pitch reen plu for

power supply and analo ue output 1 2 1 1 1 1 1

7-pos and 3,81 mm pitch black plu for load

cell cable 1 1 1 1 1 1 1

6-pos and 3,81 mm pitch black plu for

RS 232C&RS 485 and I/O 1 1 1 1 2 2 2

8-pos and 3,81 mm pitch reen plu for I/O 1 1 1 1 - - -

User manual 1 1 1 1 1 1 1

Installation CD (IndFace1X setup, user manua

l

and technical documents) 1 1 1 1 1 1 1

Table 3.1 - Accessories supplied with instrument

3.5.2 Accessories sold separately

The followin accessories can be supplied from BAYKON.

BX11

BX11

AN

BX11

MB

BX11

EN

BX11

PB

BX11

PN

BX11

CO

RS-232C cable for PC connection

( 3 meter ) √ √ √ √ √ √ √

Junction box for load cell connection Refer to junction box catalo

Open end load cell cable

6 wire ( 0.22 cm

2

each ) Maximum 200 meter len th

Table 3.2 - Accessories supplied separately

BX11 Smart Process Indicator, Technical Manual, Rev. 1.2, May 2013

Pa e 13 of 92

4. I

NSTALLATION

PRECAUTION: Please read this section carefully before installation of the instrument. Applying the

recommendations in this section will increase your system reliability and long term performance.

4.1 Recommendations

4.1.1 Control Cabinet Design

Warning: Please care the following warnings for designing the control cabinet which will increase your

system reliability.

The control cabinet should be desi ned so that Analo Di itizer can operate safely. The panel should be

placed clean area, not ettin direct sun li ht if possible, with a temperature between -10 ºC and +40 ºC,

humidity not exceedin 85% non-condensin . All external cables should be installed safely to avoid

mechanical dama es.

BX11 instruments are very low level si nal measurin instruments. To avoid electrical noise, BX11 should be

separated from the equipments that produce electrical noise. Preferable use metal cabinet a ainst radio

frequency interference and the cabinet shall be connected to round a ainst the electroma netic

disturbances. Load cell cable trays must be separated from others, if possible. If there are noise- eneratin

equipments such as heavy load switches, motor control equipments, inductive loads etc., please be careful

a ainst the EMC interference in the cabinet. If possible protect BX11 instruments with the faraday ca e or

install them in separate section or install them far a way from this kind of equipments. Connect parallel

reverse diodes to the DC inductive loads like relays, solenoids etc. to minimize volta e peaks on the DC

power lines.

4.1.2 Cabling

All cables comin to the control cabinet shall be shielded. Please use separate cable tray for these low

si nal level cables. Distance from load cell cables, interface cables and DC power supply cables to power

line cables shall be minimum 50 cm.

4.2 Mechanical Installation

Take care to the housin dimensions and the su ested panel hole dimensions iven in the Page 10. To

avoid electrical noises, protect your indicator which has very low input si nal level from the equipment that

produces electrical noise in panel mountin .

4.3 Electrical Connections

Warning: Please always remember that BX11 instruments are very low voltage measuring instruments. Your

control cabinet design and proper installation increases reliability and performance of the instrument. Please

do not forget that the instrument must be powered off before inserting or removing any peripheral

connector.

The electrical installation and quality of instrument’s roundin will provide wei hin accuracy and the

safety of your indicator. If the ener y condition of your plant is bad, prepare a special power line and

roundin . All required electrical connections should be done as described below.

If you have to service the indicator, turn the power off and wait at least 30 seconds before interferin .

BX11 Smart Process Indicator, Technical Manual, Rev. 1.2, May 2013

Pa e 14 of 92

There is a DIP switch on BX11’s rear side and its position should be “ON” ( downward ) to chan e the

metrolo ical related parameters includin calibration. There is no need to open the housin to chan e the

position of this DIP switch. If there is not set-up DIP switch on the instrument for industrial usa e, its

position is always ON.

Figure 4.1 - The location of calibration DIP switch

4.3.1 Power Supply Connection and Grounding

Power supply volta e of the instrument shall be between 12 VDC and 28 VDC. The pin confi uration of the

24 VDC power supply connector located ri ht - bottom of the instrument is shown in Fi ure 4.2 below.

The pin layout of the 24 VDC connector of

BX11 Series

( rear view )

0V 24V

Figure 4.2 - The pin layout of 24VDC connector

The quality of the instrument’s round will determine the accuracy and the safety of your measurin system.

A proper round connection is needed to minimize extraneous electrical noise affects on the measurement.

A poor round can result in an unsafe and unstable operation. It is important that the instrument should not

share power lines with noise- eneratin parts such as heavy load switchin relays, motor control

equipments, inductive loads, etc. If the condition of the power line in the plant is poor, prepare a special

power line and roundin .

Before interferin the instrument, turn off the power and wait at least for 30 seconds.

Warning: onnect the Shield pin to the reference ground.

BX11 Smart Process Indicator, Technical Manual, Rev. 1.2, May 2013

Pa e 15 of 92

4.3.2 Load Cell Connection

To avoid dama es, the load cell wirin should be made carefully before ener izin the instrument. Load cell

connection detail is shown in Fi ure 4.3. In 4-wire installations the sense and excitation pins with the same

polarity should be short circuited at the connector side. If you have junction box, use 6 wire cable between

BX11 and the junction box, and short circuit these pins at junction box for better performance.

4 wire LC connection

6 wire LC connection

Figure 4.3 - Load cell connections

Warning: Always connect Sense pins to Excitation pins for 4 wire connection. Non-connected sense pins

may cause the wrong Excitation voltage measurement and create an accuracy problem.

Warning: onnect the load cell cable shield to the reference ground or shield pin of the load cell connector.

4.3.3 RS 232C Connection

RS 232C port usa e and specifications are shown in the table below ( Page 36 ).

Usa e Interfacin with PC or PLC, remote display connection,

pro rammin via IndFace1X

Data formats Continuous, Fast Continuous, Printer Format, BSI Protocol,

Modbus-RTU Hi h-Low, Modbus-RTU Low-Hi h

Baud rate 1200 / 2400 / 4800 / 9600 (Default) / 19200 / 38400 / 57600 / 115200 bps

Len th and parity 8 bit no parity (Default), 7 bit odd, 7 bit even

Start / Stop bits 1 start bit and 1 stop bit

Table 4.1 – RS 232C Serial Interface Specifications

RS 232C serial connection is done with three wire as indicated below in Fi ure 4.4

Figure 4.4 - RS 232C serial interface connections

Warning: onnecting the shield to the reference ground will protect your weighing system against EM

disturbances.

BX11 Smart Process Indicator, Technical Manual, Rev. 1.2, May 2013

Pa e 16 of 92

4.3.4 RS 485 and Modbus-RTU Connection

RS 485 port usa e and specifications are shown in the table below ( Page 37 ).

Usa e Interfacin with PC or PLC, remote display,

pro rammin via Indface,

Data formats Continuous, Fast Continuous, Printer Format, BSI Protocol,

Modbus-RTU Hi h-Low, Modbus-RTU Low-Hi h

Baud rate 1200 / 2400 / 4800 / 9600 (Default) / 19200 / 38400 / 57600 / 115200 bps

Len th and parity

8 bit no parity (Default), 7 bit odd, 7 bit even

Start / Stop bits 1 start bit and 1 stop bit

Table 4.2 - RS 485 Serial Interface Specifications

RS 485 serial connection is done with three wire as indicated below in Fi ure 4.5. Line termination resistors

( 110 ohm ) are needed both ends of the RS 485 line.

Figure 4.5 – RS 485 serial interface connections

Warning: onnect the shield to the reference ground.

Warning: Disconnect IndFace1X P software before starting Modbus-RTU interfacing.

4.3.5 Analogue Connection (only BX11 AN )

BX11AN is pro rammable to 4 – 20 mA, 0 – 20 mA, 0 – 5 V or 0 – 10 V analo ue output types.

Analo ue connections are done as indicated below in Fi ure 4.6 and Fi ure 4.7.

Figure 4.6 - BX11 AN Volta e output connections

BX11 Smart Process Indicator, Technical Manual, Rev. 1.2, May 2013

Pa e 17 of 92

Figure 4.7 - BX11 AN Current output connections

4.3.6 Pro ibus Connection (only BX11 PB )

Profibus connection is done as indicated below in Fi ure 4.8.

Figure 4.8 - BX11 PB serial interface connections

PROFIBUS Connector pin con iguration (DB9F)

Pin Signal Description

1 - -

2 - -

3 B Line Positive RxD / TxD, RS-485 level

4 RTS Request to send

5 GND Bus Ground (isolated)

6 +5V Bus Output +5V termination power (isolated)

7 - -

8 A Line Ne ative RxD / TxD, RS-485 level

9 - -

Housin Cable Shield Ground

4.3.7 Pro inet Connection (only BX11 PN )

Profinet connection is done as indicated below in Fi ure 4.9.

Figure 4.9 - BX11 PN serial interface connections

BX11 Smart Process Indicator, Technical Manual, Rev. 1.2, May 2013

Pa e 18 of 92

PROFINET Connector pin con iguration (RJ45)

Pin

Signal

DIR

Description

1 TX+ Out Differential Ethernet transmit data +

2 TX− Out Differential Ethernet transmit data −

3 RX+ In Differential Ethernet receive data +

6 RX− In Differential Ethernet receive data −

4 Not used Terminated

5 Not used Terminated

7 Not used Terminated

8 Not used Terminated

Shield Chasis round

The HUB connection cablin will be a direct connection as shown below:

Figure 4.10 - HUB connection

The PC connection cablin will be done via cross cable as shown below. IP address blocks and ateway

address of BX11 and PC should be the same in cross connection.

Figure 4.11 - Cross PC connection

Warning: onnect the shield to the reference ground or shield pin of the power connector.

Warning: Disconnect IndFace1X P software before starting Profinet interfacing.

4.3.8 Ethernet Connection (only BX11 EN )

Ethernet interface is used for data transfer to PC or PLC in the formats shown below.

Usa e Ethernet interface with PC or PLC

Data formats

Continuous, Fast Continuous, Printer Format, BSI Protocol,

Modbus TCP/IP Hi h-Low,

Modbus TCP/IP Low-Hi h

Ethernet The Ethernet interface operates at 10Mbit, half duplex

Other manuals for BX11

1

Table of contents

Popular Touch Panel manuals by other brands

Touch International

Touch International MulTI-Touch Integration guide

AIS

AIS HMI?TCND0U?15AR?X00H HMI?TCND0U?07AR?X00H user manual

Panduit

Panduit ATLONA Velocity AT-VTP-1000VL-BL installation guide

inohom

inohom STPM1710 user manual

Crestron

Crestron STX-1550C Operation guide

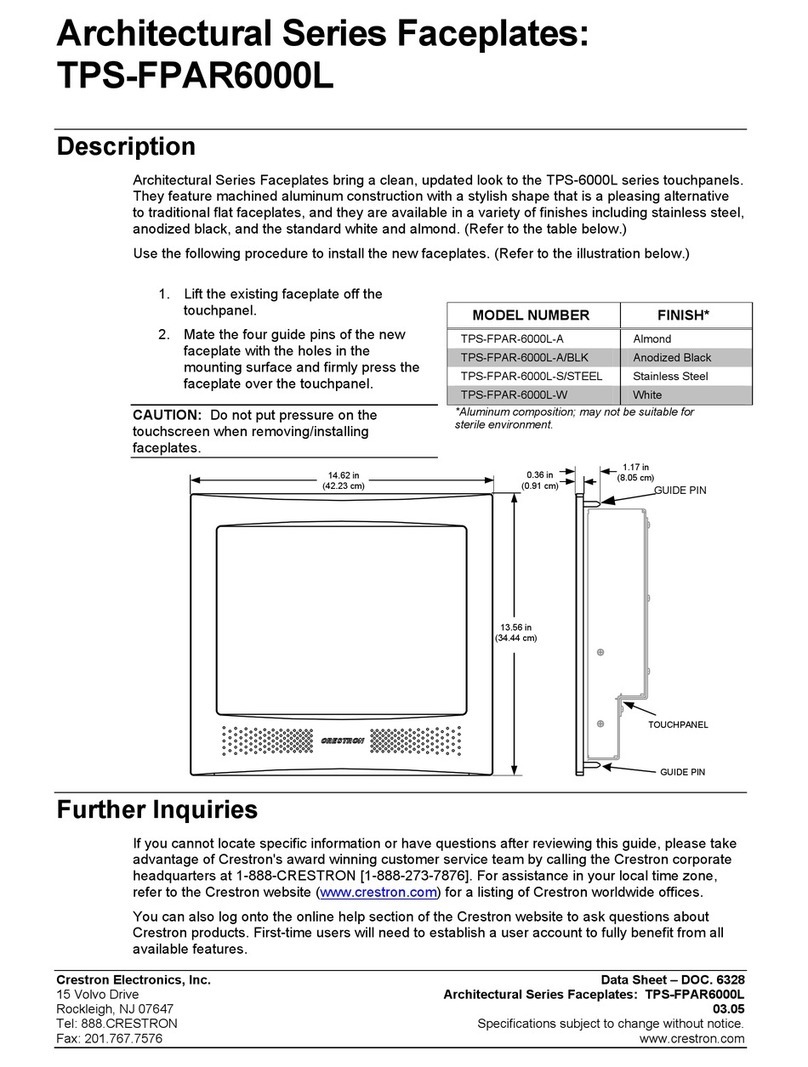

Crestron

Crestron TPS-FPAR6000L datasheet