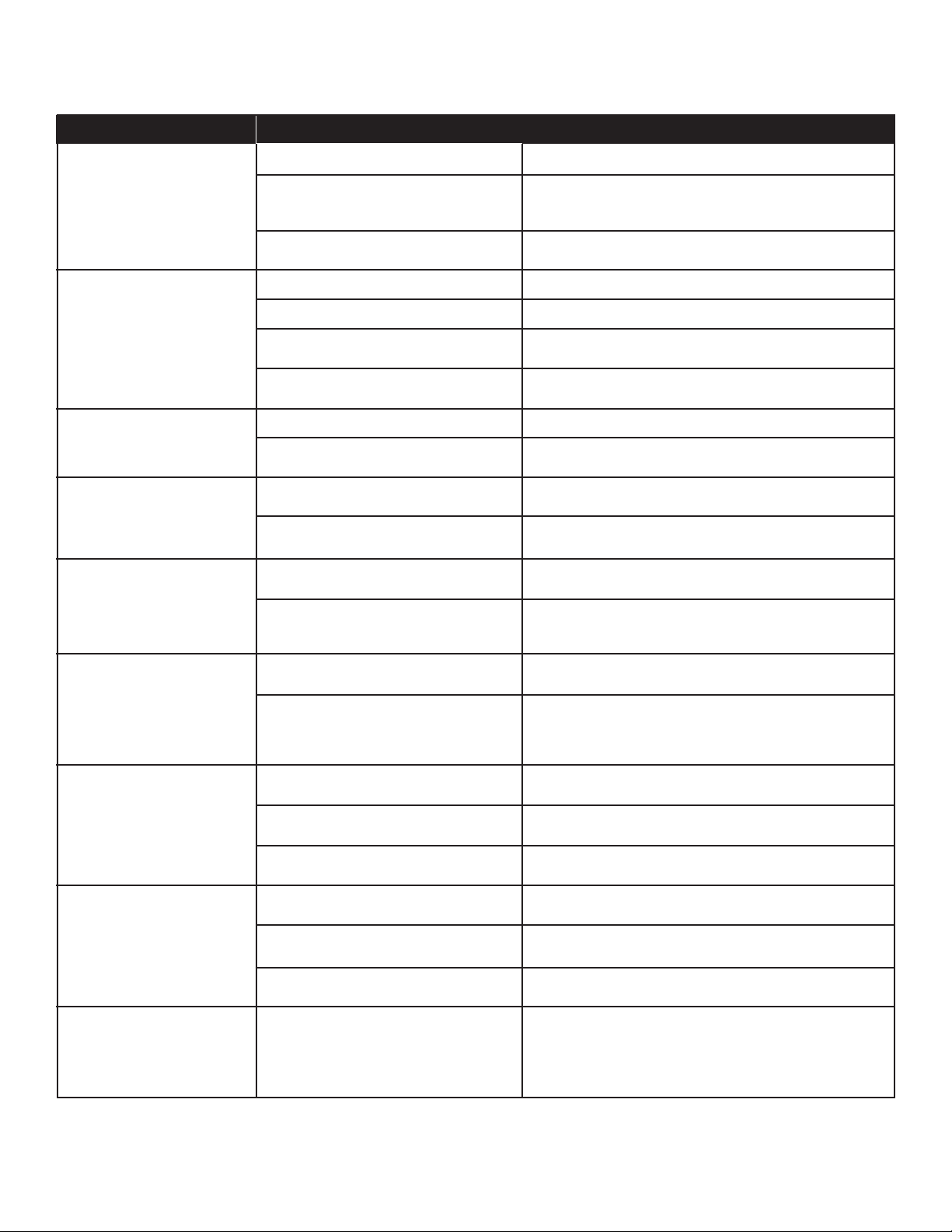

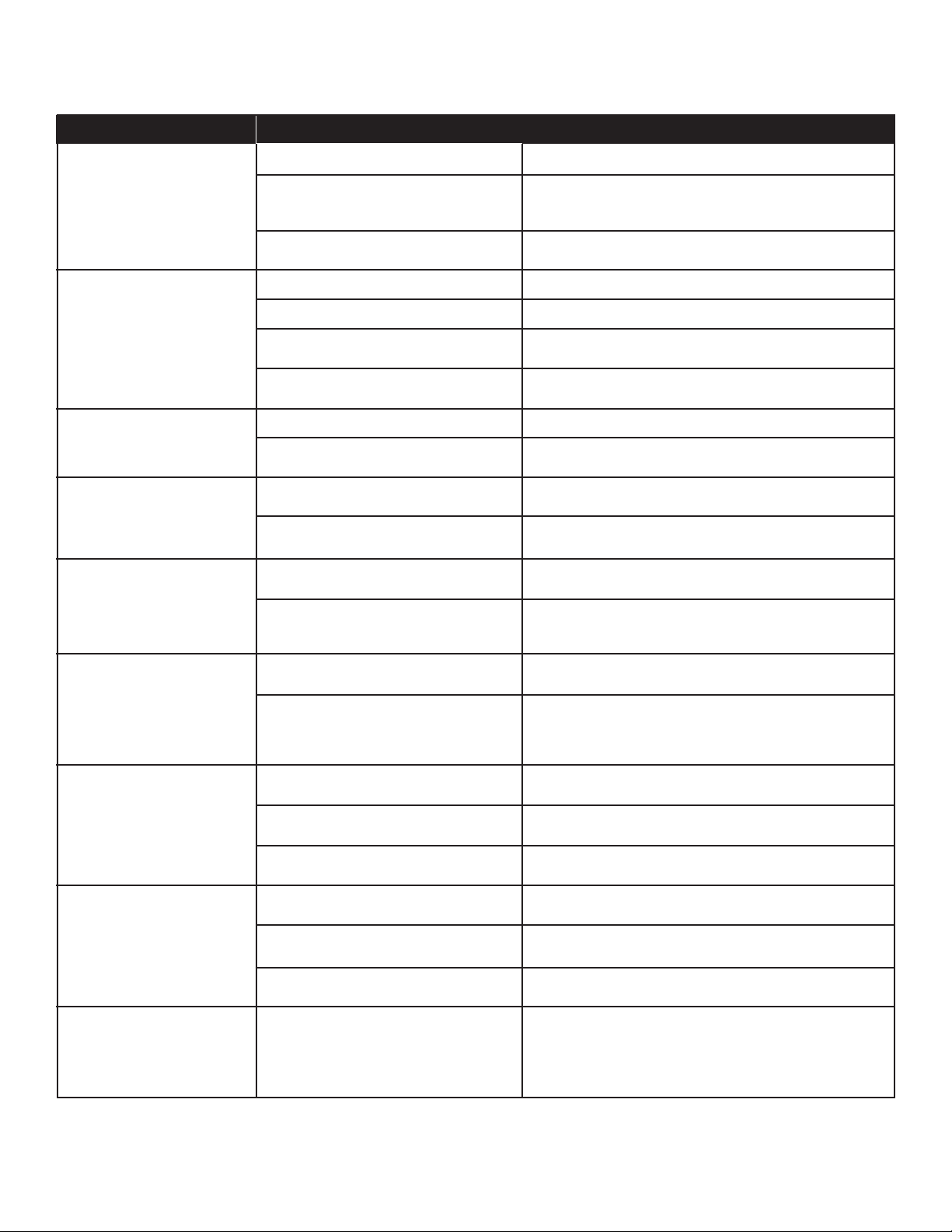

19

Model #

Burner will not light

Yellow, sooty irregular

flame

Cooker lights, but

flame is very small

Flame dramatically

reduces, and LP

cylinder has frost on it.

Hissing or gurgling

sounds coming from

appliance

Flame has gone out

Timer will not work

Burner is clean, but

still will not light

TROUBLE-SHOOTING

Symptom Cause Possible Solution

Obstruction in the burner

Obstruction in the burner

Batteries are dead

Did not press Power or Start button

Faulty Timer

Poor oxygen/gas mixture

Obstruction in the burner

LP tank has low fuel

LP tank has low fuel

LP tank has low fuel

Too windy

Moisture in the burner

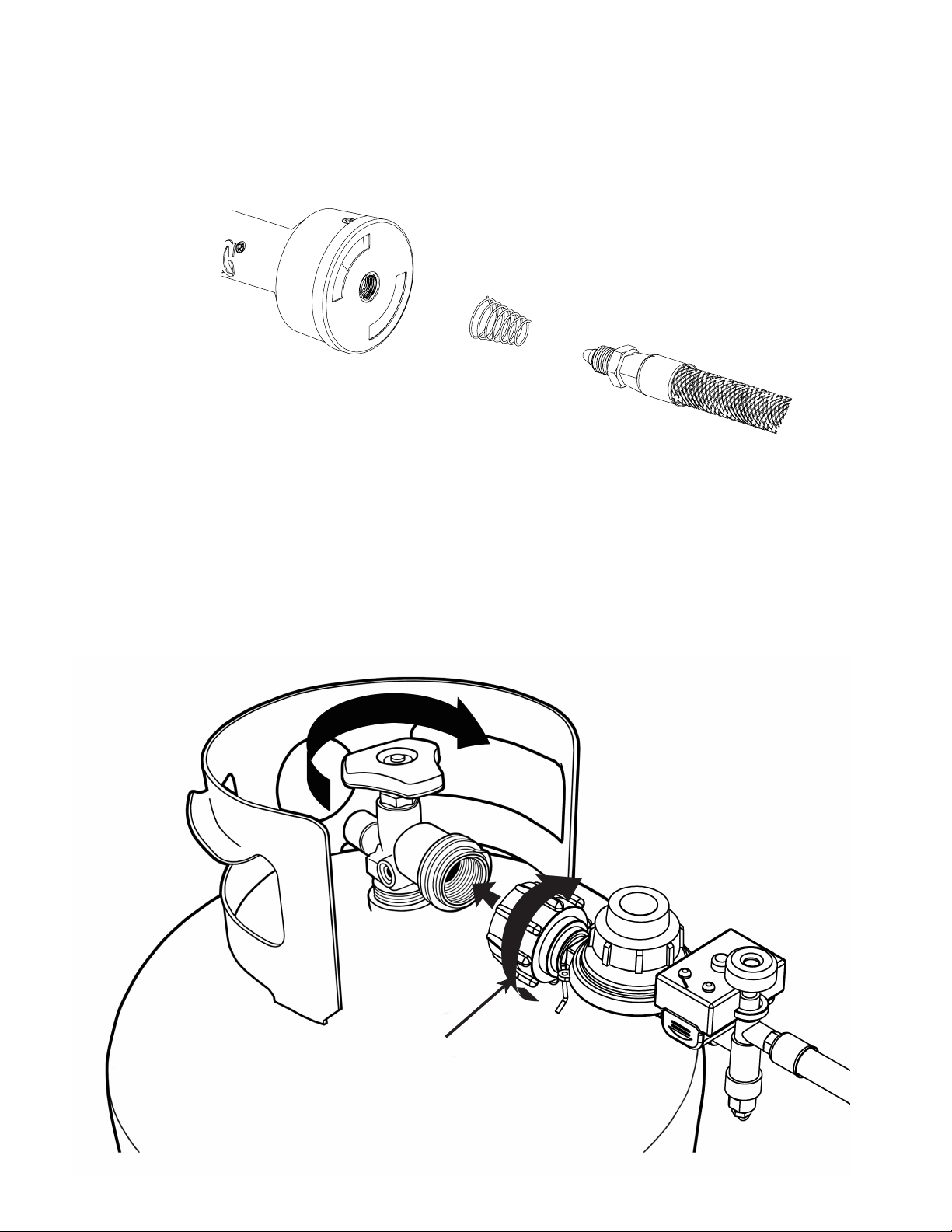

Gas Flow Limiting Device has

activated

Extended cooking on HIGH; the liquid

propane is freezing inside the tank.

Damaged or leaking hose and

regulator assembly

Poor oxygen/gas mixture

Not enough gas flow from tank

LP tank has low fuel

Part of appliance is damaged

LP tank has low fuel

Damaged hose & regulator assembly

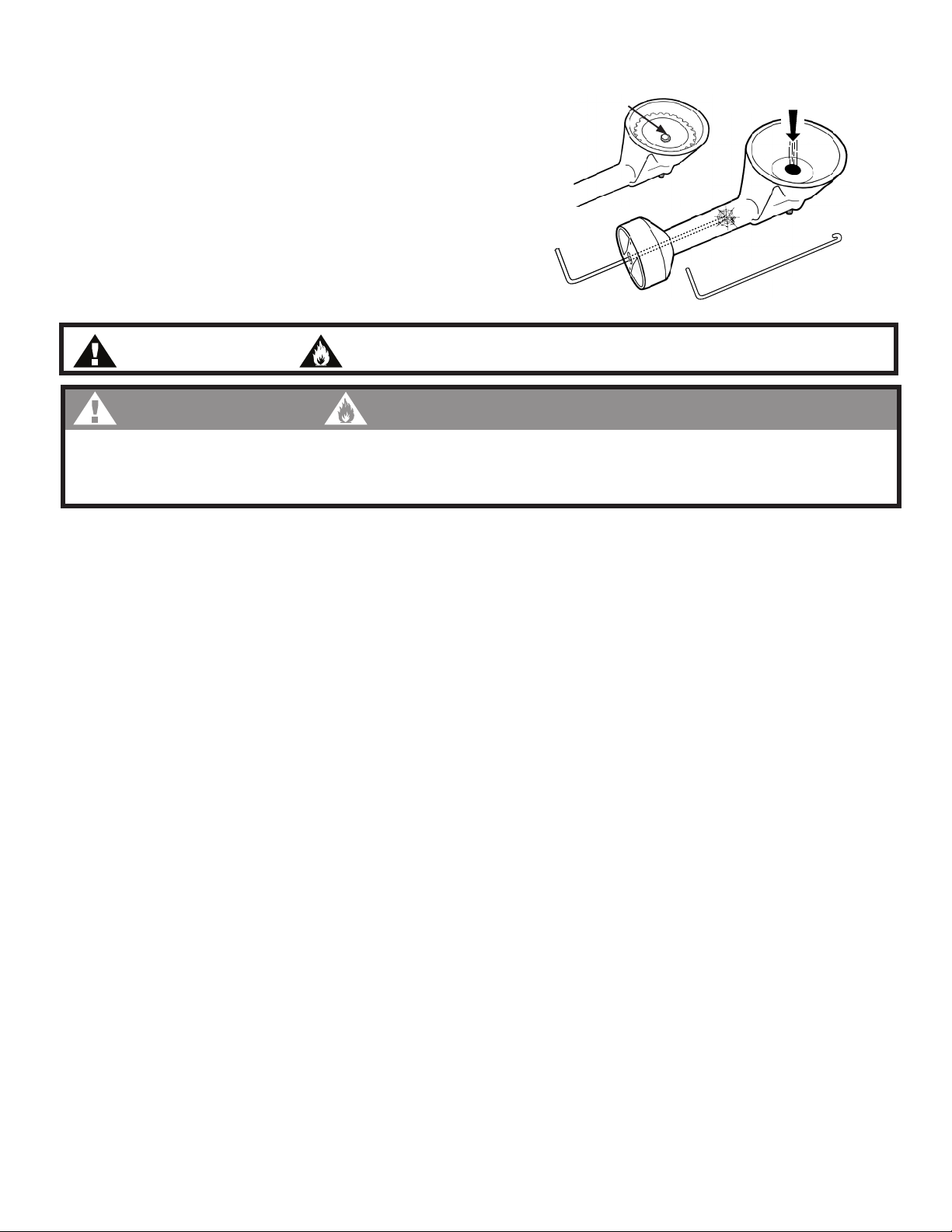

Disconnect hose and regulator. Inspect and clean burner.

Flush burner if necessary.

Disconnect hose and regulator. Inspect and clean burner.

Flush burner if necessary.

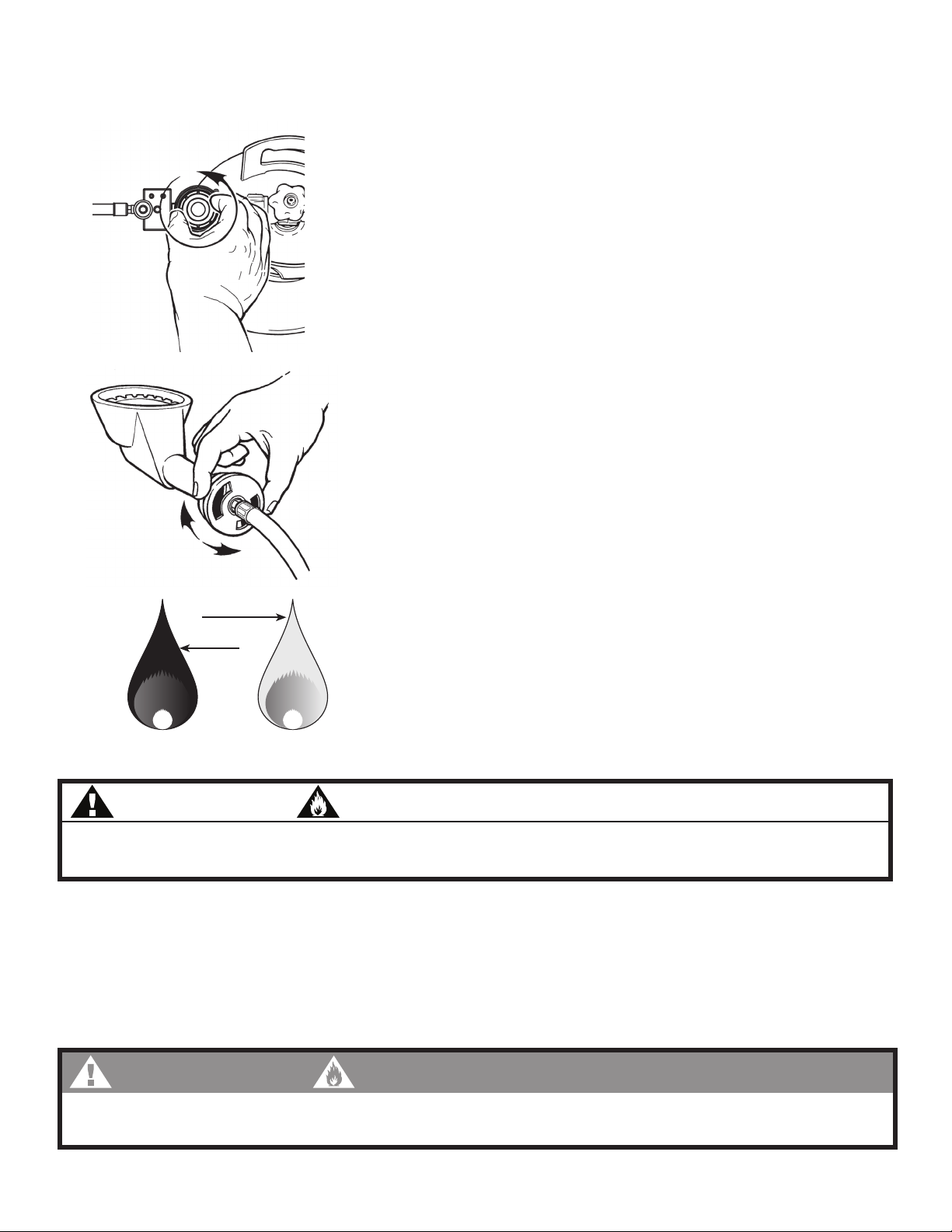

Adjust air shutter to obtain optimum blue flame.

Disconnect hose and regulator. Inspect and clean burner.

Flush burner if necessary.

Use a tank fill gauge to always know gas level.

If gas is too low to operate, refill or exchange tank.

Use a tank fill gauge to always know gas level.

If gas is too low to operate, refill or exchange tank.

Use a tank fill gauge to always know gas level.

If gas is too low to operate, refill or exchange tank.

Check wind direction and wait for wind to die

down, or set cooker away from windy areas.

Turn unit OFF and wait for it to cool down. Inspect burner

and pour water out.

Turn LP cylinder valve and HVR brass valve OFF.

Wait 30 seconds and repeat steps for lighting.

Turn unit OFF, and stop cooking until frost melts and tank

is no longer cold to the touch. If you return to cooking with

the same LP tank, operate on MEDIUM to MEDIUM-HIGH.

Turn unit OFF and wait for it to cool down. Perform

Gas Leak Test to confirm gas leak. Contact Barbour

International, Inc. to replace damaged hose and regulator

assembly, Model# M5HPR-TMR.

Turn air shutter to almost closed position, then try to re-light.

Open LP cylinder valve all the way.

Use a tank fill gauge to always know gas level.

If gas is too low to operate, refill or exchange tank.

Inspect LP tank, burner, and HVR assembly for

damage. Contact Barbour International, Inc. to replace

damaged parts.

Use a tank fill gauge to always know gas level.

If gas is too low to operate, refill or exchange tank.

Contact Barbour International, Inc. to replace

damaged hose and regulator assembly.

Contact Barbour International, Inc. customer service at

1-800-864-6194, or visit www.thebayou.com.

Replace Batteries - See page 11

Follow Timer instructions - See page 12

Contact Barbour International, Inc. to replace hose

and regulator assembly, Model# M5HPR-TMR.

Timer stopped before

time was up Batteries are dead Replace Batteries - See page 11

REV. 08/2017