BBC Bircher ProAccess User manual

1

175

80 72.5

175

80 72.5

5928442

ProAccess

LED

Vehicle detection sensor for gates and barriers

Original operating instructions

General

1Safety instructions

ENGLISH

399452E

03/21

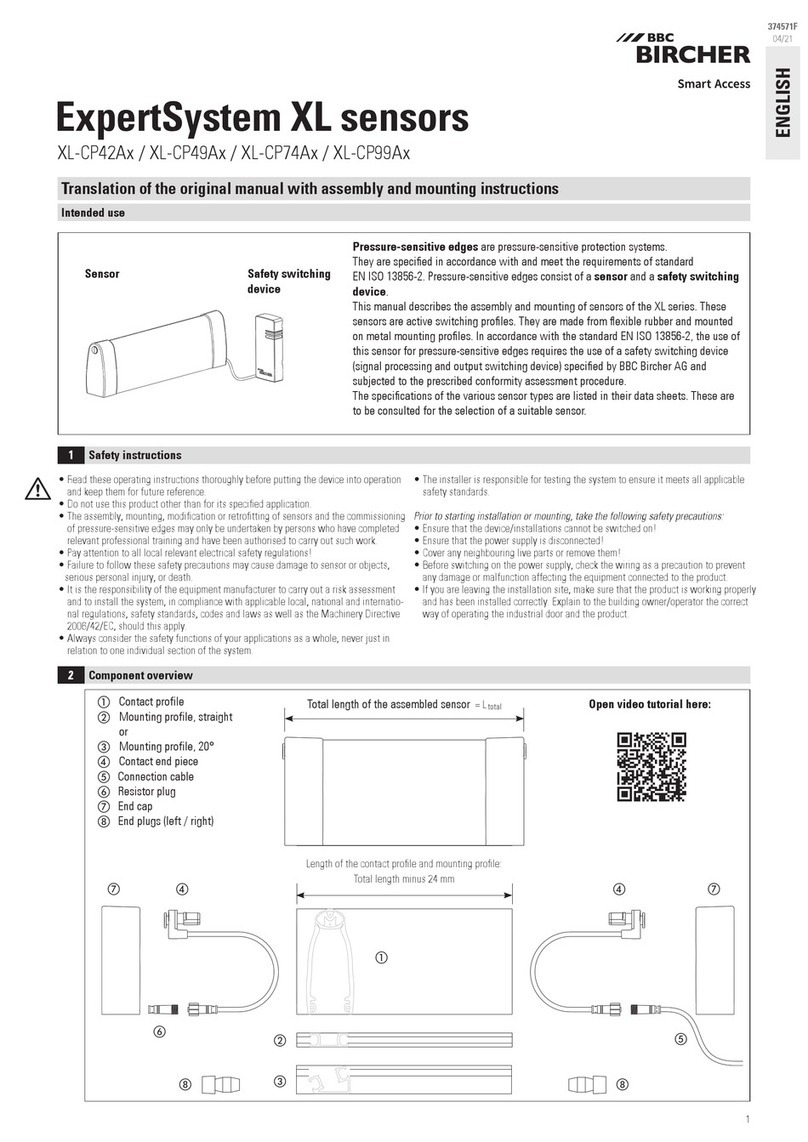

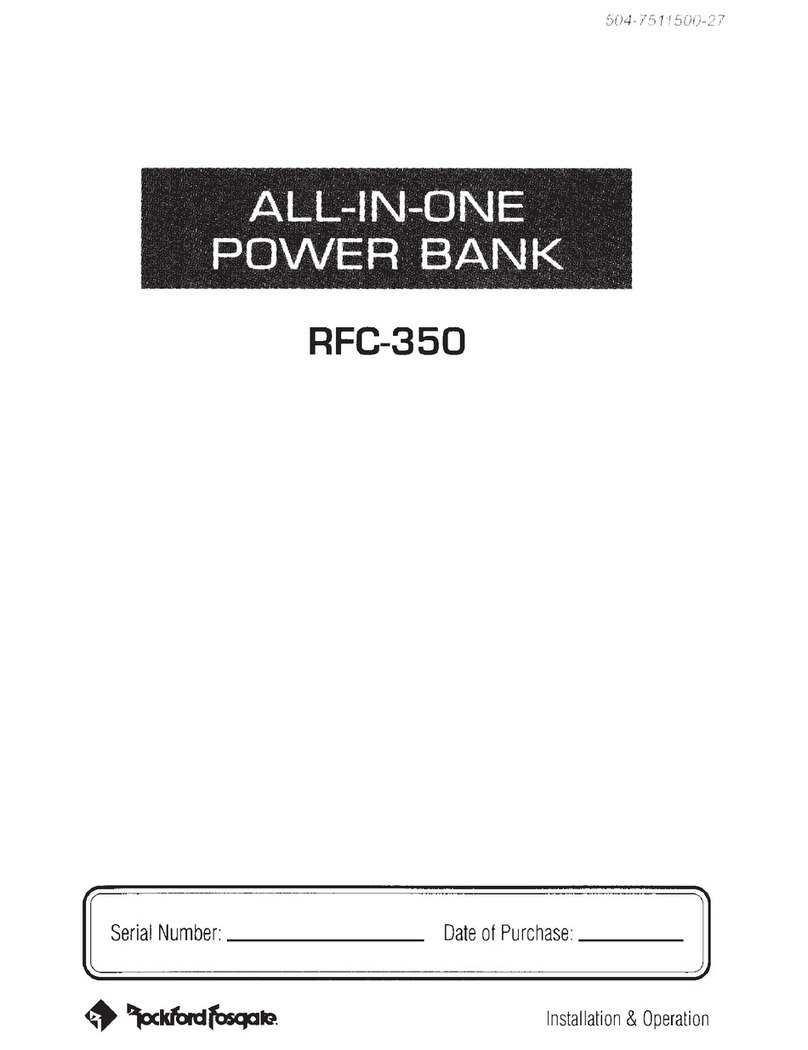

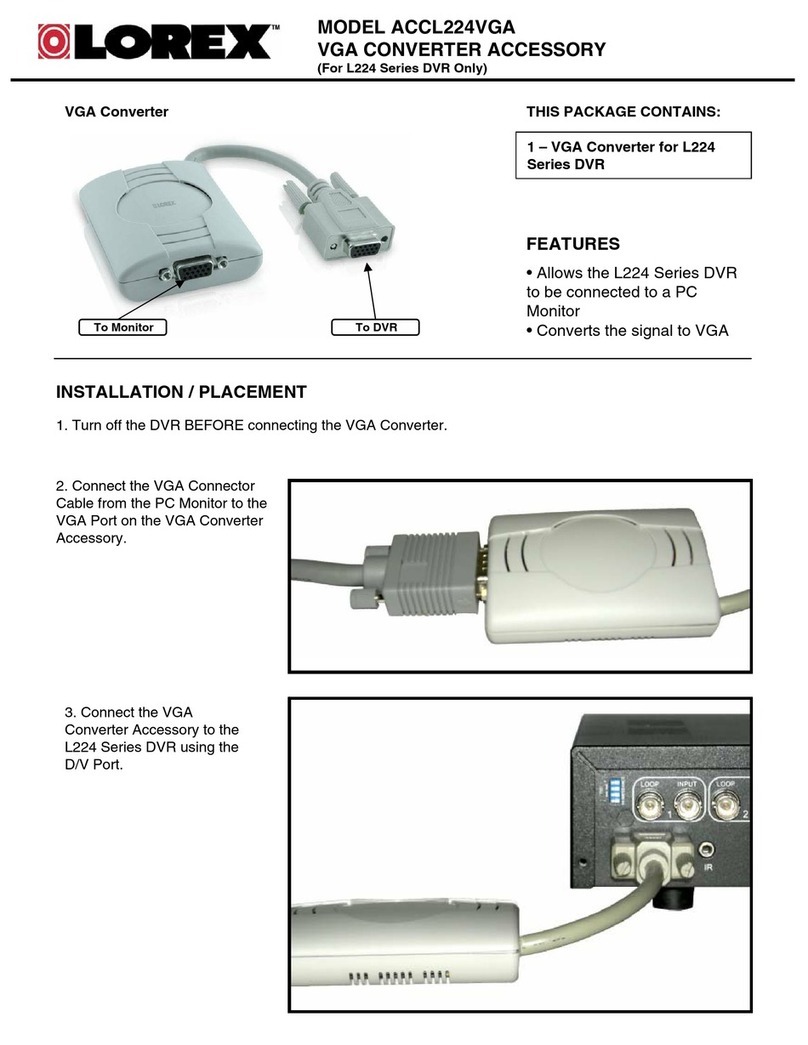

Sensor unit Control unit

Control

Unit

Mode indicator

Button: VALUE

selection

Value indicator

Button: Area Check

Button: PARAMERTER

selection

Button:

Microwave Range

Button: Output logic

Button: Sensor Mode Button: Calibration

Dimensions

Sensor

Unit

(Further details see chapter 3)

• Read these operating instructions thoroughly before putting the device into

operation and keep them for future reference.

• This product is a vehicle detection sensor designed to detect approach and

presence of a vehicle in proximity of a gate or barrier.

• Do not use this product other than for its specied application.

• The assembly, commissioning, modications and extensions may only be

completed by an experienced electrician!

• Pay attention to all local relevant electrical safety regulations!

• Failure to follow these safety precautions may cause damage to sensor or

objects, serious personal injury, or death.

• It is the responsibility of the equipment installer to carry out a risk assessment

and to install the system, in compliance with applicable local, national and

international regulations, safety standards, codes and laws as well as the

Machinery Directive 2006/42/EC, should this apply.

• Observe all applicable local, national, and international door safety standards,

codes, and laws.

• Always consider the safety functions of your applications as a whole, never

just in relation to one individual section of the system.

• The installer is responsible for testing the system to ensure it meets all

applicable safety standards.

• During the operation of electrical components – e. g. in the case of a short

circuit hot and ionised gases can be emitted; protection covers must not be

removed!

• The device should only be operated from a safety extra low voltage (SELV)

system with safe electrical separation according to EN 61558. The wiring must

be protected against mechanical damage.

Prior to starting installation or mounting, take the following safety precautions:

• Check the voltage data on the label of the sensor.

• Ensure that the device/installations cannot be switched on!

• Ensure that the power supply is disconnected!

• Protect the device with a housing against contamination or harsh environ-

ments!

• Protect the sensor against rain and snow.

• Disconnect device from mains in the event of a fault.

• Avoid touching any electronic and optical components.

• The door drive and the transom must be properly earthed.

• After accessing the inside of the device, ensure the cover/protection seal is

closed tightly to achieve designated protection rating.

• Ensure the commercial door operator has all of its monitored entrapment

protection devices installed and operational. This sensor does not replace any

entrapment protection devices.

• Limited protection against accidental contact!

• Read these operating instructions thoroughly before putting the device into

operation and keep them for future reference.

• This product is a vehicle detection sensor designed to detect approach and

presence of a vehicle in proximity of a gate or barrier.

• Do not use this product other than for its specied application.

• The assembly, commissioning, modications and extensions may only be

completed by an experienced electrician!

• Pay attention to all local relevant electrical safety regulations!

• Failure to follow these safety precautions may cause damage to sensor or

objects, serious personal injury, or death.

• It is the responsibility of the equipment installer to carry out a risk assessment

and to install the system, in compliance with applicable local, national and

international regulations, safety standards, codes and laws as well as the

Machinery Directive 2006/42/EC, should this apply.

• Observe all applicable local, national, and international door safety standards,

codes, and laws.

• Always consider the safety functions of your applications as a whole, never

just in relation to one individual section of the system.

• The installer is responsible for testing the system to ensure it meets all

applicable safety standards.

• During the operation of electrical components – e. g. in the case of a short

circuit hot and ionised gases can be emitted; protection covers must not be

removed!

• The device should only be operated from a safety extra low voltage (SELV)

system with safe electrical separation according to EN 61558. The wiring must

be protected against mechanical damage.

Prior to starting installation or mounting, take the following safety precautions:

• Check the voltage data on the label of the sensor.

• Ensure that the device/installations cannot be switched on!

• Ensure that the power supply is disconnected!

• Protect the device with a housing against contamination or harsh environ-

ments!

• Protect the sensor against rain and snow.

• Disconnect device from mains in the event of a fault.

• Avoid touching any electronic and optical components.

• The door drive and the transom must be properly earthed.

• After accessing the inside of the device, ensure the cover/protection seal is

closed tightly to achieve designated protection rating.

• Ensure the commercial door operator has all of its monitored entrapment

protection devices installed and operational. This sensor does not replace any

entrapment protection devices.

• Limited protection against accidental contact!

2

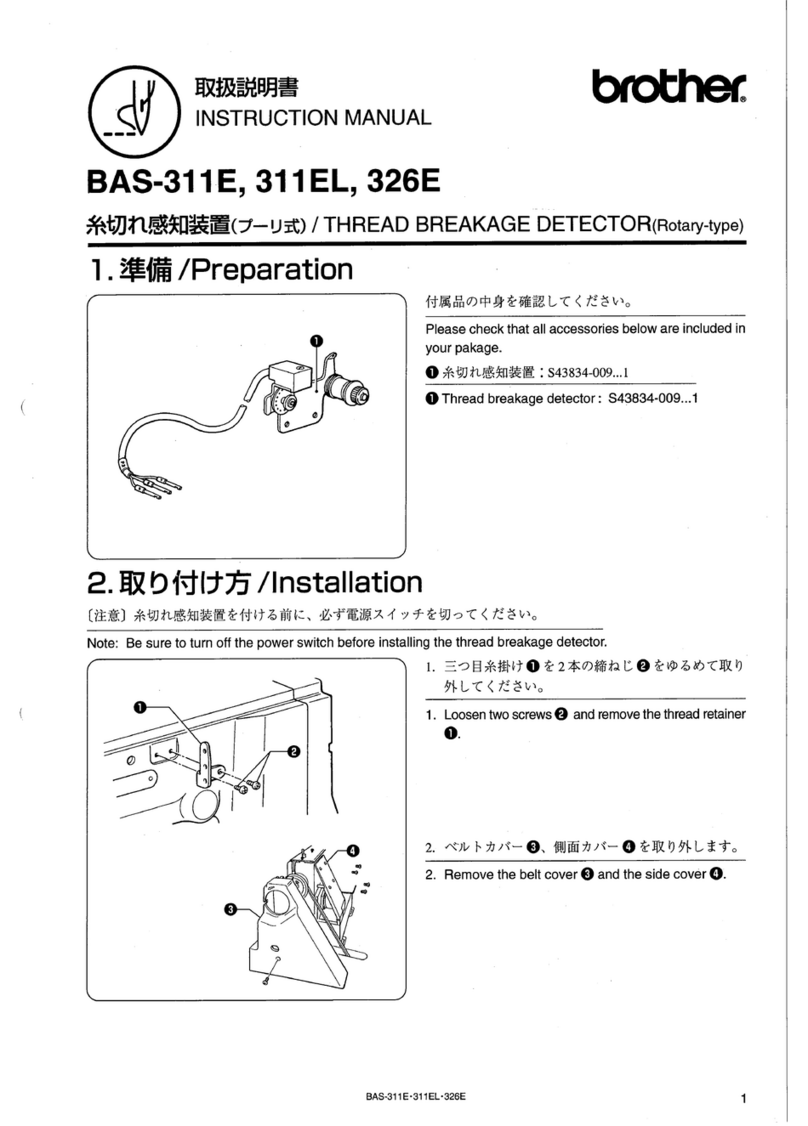

90° 90°

150 mm

*

*400 mm

100 mm

90° 90° ≤45°

500 mm

> 300 mm

500 mm 500 mm

500 mm

500 mm

i

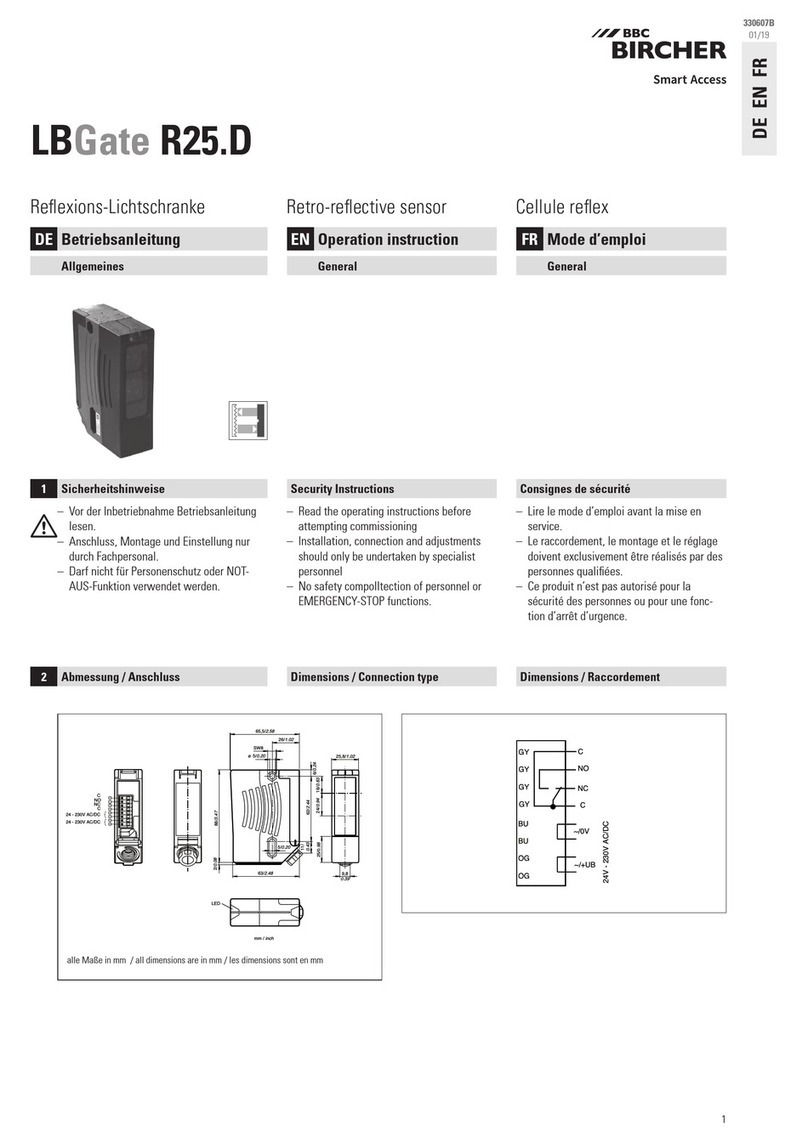

2Sensor installation recommendations

The sensor will not work correctly unless the height, direction and sensor mode are set correctly.

Barrier Mounting height

Sliding gate

Barrier arm

Closed barrier

arm

Moving gate

panel

Perpendicular mode

Perpendicular mode

Level

Uphill

Downhill

Shim

Shim

Perpendicular

mode

* distance see sensing zone diagram (5.3)

Public side

Public side

Secure side

Secure side

Perpendicular mode

Angled mode

Ticket vending machine

Island

or less

Vehicle path

Vehicle path

Hint:

Use the 45 ˚ bracket

(Part No. 399601)

Notes:

Please make adjustment to ensure the detection plane is parallel to the road surface.

Some vertical adjustment may be required if the road surface rises or falls.

or

Do not install any moving object such as ags or banners within the sensing zone.

Remove any vegetation from sensing zone, or recongure the sensing zone to be smaller. Not following these steps may prevent the sensor

to leave the state of detection or delay the

change of the state.

Do not place an object such as a signboard close to the sensor’s detection area.

Make sure there is no irregularity on the ground within the sensing zone.

Do not use a uorescent lamp around the detection area. It may prevent proper operation of the sensor.

A barrier arm with a skirt or placcard may cause unstable detection by the sensor. In such a case, remove the placcard or relocate

the sensor to prevent such issue.

3

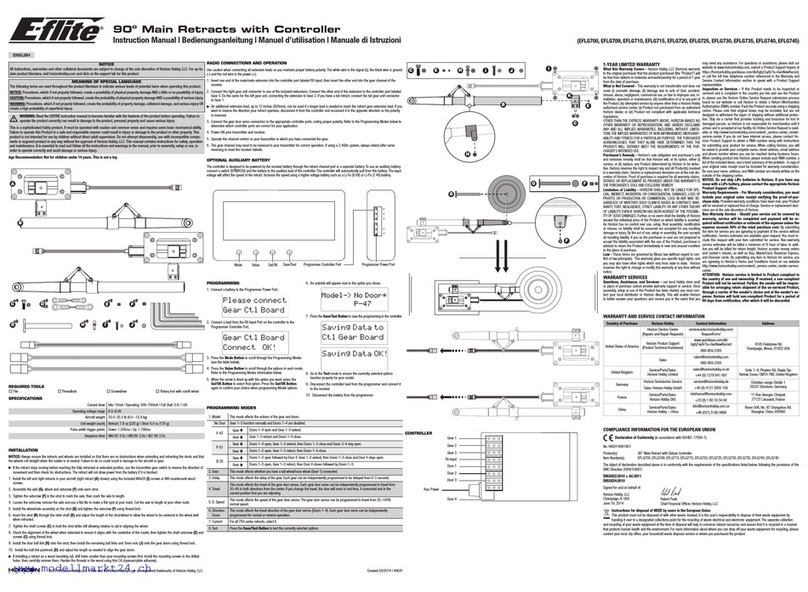

1

3

2

4

56

5 mm

70 ± 1 mm

32 ± 1 mm

80 mm

500 mm

29 mm

40 mm

29 mm

53 mm

175 mm

53 mm

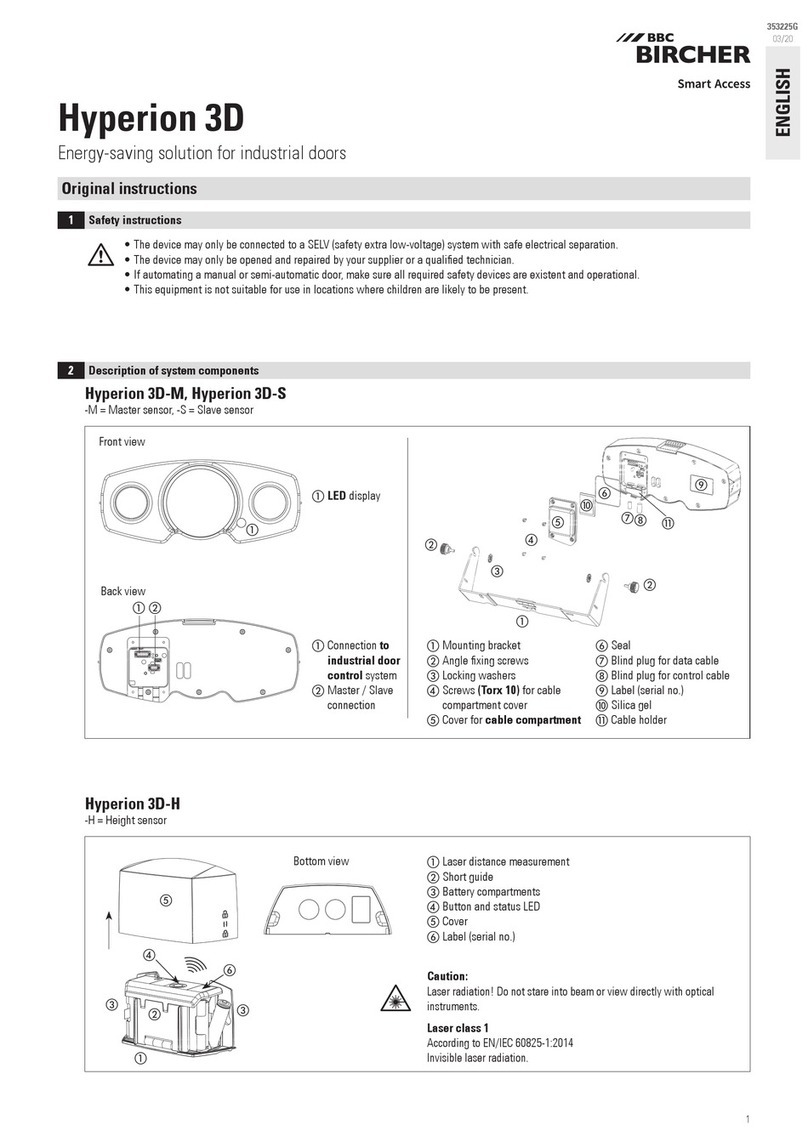

3Installation of the unit

Power Output Input

GND

12 – 24 V DC

N.O. / N.C.

≤ 30 V DC / 0.3 A

≤ 5 V DC / ≤ 0.5 mA

Uth = 0.75 V DC

Mounting

pitch

from the road surface

Mounting

pitch

M4

Max 7 mm

cable diameter

Drill holes.

Route cable.

Required tools:

• Precision screwdriver, Phillips #1

• Screwdriver, Phillips #2

Loosen the retaining screws on the bottom of the front cover

and remove the front cover.

(Do not loosen the screw completely. The screw may fall out.

If the screw is lost, use a M3 x 10 Philips screw.)

Attach the base to the mounting

surface using 4 screws.

Push the sensor unit back

into the base. Push the

excess wire (≥ 10 cm)

back into the mounting

surface.

➔ Setup

see page 4

Connect wires to the terminals.

To detach the sensor unit:

Hold here and pull forward

(see chapter 2)

wire cross section:

solid 0.5 – 1.2 mm2

stranded 0.3 – 2.0 mm2

4

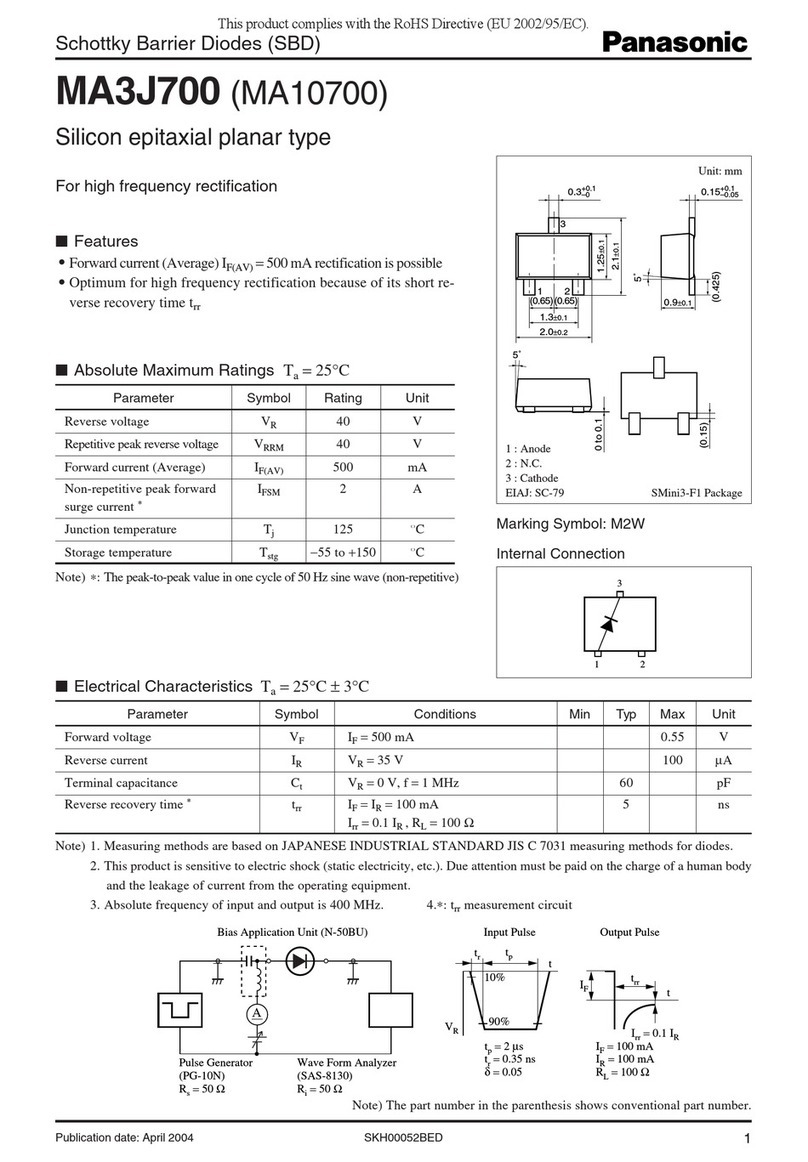

7 8

1

2

90°

± 10° ≤45°

4Setup

Sensor Mode Congure the proper sensor mode by pressing and holding

the Sensor Mode button for 2 seconds. Factory setting:

Perpendicular

Output Select the output logic type

(by pressing the Output Logic button). Factory setting:

N.O.

Microwave

Range

Adjust the detection range

(by pressing the Microwave Range button).

Recommendation: Set the range 500 mm shorter than the actual width of the road.

Factory setting:

3.5 m

Sensor Mode:

Perpendicular

Sensor Mode:

Angled

Calibration memorizes the background of the detection area ➔perform without any pedestrians or vehicle present!

• Press and hold the Calibration button on the sensor unit for 2 seconds and verify that the LED is blinking slowly in blue.

The LED blinks for 8 seconds and blinks more quickly for 2 seconds.

• If the ultrasonic sensor detects an object during calibration, the LED blinks in red and blue alternately, resulting in calibration error.

If the cause cannot be eliminated reduce the range.

• When the calibration is complete, the LED turns solid green.

• If a noticeable change occurs around the detection area (such as construction of a wall or fence), the calibration must be performed again.

• If a vehicle or pedestrian enters the detection area during the calibration, perform the calibration again.

• If a change is made to the sensor installation height, direction angle, and/or Microwave Range perform the calibration again.

4.1 Calibration

Rotate the sensor unit to the correct angle.

First hook the front cover on the top of the base and then

snap it onto the base while pulling down.

Tighten the front cover retaining screw.

5

Press the Area Check button

The LED blinks green.

• If there is a pedestrian or an object in the detection area, the LED lights up:

– Blinking yellow: Only the microwave sensing element is detecting

– Blinking purple: Only the ultrasonic sensing element is detecting

– Blinking red: Both the microwave and the ultrasonic are detecting

• If requested:

adjust the ultrasonic sensor range

1. Press the MODE button and select Ultrasonic Range

2. Press the VALUE button and select the desired sensing distance

• After 30 seconds without detection it will automatically change back to the normal operation mode.

4.2 Detection area check (can be performed after calibration)

4.3 System operation check

Factory setting:

1 m

Stand at the center of the vehicle lane (see gure [A]) and walk in the

direction of vehicle access.

When the LED turns from slow green blinking (non-detection) to fast

blinking (detecting), it is the edge of the detection area, depending on

your position the LED might blink fast in yellow, red or purple, see

LED colors on last page.

Stand at the edge of the vehicle lane (see gure [B]), walk along the

edge and verify that the LED keeps blinking slowly green (not detec-

ting).

Barrier arm

(Barrier open) (Barrier closed)

After verifying the detection area: Press the Area check button again

After verifying the detection area, check the entire system using a vehicle.

For this purpose, approach with a vehicle over the full width of the driveway.

For advanced settings (if needed): ➔go to page 6

Right side of the lane

Center of the lane

Left side of the lane

6

3 m 5.5 m

5.5 m3 m2 m

2 m

5Advanced settings

5.1 Trigger sensitivity

5.2 Static sensitivity (after initital detection)

5.3 Sensing zone diagram

5.4 Presence detection

The sensor periodically performs re-calibration. This can prevent the sensor from permanently staying switched on.

If any of the following conditions is fullled, change the presence detection value:

• The sensor keeps detecting due to an object in the detection area.

• The sensor keeps detecting after installing a roadblock.

Description:

• An object is placed in the detection eld of the microwave area and the sensor detects the object.

• When the presence timer has run out, the sensor changes to non-detection state because the object is memorized as a background.

• When the object is removed, the sensor may stay in a non-detection or detection state.

• If the sensor stays in the non-detection state, it may be less sensitive for a while.

• When the object is removed after the time period of presence detection, the sensor will memorize again the background and be in non-detection

state.

Factory setting:

3

Factory setting:

3

Increase the value if: • A person is detected occasionally

• The sensor detects a vehicle passing close to (but not within) the detection area

Decrease the value if: • Occasionally a vehicle is not detected

• Response of detection is too slow

Increase the value if: Occasionally a vehicle presence is not held or the detection response is too slow

Decrease the value if: The sensor stays in detection after a vehicle has left

Note: Once the level is set to special, the sensor will trigger to any type of object (see chapter 5.1).

Top view Side view Microwave

Ultrasonic

[Unit: m]

setting

Factory setting:

5 min.

All these parameters are to be adjusted if the sensor does not operate as expected. They are not necessary for a normal installation.

i

7

o on

5.7 Factory reset

5.6 Input

5.5 Sensitivity boost

Press and hold both the Calibration button and Area Check button at the same time for 2 seconds.

Use INHIBIT to deactivate output e.g. while swing gate is moving into sensing zone.

Use WAKE to detect any object within the sensing zone similar to light beam.

Use only with perpendicular mode.

The sensitivity boost enhances the sensitivity for a certain period of time after a vehicle has passed through

the detection area. Enable this function if a vehicle may back up unintentionally due to a slope in the exit area.

• While the sensitivity boost is enabled, a human or an object other than a vehicle may be detected.

• The function cannot be used for a gate system without a reopen function.

Factory setting:

Wake L

Factory setting:

Off

The barrier arm reopens to prevent a contact

o on

Threshold

Signal

Output

Sensitivity boost

8

Made in Japan

BBC Bircher Smart Access, BBC Bircher AG, Wiesengasse 20, CH-8222 Beringen, www.bircher.com

7Technical data

6LED signals / troubleshooting

8EU Declaration of Conformity

11 Contact

See attachment

10 FCC approval

9WEEE

This device meets the requirements of Part 15 of the FCC regulations and the RSS-210 standard of Industry Canada.

Warning: Changes or modications made to this device may void the FCC authorisation to operate this device.

Devices with this symbol must be treated separately during disposal. This must be done in accordance with the laws of the

respective countries for environmentally sound disposal, processing and recycling of electrical and electronic equipment.

Sensor technology Microwave: 24 GHz, Ultrasonic: 56 kHz

Supply voltage 12 – 24 V DC, ±15%

Response time 500 ms

Power consumption

Heater disabled

Heater enabled

Up to 80 mA (at 24 V)

Max. 200 mA (at 12 V)

Output Solid state relay 30 V DC, 0.3 A

resistive (N.O. / N.C. selectable)

Input Use dry contact switch

≤ 5 V DC / ≤ 0.5 mA

Uth = 0.75 V DC

Sensing distance

Microwave sensor

Ultrasonic sensor

0.8 to 5.5 m (max. range adjustable)

0.1 to 1.5 m (max. range adjustable)

LED X) Mode Output

Colour Solid / blinking Indication logic NO logic NC

none off Unpowered open open

green solid Standard operation Standby open CLOSED

green blinking twice Standard operation Large metal object present (best

remove)

open CLOSED

green blinking Detection Area Check Outside detection area open CLOSED

yellow blinking Detection Area Check Within microwave detection area CLOSED open

yellow solid 2 seconds Factory reset Reset completed open CLOSED

red solid Standard operation Detection CLOSED open

red blinking Detection Area Check Within microwave & ultrasonic detec-

tion area

CLOSED open

purple blinking Detection Area Check Within ultrasonic detection area CLOSED open

blue blinking slowly Calibration Preparation ➔leave detection area! open CLOSED

blue blinking fast Calibration Calibrating open CLOSED

blue – red alternate blinking Calibration Ultrasonic sensor detection error CLOSED /

open

CLOSED /

open

X) Status of Input will not affect LED

Detectable vehicle speed 2 – 20 km/h

Operating temperature –30 °C to 50 °C

Operating relative humidity 95% max. (no condensation)

Protection class IP65

Installation height 500 mm (distance from the road

surface to the bottom of the unit)

Sensor angle adjustment Left and right: ±30 degrees (5-degree

steps)

Dimensions 175 x 80 x 72.5 mm

Weight 420 g

In the box M4 mounting screws (4x), manual

Table of contents

Other BBC Bircher Accessories manuals