BBC Bircher Hyperion 3D User manual

1

Hyperion 3D

Energy-saving solution for industrial doors

Original instructions

1Safety instructions

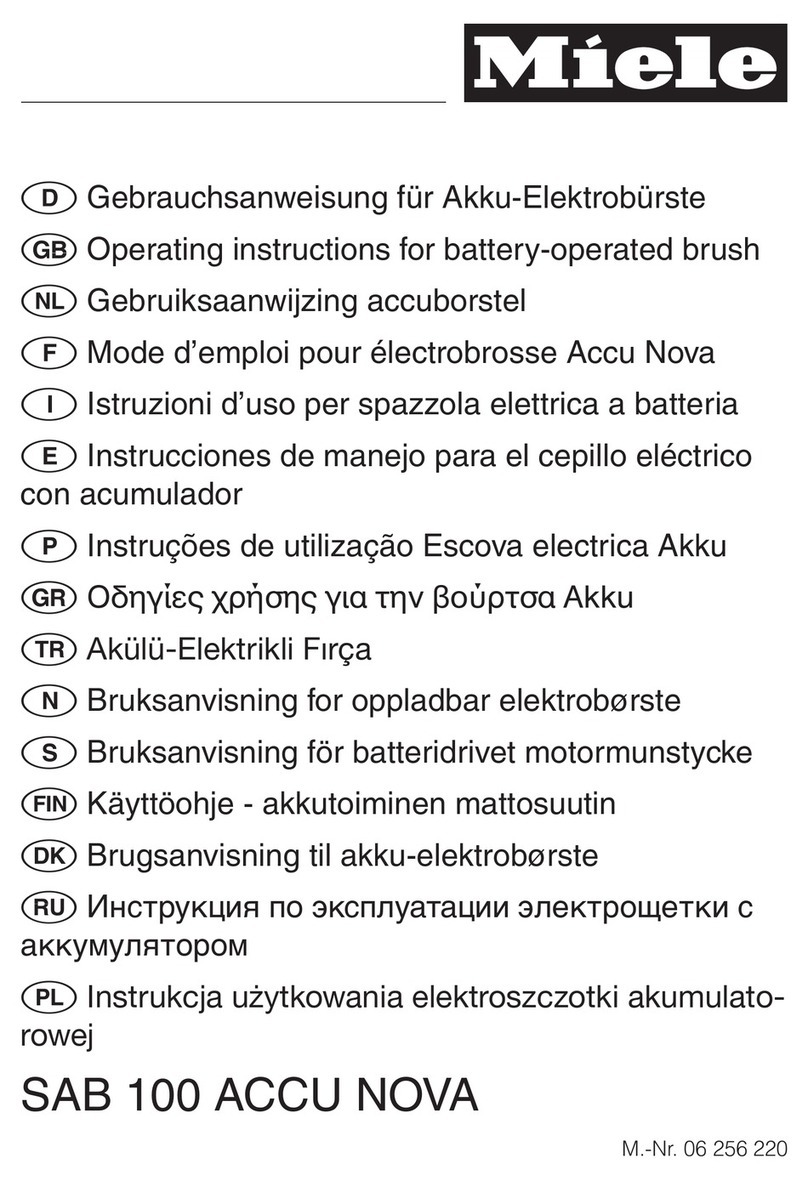

2Description of system components

ENGLISH

353225G

03/20

• The device may only be connected to a SELV (safety extra low-voltage) system with safe electrical separation.

• The device may only be opened and repaired by your supplier or a qualied technician.

• If automating a manual or semi-automatic door, make sure all required safety devices are existent and operational.

• This equipment is not suitable for use in locations where children are likely to be present.

Connection to

industrial door

control system

Master / Slave

connection

LED display

Mounting bracket

Angle xing screws

Locking washers

Screws (Torx 10) for cable

compartment cover

Cover for cable compartment

Seal

Blind plug for data cable

Blind plug for control cable

Label (serial no.)

Silica gel

Cable holder

Laser distance measurement

Short guide

Battery compartments

Button and status LED

Cover

Label (serial no.)

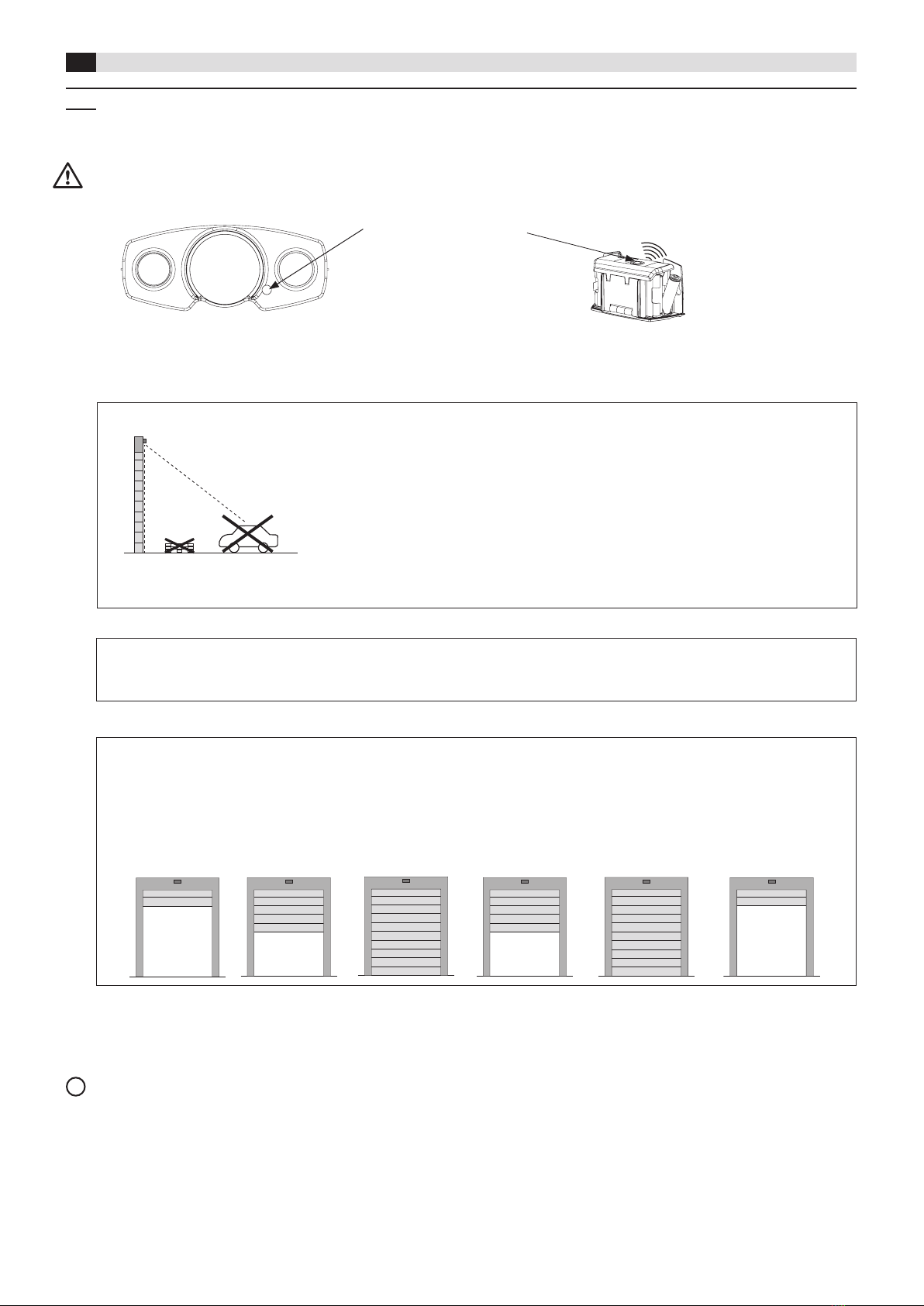

Caution:

Laser radiation! Do not stare into beam or view directly with optical

instruments.

Laser class 1

According to EN/IEC 60825-1:2014

Invisible laser radiation.

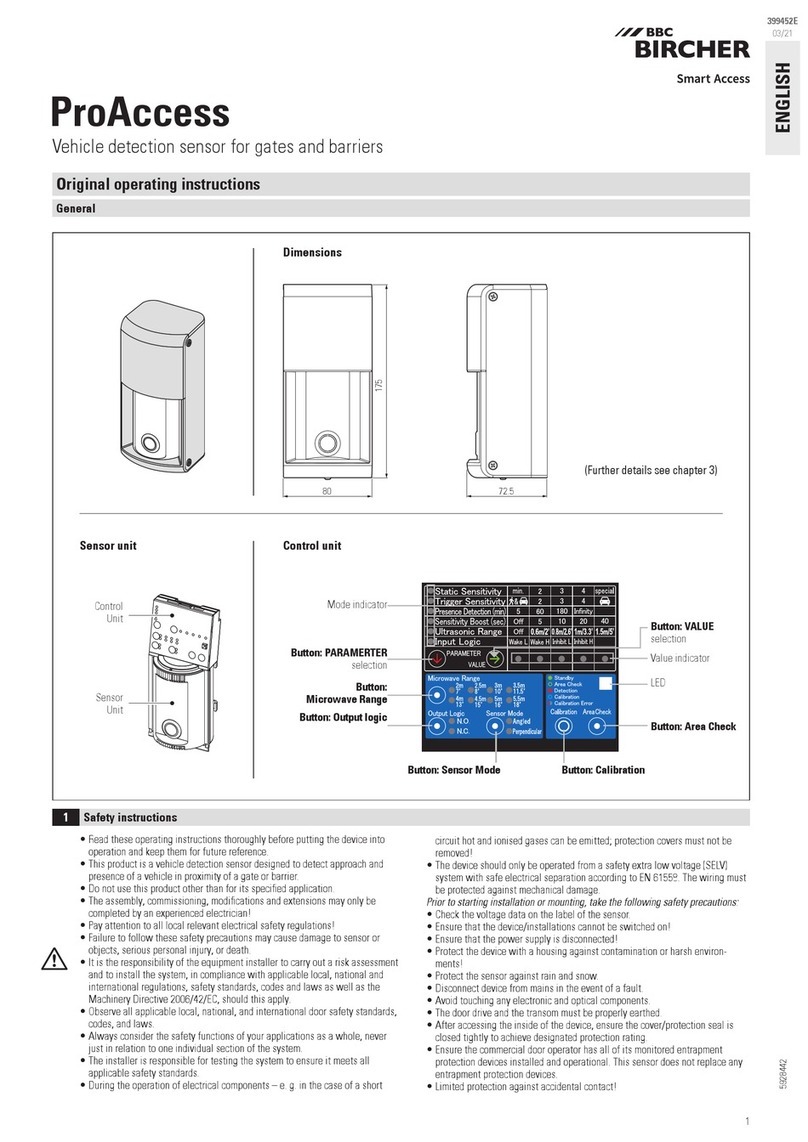

Front view

Back view

Bottom view

Hyperion 3D-M, Hyperion 3D-S

-M = Master sensor, -S = Slave sensor

Hyperion 3D-H

-H = Height sensor

2

= =

max. 20 cm

min. 10 cm

i

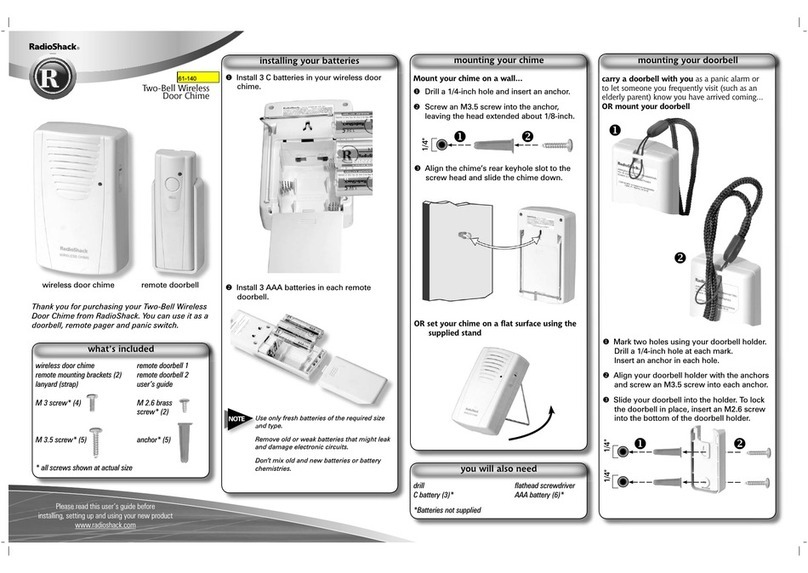

4.1 Mechanical mounting

4Installation

3Manufacturer declarations

The sensor is to be used for industrial doors.

2-way kit: Master /slave sensor can be mounted

inside or outside of the industrial door. Choose

position for easiest wiring. Mounting of master and

height sensor on the inside is preferred in order to

ensure optimal sensor communication.

Width

Depth Depth

Width

Depth

Depth

min. 50 cm

Control

box

Control

box

Outside Inside

Inside view

2-way kit

Outside view

Recommended mounting

height: 2.5 m to 7.5 m

Installation

area

Height

sensor

Master

sensor

Control

box

Master

sensor

Slave

sensor

Slave

sensor

Height

sensor

Master

sensor

1-way kit

Height

sensor

Depth

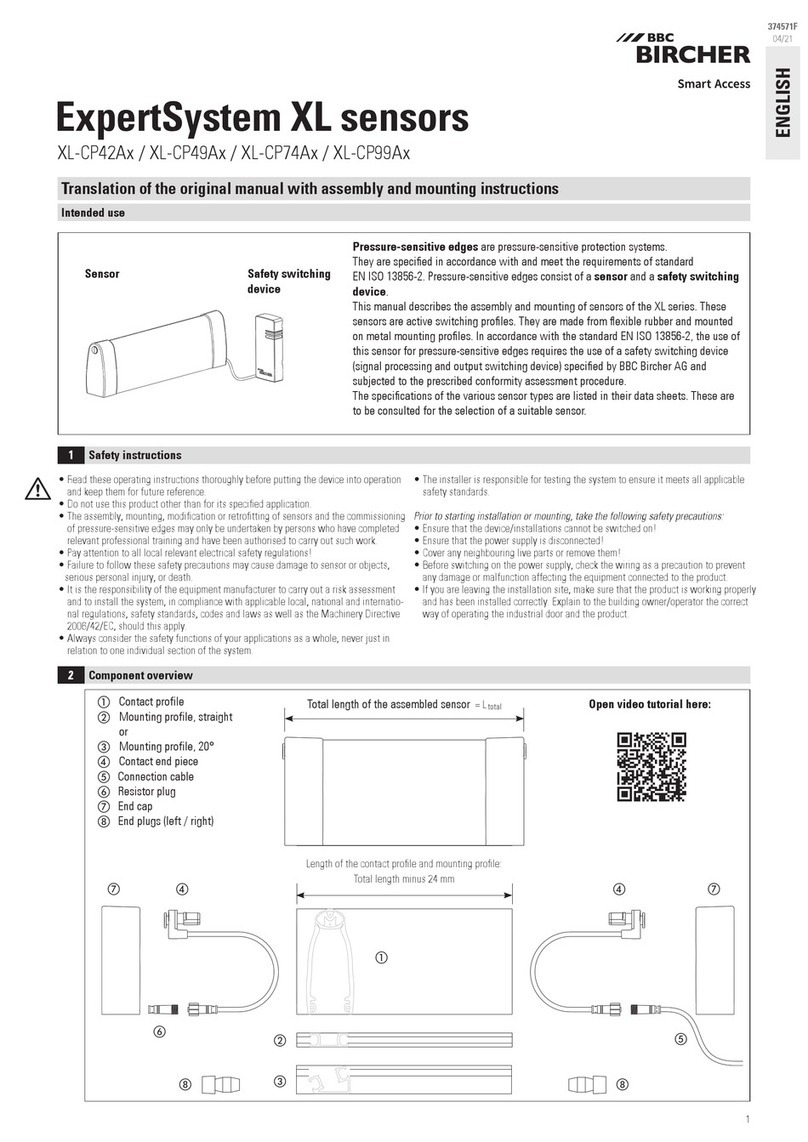

1. This product is a optical sensor system intended for mounting on a wall

or ceiling and used with an industrial door.

2. When adjusting the detection zone, make sure that

there are no moving objects inside the zone.

3. Before switching on the power supply, check the wiring as a precaution

to prevent any damage or malfunction affecting the equipment

connected to the product.

4. Only use the product as described in this manual.

5. Make sure to install and adjust the sensor in line with the laws and

safety standard that apply in the country where the product is being

installed (e.g. DIN EN 12453).

Caution: Failure to observe the applicable instructions and

handling the equipment incorrectly can result in personal injury

and/or damage to property.

Note: Pay particular attention to sections with this symbol.

6. If you are leaving the installation site, make sure that the product is

working properly and has been installed correctly. Explain to the

building owner/operator the correct way of operating the industrial

door and the product.

7. Only an installer or a service technician may change the product

settings. If changes are required, the settings that are made and the

date on which they are made must be recorded in the industrial door

maintenance manual.

The following conditions are unsuitable for detector installation:

Fog, smoke Moisture Vibrations Objects Reections

Make sure vision of sensor is not obstructed (e.g spider web)

Hyperion 3D-2W (2-way kit)

– Sensor

– Mounting bracket

– Control cable master sensor to industrial door control system, 12 m

– Data cable master to slave sensor, 10 m

–

QR codes of sensor (for establishing connection via app

Bircher SmartConnect)

Hyperion 3D-H

– Sensor

– 4 AA batteries, > 2700 mAh

2.1 Box contents

Screw recommendation

– metal surface:

self-drilling Ø 4.2 x 22 mm

– concrete surface:

pan head Ø 4.2 x 22 mm

(anchor 6 x 30 mm)

3

Hyperion 3D }

168 mm

70 mm

93 mm

105 mm

Max. 114 mm

295 mm

272 mm

5 mm

267 mm

10 mm

15 mm

90 mm90 mm

113 mm

40 mm

69 mm

4.4 mm

9 mm

10 mm

10 mm

134 mm

75 mm

69 mm 44 mm

B

A

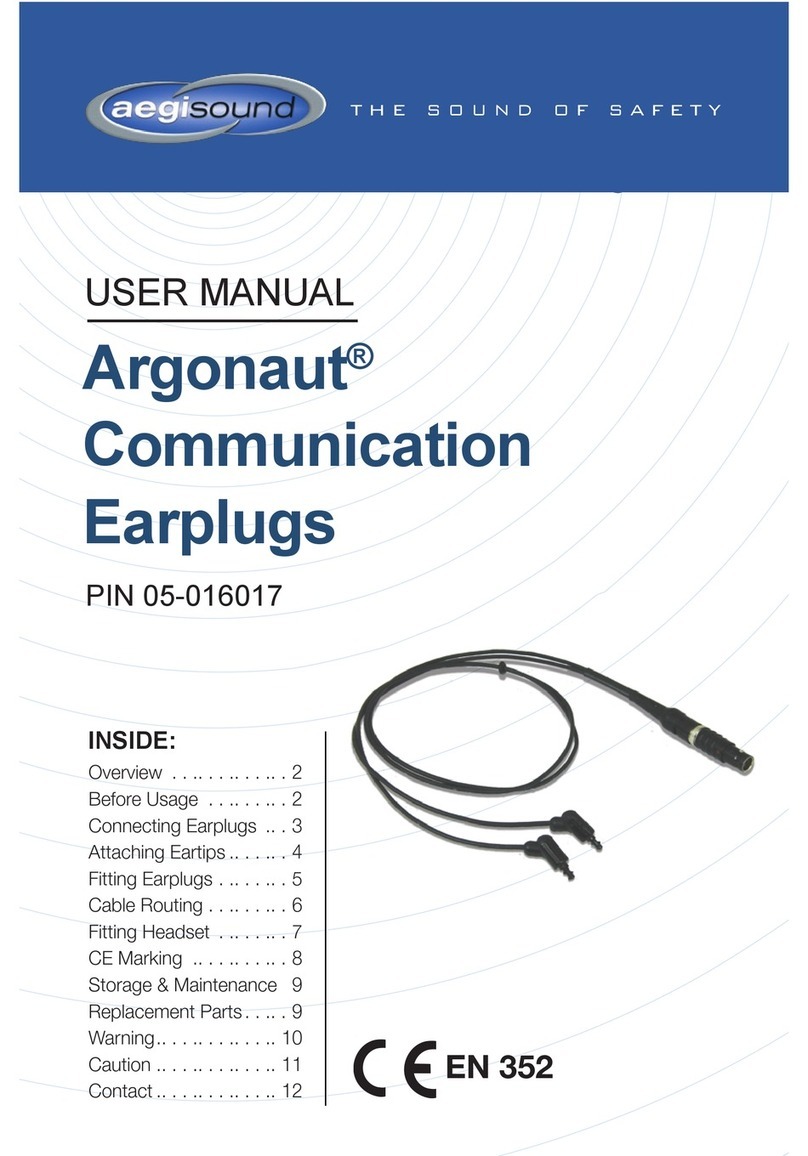

4.2 Electrical connections

brown

green

yellow

pink

grey

red

pink / grey

purple

white –0 V

+ 24 V

COM

open

close

COM stop NC

COM stop NO

stop NO

stop NC

COM dig IN

dig IN

Signals to door

control unit

50 mA / 48 V

24 V DC / < 400 mA (2-way kit)

< 48 V / 5 mA

Threshold 15 V

Digital Input (dig IN):

With the digital input, the sensor can be deactivated,

e.g. overnight by a timer or by a remote program selector

switch.

BBC Bircher AG declines all responsiblity regarding the

use of the digital input. To deactive the door, we recom-

mend to switch off (unpower) the door control.

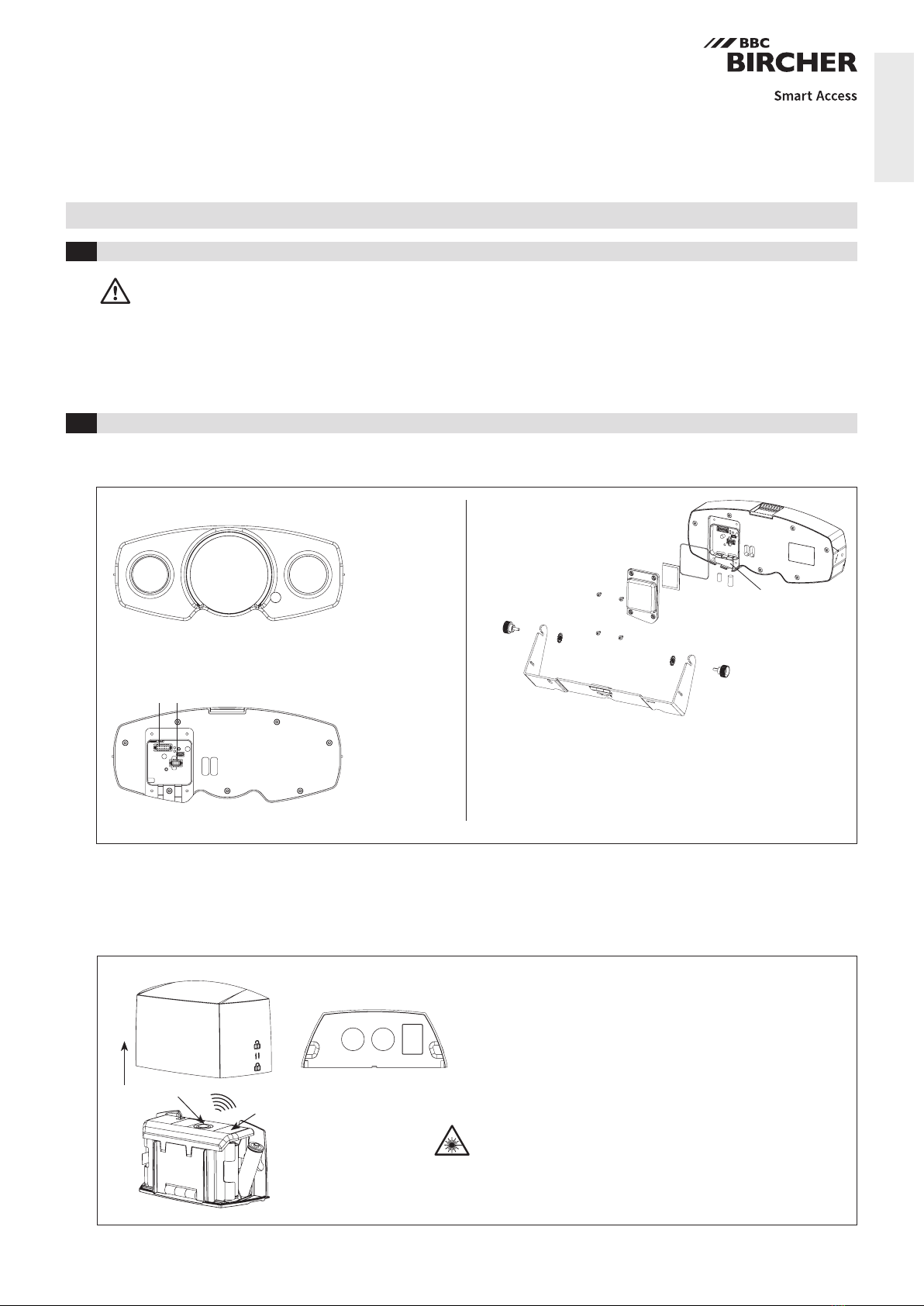

Hyperion 3D-H

Installation site

Mount the height sensor in the marked area at the bottom of the

industrial door panel (see illustration above).

The sensor must not collide with anything while the industrial door

is moving.

The height sensor must be mounted on the inside of the industrial door.

1. Remove the cover.

2. Insert 4 AA batteries.

3. Attach the sensor with screws to the bottom of the industrial door.

4. Plug in battery cable. Caution: observe polarity.

Hyperion 3D-2W (2-way kit)

Installation site

Mount the device in the middle above the industrial door.

The sensor must be mounted safely on a at surface (avoid vibrations).

The sensor’s eld of vision must not be obscured by covers or

signs.

1. Attach the mounting bracket rmly and horizontally onto the wall (2x)

2. Route the control cable (to door control unit 12 m, Ø 8 mm,

plug 12 mm), best below mounting bracket.

3. Plug the connector into the sensor

4. Screw on the cable compartment cover (60 cNm)

5. Hook the sensor into the mounting bracket:

for a mounting height up to 4.5 m align letter with “A”,

for a mounting height > 4.5 m align with letter “B”

then tighten handscrews (~ 1 Nm).

The sensing field shall not see the door, it can be viewed with help of

the app Bircher SmartConnect, see chapter 4.2, no. 3a.

6. Add weather shield to weather exposed sensor.

1-way kit

Master sensor

2-way kit

Master sensor Slave sensor

Control

cable

Data

cable

Control

cable

Blind plug for

control cable

Shielding

cable

Shielding

cable

Blind plug for

data cableLocking washer

Space needed

for hanging

onto screw

Space needed

for removing

cover

black

blue

On door control: Remove automatic closing time-out to prevent forced closing of the door while presence zone still busy.

4

LED

i

Button

5.1 Starting up sensor system

Note

You can abort the calibration sequence by cutting power to the

sensor. The calibration starts again (according to the description

above) once the device has been powered again.

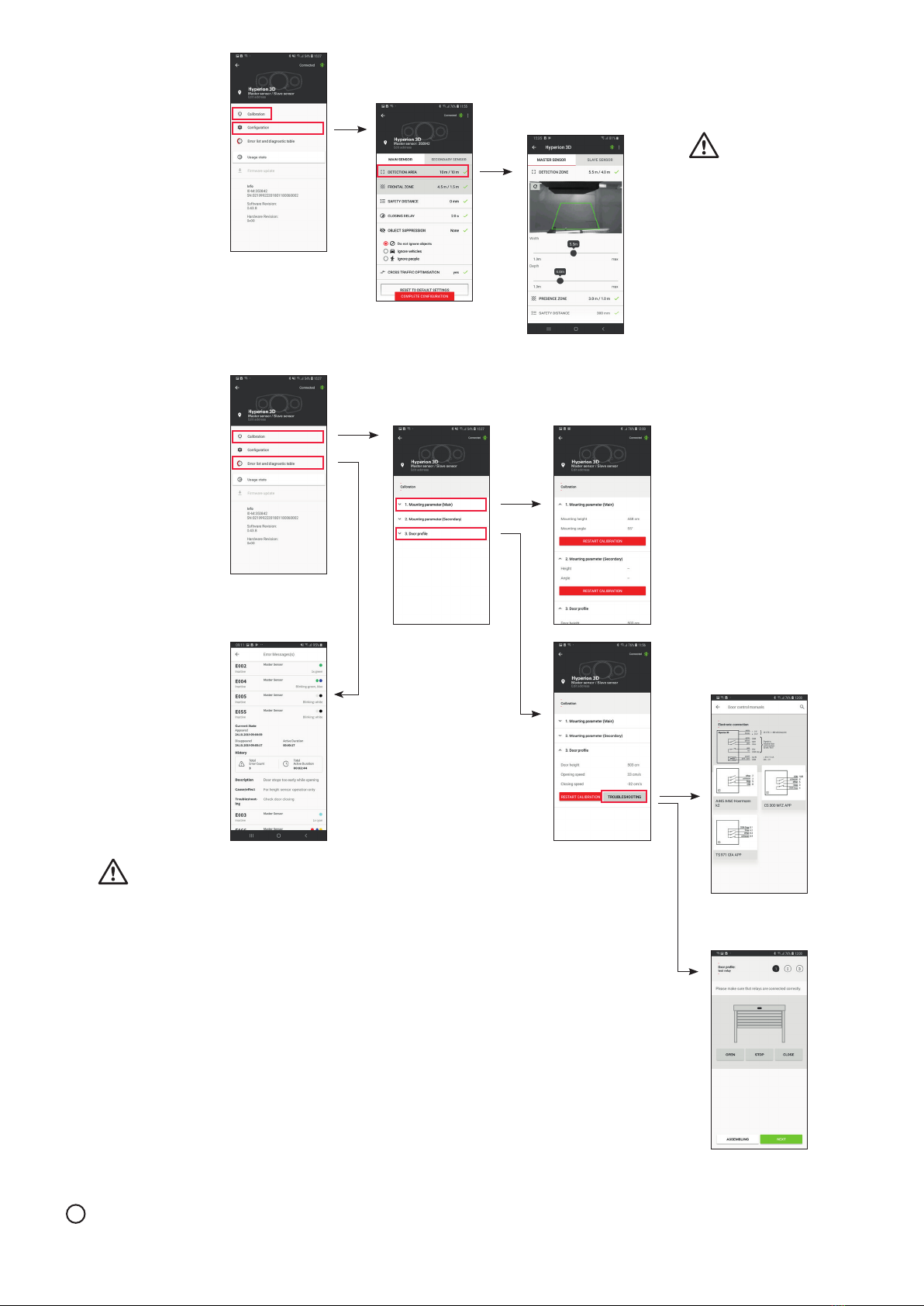

2. Pairing of height sensor with master sensor

Is carried out simultaneously.

There must not be any vehicles or other objects such as

containers, forklifts, etc. in the detection area.

5Settings

1. Installation calibration

After successful teaching-in the door motion paramenters

→ The sensor restarts automatically and LED lights up red,

then white.

Note:

In case of failure or changes to the system (e.g. sensor mounting angle, door motion paramenters or changing height sensor),

the 3 teach-in phases can be restarted manually.

In order to avoid condensation, the sensor must not be switched off or disconnected from the mains after start-up.

After connecting the supply voltage to the master sensor:

Master / Slave sensor: the LED lights up red continuously, then blinking (approx. 90 s). → The sensor will not accept any commands.

When powered for the rst time or with unnished calibration sequence the sensor initiates the calibration sequence automatically.

Caution: If the industrial door is open, the teach-in procedure starts with a closing procedure.

Calibration / Teach-in sequence

– This procedure can last up to 5 minutes. The LED blinks red-green-blue during calibration/teach-in.

– Press button from the height sensor for 3 seconds (pairing mode starts), re-attach the cover.

3. Teach-in of the door motion parameters

This triggers several cycles with intermediate stops (complete

and partial opening and closing movements), that the sensor can

learn the industrial door motion parameters.

Master / Slave sensor Height sensor

5

*

Bircher

SmartConnect

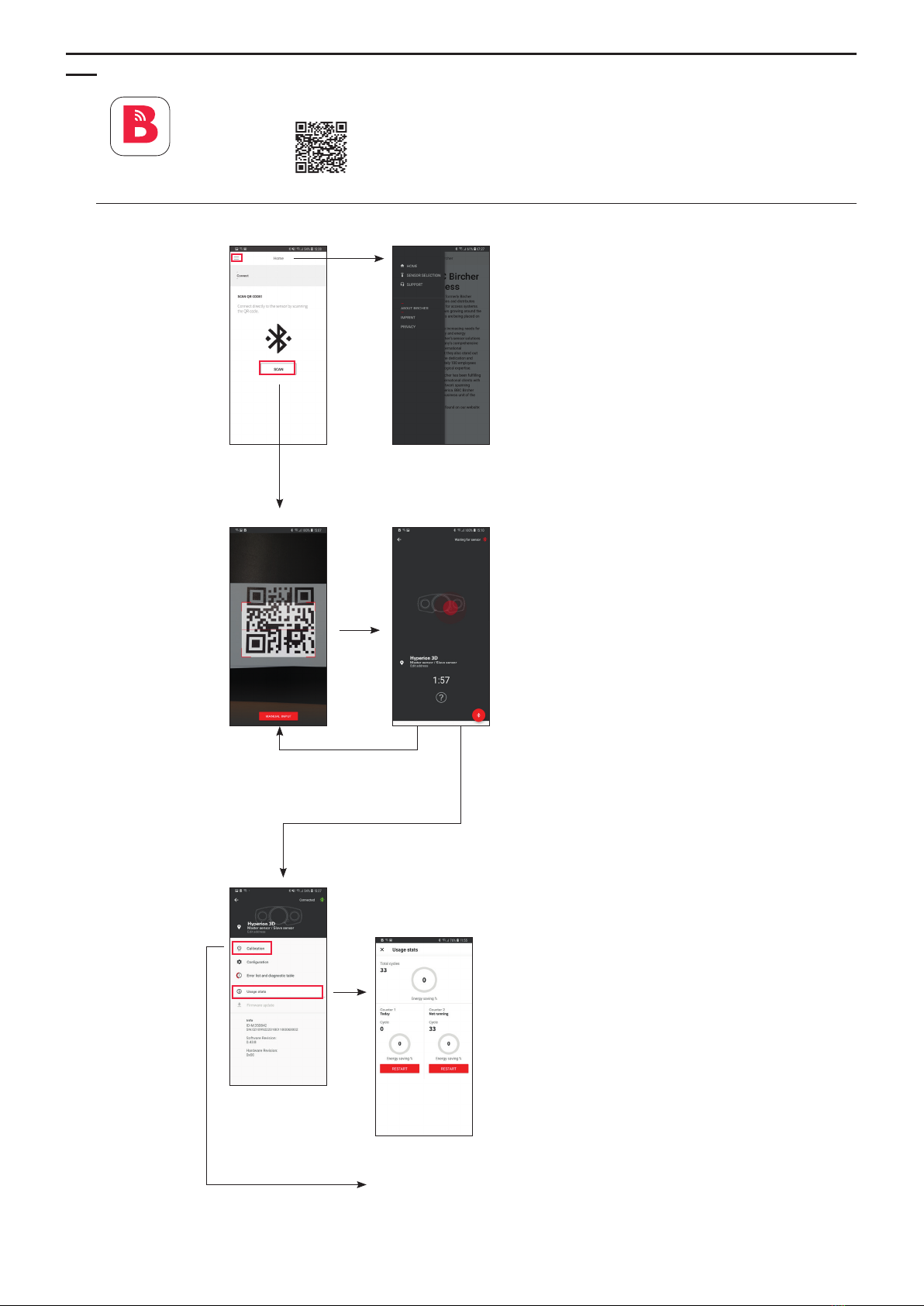

5.2 Conguration via app “Bircher SmartConnect”

The app is available in Google Play Store

directly via

The screens are shown with Android 8.0.0

1. Start app Base Menu

Available before scanning QR code

(respectively after terminating communication with sensor)

Caution:

The sensor is inactive while accessed by the app

Bircher SmartConnect (blinking red)

2. Scan sensor's QR code

QR code to be found

– at time of delivery:

in product box

– after installation:

in- or outside

door control cabinet

– Wait for connection to establish

– Master and slave sensors show up joint in app

Bircher SmartConnect

(no new scan necessary)

*To communicate with other sensor

go back and scan next QR code

QR code 1

for building owner /

user: Allows access

only to “Usage statis-

tics” and “Base menu”

(Page 5)

QR code 2

for service personnel:

Allows access to all

parameters / functions

3. a Main screen

Usage statistics

Conguration

see next page

Calibration

(1st install) see next page

6

i

3. b Main screen Conguration

Optimize detection settings or other options

3. cMain screen Calibration

1st install

Error list

Troubleshooting

Wiring

Test outputs

Note:

It is mandatory to perform a test operation after completing the calibration and the teach-in procedure. The correct door opening height must be mon-

itored during this test operation (object height plus safety distance).

Do not park vehicles in the path

of the moving door.

– On door control:

Remove automatic closing time-out to prevent forced

closing of the door while presence zone still busy.

7

6LED signals / troubleshooting

6.1 Hyperion 3D-M, Hyperion 3D-S

6.2 Hyperion 3D-H

Button LED Description Troubleshooting

Brief press

(< 1 s)

1x green Battery full

1x yellow Low battery Plan battery change

1x red Battery critical Change battery

Long press

(> 3 s,

LED ashes

white 1x/s)

Blue ashing Searching for master sensor

3x green Connection to master sensor

established successfully

3x red Connection to master sensor failed Repeat pairing to master sensor:

Use app Bircher SmartConnect

LED Description Troubleshooting

White Sensor powered,

ready for operation

Red Power-up The sensor will not detect objects or react to commands

Red blinking Conguration mode

(parameter change in progress)

The sensor will not detect objects.

Exit access by app Bircher SmartConnect

Red/green/blue

blinking

Calibration

(1st time background teach-in)

The sensor will not detect objects or react to commands

Blue Vehicle approaching door To prevent door opening set people/vehicle parameter

Green Person approaching door To prevent door opening set people/vehicle parameter

Turquoise Unknown object approaching

door

Door might open to full height

Blue/green blinking Object in presence zone Free presence zone

White blinking Manual operation of door or

digital input (dig IN) active i.e.

sensor deactivated, see page 3

The automatic operation of the door will be ceased until the door gets

closed again by manual command.

red yellow Error Start calibration again by app Bircher SmartConnect or temporary

cutting power

red blue Error Press button on height sensor for 3s (remove cover), possibly start

calibration again

red yellow white Error Clean lenses on master sensor (slave sensor).

Check light condition > 50 lux.

red yellow blue Error Check power supply on master sensor, if error only on slave sensor ->

Check wiring from master sensor to slave sensor

red yellow yellow Error Observe temperature specication, possibly add weather hood

red yellow red Error Exchange master sensor (slave sensor)

red blue white Error Clean lenses on height sensor

red blue blue Error Check batteries on height sensor

red blue yellow Error Restart height sensor by temporary cutting power, possibly change

batteries. Check if door can be manually opened by door controller.

red blue red Error Exchange height sensor

red white blue Error Check wiring from master to slave sensor,

Exchange slave sensor

red white red Error Check opposite sensor

A list of previous errors can be found in the mobile app.

8

Made in Switzerland

BBC Bircher Smart Access, BBC Bircher AG, Wiesengasse 20, CH-8222 Beringen, www.bircher.com

8EU Declaration of Conformity

11 Contact

See attachment

10 FCC approval

9WEEE

Devices with this symbol must be treated separately during disposal. This must be done in accordance with the laws of

the respective countries for environmentally sound disposal, processing and recycling of electrical and electronic equipment.

This device meets the requirements of Part 15 of the FCC regulations and the RSS-210 standard of Industry Canada.

Warning: Changes or modications made to this device may void the FCC authorisation to operate this device.

7Technical data

Electrical data Master, slave

sensor

Height sensor

Supply voltage 24 V DC ±15% 4x AA batteries

Power consumption < 10 W (2way kit) > 2700 mAh

Outputs potential-free

max. 50 mA / 48 V

–

Digital input potential-free

max. 48 V (5 mA)

Threshold 15 V

–

System description Min. Max. Unit

Industrial door speed 0.1 1.5 m/s

height 2 10.0 m

Detection zone 1width 3 2x mounting height m

depth 2 2x mounting height m

Presence zone 1width 2 1.5x mounting height m

depth 0.1 3 m

1Objects up to 0.3 m height are ignored.

Mechanical data Master, slave

sensor

Height sensor

Dimensions

(W x D x H)

Approx.

260 x 110 x 55 mm

Approx.

135 x 55 x 75 mm

Material PC–ABS–GF20,

Aluminium

ABS

Color Black

IP protection class IP65

Operating temperature Min. –20°C

Max. +60°C

Storage temperature 0 – 40°C

Mounting height 2.5 m to 7.5 m

This manual suits for next models

4

Table of contents

Other BBC Bircher Accessories manuals

Popular Accessories manuals by other brands

Philips

Philips INFRACARE HP3643 Service manual

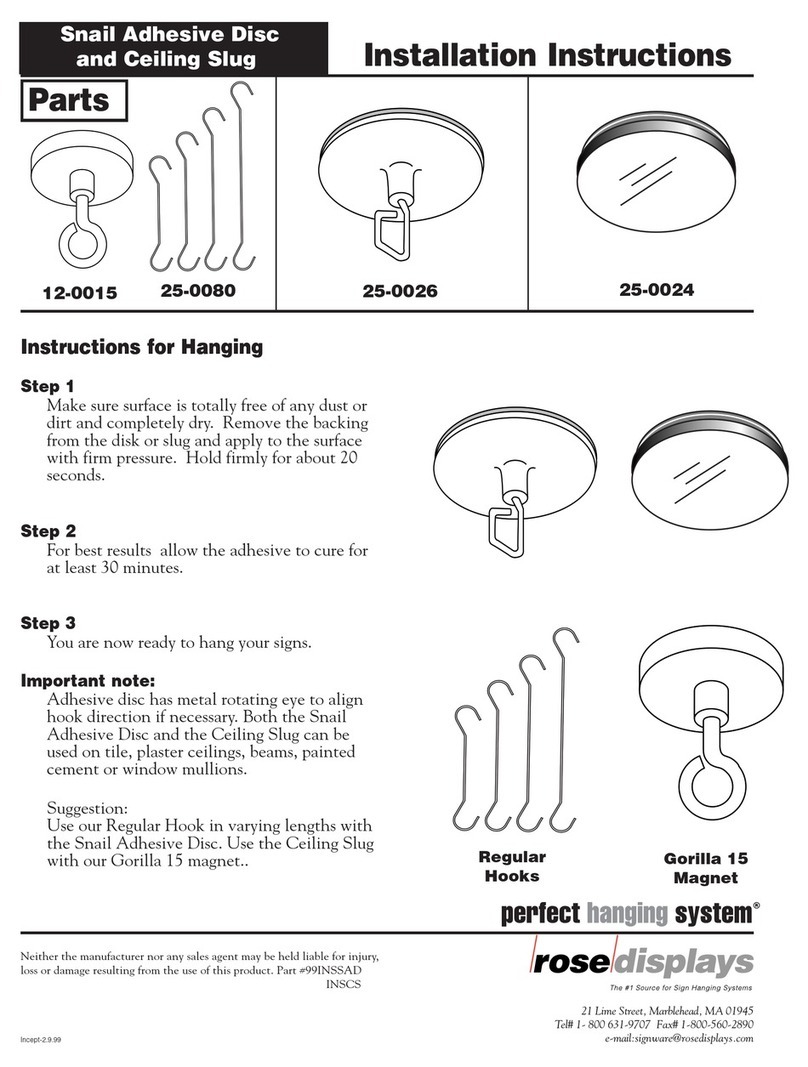

ROSE DISPLAYS

ROSE DISPLAYS SNAIL ADHESIVE WITH CEILING SLUG installation instructions

Changhong Electric

Changhong Electric CH7804-UC user guide

DIS Sensors

DIS Sensors CAN user manual

Little Tikes

Little Tikes Bounce House 620058 quick start guide

Intenda

Intenda Box Tunnel Installation, use and maintenance