BCE T-4 adjustable DESKING SYSTEM User manual

DESKING SYSTEM

T-4

®

adjustable

assembly instructi ns

Assemble units as described erein only. To do ot erwise

may result in instability. All screws, nuts and bolts must be

tig tened securely and must be c ecked periodically after

assembly. Failure to assemble properly, or to secure parts

may result in assembly failure and injury.

T-4®Desking

As sembl y Ins truct ions

2

Tools equired:

3/8" ex driver socket

Driver extension at least 2"

P illips screwdriver

Note: Screens are optional. Skip

to page 4 “Attac ing Cross Brace

and/or Wire Troug ” if no screen

attac ment is required.

Attaching Screen(s) (optional)

1. Carefully unpack all parts and place

screens onto a soft, protective surface.

Identify screens from t e “Screen

Part Numbers” diagram & Figure 1.

2. Identify t e applicable brackets

below from Figures 2, 3 & 4.

Note: All screen brackets must

be assembled to table(s) before

proceeding wit table assembly.

Screens may be attac ed to brackets

at end of table assembly if desired.

a. Standard Leg Brackets: Used

to attac straig t (A) and corner

(C & D) screens to standard legs

(Figure 2).

b. Screen-to-Table Brackets: Used

to attac end of run screen (B)

to underside of table worksurface

(Figure 3). T ese brackets are used

on non-adjustable tables only.

c. Corner Post Leg Brackets: Used

to attac corner screens (C & D)

to corner post leg.

3. Attac t e brackets as follows:

a. Attac left- and rig t- and

brackets to t e standard legs

using t e 1/4"-20 x 1/2" Allen

socket ead screws (two per

leg). See Figure 2.

b. Attac left- and rig t- and

brackets to t e end screen B

using t e 1/4"-20 x 3/4" Allen

socket ead screws (Figure 3).

c. Attac left- and rig t- and

brackets to t e corner post leg(s)

using t e 1/4"-20 x 1/2" Allen

socket ead screws (Figure 4)

A

C

D

B

B

standard leg standard leg

standard leg

corner post leg

corner desk

desk

Figure 1

right-hand

bracket

Standard Leg Brackets

(for straight and corner screens - A, C & D)

right-hand leg left-hand leg

left-hand

bracket

1/4-20 x 1/2”

Allen head

screw

Figure 2

Screen-to-Table Brackets

(worksurface-to-end screens B)

right-hand

bracket

left-hand

bracket

end screen (B)

#12 x 1

sheet metal screw

1/4-20 x 3/4”

Allen head

screw

Figure 3

Corner Post Leg Brackets

(for corner screens - C & D)

left-hand bracket

(on left-hand of a

right-hand corner screen)

right-hand bracket

(on right-hand of a

left-hand corner screen)

1/4-20 x 1/2”

Allen head

screw

Figure 4

Screen Part Numbers

GSCR/_XXX/...where XXX denotes

table type and/or locations

ASTR (Straight) back of rectangles

and peninsulas

BEND (End of any table) mounts

to top

CCLH (Corner LH) to the left-hand

of user on corners or shoes

DCRH (Corner RH) to the right-hand

of user on corners or shoes

Straight Screen Brackets

SL - 55354L

SR - 55354R

CL - 55355L

CR - 55355R

EL - 55357L

ER - 55357R

Corner Screen Brackets

End-of-Run Screen Brackets

P

T-4®Desking

As sembl y Ins truct ions

Assemble units as described erein only. To do ot erwise

may result in instability. All screws, nuts and bolts must be

tig tened securely and must be c ecked periodically after

assembly. Failure to assemble properly, or to secure parts

may result in assembly failure and injury.

3

Attaching Screen(s) (optional)

continued

Note: To make installation easier,

ave a second tec nician old t e

screen in place w en attac ing

screen.

END (B) Screen

4. Position t e screen and bracket

assembly flus wit t e rear edge

of t e table top leaving 1" space

between front surface of t e screen

frame and side edge of t e table

top. Using t e brackets as a

template, mark t e four attac ment

screw ole locations on t e table

top.

5. Drill four 1/8" diameter pilot oles,

1/2" to 3/4" deep.

6. Attac t e screen and bracket

assembly to t e table using four

#12 x 1" s eet metal screws. See

Figure 5).

ST (A), CLH (C) & C H (D)

Screens

7. Install screen to bracket and trim

casting using two 1/4"-20 x 3/4"

Allen socket screws (Figure 6).

8. To adjust screen tilt (if required),

loosen t e 1/4"-20 x 1/2" Allen

socket ead screws and turn in top

OR bottom screw to ac ieve vertical

adjustment of screen (Figure 7).

Tig ten 1/4"-20 x 3/4" Allen

socket ead screws.

1/4-20 x 1/2”

Allen head

screw

trim casting

1/4-20 x 3/4”

Allen head

screw

setscrew

Figure 6

1/4-20 x 3/4”

Allen head screw

setscrew

Figure 7

Figure 5

#12 x 1”

sheet metal

screw

#12 x 1”

sheet metal

screw

Assemble units as described erein only. To do ot erwise

may result in instability. All screws, nuts and bolts must be

tig tened securely and must be c ecked periodically after

assembly. Failure to assemble properly, or to secure parts

may result in assembly failure and injury.

4

Note: Worksurface dividers are

optional. Skip to page 5 “Attac ing

Cross Brace and/or Wire Troug ” if

no divider attac ment is required.

Worksurface Divider Attachment

(optional)

Note: Worksurface dividers may

be used in place of ganging plates

between desks.

Note: W en tables ave bot

dividers and table-to-table troug

jumpers, assemble t e bases,

troug s and joiners first and install

t e divider after attac ing one

worksurface but before attac ing

t e adjacent worksurface.

1. Position t e divider w ere it

is most appropriate for t e

installation (usually wit t e back

of t e divider flus wit t e back

of t e worksurface). Mark t e

underside of t e worksurface

to drill t ree oles.

2. Drill 1/8" diameter by 1/2" deep pilot

oles being careful not to drill

t roug t e worksurface. Attac

t e divider using t ree of t e

#14 x 7/8" long screws provided

(Figure 8).

3. Attac t e worksurface to t e base

of t e adjacent table. Using t e

divider as a template, drill oles

and secure t e divider to t e top

using remaining t ree #14 x 7/8"

long screws (Figure 8).

Figure 8

divider divider

worksurface worksurface

#14 x 7/8”

screw

#14 x 7/8”

screw

T-4®Desking Assembly

As sembl y Ins truct ions

T-4®Desking

As sembl y Ins truct ions

Assemble units as described erein only. To do ot erwise

may result in instability. All screws, nuts and bolts must be

tig tened securely and must be c ecked periodically after

assembly. Failure to assemble properly, or to secure parts

may result in assembly failure and injury.

5

Attaching Cross Brace and/or

Wire Trough

Note: If using leg-mounted

screens, attac screen brackets

before proceeding wit t is

assembly. See Attac ing Screen(s).

Note: Heig t adjustable table

bases are built wit out t e top and

require cross braces to increase t e

table stability.

1. Remove rear leg covers.

2. For 2 leg tables, slide t e cross

brace (Figure 9) or wire troug into

t e opening between t e back of

t e leg and t e bracket. Attac to

eac standard leg on t e inside set

of oles using two 1/4"-20 x 1/2"

ex ead screws.

For 3 leg tables, cross brace and

wire troug ave a bent tab on one

end for attac ing to t e post leg.

(Figure 10). Slide t e cross brace

or wire troug bent tap into t e

opening between t e back of t e

leg and t e bracket (Figure 8 on

page 4). Attac using two

1/4"-20 x 1/2" ex ead screws.

Figure 9 - 2 Leg Table

1/4-20 x 1/2”

hex head

screw

cross brace

standard leg

Figure 10 - 3 Leg Table

1/4-20 x 1/2”

hex head

screw

wire trough

cross brace

1/4-20 x 1/2”

hex head

screw

Assemble units as described erein only. To do ot erwise

may result in instability. All screws, nuts and bolts must be

tig tened securely and must be c ecked periodically after

assembly. Failure to assemble properly, or to secure parts

may result in assembly failure and injury.

T-4®Desking

As sembl y Ins truct ions

6

Installing Crank Table Chain

1. Wit cross brace or wire troug

securely attac ed to legs, lay t e

plastic c ain c annel in t e leg

pockets (Figure 11).

2. Remove t e cotter pin and plastic

sprocket from t e exagonal s aft

in eac leg.

3. Insert sprockets into c ain loop

and slide sprockets down over

exagonal s afts, leaving equal

amounts of slack on bot sides.

Make sure eac side of t e c ain

loop is positioned wit in t e leg

pocket.

Note: On 3 leg tables, t ere are

two sprockets and a was er on t e

post leg exagonal s aft. T e

was er is positioned on top of t e

top sprocket (Figure 12).

4. Secure eac sprocket wit a cotter

pin.

plastic chain channel

cotter pin

plastic sprocket

leg pocket

leg pocket

standard leg

cross brace

standard leg

chain

Figure 11 - 2 Leg Table

chain

standard leg

leg pocket

plastic chain

channel

plastic sprocket

cotter pin

cross brace

standard leg

leg pocket

plastic sprocket

wire trough

post leg

washer

Figure 12 - 3 Leg Table

T-4®Desking

As sembl y Ins truct ions

Assemble units as described erein only. To do ot erwise

may result in instability. All screws, nuts and bolts must be

tig tened securely and must be c ecked periodically after

assembly. Failure to assemble properly, or to secure parts

may result in assembly failure and injury.

7

T-4 Wire Management Troughs &

Universal 10 Wire Power System

Note: T e troug s come fully

assembled and ready for

attac ment to t e base legs.

Some disassembly may be

required for t e installation

of some components suc as

receptacles, power ways, troug

end caps and/or troug joiners.

Note: Before assembling

electrical components, troug s

s ould be assembled to t e table

legs (see previous sections)

1. See Figure 13 for troug

components.

2. See Figure 14 for electrical

components.

Leg attachment tab

is bent for tripod

post leg attachment

mitered foor trim

(does not open)

(corner & shoe tables only)

1/4-20 x 5/8” screw

for leg attachment

LH back cover

trim casting

all other trough

assembly screws are

#10-24 x 1/4” Torx drive

access door

extrusion

back cover

extrusion

RH back cover

trim casting

interior

cover

Figure 13

Figure 14

trough access

by opening door

opening along entire

length of spline for

easy drop in cord

management

2 receptacles out through

bottom of trough

2 receptacles

inside trough

2

#8 x 5/8”

Phillips head

screw

#10-24 x 1/4”

Torx head screw

(1 per clip)

rigid wireway

attachment clip

(2 per wireway)

rigid wireway

(approximately 153/8” shorter

than table width)

receptacles

(typically 4 per wireway)

In-feed

(replaces 1 receptacle)

end-of-trough run

end caps

table-to-table

trough joiner

trough

assembly

(straight)

Infeed replaces 1 of

the bottom receptacles

Assemble units as described erein only. To do ot erwise

may result in instability. All screws, nuts and bolts must be

tig tened securely and must be c ecked periodically after

assembly. Failure to assemble properly, or to secure parts

may result in assembly failure and injury.

T-4®Desking

As sembl y Ins truct ions

8

Preparing for Electrical

Installation

Note: Before assembling electrical

components, troug s s ould be

assembled to t e table legs (see

previous sections)

1. Prepare troug by removing t e

inner cover (Figure 15). Lift up on

t e return lip of t e cover to swing

cover up, t en remove cover and

set aside near t e table.

Note: It is sometimes elpful to

remove t e rear aluminum cover.

2. Install wireway attac ment brackets

(2 per troug ) using #10-24 x 1/4"

Torx ead screw. T e brackets

attac near t e outside edge of t e

receptacle oles as s own in

Figure 15.

rear aluminum cover inner cover

table base not shown for clarity

wireway attachment bracket

#10-24 x 1/4”

Torx head screw

Figure 15

T-4®Desking

As sembl y Ins truct ions

Assemble units as described erein only. To do ot erwise

may result in instability. All screws, nuts and bolts must be

tig tened securely and must be c ecked periodically after

assembly. Failure to assemble properly, or to secure parts

may result in assembly failure and injury.

9

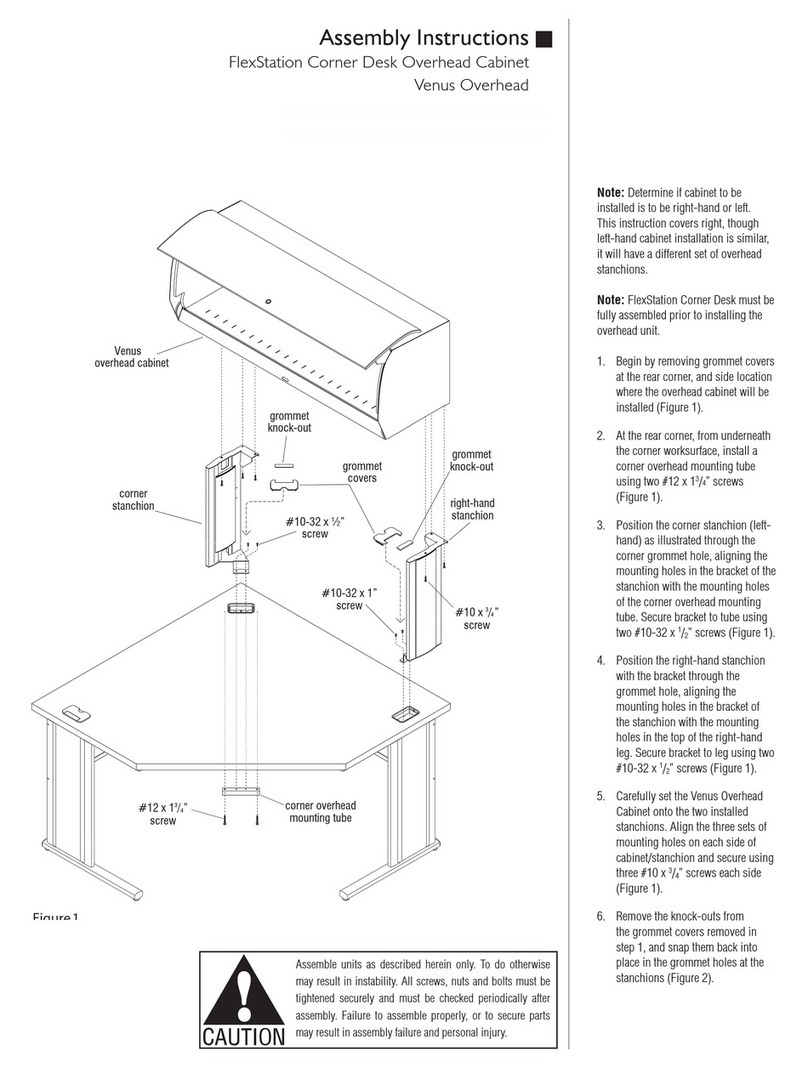

Installing Overhead Stanchion

Note: T ere is no difference

between assembling over ead

stanc ions to straig t, s oe or

corner tables.

1. T e over ead stanc ions are

factory assembled and ready for

installation. Identify t e proper

stanc ions to be used (Figure 16).

2. Stanc ions attac to t e table top

using six #14 x 1" P illips ead

s eet metal screws (Figure 17).

plate corner matches

back corner of overhead

thin edge

toward user

flat surface near flush

to edge of table top

channel for task light

cord facing rear

#14 x 1

Phillips head

screw

#14 x 1

Phillips head screw

left-hand stanchion

right-hand stanchion

table

Figure 17

Left-Hand Stanchions

For Venus For Universal

®®

Right-Hand Stanchions

For Venus For Universal

®®

Figure 16

Assemble units as described erein only. To do ot erwise

may result in instability. All screws, nuts and bolts must be

tig tened securely and must be c ecked periodically after

assembly. Failure to assemble properly, or to secure parts

may result in assembly failure and injury.

T-4®Desking

As sembl y Ins truct ions

10

Installing Overhead Stanchion

continued

Note: T e over ead stanc ion

attac es to t e underside of t e

table top. T ere are two met ods

to attac t e over ead stanc ions

(step 3A or 3B).

3A. Attac eac stanc ion fully

assembled using six #14 x 1"

P illips ead screws (Figure 18).

3B. Remove t e two #14 x 11/2"

P illips ead screws and

attac ment plate from t e

stanc ion (Figure 19A), t en

attac t e plate to t e table top

using six #14 x 1" P illips ead

screws (Figure 19B). T is allows

t e legs to be installed to t e table

top wit out t e stanc ions (see

below). Stanc ions can be attac ed

later to t e attac ment plate using

t e two #14 x 11/2" P illips ead

screws (Figure 19C).

4. Install t e left- and rig t- and

grommet trim pieces to t e cutout

in t e top (Detail A).

Installing Legs

1. Attac t e legs to t e underside

of t e table top using six #14 x 1"

P illips ead screws per leg

(Figure 20).

stanchion

#14 x 1”

Phillips head

screw

attachment

plate

table top

Figure 18

#14 x 11/2”

Phillips head

screw

stanchion

attachment

plate

attachment

plate

#14 x 1”

Phillips head

screw

stanchion

#14 x 11/2”

Phillips head

screw

Figure 19A

Figure 19B

Figure 19C

Figure 20

Detail A

grommet

trim piece

table top underside

#14 x 1”

Phillips head

screw

standard leg

standard

leg

post

leg

table top

underside

Assemble units as described erein only. To do ot erwise

may result in instability. All screws, nuts and bolts must be

tig tened securely and must be c ecked periodically after

assembly. Failure to assemble properly, or to secure parts

may result in assembly failure and injury.

11

T-4®Desking Assembly

Wir e Mana g emen t & Po wer

Installing Overhead

Note: If task lig ts are to be

installed, install t em to t e

over ead before installing

over ead to stanc ions.

1. T e ardware pack contains

four #8-32 x 1/2" P illips locking

pan ead screws. Only two of

t ese will be used in t e over ead

installation. T e ot er two

mounting screws must be removed

from t e over ead prior to setting

t e over ead on t e stanc ions

(Figure 21).

2. Set t e over ead onto t e

stanc ions so t e back of t e

over ead is fairly flus wit t e

back of t e stanc ion plates.

Align t e attac ment oles on

t e over ead wit t e two angle

bracket oles (Figure 21).

3. Attac t e over ead to t e angle

bracket at t e top of eac stanc ion

using four #8-32 x 1/2" P illips

locking pan ead screws (two

from t e ardware pack and two

removed from t e stanc ion)

(Figure 21).

Note: T e Venus®clam s ell

style over ead uses an additional

5/16-18 x 3/4" P illips pan ead

screw for mounting (one per

stanc ion) (Figure 22).

Figure 22

#8-32 x 1/2”

Phillips pan head screw

#8-32 x 1/2”

Phillips pan head screw

(from hardware pack)

Remove this screw from the

overhead and reassemble

through the rear slotted hole

in the stanchion

angle bracket

stanchion angle bracket

stanchion

overhead

Figure 21

#8-32 x 1/2”

Phillips pan head screw

right-hand

stanchion

5/16-18 x 3/4”

Phillips pan head screw

(used on Venus®Clam Shell

overheads only)

left-hand

stanchion

Assemble units as described erein only. To do ot erwise

may result in instability. All screws, nuts and bolts must be

tig tened securely and must be c ecked periodically after

assembly. Failure to assemble properly, or to secure parts

may result in assembly failure and injury.

12

T-4®Des ki ng As sembl y

Wir e Mana g emen t & Po w er

Installing Stanchion Tool ail

Note: One or more tool rails

may be attac ed to t e back of

t e over ead stanc ions.

1. To determine t e eig t of t e tool

rail, place one attac ment bracket

at t e back of t e left stanc ion

and mark t e desired location.

Measure t is location and mark

t e same position on t e back of

t e rig t stanc ion.

2. Press a plastic end cap and

attac ment bracket onto left end of

t e aluminum tool rail (Figure 23).

3. Insert four #14 x 1" s eet metal

screws into four w ite plastic screw

bases. Using t ese four screw

assemblies, attac t e left end of

t e tool rail to t e location marked

on t e back of t e left stanc ion in

step 1 (Figure 23).

4. Press a plastic end cap and

attac ment bracket onto rig t end

of t e aluminum tool rail and place

in t e marked position on t e rig t

stanc ion. Make sure t e tool rail

is level wit t e table top.

5. Insert four #14 x 1" s eet metal

screws into four w ite plastic

screw bases. Using t ese four

screw assemblies, attac t e rig t

end of t e tool rail (Figure 23).

Note: T e tool rail may be

positioned at any eig t on t e

back of t e stanc ions, and may

be repositioned at a later time if

desired (Figure 24).

plastic end cap

attachment

bracket

tool rail

plastic

screw

base

#14 x 1”

sheet metal

screw

plastic

screw cover

Figure 23

Figure 24

per user requirements

T-4®Des ki ng

As s embl y Inst r ucti o ns

Assemble units as described erein only. To do ot erwise

may result in instability. All screws, nuts and bolts must be

tig tened securely and must be c ecked periodically after

assembly. Failure to assemble properly, or to secure parts

may result in assembly failure and injury.

13

Transaction Worksurface

Attachment

1. Remove appropriate worksurface

grommets and covers. Remove

t e two outside 5/16-18 x 2"

s ort- ead bolts from t e bolt

cluster t at secures t e

worksurface to t e leg supports.

T e center bolt does not require

removal and can be loosened

approximately 1/8" and left in place.

Repeat on ot er end of worksurface

(Figure 25).

2. Place transaction worksurface

laminate side down on a soft

surface to avoid scratc ing.

Align small oles in transaction

worksurface supports wit drilled

oles near outside of worksurface

and secure wit two #14 x 7/8"

screws per support. Align oles

in transaction panel (flanges facing

toward inside of desk) wit drilled

oles in underside of worksurface

and secure wit t ree #14 x 7/8"

screws per panel (Figure 25).

3. Set transaction worksurface

assembly onto desk assembly

and ook transaction worksurface

support slots onto eads of t e

5/16-18 x 2" s ort- ead bolts.

Secure wit remaining 5/16-18 x 2"

s ort- ead bolts and tig ten

(Figure 25).

Figure 25

#14 x 1”

Phillips pan head

sheet metal screw

#12 x 1”

transaction worksurface

worksurface

stanchion

leg support

Assemble units as described erein only. To do ot erwise

may result in instability. All screws, nuts and bolts must be

tig tened securely and must be c ecked periodically after

assembly. Failure to assemble properly, or to secure parts

may result in assembly failure and injury.

T-4®Des ki ng

As s embl y Inst r ucti o ns

14

Figure 26

Installing Modesty Panel

(optional)

1. Identify correct lengt modesty

panel for lengt of table side

(60" and 48" s own). Radius bends

(if applicable) orient toward corner

post or peninsula post leg

(Figure 26).

2. Rotate mounting brackets at an

angle to fit between panel flanges.

Rotate mounting brackets vertically

to lock in place on panel

(Figure 27).

3. Attac assembled modesty panel to

oles on underside of worksurface.

Use two #14 x 1" P illips screws

for mounting eac bracket

(Figure 28).

modesty panel

Figure 27

Figure 28

modesty panel flanges

top and bottom

rotate mounting brackets vertical

to lock in place on panel and

slide to approximate location

on panel

#14 x 1”

15

Other BCE Indoor Furnishing manuals

Popular Indoor Furnishing manuals by other brands

Regency

Regency LWMS3015 Assembly instructions

Furniture of America

Furniture of America CM7751C Assembly instructions

Safavieh Furniture

Safavieh Furniture Estella CNS5731 manual

PLACES OF STYLE

PLACES OF STYLE Ovalfuss Assembly instruction

Trasman

Trasman 1138 Bo1 Assembly manual

Costway

Costway JV10856 manual