BE Ag & Industrial BE-MTR2 Application guide

PURCHASE DATE MODEL NO. SERIAL NUMBER

DEALER

MINI TILLER

CULTIVATOR

BE-MTR2

OPERATIONS & PARTS MANUAL

MANUAL CODE: 102.107B

FOR MODELS:

• BE-MTR2

2 BE-MTR2 USER MANUAL

TABLE OF CONTENTS

3Introduction

4Safety

5Structure

6Assembling Adjustment and Operation

8Maintenance

9Troubleshooting

10 Exploded view and partst list

BE-MTR2 USER MANUAL 3

INTRODUCTION

IMPORTANT

This is a motorized rotary cultivator that works the soil by means of rotating tines. It is pedestrian-controlled,

but not self-propelled, with a gasoline-fueled internal combustion engine to power the tines. It shall not be

used for any other purpose.

For your own safety, always follow these basic precautions when using this appliance.

1. Read the user Manual carefully for operating instructions. Read all instructions in this manual before use.

2. DO NOT use this product for anything other than its intended purpose.

3. DO NOT use attachments other than those available from the manufacturer.

4. DO NOT alter this product in any manner; doing so is dangerous and will void all warranties.

5. DO NOT allow children or adults weighing under 100 lbs. to operate this unit.

6. DO NOT allow your body, loose clothing, drawstrings, scarves, hats or other materials to touch the power

head, or tines at any time.

7. DO NOT operate under the influence of drugs or alcohol.

8. DO NOT continue to use this product in the event of mechanical or electrical failure.

9. The tines are very sharp. Use extreme caution when cultivation or replacing the tines.

10.This product produces considerable cutting force that is felt by the operator. Make sure your feet are

firmly planted and the handles are firmly held while operating this product.

11. During operation, the tines unit could possibly stop. Be prepared at any time to release the buttons.

12. Check tines shaft screws before and after each use to make sure they are tight.

13. Disconnect and insulate spark plug wire before maintenance and/or changing blades

14. Do not put hands or feet near or under rotating parts

15. Never operate machine in wet grass. Always be sure of your footing; keep a firm hold on the handle and

walk; never run.

16. Never pick up or carry the machine while the engine is running

17. Keep all screws, nuts and bolts tight.

TECHNICAL DETAILS

Engine type 2-stroke

Engine Displacement 51.7cc

Engine power 1.3kw/7000rpm

Fuel tank capacity 36 ounces

Mixing ratio gasoline: 0il 30:1

Tilling Width 10" maximum

Tilling depth 10" maximum

Tine speed 256rpm

Weight 14 kg

PREFACE

The mini rotating plough machine has character of reasonable constructions, beautiful outlook, etc. For

better convenient operation, please strictly complying the following items:

1. Before operating the machine, please read the manual carefully, keeping the manual for reading at any

moment.

2. The machine was designed for garden, Not using in other.

3. When machine is operation, prohibit touching the gear wheel.

In order to improve the quality, the changes of some parts which are changed according to the market will

not be informed separately. Please give enough understanding.

4 BE-MTR2 USER MANUAL

SAFETY

Special safety precautions must be observed when working with the machine.

1. Demand for protective clothing

• Clothing must be sturdy and snug-fitting;

• Wear flanged cap, wear dirt/fog-proof glasses;

• Wear Long boots or no-slippery shoes, prohibited wear slip-on shoes to operate.

2. Do not operate the machine in no accordance with these

• Person without knowledge of the machine;

• Over-tired or patients;

• Drunk;

• Children.

3. Avert fire

• Stop the machine when fill the fuel, prohibited fire and smoke;

• Keep away fuel from the fire.

4. Preparation before operating

• Check whether the screws and nuts are loose: check whether the passage is good.

• Inspected all control rod and safe devices whether they are assembled right.

• Prohibited using the machines which have fault.

5. Start-up

• Make sure there is no others in the work area;

• When the machines recoiled start, you must keep away from tines and close upon it, prevent it from

moving, and make sure it is safe.

6. Safe operation

• When use the machine, please keep right posture, close upon the handle;

• When operating, forbid anybody enter the work area;

• While the weather raining, please take care of the slippery ground;

• When the tines is locked, please power o the machine, start again after clean it o;

• When scarifying, please move ahead and counter-march is prohibited;

• When change the work area, stop the machine, then check whether the screws and nuts are loose.

7. Examine and Repair

• Make sure the professional person maintains the machine;

• Should inspect the machine termly, if appear abnormity when operating, must stop the machine for

repairing at once;

• Need for repairing or service, please contact our SuperHandy customer service center

by 1-866-493-0524 for assistance.

BE-MTR2 USER MANUAL 5

STRUCTURE

REF DESCRIPTION

1 Right handle

2 Left handle

3 Stop switch

4Throttle lever

assembly

5 Fasten buckle

6 Middle handle

7 Down handle

8 Back bracket

9 Wheel adjuster base

10 Wheel

11 Wheel adjuster plate

12 Depth skid

13 Blade

14 Mud guard

15 Engine

WARNING

1. DO NOT STORE ENGINE INDOORS WITH FUEL IN THE TANK. FUEL AND FUEL VAPORS ARE HIGHLY

FLAMMABLE.

2. NEVER MIX FUEL AND OIL DIRECTLY IN ENGINE FUEL TANK. USE ONLY NONMETAL, PORTABLE FUEL

CONTAINERS APPROVED BY THE UNDERWRITER’S LABORATORY (U.L.) OR THE AMERICAN SOCIETY

FOR TESTING & MATERIALS (ASTM).

3. AN ADULT MUST ALWAYS HANDLE AND FILL THE ENGINE WITH FUEL.

4. ALWAYS HANDLE GAS IN A WELL VENTILATED AREA, OUTDOORS, AWAY FROM FLAMES OR SPARKS.

5. DO NOT START ENGINE IF FUEL IS SPILLED. WIPE OFF EXCESS FUEL AND ALLOW TO DRY. REMOVE

ENGINE FROM AREA TO AVOID SPARKS.

6. EVER RUN ENGINE INDOORS. EXHAUST FUMES ARE DEADLY.

7. FAILURE TO FOLLOW THESE WARNINGS CAN CAUSE DAMAGE TO EQUIPMENT AND INJURY TO

PERSONNEL.

6 BE-MTR2 USER MANUAL

Fig. 1

ASSEMBLING AND ADJUSTMENT

Assembly of middle and down handles. (Fig.1)

As fig 1 shows, insert the middle handle to down handle until the holes match, and then fasten the two

handles by the bolts and nuts.

Assembly of left / right handle.

As above Fig 2. first, match the left/right handle holes to the middle handle holes, fasten the bolts and nuts.

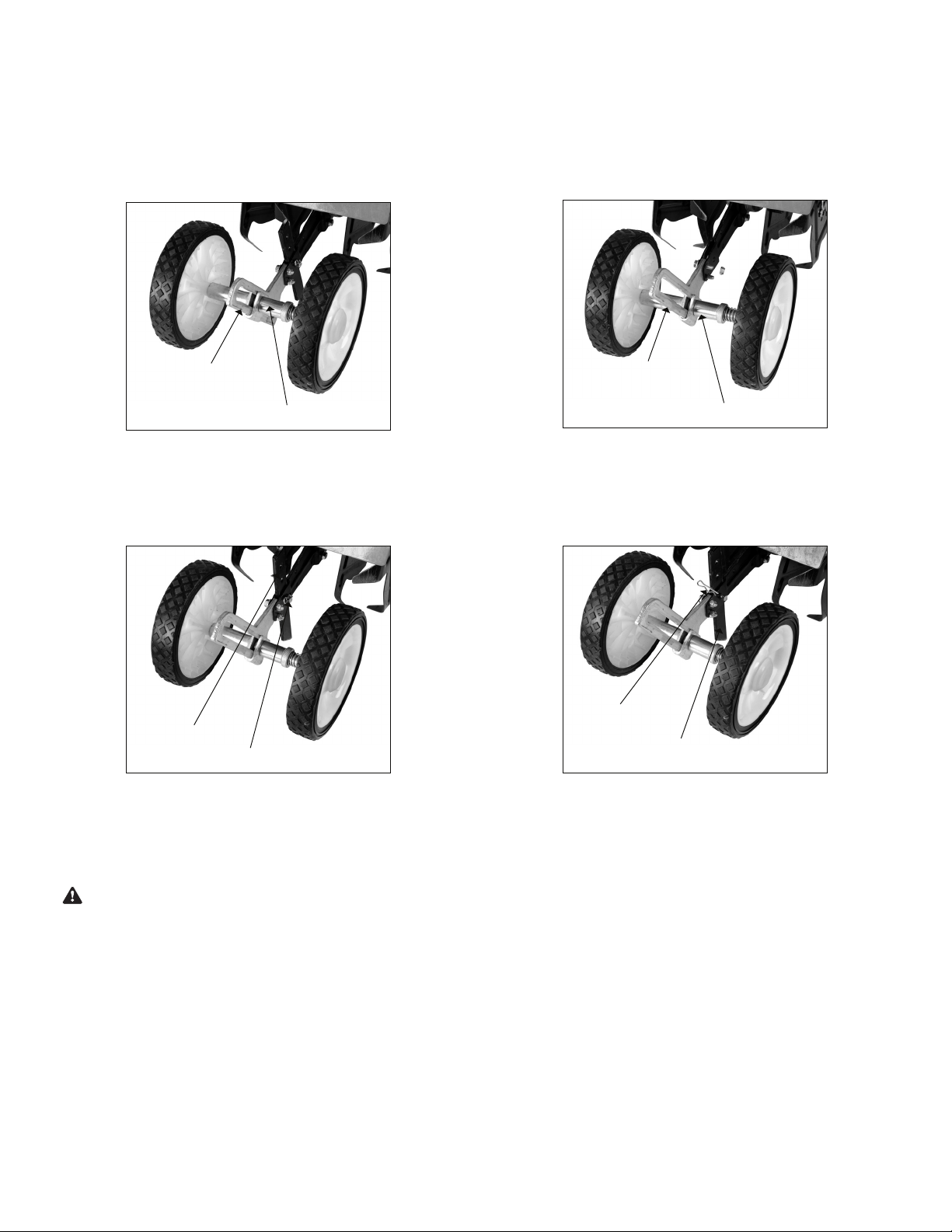

Adjusting Wheels and depth skid. There are three grooves in the wheel adjuster plate (No.11), the wheels on

the cultivator can be adjusted to one of three positions. Adjust Wheels Up Or Down do as follows:

Fig. 2

Locking metal sleeve

(locked position)

Expanded spring

Fig. 3

1. Pull the locking metal sleeve against the spring, away from the wheel adjuster plate (No.11) until it releases

from one of the three grooves in the wheel adjuster plate (No.11). Fig 3

Fig.4

Locking metal sleeve,

(unlocked position)

Compressed spring

Fig.5

Highest groove

No.11 Wheel adjuster plate

BE-MTR2 USER MANUAL 7

2. Slide the wheel set up or down to the desired position, and release the locking metal sleeve until it locks

into desired groove in the wheel adjuster plate (No.11). wheel adjuster plate (No.11). Fig 4

• When working should put the wheels in the highest groove. Fig 5

• When not working, the wheels need putting in the middle or the bottom groove (depend on operators

height). Fig 6 & Fig 7

Fig.6

No.11 Wheel

adjuster plate

Middle groove

Fig.7

No.11 Wheel

adjuster plate

Bottom groove

Adjust depth skid (No12), there are several holes in the depth skid, you can adjust it according to self-

request. Fig 8 & Fig 9

Fig.8

Depth skid

Pin

Fig.9

Depth skid

Pin

OPERATION

WARNING

Thoroughly inspect the area where the machine is to be used and remove all foreign objects.

Your equipment can propel small objects at high-speed causing personal injury or property damage. Stay

away from breakable objects, such as house windows, automobile, greenhouses, etc.

Always wear safety goggles or safety glasses with side shields when operating the machine to protect your

eyes from foreign objects which can be thrown from the unit. Always wear a protective hearing device.

It is advisable to wear protective headgear to prevent the possibility of being struck by small flying particles,

or being struck by low hanging branches, twigs, or other objects which may be unnoticed by the operator.

If the equipment should start to vibrate abnormally, stop the engine, disconnect the spark plug wire and

prevent it from touching the spark plug. Check immediately for cause. Vibration is generally a warning of

trouble. If the noise or vibrations of the machine increase, stop immediately and perform an inspection.

8 BE-MTR2 USER MANUAL

Adding oil

Mixing rate between 93 # gasoline and two-stroke oil is 30:1

Attention:

• Forbid to use pure gasoline or the mixture oil rate above 30:1

• Adding fuel must be done under the instruction of the fireproofing

Start up

1. Press the button of carburetor 5-6 times, until some fuel in the tube, then close the broker;

Note: If engine is in high temperature , you should put the choker on the original position.

2. Open the accelerograph 1/3-1/2;

3. Pull the starter smoothly, after starting the engine, open choker fully.

Note:

• Make sure there is nothing lock the gear wheels before starting

• When the gear blade is running, make sure the gear blade do not come up against anything or anybody.

Assignment

Strictly control the rotating speed, the free-load forward speed should be at 0.5m / sec when the rotate

speed arrive at 8000-9000/min.

To be ensure the quality of rotating blade, don’t touch it to other objects, such as stone.

Stopping

1. Put the throttle lever at the idle speed, make the engine run 2-3 minutes;

2. Turn o the stop switch.

Note: In urgent case, turn o the throttle switch, and turn o the stop switch. Keep your hands far away

from rotating blade, the gear is still turning after stopping the machine.

MAINTENANCE

Maintenance body

1. After the machine works for one or two hours or when stopping to add oil: you must check each screw

and nut on the machine to make sure they are not loosen

2. Add the lube in the gear box when the machine works around 20 hours

3. When the blade or gear damaged, please repair or replace at once.

Maintenance engine

1. Maintenance spark plug

Keep the spark plug cleaning, the electrode gap should be moderate suitable to ensure the engine

working well. The correct gap should be around 0.028in, check frequently and adjust it when the gap is

too long or too short.

2. Maintenance the air filter

Air filter surface should be cleaned often, if the cleaner element were jammed, clean the element. Clean

the filter body by gas. Drop a lie motor oil on the cleaner element, not attach it back to the inside cover

until the oil dry. If the sponge is too dirty, please change a new one.

BE-MTR2 USER MANUAL 9

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSES POSSIBLE SOLUTION

Engine will not start

Power switch o Flip switch to ON position

Spark plug wire disconnected Connect spark plug wire to spark plug

Out of fuel Refuel

Spark plug wet, faulty or improperly

gapped Clean, replace or gap spark plug

Fuel line hose not positioned in

bottom of gas tank Push fuel line down into fuel in gas tank

Engine runs rough, floods

during opration

Dirty air filter Clean or replace air filter

Choke partially engaged Turn o choke

Carburetor out of adjustment Call customer service

Engine is hard to start

Stale fuel Drain old fuel and replace with fresh. Use

gas stabilizer at end of season

Spark plug wire loose Make sure spark wire is securely attached

to spark plug

Dirty carburetor Clean carburetor, use gas stabilizer, new

gas can

Engine misses or lacks

power

Clogged gas tank Remove and clean gas tank

Clogged air filter Clean or replace air filter

Carburetor out of adjustment or bad Call customer service

Spark plug wet, faulty or improperly

gapped Clean, replace or gap spark plug

Engine runs, then quits

Gas cap not venting Clean or replace gas cap, check vent

Plugged fuel filter Clean or replace fuel filter

Carburetor out of adjustment or bad Call customer service

Engine revs too high Carburetor out of adjustment Call customer service

Tines turn at idle Idle speed too high Adjust idle speed lower

Broken clutch spring Replace spring

10 BE-MTR2 USER MANUAL

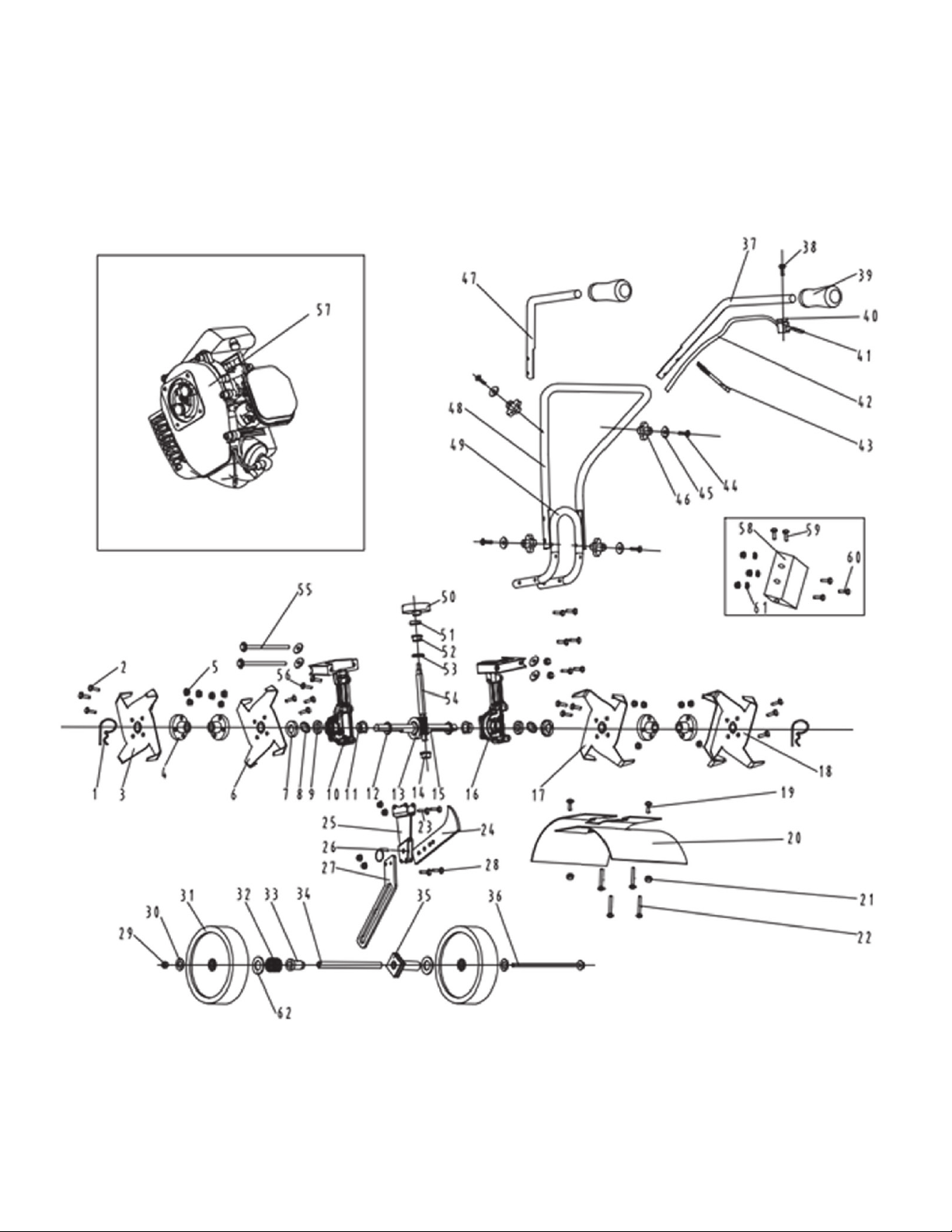

TILLER EXPLODED VIEW AND PARTS LIST

BE-MTR2 USER MANUAL 11

REF PART NO DESCRIPTION QTY

1 102.107B.001 Tear pin 2

2 102.107B.002 Bolt M6x20 14

3 102.107B.003 4 sided tiller blade 1

4 102.107B.004 Setting 4

5 102.107B.005 Screw M6 16

6 102.107B.003 4 sided tiller blade 1

7 102.107B.007 Oil seal shell 2

8 102.107B.008 Felt washer 2

9 102.107B.009 Oil seal 2

10 102.107B.010 Left crankcase 1

11 102.107B.011 Big copper cap 2

12 102.107B.012 Washer 2

13 102.107B.013 Turbo 1

14 102.107B.014 Small copper cap 1

15 102.107B.015 Tube cope 1

16 102.107B.016 Right crankcase 1

17 102.107B.003 4 sided tiller blade 1

18 102.107B.003 4 sided tiller blade 1

19 102.107B.019 Bolt M5x12 2

20 102.107B.020 Protected cover 2

21 102.107B.021 Screw M5 5

22 102.107B.022 Bolt M6x40 4

23 102.107B.023 Bolt M6x20 6

24 102.107B.024 Wheel 1

25 102.107B.025 Connect bat I 1

26 102.107B.026 Bolt assy 1

27 102.107B.027 Connect bat II 1

28 102.107B.028 Bolt M6x20 2

29 102.107B.029 Screw M8 3

30 102.107B.030 Washer 8 2

31 102.107B.031 Wheel 2

REF PART NO DESCRIPTION QTY

32 102.107B.032 Spring 1

33 102.107B.033 Bushing I 1

34 102.107B.034 Wheel Axle 1

35 102.107B.035 Bushing II 1

36 102.107B.036 Wheel bolt 1

37 102.107B.037 Right handle 1

38 102.107B.038 Bolt M5x30 3

39 102.107B.039 Rubber handle Sheath 2

40 102.107B.040 Rubber gasket 1

41 102.107B.041 Throtle hand assy 1

42 102.107B.042 Throtle line assy 1

43 102.107B.043 Tube 4

44 102.107B.044 Profiled bolt 4

45 102.107B.045 Washer 8 8

46 102.107B.046 Knob comp 4

47 102.107B.047 Left handle 1

48 102.107B.048 Machine fram I 1

49 102.107B.049 Machine fram II 1

50 102.107B.050 Knob comp 1

51 102.107B.051 Bearing 1

52 102.107B.052 Wheel bolt 2

53 102.107B.053 Piane bearing 1

54 102.107B.054 Washer 1

55 102.107B.055 Bolt M8x135 2

56 102.107B.056 Bolt M6x8 2

57 102.107B.057 Engine 1

58 102.107B.058 Electrical assing 1

59 102.107B.059 Bolt M6x12 2

60 102.107B.060 Bolt M5x12 1

61 102.107B.061 Washer 5 3

62 102.107B.062 Washer 12 2

12 BE-MTR2 USER MANUAL

TILLER EXPLODED VIEW AND PARTS LIST

BE-MTR2 USER MANUAL 13

REF PART NUM. DESCRIPTION QTY

1 102.107B.001 Oil tank 1

2 102.107B.002 Allen screw M5*20 2

3 102.107B.003 Oil tank bracket 1

4 102.107B.004 Allen screw M5*35 4

5 102.107B.005 M8 nut 1

6 102.107B.006 Washer 1

7 102.107B.007 Washer 2

8 102.107B.008 Allen screw M5*20 2

9 102.107B.009 Left cover 1

10 102.107B.010 Spring washer 2

11 102.107B.011 Step screw M8*24 1

12 102.107B.012 Clutch 1

13 102.107B.013 Fly wheel 1

14 102.107B.014 15*30*7 oil seal 1

15 102.107B.015 6202 bearing 2

16 102.107B.016 Left case 1

17 102.107B.017 Crankshaft 1

18 102.107B.018 Woodrukey 1

19 102.107B.019 Case washer 1

20 102.107B.020 Right case 1

21 102.107B.021 Allen screw M5*12 1

22 102.107B.022 12*22*7 oil seal 1

23 102.107B.023 Recoil starter aluminum

gasket 1

24 102.107B.024 Start dial 1

25 102.107B.025 Recoil start 1

26 102.107B.026 Needle bearing 1

27 102.107B.027 Piston pin clip 1

28 102.107B.028 Piston pin 1

29 102.107B.029 Piston 1

REF PART NUM. DESCRIPTION QTY

30 102.107B.030 Piston ring 1

31 102.107B.031 Allen screw M5*20 4

32 102.107B.032 Cylinder 1

33 102.107B.033 Muer gasket 1

34 102.107B.034 Muer 1

35 102.107B.035 Allen screw M6*60 2

36 102.107B.036 Muer cover 1

37 102.107B.037 Allen screw M5*12 1

38 102.107B.038 Allen screw M5*25 2

39 102.107B.039 Ignition coil 1

40 102.107B.040 Spark plug 1

41 102.107B.041 Allen screw M5*30 2

42 102.107B.042 Intake manifold 1

43 102.107B.043 Carburetor paper gasket 1

44 102.107B.044 Carburetor 1

45 102.107B.045 Air filter 1

46 102.107B.046 Allen screw M5*55 2

47 102.107B.047 Air filter gasket 1

48 102.107B.048 Air filter net 2

49 102.107B.049 Air filter sponge 1

50 102.107B.050 Air filter cover 1

51 102.107B.051 Cylinder cover 1

52 102.107B.052 Allen screw M5*12 1

53 102.107B.053 Allen screw M5*20 1

54 102.107B.054 Cylinder cover cap 1

55 102.107B.055 Cylinder paper gasket 1

56 102.107B.056 Intake manifold paper

gasket 1

57 102.107B.057 Allen screw M5*20 4

58 102.107B.058 Locating pin 4

14 BE-MTR2 USER MANUAL

PHONE: 604-850-7770

FAX: 604-850-7774

TOLL FREE PHONE: 1-877-588-3311

TOLL FREE FAX: 1-800-665-7334

BRABEREQ.COM

WGSALES@BRABEREQ.COM

Other BE Ag & Industrial Tiller manuals