Toro 58603 User manual

FormNo.3443-831RevA

RearTineTiller

ModelNo.58603—SerialNo.321000001andUp

Registeratwww.Toro.com.

OriginalInstructions(EN)*3443-831*

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineon

anyforest-covered,brush-covered,orgrass-covered

landunlesstheengineisequippedwithaspark

arrester,asdenedinSection4442,maintainedin

effectiveworkingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionofre.

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Introduction

Thistillerisintendedtobeusedbyresidential

homeownersorprofessional,hiredoperatorsto

breakthroughhardsoilconditionsforplantingand

cultivatinggardens.Usingthisproductforpurposes

otherthanitsintendedusecouldprovedangerousto

youandbystanders.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely.

Visitwww.T oro.comformoreinformation,including

safetytips,trainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorT oroCustomerServiceandhavethemodel

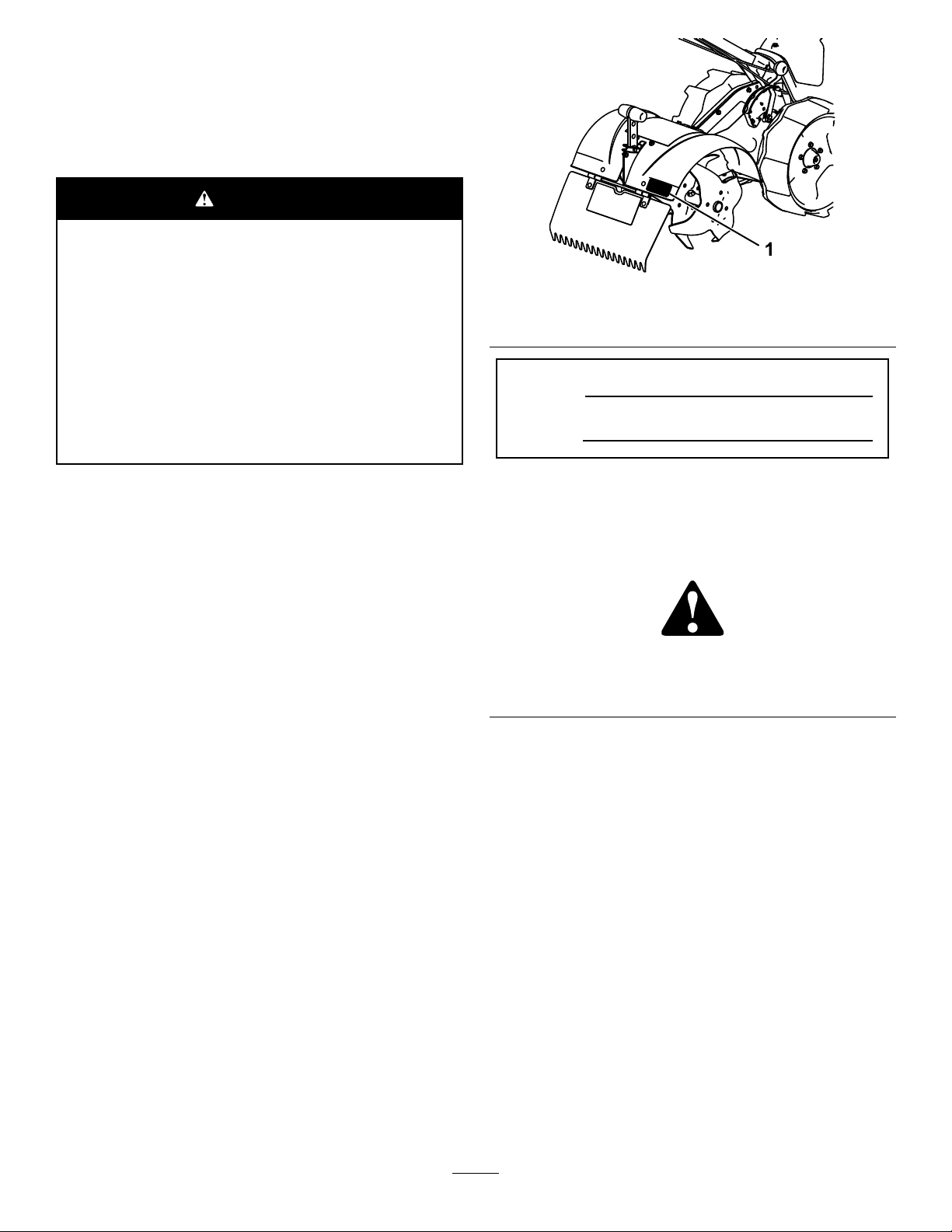

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

g356747

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

©2021—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN554202

Contactusatwww.Toro.com.

PrintedintheUSA

AllRightsReserved

Contents

Safety.......................................................................3

GeneralSafety...................................................3

SafetyandInstructionalDecals..........................4

Setup........................................................................6

1AssemblingtheMachine..................................7

2AddingOiltotheEngine...................................9

ProductOverview...................................................10

Controls...........................................................10

Specications...................................................11

BeforeOperation.................................................12

BeforeOperationSafety...................................12

AddingFuel......................................................13

AdjustingtheHandlebarHeight........................13

DuringOperation.................................................14

DuringOperationSafety...................................14

StartingtheMachine.........................................15

ShuttingOfftheEngine.....................................15

AdjustingtheDragStake..................................15

OperatingTips.................................................16

AfterOperation....................................................16

AfterOperationSafety......................................16

Maintenance...........................................................17

MaintenanceSafety..........................................17

RecommendedMaintenanceSchedule(s)...........17

Pre-MaintenanceProcedures..............................18

PreparingforMaintenance...............................18

Lubrication..........................................................18

GreasingtheMachine.......................................18

EngineMaintenance...........................................19

ServicingtheAirCleaner..................................19

ServicingtheEngineOil....................................20

ServicingtheSparkPlug...................................21

BeltMaintenance................................................22

CheckingandAdjustingtheDrive

Belts..............................................................22

ReplacingtheBelts...........................................23

Cleaning..............................................................26

CleaningtheMachine.......................................26

Storage...................................................................26

StorageSafety..................................................26

StoringtheMachine..........................................26

Troubleshooting......................................................28

Safety

Thismachinehasbeendesignedinaccordancewith

ANSIB71.8-2016.

DANGER

Theremaybeburiedutilitylinesinthework

area.Diggingintothemmaycauseashock

oranexplosion.

Havethepropertyorworkareamarkedfor

buriedlinesanddonotdiginmarkedareas.

Contactyourlocalmarkingserviceorutility

companytohavethepropertymarked(for

example,intheUS,call811forthenationwide

markingservice).

GeneralSafety

Thisproductiscapableofamputatinghandsand

feetandofthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriouspersonalinjuryordeath.

•Read,understand,andfollowtheinstructions

andwarningsinthisOperator’sManualandon

themachineandattachmentsbeforestartingthe

engine.

•Bethoroughlyfamiliarwiththecontrolsandthe

properuseoftheequipment.Knowhowtostop

themachineanddisengagethecontrolsquickly.

•Donotputyourhands,feet,otherbodyparts,or

clothingnearorundertherotatingtinesorother

movingpartsofthemachine.

•Donotoperatethemachinewithoutallproper

shields,guards,andothersafetyprotective

devicesinplaceandfunctioningproperlyonthe

machine.

•Keepbystanders,especiallysmallchildren,and

petsoutoftheoperatingarea.

•Donotallowchildrentooperatethemachine.

Allowonlypeoplewhoareresponsible,trained,

familiarwiththeinstructions,andphysically

capabletooperatethemachine.

•Shutoffthemachineandwaitforallmovingparts

tostopbeforeyouleavetheoperator’sposition.

Disconnectthespark-plugwire,keepitawayfrom

theplugtopreventaccidentalstarting,andallow

themachinetocoolbeforeadjusting,fueling,

unclogging,servicing,cleaning,orstoringthe

machine.

Improperlyusingormaintainingthismachinecan

resultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafety-alertsymbol,which

meansCaution,Warning,orDanger—personalsafety

3

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

decal133-8062

133-8062

decal144-4853

144-4853

1.Engine—shutoff

decal144-4857

144-4857

1.Entanglementhazard,belt—stayawayfrommovingparts;

keepallguardsinplace.

decal144-4861

144-4861

1.Forwardlever

decal144-4862

144-4862

1.Reverselever

4

decal144-4864

144-4864

1.Drivemodeselector;Standard-RotatingTines;Drive;Counter-RotatingTines;Neutral.

decal148-4868

144-4866

1.Warning—readtheOperator’sManual.6.Warning—lookbehindyouwhenoperatingthemachinein

reverse.

2.Warning—alloperatorsshouldbetrainedbeforeoperating

themachine.

7.Warning—donotoperateoverburiedlines.

3.Warning—keepbystandersaway.8.Warning—keepfeetawayfrommovingparts.

4.Warning—stayawayfrommovingparts;keepallguardsin

place.

9.Warning—shutofftheengine,disconnectthesparkplug,and

readtheOperator’sManualbeforeperformingmaintenance.

5.Entanglementhazard,belt—stayawayfrommovingparts.

decal144-4867

144-4867

1.Tostartthemachine,movetheswitchtotheONposition,movethefuel-valvelevertoopen,movethethrottlelevertothe

FASTposition,engagethechoke,placeonehandonthemachineandpulltherecoilhandle,andmovethechokelevertothe

RUNposition.

5

Setup

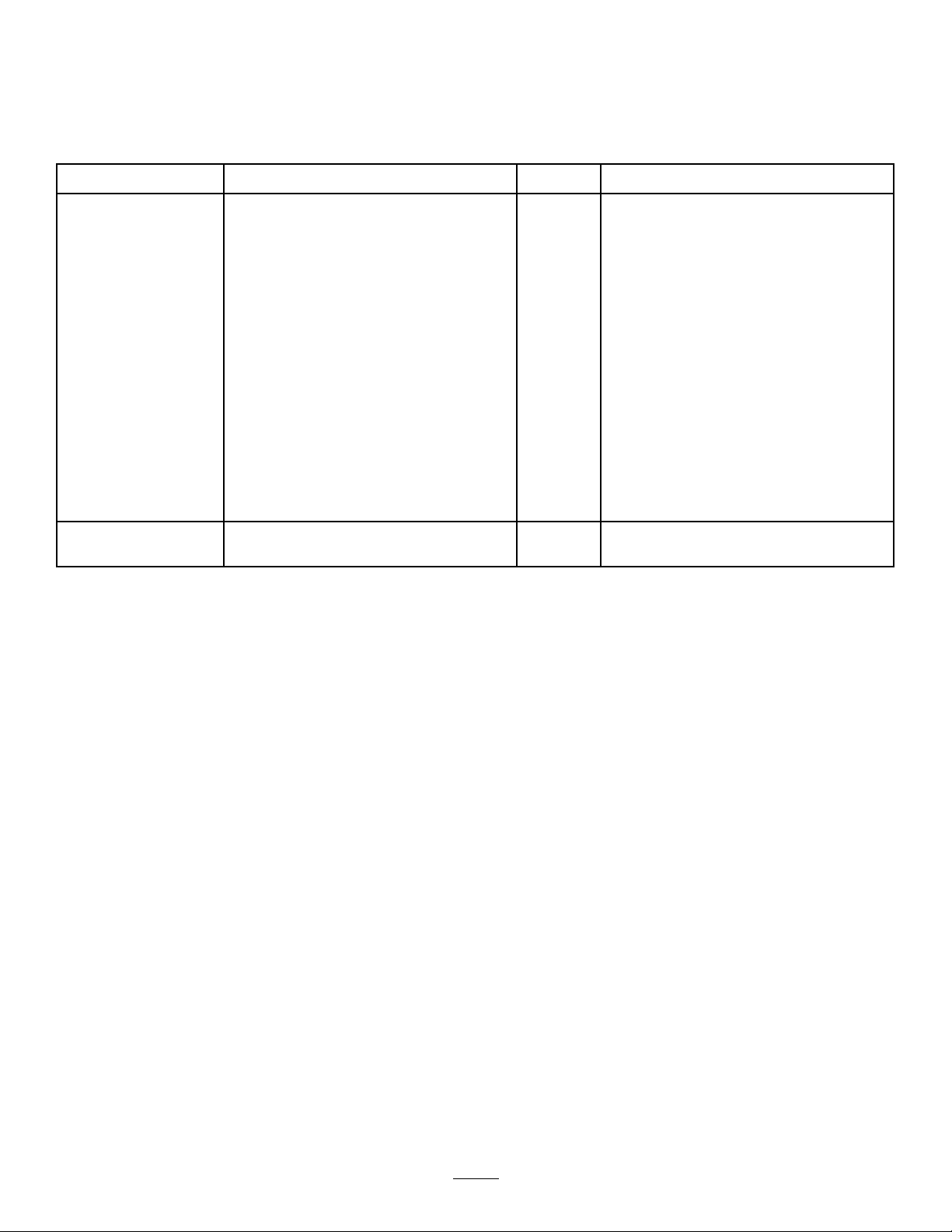

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescriptionQty.Use

Tillerassembly1

Handlebarassembly1

Handlebartube1

Wheel2

Lowerpulleyguard1

Pulleyguardplate1

Dragstake1

Bolt(M8x85mm)1

Bolt(M6x65mm)2

Bolt(M8x16mm)2

Bolt(M6x14mm)4

Nut(M8)1

Nut(M6)4

Screw4

Pin2

1

Lockpin1

Assemblethemachine.

2Engineoil1Addoiltotheengine.

6

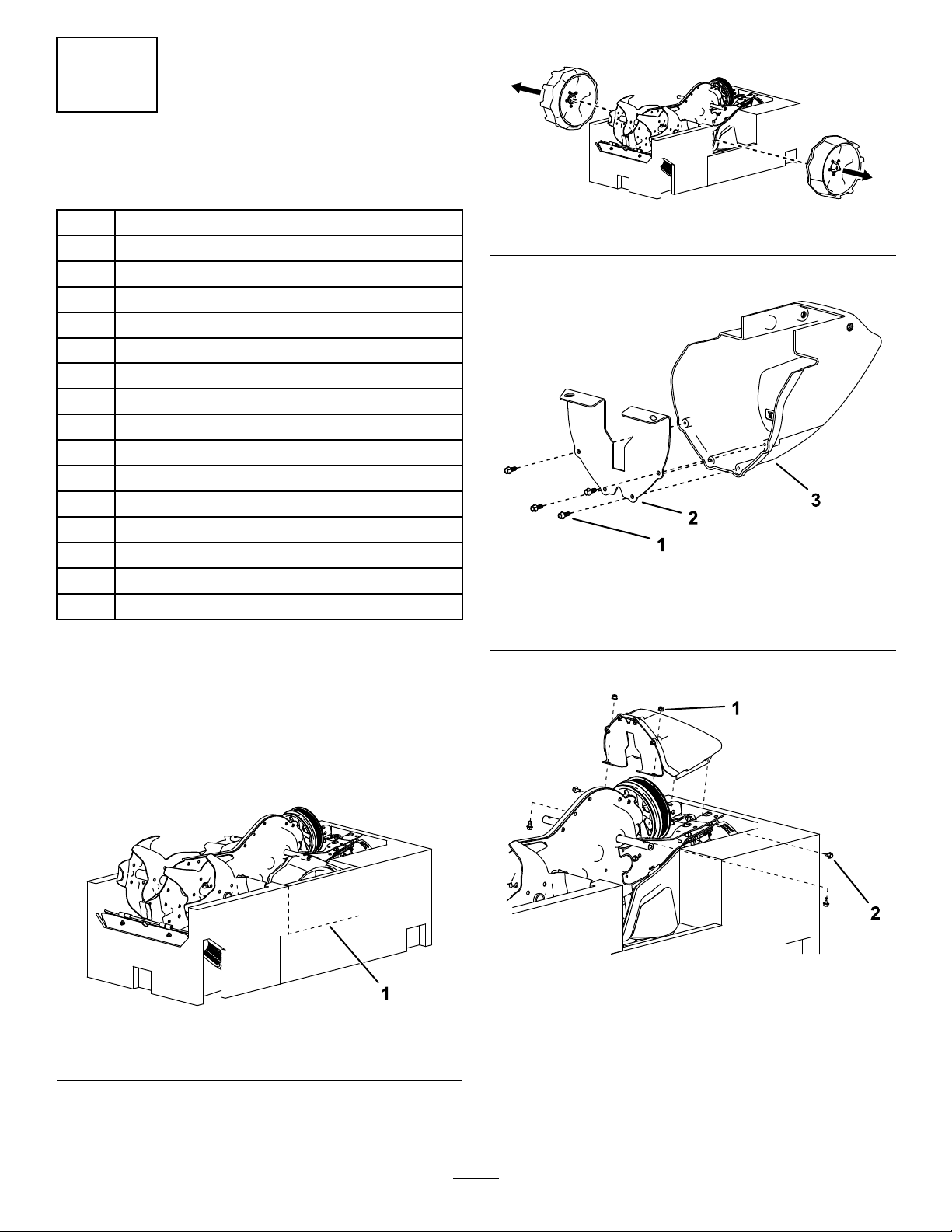

1

AssemblingtheMachine

Partsneededforthisprocedure:

1Tillerassembly

1Handlebarassembly

1Handlebartube

2Wheel

1Lowerpulleyguard

1Pulleyguardplate

1Dragstake

1Bolt(M8x85mm)

2Bolt(M6x65mm)

2Bolt(M8x16mm)

4Bolt(M6x14mm)

1Nut(M8)

4Nut(M6)

4Screw

2Pin

1Lockpin

Procedure

1.Removetheloosepartsfromthetopofthebox.

2.Closethebox,turnitupside-down,andcutit

openatthecorners.

3.Cut,remove,anddiscardtherectangleshown

onbothsidesofthefoam.

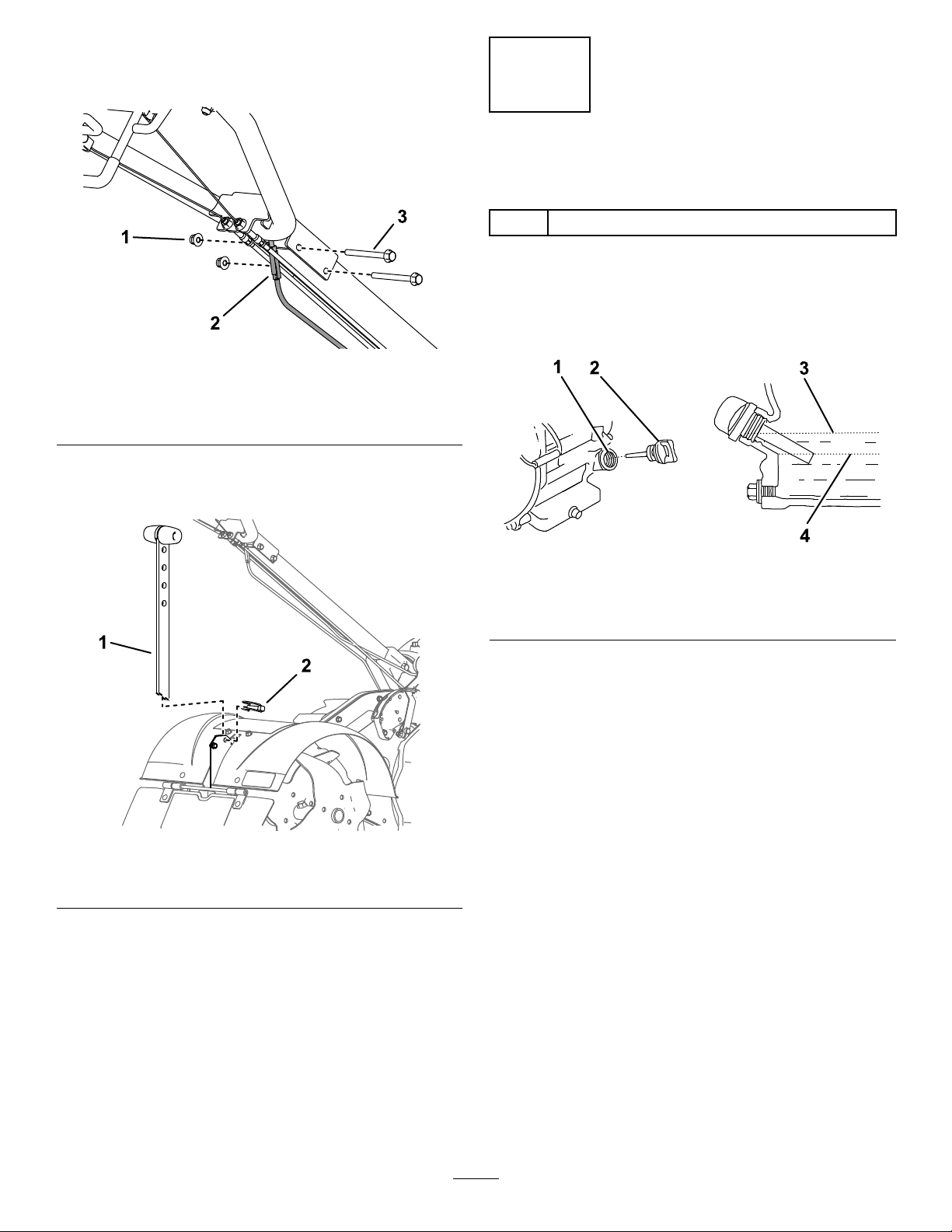

g361865

Figure3

1.Cuthere.

4.Removethewheels.

g361871

Figure4

5.Assemblethepulleyguards.

g361864

Figure5

1.Screw(4)3.Lowerpulleyguard

2.Pulleyguardplate

6.Installtheguardstothetillerassembly.

g361866

Figure6

1.Bolt—M6x14mm(4)2.Nut—M6(2)

7

7.Foreachwheel,slideinthepinandsecurethe

wheelwiththebolt.

g361868

Figure7

1.Bolt—M8x16mm(2)2.Pin(2)

8.Turnthemachineoverandremovethefoam.

9.Installthehandlebartubeasfollows:

A.Rotatethespreaderboltclockwise.

g361872

Figure8

1.Spreaderbolt

B.Insertthehandlebartubeintothered

bracketandsecureitasshown.

g361867

Figure9

1.Nut(M8)3.Bolt(M8x85mm)

2.Handlebartube

C.Removeanddiscardthespreaderbolt.

D.Tightenthefastenersuntilthehandlebar

tubeissnug.

10.Onthehandlebarassembly,connectthecables

tothedriveleversiftheyarenotattached.

g361873

Figure10

1.Reardrivelevercable2.Frontdrivelevercable

8

11.Installthehandlebarassemblyandadjust

theheightasdesired;refertoAdjustingthe

HandlebarHeight(page13).

g361870

Figure11

1.Nut—M6(2)3.Bolt—M6x65mm(2)

2.Wireharnessconnectors

12.Connectthe2wireharnessconnectors.

13.Installthedragstake.

g361869

Figure12

1.Dragstake2.Lockpin

2

AddingOiltotheEngine

Partsneededforthisprocedure:

1Engineoil

Procedure

1.Movethemachinetoalevelsurface.

2.Removethedipstick.

g360549

Figure13

1.Fillertube3.Upperlimit

2.Dipstick4.Lowerlimit

3.Slowlyaddoilintothellertubeuntilitis

overowing.

4.Installthedipstickandtightenit.

9

ProductOverview

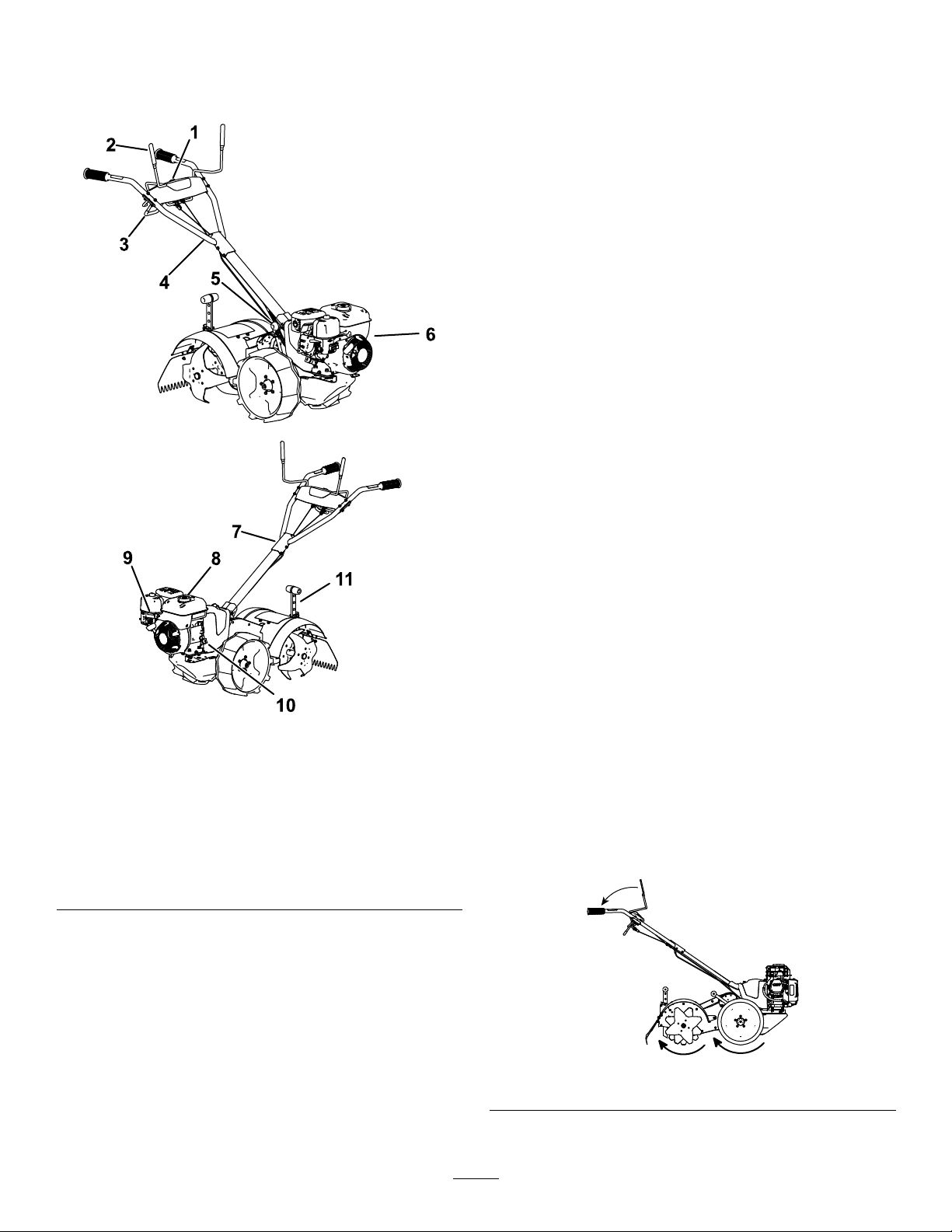

g356778

Figure14

1.Engineon/offswitch7.Handlebarheight

adjustment

2.Forwardcontrollever8.Fuelcap

3.Rearcontrollever9.Enginecontrols

4.Cableadjustment10.Oil-llcap

5.Drive-modeselectorlever11.Dragstake

6.Recoilhandle

Controls

EngineOn/OffSwitch

UsetheengineOn/Offswitchtoshuttheengineoff.

EnsurethattheswitchisintheONpositionbefore

startingtheengine.

Fuel-ValveLever

MovetheleverforthefuelvalvetotheONposition

beforeattemptingtostarttheengine.Afteroperation,

shutofftheengineandmovethefuel-valveleverto

theOFFposition.

ThrottleControl

Thethrottlecontrolstheenginespeed,andithasa

continuous-variablesetting.

Operatethemachineusingfullthrottleforbest

performance.

ChokeLever

MovethechokeleverontheenginetotheCHOKE

positionwheninitiallystartingacoldengine,then

moveitintotheRUNpositiononcestarted.

Drive-ModeSelector

Shiftthedrive-modeselectorlevertothedesired

modetochangethetransmission.

Important:Donotshiftthedrive-modeselector

leverwhileengagingtheforwardorreverse

controllevers.

•Standard-rotatingtines(SRT):Thewheelsand

tinesarebothengagedwiththeengine;thetines

spininthesamedirectionasthewheels.Usethis

modeforestablishedgardenbedsandtillingin

softsoilconditions.

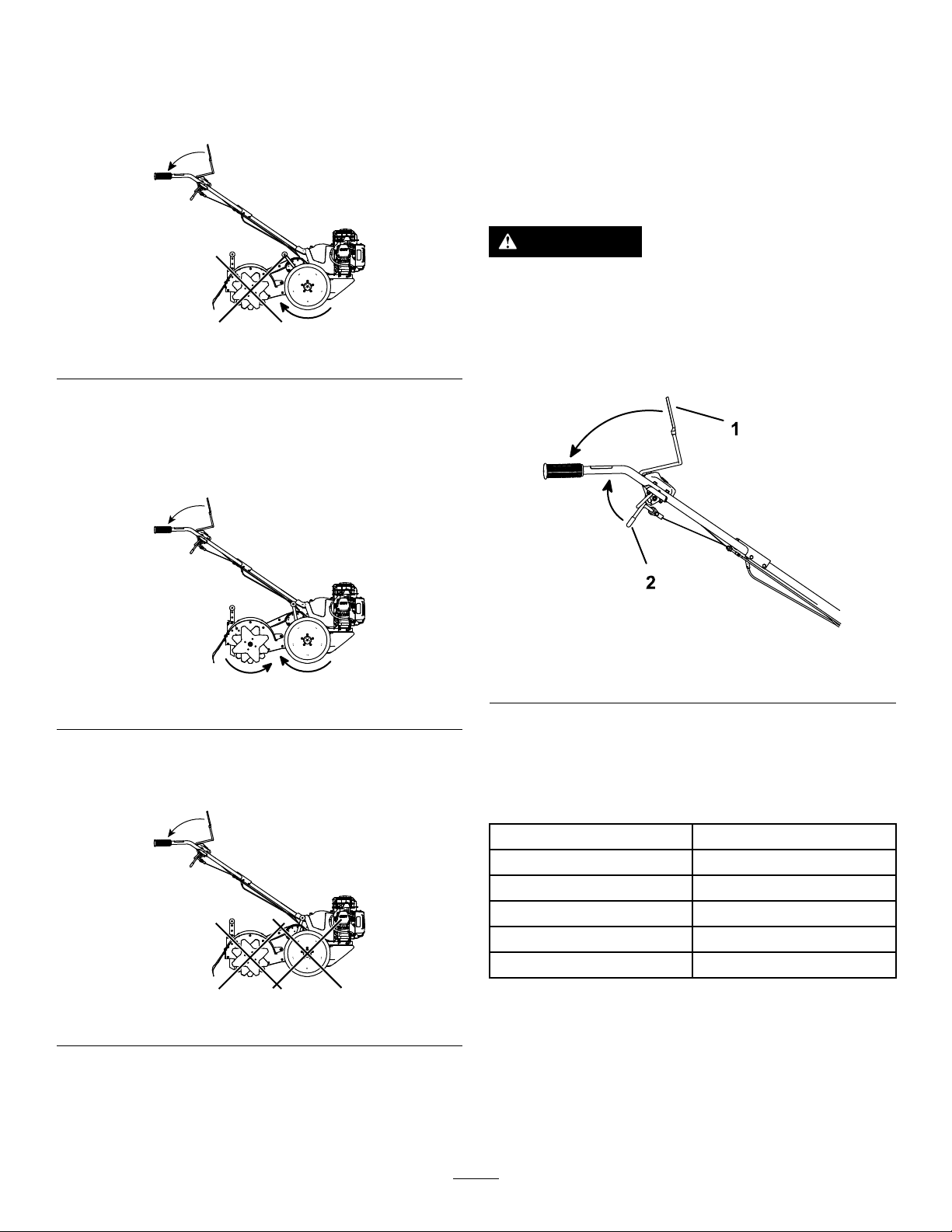

g356990

Figure15

10

•Drive:Onlythewheelsareengagedwiththe

engine;thetinesaredisengaged.Usethismode

forpoweredtransportationwhendrivingupsteep

inclinesandmovingthemachinetoandfromyour

garden.

g356988

Figure16

•Counter-rotatingtines(CRT):Thewheelsand

tinesarebothengagedwiththeengine;thetines

spinintheoppositedirectionofthewheels.Use

thismodewhenbreakingnewgroundortillingin

compactedsoilconditions.

g356987

Figure17

•Neutral:Thewheelsandtinesareboth

disengagedfromtheengine.Usethismodefor

storageandnon-poweredtransportation.

g356989

Figure18

Drive-ControlLevers

Pulldowntheforwardlevertoengagethetransmission

intheforwarddirection;pulluponthereverseleverto

engagethetransmissioninthereversedirection.

Releasetheleverstodisengagethetransmission.

Important:Donotattempttoengagetheforward

andreverseleversatthesametime.

WARNING

Contactwithmovingtinescanresultin

personalinjury.

Whenmovingthemachineinreverse,watch

forobstaclesbehindyouandkeepyourfeet

awayfromthetines.

g357052

Figure19

1.Forwardlever2.Reverselever

Specications

Specicationsanddesignaresubjecttochange

withoutnotice.

Height103.1cm(40.6inches)

Length158.8cm(62.5inches)

Width50.8cm(20.0inches)

Weight72.6kg(160lb)

Tillingwidth43.2cm(17inches)

Tillingdepth28cm(11inches)

Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineT oro

replacementpartsandaccessories.Replacement

partsandaccessoriesmadebyothermanufacturers

couldbedangerous,andsuchusecouldvoidthe

productwarranty.

11

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

BeforeOperation

BeforeOperationSafety

GeneralSafety

•Donotallowchildrenoruntrainedadultstooperate

orservicethemachine.Localregulationsmay

restricttheageoftheoperator.

•Usingthismachineisstrenuous.Youmustbein

goodphysicalconditionandmentallyalert.Ifyou

haveanyconditionthatmightbeaggravatedby

strenuouswork,checkwithyourdoctorbefore

operatingthemachine.

•Shutoffthemachineandwaitforallmovingparts

tostopbeforeyouleavetheoperator’sposition.

Disconnectthespark-plugwire,keepitawayfrom

theplugtopreventaccidentalstarting,andallow

themachinetocoolbeforeadjusting,fueling,

unclogging,servicing,cleaning,orstoringthe

machine.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Checkthatallguardsandsafetydevices,suchas

deectors,areinplaceandfunctioningproperly.

Donotoperatethemachineunlesstheyare

functioningproperly.

•Knowhowtoshutofftheenginequickly.

•Keepbystanders,especiallysmallchildren,and

petsoutoftheoperatingarea.

•Thoroughlyinspecttheareawhereyouwilluse

themachineandremoveallobjectsthatcould

interferewiththeoperationofthemachineorthat

themachinecouldthrow.

FuelSafety

•Useextremecareinhandlingfuel.Itisextremely

ammableanditsvaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andother

sourcesofignition.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporaddfueltothetank

whiletheengineisrunningorhot.

•Allowtheenginetocoolbeforellingthefueltank.

•Donotllthefueltankindoors.

•Donotoverllthefueltank.Replacethefuelcap

andtightenitsecurelyafterfueling.Cleanup

spilledfuelbeforestartingtheengine.

•Donotllcontainersinsideavehicleoronatruck

ortrailerbedwithaplasticliner.Alwaysplace

containersontheground,awayfromthevehicle

beforelling.

•Removethemachinefromthetruckortrailer

beforellingthefueltank.Ifthisisnotpossible,

thenaddfuelfromaportablecontainerratherthan

fromafuel-dispensernozzle.

•Keepthefuel-dispensernozzleincontactwith

therimofthefueltankorcontaineropeningat

alltimesuntilfuelingiscomplete.Donotusea

nozzlelock-opendevice.

•Ifyouspillfuelonyourclothing,changeyour

clothingimmediately.

•Ifyouspillfuel,donotattempttostarttheengine;

movethemachineawayfromthespillandavoid

creatingasourceofignitionuntilthefuelvapors

havedissipated.

•Ifyoumustdrainthefueltank,doitoutdoors.

•Storefuelinafuelcontainerandkeepitoutofthe

reachofchildren.

•Donotstorethemachinewithfuelinthefueltank

orfuelcontainerwherethereisanopename,

spark,orpilotlight,suchasonawaterheateror

otherappliance.Allowtheenginetocoolbefore

storingthemachineinanyenclosure.

•Fuelisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

–Avoidprolongedbreathingofvapors.

–Keepyourhandsandfaceawayfromthe

nozzleandthefuel-tankopening.

–Keepfuelawayfromyoureyesandskin.

12

AddingFuel

FuelSpecications

TypeUnleadedgasoline

Minimumoctanerating87(US)or91(research

octane;outsidetheUS)

EthanolNomorethan10%byvolume

MethanolNone

MTBE(methyltertiarybutyl

ether)

Lessthan15%byvolume

OilDonotaddtothefuel

Useonlyclean,fresh(nomorethan30daysold),fuel

fromareputablesource.

UsingStabilizer/Conditioner

Usefuelstabilizer/conditionerinthemachinetokeep

thefuelfreshlongerwhenusedasdirectedbythe

fuel-stabilizermanufacturer.

Important:Donotusefueladditivescontaining

methanolorethanol.

Addtheamountoffuelstabilizer/conditionertofresh

fuelasdirectedbythefuel-stabilizermanufacturer.

FillingtheFuelTank

FillthefueltankasshowninFigure20.

g230458

Figure20

AdjustingtheHandlebar

Height

Thehandlebarhas3heightpositionstoaccommodate

varyinguserheights.Whenadjustingtheheight,

notethatduringnormaltillingoperation,theactual

handlebarpositiondropsupto25cm(10inches)from

normalheight.

Removethehardwarefromthehandlebarassembly,

rotatetheassemblytomatchtheholesatthedesired

position,andinstallthehardware.

•Lowheight:UseholesBandC.

•Middleheight:UseholesCandD.

•Highheight:UseholesAandD.

g357053

Figure21

13

DuringOperation

DuringOperationSafety

GeneralSafety

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Wearappropriateclothing,includingeye

protection;longpants;substantial,slip-resistant

footwear;hearingprotection;andgloves.Tieback

longhairanddonotwearlooseclothingorloose

jewelry.

•Keepyourhands,feet,otherbodyparts,and

clothingawayfromrotatingtinesandmovingparts

ofthemachine.Thetinesbeginrotatingwhen

youstarttheengineandmaycontinuetorotate

momentarilyafteryoushutofftheengine.

•Starttheenginecarefullyaccordingtoinstructions

inthisOperator’sManualandwithyourfeetwell

awayfromthetines.

•Useextremecautionwhenreversingorpulling

themachinetowardyou.T oavoidgettingpinned

againstastructure,allowenoughdistanceto

reversedirectionnearawallorfence.

•Keepbystandersoutoftheoperatingarea.Keep

smallchildrenoutoftheoperatingareaandunder

thewatchfulcareofaresponsibleadultwhois

notoperatingthemachine.Stopthemachineif

anyoneentersthearea.

•Beforeyoustarttheengine,ensurethatalldrives

areinneutralandyouareintheoperatingposition.

•Operatethemachineonlyingoodvisibilityand

appropriateweatherconditions.Donotoperate

themachinewhenthereistheriskoflightning.

•Donotattempttoadjustthemachinewhilethe

engineisrunning.

•Ifthemachinestrikesanobjectorstartstovibrate

abnormally,immediatelyshutofftheengine,wait

forallmovingpartstostop,anddisconnectthe

wirefromthesparkplugbeforeexaminingthe

machinefordamage.Vibrationisoftenawarning

signoftrouble.Makeallnecessaryrepairsbefore

resumingoperation.

•Donotoperatethemachineathightransport

speedsonhardorslipperysurfaces.

•Lookbehindanddownandusecarewhen

reversing.

•Donotoverloadthemachinecapacityby

attemptingtotillorcultivatetoodeepandattoo

fastarate.

•Donotpickuporcarryamachinewhiletheengine

isrunning.

•Exercisecautionandbesureofyourfooting,

especiallywhenbackingup,toavoidslippingor

falling.

•Becarefulwhenoperatingthemachineinhard

ground.Thetinescancatchinthegroundand

propelthemachineforward.Ifthisoccurs,letgo

ofthemachine;donottrytorestrainit.

•Exerciseextremecautionwhencrossinggravel

surfaces.Stayalertforhiddenhazardsortrafc.

•Donotleavearunningmachineunattended.

•Shutoffthemachineandwaitforallmovingparts

tostopbeforeyouleavetheoperator’sposition.

Disconnectthespark-plugwire,keepitawayfrom

theplugtopreventaccidentalstarting,andallow

themachinetocoolbeforeadjusting,fueling,

unclogging,servicing,cleaning,orstoringthe

machine.

•Operatetheengineonlyinwell-ventilatedareas.

Exhaustgasescontaincarbonmonoxide,whichis

anodorless,deadlypoison.

•Useonlyaccessoriesandattachmentsapproved

byTheToro®Company.

•Donotchangetheenginegovernorsettingsor

overspeedtheengine.

•Alwaysbesureofyourfooting;keeparmholdon

thehandleandwalk,neverrun.

•Allowthemuferandengineareatocoolbefore

touchingthem.

•Thetinesshouldnotrotatewhentheengineis

idling;iftheydorotate,contactyourAuthorized

ServiceDealer.

•Ifanobjectbecomeslodgedinthetines,shutoff

theengine,disconnectthewirefromthespark

plug,andallowtheenginetocoolbeforeremoving

theobject.

•Donotoperatethemachineonsteepslopes.T o

preventoverturning,operatethemachineupand

downtheslope.

14

StartingtheMachine

1.Movetheengineon/offswitchtotheONposition.

2.Movethefuel-valvelevertotheOPENposition.

3.MovethethrottlelevertotheFASTposition.

4.MovethechokelevertotheCHOKEposition.

Note:Awarmorhotenginemaynotrequire

choking.

5.Pullthestarterhandlelightlyuntilyoufeel

resistance,thenpullthehandlebriskly.Return

thestarterhandlegently.

6.Aftertheenginestarts,graduallymovethe

chokelevertotheRUNpositionandthethrottle

levertotheFASTposition.

ShuttingOfftheEngine

1.Releasethedrive-controllevers.

2.MovethethrottlelevertotheSLOWposition.

3.Movetheengineon/offswitchtotheOFF

position.

4.Movethefuel-valvelevertotheCLOSEDposition.

5.Waitforallmovingpartstostopbeforeleaving

theoperatingposition.

AdjustingtheDragStake

Adjustthedragstakeasneededforthedrivemode.

•CRTmode:Thedragstakehelpsregulatetilling

depthduringCRTmode.Lowerthedragstake

toreducethetillingdepth;raisethedragstaketo

increasethetillingdepth.

•SRTmode:Thedragstakelimitstheforward

speedduringSRTmode.Lowerthedragstaketo

reducetheforwardspeedorifthemachinejerks

forward

•Driveorneutralmode:Raisethedragstake

whentransportingthetiller.

1.Movethemachinetoalevelsurface,shutoffthe

engine,andwaitforallmovingpartstostop.

2.Removethelockpin.

3.Positionthedragstaketothedesireddepth.

Note:Adjustthedragstake1holeatatimeand

testthetilleroperationaftereachadjustment.

Raisingthedragstaketoohighcanresultinloss

ofcontrolofthetiller.

4.Securethedragstakewiththelockpin.

g357054

Figure22

1.Lockpin3.Dragstake—shallowtilling

2.Dragstake—deeptilling

15

OperatingTips

•Inspecttheareawhereyouwillusethemachine

andremoveallobjectssuchaslargerocks,trash,

andbranchesbeforetillingtopreventequipment

damage.

•Donotplaceexcessivebodyweightonthe

machine.Usetheweightofthemachinetotillthe

soilmoreefciently.

•Whentilling,beginwithashallowcutontherst

passandthenincreasethedepthby2.5to5.1cm

(1to2inches)oneachsuccessfulpathuntilyou

reachthedesireddepth.

•Plantgardenrows51to56cm(20to22inches)

aparttoalloweaseofturningattheendofeach

row.

•Whennottilling,movethethrottleleverbetween

halfthrottleandtheSLOWpositiontoextendengine

life,conservefuel,andreducesoundlevels.

AfterOperation

AfterOperationSafety

GeneralSafety

•Shutoffthemachineandwaitforallmovingparts

tostopbeforeyouleavetheoperator’sposition.

Disconnectthespark-plugwire,keepitawayfrom

theplugtopreventaccidentalstarting,andallow

themachinetocoolbeforeadjusting,fueling,

unclogging,servicing,cleaning,orstoringthe

machine.

•Cleandebrisfromthemachinetohelpprevent

res.Cleanupoilorfuelspills.

HaulingSafety

•Disconnectthewirefromthesparkplugbefore

loadingthemachineforhauling.

•Usecarewhenloadingorunloadingthemachine.

16

Maintenance

MaintenanceSafety

•Inspectthemachinefrequentlytoensurethatit

isinsafeworkingconditionandthatshearbolts,

engine-mountingbolts,andotherfastenersare

properlytightened.

•Shutoffthemachineandwaitforallmovingparts

tostopbeforeyouleavetheoperator’sposition.

Disconnectthespark-plugwire,keepitawayfrom

theplugtopreventaccidentalstarting,andallow

themachinetocoolbeforeadjusting,fueling,

unclogging,servicing,cleaning,orstoringthe

machine.

•Wearglovesandeyeprotectionwhenservicing

themachine.

•Nevertamperwithsafetydevices.Checktheir

properoperationregularly.

•Toensureoptimumperformanceofthemachine,

useonlygenuineTororeplacementpartsand

accessories.Replacementpartsandaccessories

madebyothermanufacturerscouldbedangerous,

andsuchusecouldvoidtheproductwarranty.

•Replacetinesthatarebent,damaged,orloose;do

notrepairoralterthem.

•Keepthemachine,attachments,andaccessories

insafeworkingcondition.

•Donotattempttorepairthemachineunless

youhavethepropertoolsandinstructionsfor

disassembling,assembling,andrepairingthe

machine.

RecommendedMaintenanceSchedule(s)

MaintenanceService

IntervalMaintenanceProcedure

Aftertherst5hours•Changetheengineoil.

Beforeeachuseordaily

•Checktheengine-oillevel.

•Cleandebrisfromthemufer,controls,andair-intakegrille.

•Cleanthetineandwheelshafts

Every10hours•Lubricatemovingparts.

•Checkthebelttension.

Every25hours•Servicetheaircleaner(moreoftenindirtyordustyconditions).

•Cleanthepre-cleanerelement.

Every50hours

•Changetheengineoil(moreoftenindustyconditions).

•Replacethebelts.

•Checkthemuferandsparkarrester.

Yearly

•Replacethepre-cleanerelement.

•Replacethefuellter.

•Replacethesparkplug.

•Checkthebelttension.

•Cleantheengineair-coolingsystem(moreoftenindustyconditions).

Important:Refertoyourenginemanualforadditionalmaintenanceprocedures

17

Pre-Maintenance

Procedures

PreparingforMaintenance

1.Movethemachinetoalevelsurface,shutoffthe

engine,andwaitforallmovingpartstostop.

2.Disconnectthespark-plugwirefromthespark

plug.

g361695

Figure23

1.Spark-plugwire

3.Afterperformingthemaintenanceprocedure(s),

connectthespark-plugwiretothesparkplug.

Important:Beforetippingthemachine,

allowthefueltanktorundrythroughnormal

usage.Ifyoumusttipthemachinepriorto

runningoutoffuel,useahandfuelpumpto

removethefuel.

Lubrication

GreasingtheMachine

Greasetype:Whitelithiumgrease

Greasethemachineatthefollowinglocations:

•Forwardandreversearmassemblies

•Forwardandreverseengagementlevers

•Forwardandreversecables.

18

EngineMaintenance

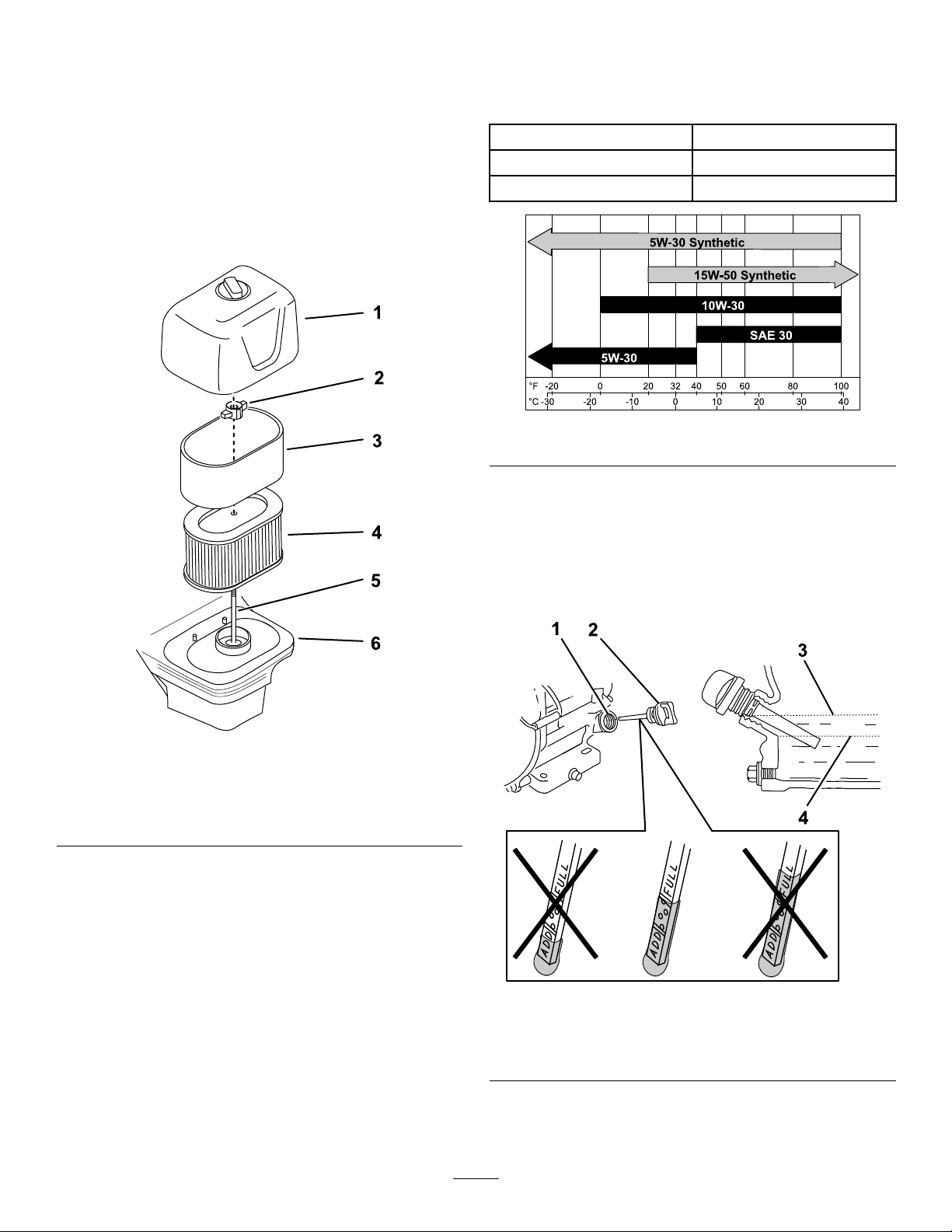

ServicingtheAirCleaner

ServiceInterval:Every25hours/Yearly(whichever

comesrst)—Servicetheair

cleaner(moreoftenindirtyordusty

conditions).

Every25hours/Yearly(whichevercomes

rst)—Cleanthepre-cleanerelement.

Yearly—Replacethepre-cleanerelement.

RemovingtheAirCleaner

Elements

1.Cleanaroundtheair-cleanercovertoprevent

dirtfromgettingintotheengineandcausing

damage.

2.Loosenthefasteneronthecover.

3.Removethecover.

4.Removethefastenerontheelements.

5.Carefullyremovethefoampre-cleanerand

paperelementfromthebase.

g359988

Figure24

1.Cover4.Paperelement

2.Fastener5.Stud

3.Pre-cleaner6.Air-cleanerbase

ServicingtheFoamElement

1.Removethefoampre-cleanerfromthepaper

element.

2.Washthepre-cleanerwithwarmwateranda

milddetergent.

3.Rinsethepre-cleanerandallowittoairdry.

Important:Replacethefoampre-cleanerifitis

tornorworn.Donotoilthepre-cleaner.

ServicingthePaperElement

1.Cleanthepaperelementbytappingitgentlyto

removedust.

Note:Ifitisverydirty,replacethepaper

elementwithanewone.

2.Inspecttheelementfortears,anoilylm,or

damagetotherubberseal.

3.Replacetheelementifitisdamaged.

Important:Donotcleanthepaperelement.

19

InstallingtheAirCleanerElements

1.Installthefoampre-cleanerelementoverthe

paperelement.

Note:Ensurethatyoudonotdamagethe

elements.

2.Installtheair-cleanerelementsontothe

air-cleanerbaseandontothestud.

3.Securetheelementsusingthefastener.

4.Installthecoverandsecureitwiththefastener.

g359988

Figure25

1.Cover4.Paperelement

2.Fastener5.Stud

3.Pre-cleaner6.Air-cleanerbase

ServicingtheEngineOil

Engine-OilSpecications

Engineoilcapacity0.54to0.59L(18to20oz)

OilviscosityRefertothechartbelow.

APIserviceclassicationSJorhigher

g359987

Figure26

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

1.Movethemachinetoalevelsurface.

2.Removethedipstickandwipetheendclean.

g360042

Figure27

1.Fillertube3.Upperlimit

2.Dipstick4.Lowerlimit

3.Insertthedipstickfullyintotheoil-lltube,but

donotturnortightenit.

20

Other manuals for 58603

1

Table of contents

Other Toro Tiller manuals