BE Ag & Industrial 67.018.000 Application guide

PURCHASE DATE MODEL NO. SERIAL NUMBER

DEALER

18V GREASE GUN

LITHIUM ION

67.018.000

OPERATIONS & PARTS MANUAL

2 67.018.000 USER MANUAL

SPECIFICATIONS

ITEM NO.

Charger Input Power 120 VAC /230VAC

Battery Output Power 18V

Battery Capacity 1500 MAH Lithium ion

Battery Pack Charge Time 70±10min

Maximum Operating Pressure 9,000±l,000 PSI

Grease Reservoir Capacity 14oz (397g)

Minimum Flow Rate (gram/minute) 3oz /min or 75±10g/min

Hose 30"

Failure to follow all instructions listed below may result in electric shock, fire, and / or

serious injury. Please read carefully and save this manual. You will need this manual for

the safety warnings and precautions, assembly, operating, maintenance and cleaning

procedures.

WORK AREA

1. Keep your work area clean and well lit. Cluttered benches and dull areas may cause accidents.

2. Do not operate cordless grease gun in explosive atmospheres such as in the presence of flammable

liquids, gases, or dust Battery liquid may burn.

3. Keep bystanders, children, and visitors away while operating the cordless grease gun. Distractions can

lead you to lose control.

ELECTRICAL SAFETY

1. Cordless grease gun plugs must match the outlet. Never modify the plug in anyway. Do not use any

adapter plugs with earthed (grounded) cordless grease gun. Unmodified plugs and matching outlets will

reduce risk of electric shock

2. Avoid body contact with grounded surfaces such as pipes, couplers. There is an increased risk of

electric shock if your body is grounded.

3. Do not expose cordless grease gun to rain or wet conditions. Water entering a cordless grease gun will

increase the risk of electric shock.

PERSONAL SAFETY

1. Stay alert Watch what you are doing, and use common sense when operating a cordless grease gun.

Do not use a cordless grease gun while tired or under the influence of drugs, alcohol, or medication.

A moment inattention while operating cordless grease gun may result in serious personal injury.

2. Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep your hair; clothing, and

gloves away from moving parts. Loose clothes, jewelry, or long hair can be caught in moving parts.

3. Do not overreach. Keep proper footing and balance at all times. Proper footing and balance enable better

control of the power tool in unexpected situations.

4. Use safety equipment. Always wear approved safety glasses underneath a full-face safety shield. Dust

mask, non-skid safety shoes, hard hat, or hearing protection must be used for appropriate conditions.

TO FILL THE GUN WITH A FILLER PUMP

1. A bulk filler fitting will need to be installed in the grease gun head cap (not included).

2. Replace the pipe plug in the head cap with the bulk loader fitting.

3. Engage the follower rod with the follower by rotating the follower handle.

4. Insert the gun filler nipple into the filler pump socket.

5. Operate the filler pump to fill the container. When the follower rod groove is exposed, the grease tube

67.018.000 USER MANUAL 3

assembly is filled. The follower rod will be extended. DO NOT OVERFILL!

6. Disengage the follower rod from the follower by rotating the follower handle. Push the follower rod into

the grease tube assembly.

7. Purge air from assembly. See “expel air pockets”.

TO EXPEL AIR POCKETS

1. Always open vent valve after replacing cartridge. This will allow air to escape from cartridge and

prime grease gun.

2. Free the follower rod from the grease tube assembly cap and depress the vent valve when

3. pushing the follower rod forward.

4. Squeeze the switch vent valve several times to operate gun until trapped air is expelled. Push

the follower rod into the grease tube assembly.

5. Tip for Priming: While the air detent valve helps release air pockets while priming the grease gun,

sometimes it does not always clear it fully. If gun will not pump grease after standard priming procedure,

pump the trigger of the gun a few times and then loosen the barrel from the head a few rotations. This

will help expel the remaining air. You may need to repeat this step once or twice.

BATTERY AND CHARGER

DANGER

1. Do not probe with conductive objects.

2. Do not charge damaged battery, replace it immediately.

3. Failure to comply may result in serious injury.

WARNING OF BATTERY

1. Never attempt to disassemble battery for any reason.

2. Do not store in locations where the temperature may exceed 40°C such as outside sheds or metal

buildings in the summer

3. Charge the battery only at ambient temperatures between 10°C to 40°C.

4. Charge the battery only with using the charger provided with this tool.

5. Seperate collection when disposing of batteries. Do not dispose with normal household waste.

6. Do not expose battery to fire, spark, flame or any explosive atmosphere. Battery liquid may burn.

7. Do not expose battery to water, rain, snow, frost or other wet environments.

WARNING OF BATTERY CHARGER

1. The charger is intended for indoor use only. Do not expose charger to watermain, snow or frost.

2. Only use for charging the battery with this tool.

3. Do not charge battery in damp or wet location.

4. Do not abuse cord. Do not attempt to repair power cord.

5. Do not operate charger with damaged cord and plug. Replace charger immediately.

6. Do not attempt to disassemble charger.

7. Unplug charger from outlet before any cleaning to avoid electric shock.

8. Do not cover the charger and battery with anything while charging. Charge the battery in a

well-ventilated place.

9. Charge battery only at ambient temperatures between 10°C to 40°C

10.Do not charge battery in explosive atmospheres. DUST OR FUMES MAY IGNITE.

4 67.018.000 USER MANUAL

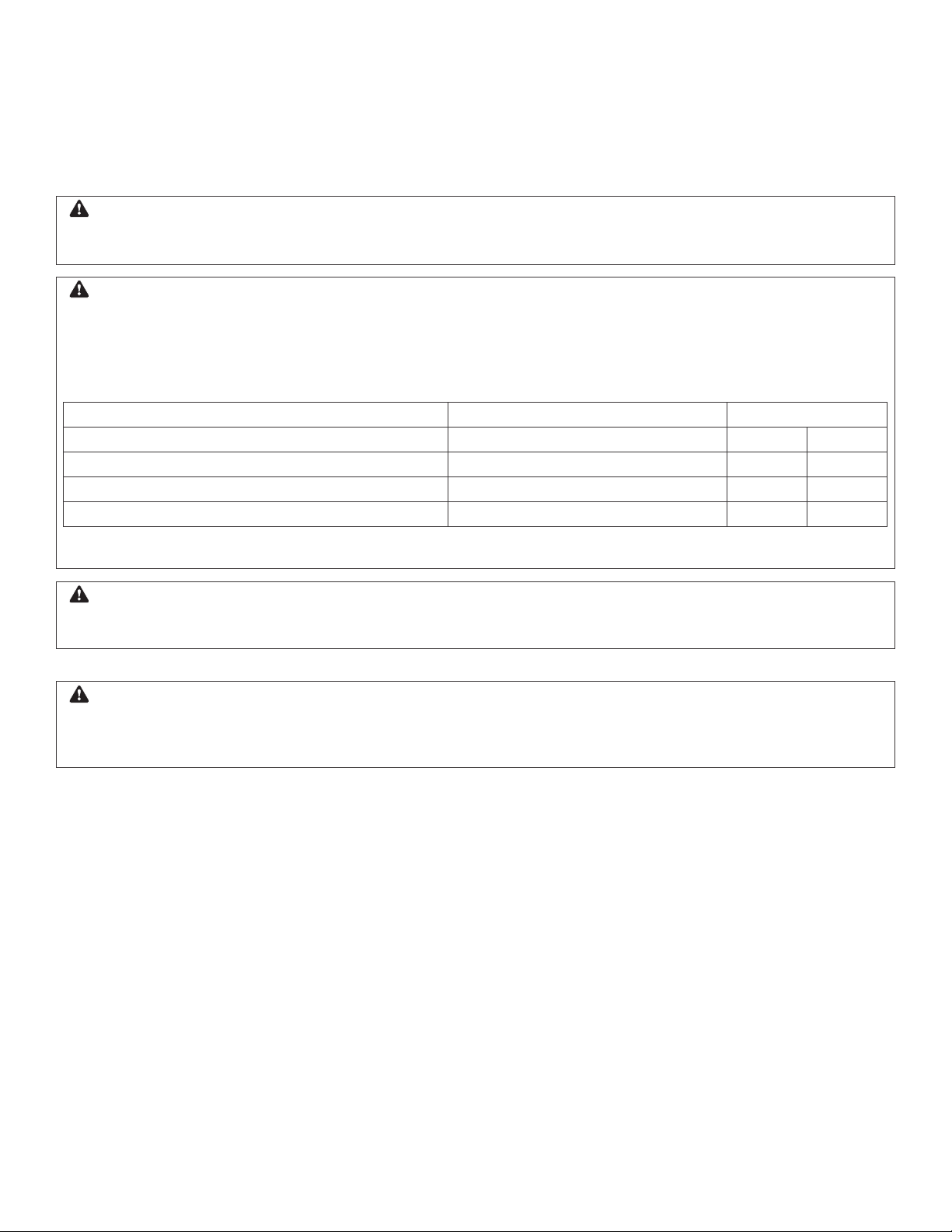

STEP CONDITION LIGHT INDICATOR

RED GREEN

1. Plug charger into power outlet Ready to charge OFF ON

2. Insert battery pack into charger On charging ON OFF

3.Battery pack is full charged Full charged OFF ON

CHARGING OPERATION

For best performance on a new battery, you must discharge it completely to get full use of the battery’s life

cycle. Using a battery that has been charged before it is completely discharged will shorten the batteries

total amount of charge it will take in future charging. This applies to a new grease gun too. Be sure to dis-

charge the new battery completely before charging. All New grease guns come with 80% charge from the

factory and no charging is needed until it is used and the battery is run down.

NORMAL CHARGING

CAUTION

Charge the battery pack in clean and dry location. Do not charge the battery pack in air temperature is

below 5°C or above 41°C

NOTE: Battery temperature will increase during and shortly after use. Batteries may not accept a full

charge if they are charged immediately after use. Allow the battery pack to cool to room temperature

before charging for best results.

CAUTION

Make sure power circuit voltage is the same as the shown on the charger specification.

1. Remove the battery pack from the cordless grease gun by press the button on the battery pack.

2. Plug the charger into power outlet before inserting battery pack.

3. Insert battery pack in to charger. Lights on charger indicate the charging process as below:

4. Remove battery pack from charger and disconnect charger from power outlet after full charger.

PRIMING INSTRUCTION

INSTALL A GREASE CARTRIDGE

1. Unscrew the grease tube assemble from the cordless grease gun.

2. Pull back on the follower handle until the follower rod is fully extended and latch the follower rod groove

into the slot on the tube end cap of the Grease Tube.

3. Carefully release the follower handle to eject the empty cartridge from container tube.

4. Remove the plastic cap from the grease cartridge and insert cartridge into the container tube.

5. Remove the pull tab from grease cartridge and screw grease tube into cordless grease gun assembly.

6. Release follower rod from slot to allow it to go forward. Purge air from assembly. See “expel air pockets”.

TO FILL THE GUN FROM BULK CONTAINER

1. Remove grease tube from the grease gun.

2. Unscrew the grease tube assembly cap from the grease tube assembly. Pull on the follower handle to

extract the follower and spring from the grease tube assembly.

3. Grasp follow seal between thumb and forefinger and flip the follow seal from the rear to the front side.

4. Reassemble follower into grease tube assembly and position with the follower handle so that the grease

tube assembly cap can be tightened onto the container tube.

5. Insert the open end of the grease tube assembly into lubricant. Slowly pull the follower handle back while

pushing the grease tube assembly deeper into the lubricant to prevent air pockets from being pulled into

the grease tube assembly.

NOTE

Remove air pocket! Air pockets in the cartridge will prevent grease from being pumped and cause the

grease gun to lose its prime. Unscrew the vent valve several times to remove small air pockets trapped

in this area.

67.018.000 USER MANUAL 5

6. When the follower rod is fully extended, pull it sideways to latch the rod groove into the keyhole slot in

the grease tube assembly cap. .

7. Turn the Grease Tube into the gun and release the follower rod from the slot on the end cap of the tube to

allow the follower rod go forward.

8. Clean any excess grease of the gun body.

9. Purge air from assembly. See “expel air pockets”.

TO EXPEL AIR POCKETS

1. Always open vent valve after replacing cartridge. This will allow air to escape from cartridge and

prime grease gun.

2. Free the follower rod from the grease tube assembly cap and depress the vent valve when

3. pushing the follower rod forward.

4. Squeeze the switch vent valve several times to operate gun until trapped air is expelled. Push

the follower rod into the grease tube assembly.

5. Tip for Priming: While the air detent valve helps release air pockets while priming the grease gun,

sometimes it does not always clear it fully. If gun will not pump grease after standard priming procedure,

pump the trigger of the gun a few times and then loosen the barrel from the head a few rotations. This

will help expel the remaining air. You may need to repeat this step once or twice.

WARNING

Grease Gun can develop high pressure - up to 9,000 PSI. Use safety glasses and gloves for protection

during operation. Keep hands clear of the exposed rubber portion of hose.

WARNING

Extreme pressure may cause Nozzle extension or Flex Hose to burst. Use only APPROVED hoses and

follow whip hose instructions and warnings.

WARNING

Make sure the switch is in its o position, and unplug the charger from its power outlet before

performing any inspection, maintenance, or cleaning.

WARNING

BEFORE EACH USE, check the general condition of the Grease Gun. Check for misalignment or binding

of moving parts, cracked or broken parts, leaking Battery Pack, damaged Hose, and any other condition

that may aect its safe operation. If abnormal noise or vibration occurs, have the problem corrected

before further use.

Do not use damaged equipment.

Table of contents

Other BE Ag & Industrial Tools manuals

Popular Tools manuals by other brands

Equalizer

Equalizer TFA12TI Operator's instruction manual

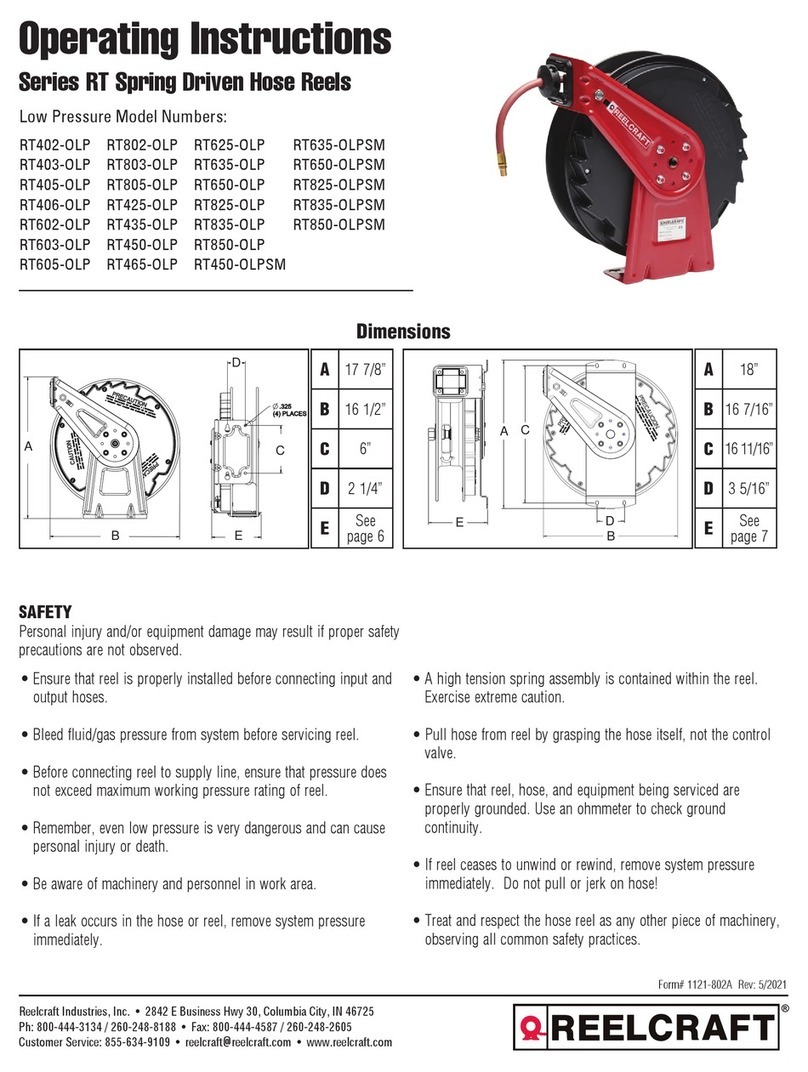

Reelcraft Industries, Inc.

Reelcraft Industries, Inc. RT Series operating instructions

Welbilt

Welbilt 18649 owner's manual

Delta

Delta 43-355 instruction manual

Deltafox

Deltafox DG-CGC 1080 Set 3in1 Translation of the original instructions for use

Equalizer

Equalizer SWi12TMEX Operator's instruction manual