Beastx MICROBEAST PLUS User manual

Version 5.0

QUICKSTART GUIDE

0118

STUDIOX.BEASTX.COM BEASTX.COM WIKI.BEASTX.COM

SAFETY NOTES

• Radio controlled (R/C) helicopters are no toys! The rotor blades rotate at high speed and pose potential

risk. They may cause severe injury due to improper usage. It is necessary to observe common safety

rules for R/C models and the local law. You can gather information from your local R/C model club or

from your national modelers association.

• Pay attention to your own safety and the safety of other people and property in your vicinity when

using our product. Always y in areas away from other people. Never use R/C models in close proximity

to housing areas or crowds of people. R/C models may malfunction or crash due to several reasons like

piloting mistakes or radio interference, and cause severe accidents. Pilots are fully responsible for their

actions, and for damage or injuries caused by the usage of their models.

• Please read the following instructions thoroughly before the rst use of your MICROBEAST PLUS and

setup the system carefully according to this manual. Allow sucient time for the setup procedure and

check each step carefully. Watch for a mechanically clean and proper build of your helicopter. A wrong

system setup can lead to a serious accident and damage to the model.

• Radio controlled (R/C) models consist of several electrical components. It is therefore necessary to

protect the model from moisture and other foreign subtances. If the model is exposed to moisture this

may lead to a malfunction which may cause damage to the model or a crash. Never y in the rain or

extremely high humidity.

• When operating the helicopter with a MICROBEAST PLUS ensure there is a suciently large and stable

receiver power supply. Because of the direct coupling of the rotor blades to the servos, without the use

of a ybar mixer, the servos are exposed to increased actuating forces. In addition, because of the

intermediary electronic gyro system, the servos are driven more often than with traditional use. These

factors can make the power consumption increase a lot compared to a ybar helicopter. When the

supply voltage falls below 3.5 volts for a short amount a of time, the system will power o and reboot.

In this case a crash of the helicopter is unavoidable.

• Do not expose the MICROBEAST PLUS system to extreme variations in temperature. Before powering

up the system, wait some time so that the electronics can acclimatize and any accumulated

condensation is able to evaporate.

• The sensors of MICROBEAST PLUS consist of highly sensitive electromechanical components. These can

be damaged due to moisture or mechanical or electrical impact. Do not continue using this product, if

it has been exposed to such inuences, e.g. due to a crash of the model or due to overvoltage caused

by a defective receiver power supply. Otherwise a failure may happen any time.

• When operating electric helicopters make sure that the electric motor cannot start inadvertently during

the setup procedure. Particularly pay attention if using a single-line receiver and if the ESC is connected

directly to the MICROBEAST PLUS. We recommend disconnecting the electric motor from the ESC during

the setup procedure. Prior the rst usage please slide the motor/pinion away from the main gear, then

check that the motor does not to start inadvertently when the receiver is switched on.

• When operating the RPM Governor feature of MICROBEAST PLUS it is essential to ensure that the motor

cannot start by accident when making adjustment or performing preparations to start the engine.

Carefully read this manual and make sure you fully understand how the RPM Governor feature is

operated before making any adjustments. Also make sure the motor does not start when the radio link

is interrupted or when you switch on the transmitter initially. With electric driven models do not dock

the motor to the main gear unless all necessary adjustment procedures have been nished. Always

maintain sucient safety distance to the motor and other rapidly rotating components of the

helicopter.

• MICROBEAST PLUS with AttitudeControl can be used as a ying aid for beginners by limiting the

reaction of the helicopter to stick inputs and by stabilizing the helicopter with a electronic control loop.

However, this does not provide that the helicopter can always be own safely! By incorrect control

inputs the helicopter still may crash or be placed in a position in which the pilot becomes disoriented

even when using AttitudeControl. In addition, the helicopter can drift due to external inuences and it

is not guaranteed that the articial horizon of the device can stabilize the helicopter at any time and

recover from any orientation. Inuences such as temperature uctuations or vibrations may cause

incorrect results and distort the position calculation of the system in consequence. There is no

guarantee that the system will always work correctly. Only the pilot is responsible for the control of the

helicopter and thus also for the use of the system. Note that the system for technical reasons will not

hold the helicopter absolutely to the point. The unstable tendency of a helicopter will cause the model

to y in a certain direction even when using AttitudeControl. External inuences such as wind can

further strengthen this eect. In addition measurement inaccuracies of the sensors can distort the

position determination slightly. You must always be able to turn o the system immediately and be

able to take over full control of the helicopter.

• We suggest you to seek the support of an experienced helicopter pilot before you undertake the rst

ight of your model. Additionally, ight training with a R/C simulator can help make ying easier and

more enjoyable. Ask your local dealer if you need technical support or if you observe problems during

the usage of our system.

• AttitudeControl can help to facilitate ying of model helicopters by briey passing over control to the

system if the pilot becomes disoriented. By using the built-in articial horizon the helicopter can be

brought to a nearly horizontal position so that the pilot gains time to reorient. Thus, there can be no

assurance that the model is saved from a crash in general. Depending on the current attitude and the

speed of the model and depending on how fast the AttitudeControl is activated, the model may crash

before or while the system tries to recover. In addition, the helicopter can drift due to external inuences

and it is not guaranteed that the articial horizon of the device can stabilize the helicopter at any time

and recover from any orientation. Inuences such as temperature uctuations or vibrations may cause

incorrect results and distort the position calculation of the system in consequence. Strictly observe the

general safety rules for dealing with RC models and do not totally rely on the system. The pilot is

responsible for the control of the helicopter and thus also for the use of the system. You must always be

able to turn o the system immediately and be able to take over full control of the helicopter.

If you like to get more insight into the system and like to have a more visualized type of setup you

can use the StudioX App for PC/mac or StudioXm for your smartphone/tablet in combination with

the USB2SYS interface (PC/mac) or BLE2SYS interface (smartphone/tablet) (optional available).

These apps are the source to get even more out of your device like saving/restoring paramaters,

firmware updates, loading preset heli configurations and making advanced adjustment to fully

customize your MICROBEAST PLUS to your needs.

StudioX can be downloaded from:

STUDIOX.BEASTX.COM

Dear customer,

thank you for purchasing our product.

MICROBEAST PLUS is a high-end gyro system for RC helicopters that has been developed in Germany using

latest technology and setting high standards. It can be used with many different types of helicopters like

3D aerobatic helis, F3C competition helicopters as well as scale helicopters with 2 or more rotorblades. The

system comes with BASIC flybarless stabilization functionality and can be upgraded by paid update to the

PROEDITION. This enables additional features like AttitudeControl for recue bailout or constant leveling and a

feature called„Bank Switching“ which allows to switch between parameter presets in flight to serve different

flight conditions or flying styles.

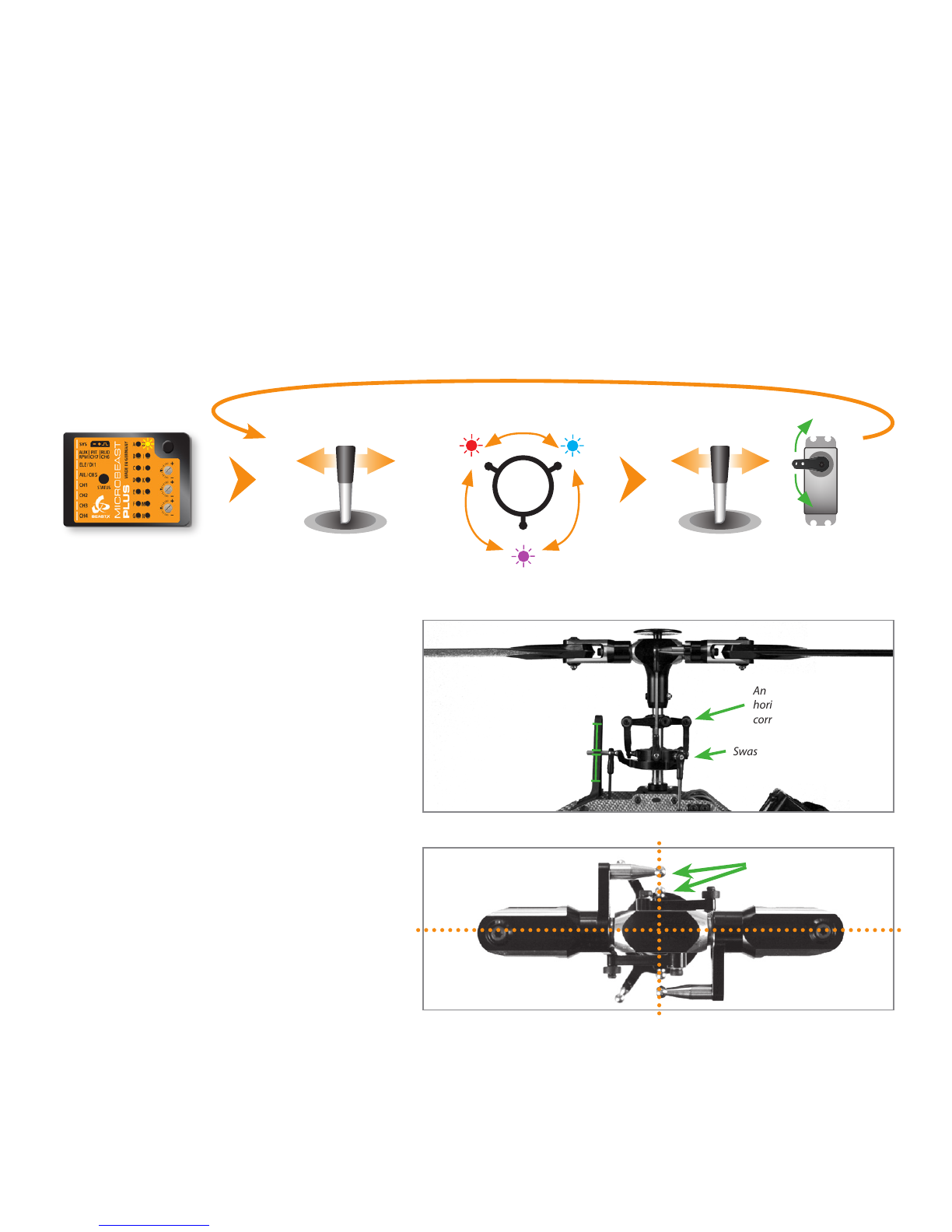

To setup MICROBEAST PLUS there is no need for any additional devices. All you need is your radio system

and your helicopter. Thanks to the well proven„EasySetup“ concept you can do all the necessary adjustment

directly at the device and you‘re ready for take off within a few minutes.

This Quickstart Guide is a clearly arranged guide that will lead you step-by-step through the basic flight

setup. Please follow this guide carefully and make sure to read the attached safety notes. For a detailed

instruction manual and further details, tipps, tricks and notes about the product please visit

WIKI.BEASTX.COM

This guide is intended to be used with MICROBEAST PLUS firmware version 5.0.x

only! After power up when the Status-LED lights red, for a few seconds in the left row

menu LEDs Aand Cindicate major version„5“. In the right row no LED lights up.

1. HARDWARE INSTALLATION

You can position MICROBEAST PLUS flat or upright on the helicopter. The large socket must point to the front or to the rear of

the helicopter. The small white socket must be aligned with the longitudinal axis.

The sensor axis (housing edges of the device) must be aligned exactly parallel to all three rotation axis of the helicopter.

However, it is allowed to position the device offset from the rotation axis.

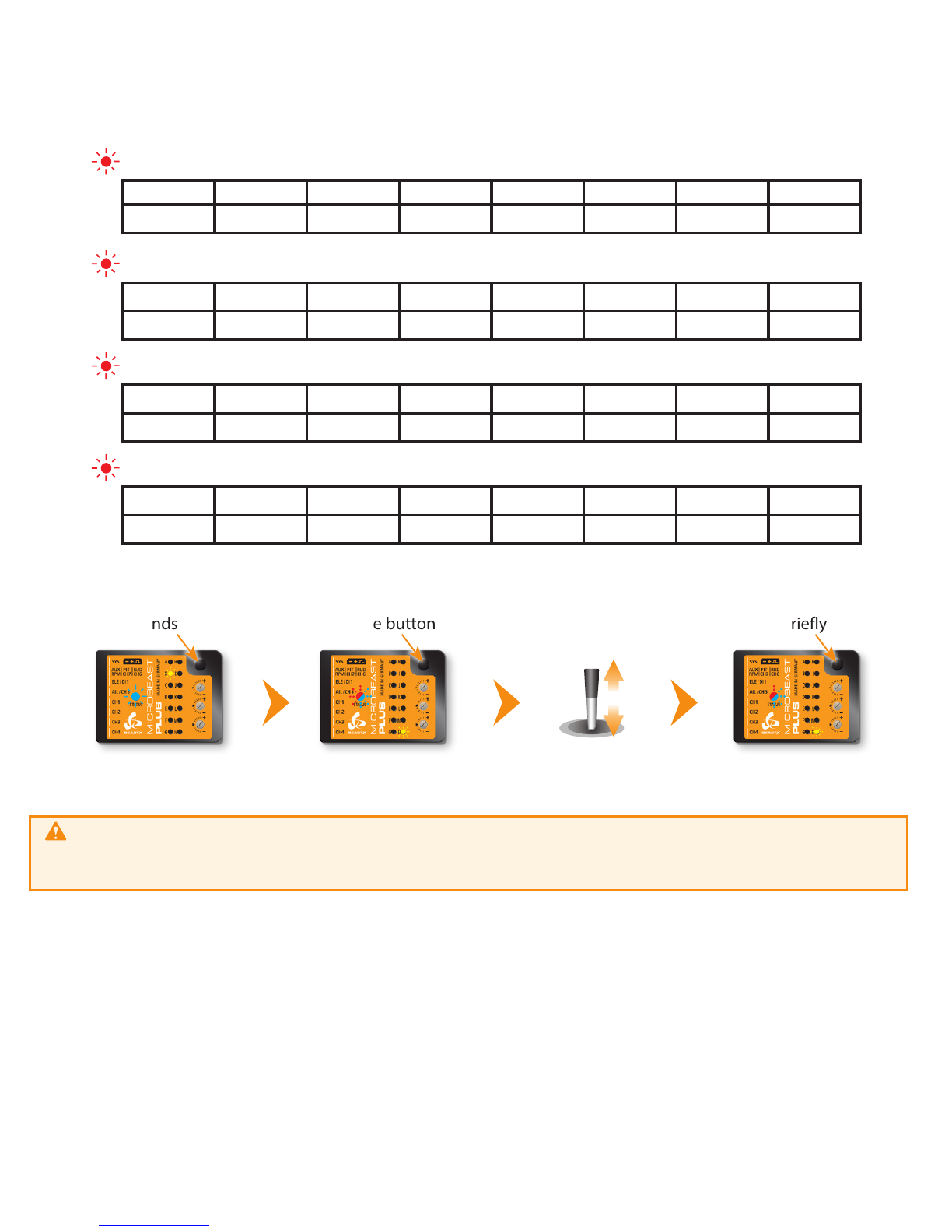

In summary there are 8 mounting orientations possible:

1. flat, sticker on top, socket pointing to front

2. upright, button up, socket pointing to front

3. flat, sticker showing to ground, socket pointing to front

4. upright, button down, socket pointing to front

5. flat, sticker on top, socket pointing to rear

6. upright, button up, socket pointing to rear

7. flat, sticker showing to ground, socket pointing to rear

8. upright, button down, socket pointing to rear

Use one of the supplied 3M gyro pads to stick the device to your helicopter. The device housing must not directly touch

the chassis of the helicopter. When connecting and laying out the servo and receiver wiring later onwards please make sure

the wires do not pass tension to the MICROBEAST PLUS. It is not recommended to bundle or tie down the leads close to the

MICROBEAST PLUS device.

1. 2. 3. 4.

5. 6. 7. 8.

Flight direction

ESC/Throttle

servo

BEC/Power supply

(if required)

JR® or

SPEKTRUM®

satelite

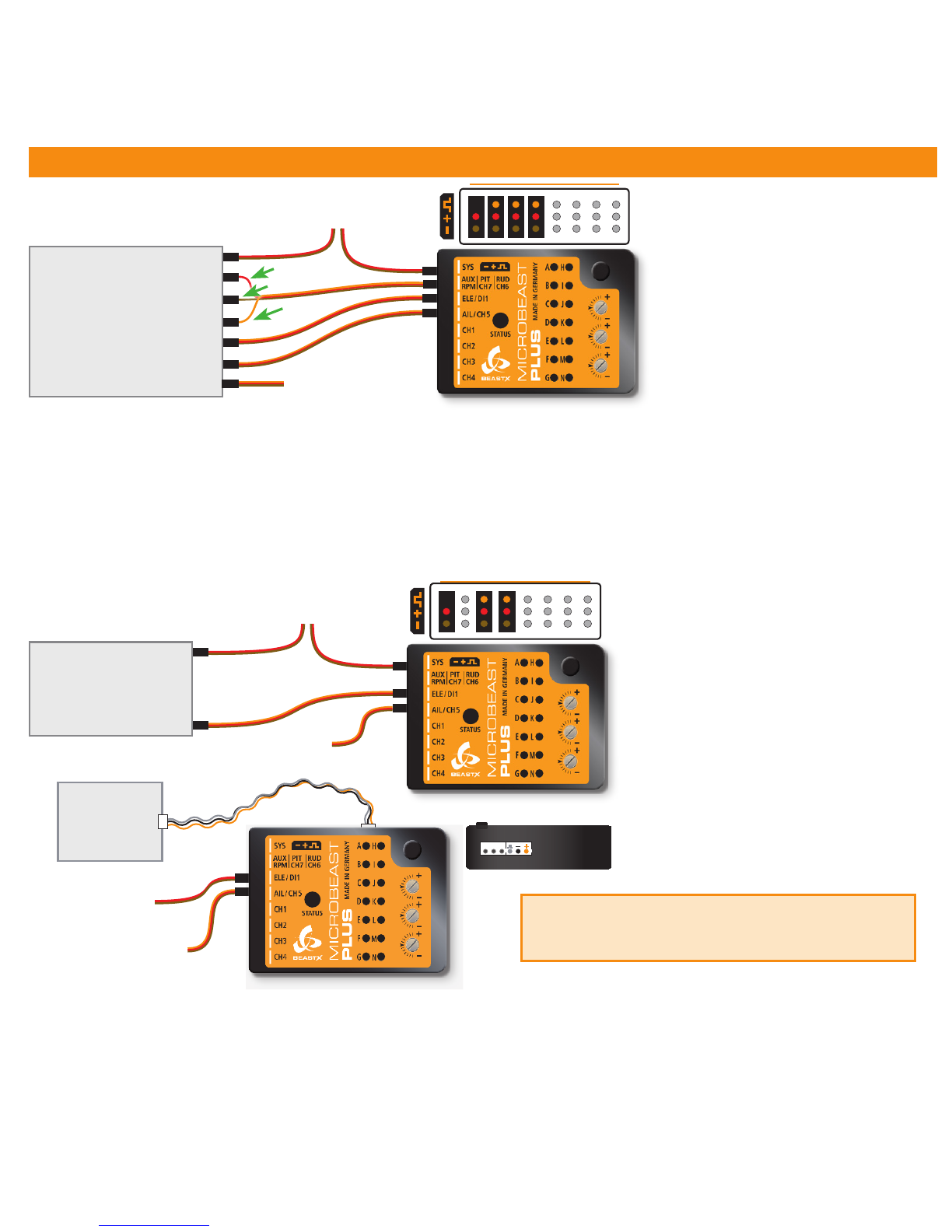

2. CONNECTING THE RECEIVER

BAT

Pitch

Gyro

Rudder

Elevator

Aileron

Throttle

STANDARD

RECEIVER

Throttle servo/ESC

red

brown

orange

BEC/Receiver battery

(if required)

BAT

SINGLELINE

RECEIVER

Throttle servo/ESC

BEC/Receiver battery

(if required)

Signal

Supported receivers/

transmission protocols:

• SRXL: JR® XBus (Mode B), Multiplex®

SRXL (V1+V2), Jeti® UDI, Graupner/SJ®

HOTT SUMD, Spektrum® SRXL

• Futaba® SBUS

• Remote satellite (Spektrum® DSM2/

DSMX, JR RJ-01 DMSS)

• Jeti® EXBUS

• ALIGN/FlySky iBus

• PPM serial signal (SPPM)

The illustrations are only

intended as examples! The

function assignment of the

transmitter determines which

channel on the receiver controls

which function.

Using a Single-Line receiver all channels/functions are transferred by one single connection wire. This allows to use even more

than 5 channels, i. e. for controlling the headspeed Governor, AttitudeControl function and additional output channels.

Always make sure the power supply is stable and dimensioned suciently for the intended application. If possible always

connect the power source directly to MICROBEAST PLUS (not at port [AUX|PIT|RUD]) but additional supply cables can be plugged

into free receiver ports, too. Especially when using standard size servos it is recommended to use more than one power supply

cable in parallel to preserve a stable voltage and to reduce power loss due to connection resistance..

The assignment of functions to the radio channels is mentioned in the manual of your radio system. Also you can nd out the

function assignment by checking your transmitter‘s servo monitor. The connectors of MICROBEAST PLUS are assigned to the

functions as follows:

AIL|CH5 = Aileron, ELE|DI1 = Elevator, RUD (orange wire) = Rudder, PIT (red wire) = Thrust, Aux (brown wire) = Gyro gain

The wires for aileron and elevator additionally transfer the power between MICROBEAST PLUS and receiver.

Using a single remote satellite is only recommended

for 450 size helis or smaller! For larger helis please use a

SRXL compatible Single-Line receiver for your radio brand.

ESC/Throttle

servo

BEC/Power supply

(if required)

JR® or

SPEKTRUM®

satelite

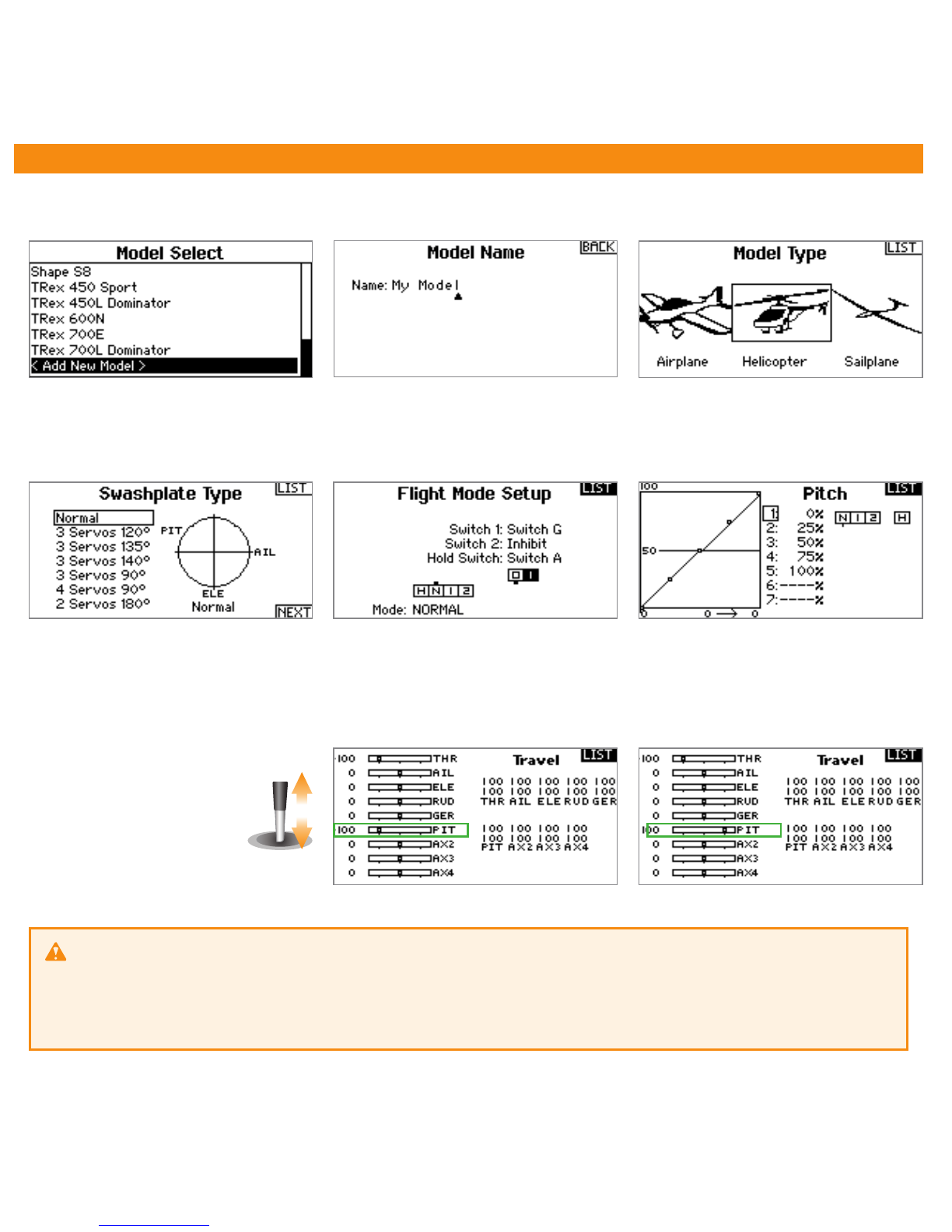

3. PREPARING YOUR TRANSMITTER

With electric driven models remove the motor from the main gear when performing the basic setup for

safety reason! Additionally deactivate the throttle by using the „Throttle HOLD“ switch, so the motor won‘t start to

turn when moving the thrust stick.

When flying a nitro or gasser heli remove the servo horn from the throttle servo before first power up to prevent

jamming the servo due to wrong servo setup.

You mustn‘t use any mixing functions on the output channels! Especially it is not allowed to use mixing functions for the

swashplate servos. Deactivate all output channels that are not used. In the basic configuration we only need pitch, aileron,

elevator, rudder, throttle and one channel to adjust the tail gyro gain.

Create a new helicopter model memory in your transmitter that supplies different flight modes for controling throttle, pitch

and the tail gyro gain in different flight situations.

Only the pitch channel must

be controled when moving

the thrust stick. The same

applies to aileron, elevator

and rudder.

Each control function must exactly control one output channel. Initially the servo throws must be set to 100% and all

trims and sub trims must be zero. For the basic setup do not change the pitch curves yet. The throttle curves and throttle

servo settings can be adjusted as necessary for this model in case you do not intend to use the internal Headspeed Governor

function of MICROBEAST PLUS.

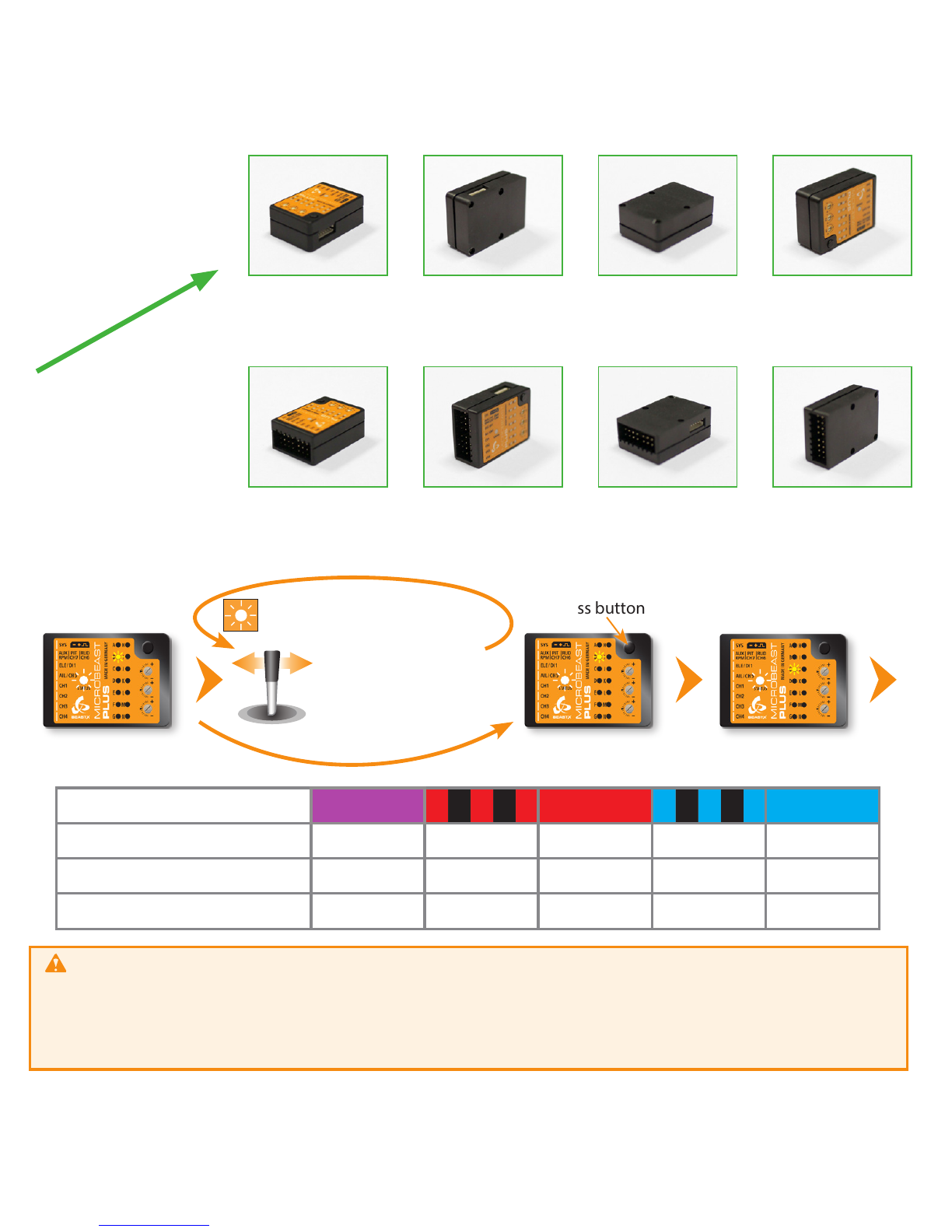

Make sure your transmitter is on and sending signals to the receiver. At menu point Ayou can start automatic receiver type

detection by briefly pressing the button once. The color and state of the Status LED indicates which type is currently scanned

for. When the receiver has been detected the menu will skip to point B; when there was some error the Status LED will flash

in red color and the menu stays at A. In this case please make sure you‘ve connected the receiver correctly and try again!

Single-Line receiver (Status LED off, purple or red at menu point A)

When at menu point Bpress and hold the button for 2 seconds to load the default function assignment that has been preset

for the detected radio system. Alternatively you may program a different function assignment manually in case the default

assignment does not match to your transmitter‘s function layout. How this works in detail you can read from the detailed

instruction manual which you can get at wiki.beastx.com.

Preset function assignment for the different single-line receiver protocols (indicated by Status LED color at A):

You mustn‘t use any mixing functions on the output channels! Especially it is not allowed to use mixing functions for the

swashplate servos. Deactivate all output channels that are not used. In the basic configuration we only need pitch, aileron,

elevator, rudder, throttle and one channel to adjust the tail gyro gain.

Create a new helicopter model memory in your transmitter that supplies different flight modes for controling throttle, pitch

and the tail gyro gain in different flight situations.

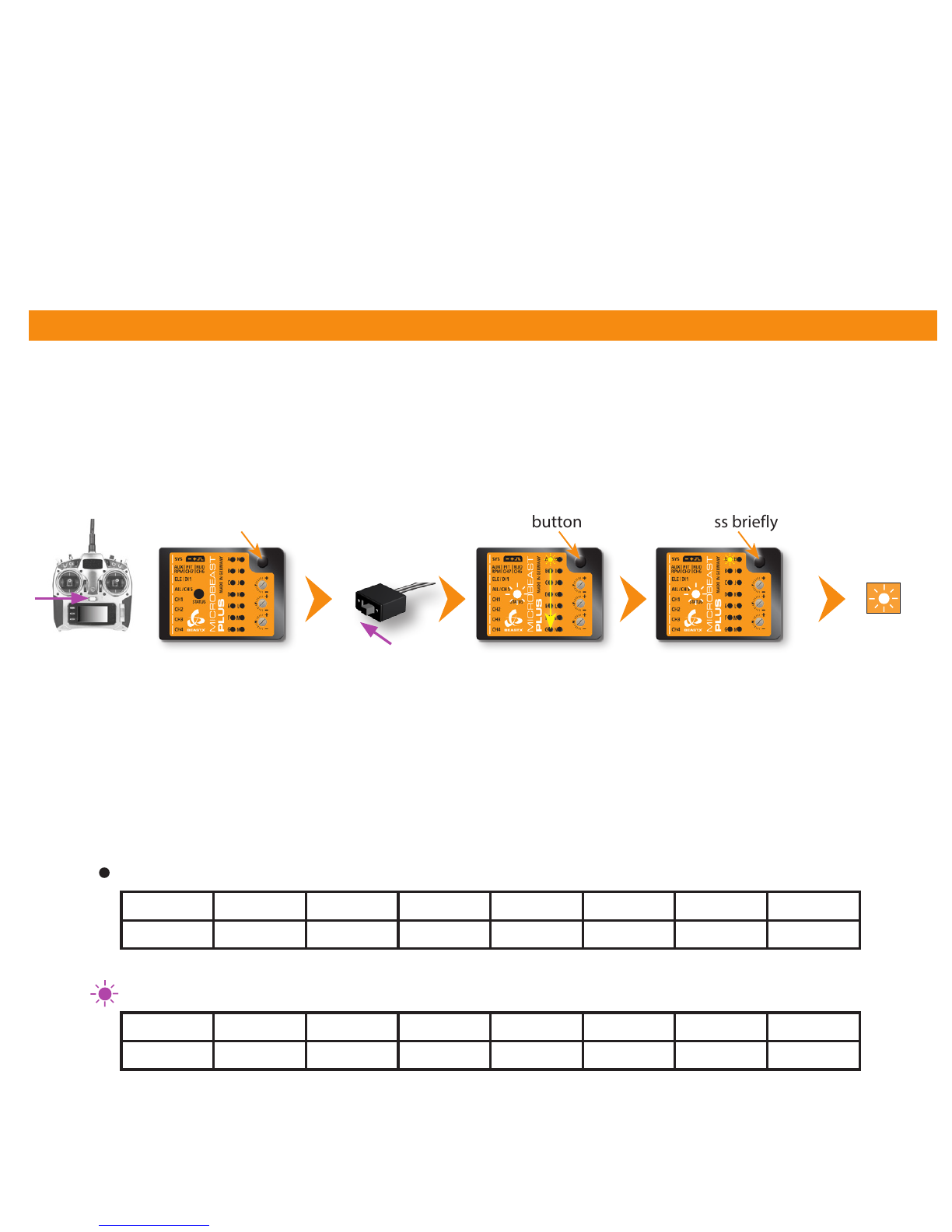

4. RECEIVER SETUP

Switch on

power supply Menu LED Aflashes

Status LED

changes color

(scanning for

receiver)

Make sure your transmitter is on and sending signals to the receiver. At menu point Ayou can start automatic receiver type

detection by briefly pressing the button once. The color and state of the Status LED indicates which type is currently scanned

for. When the receiver has been detected the menu will skip to point B; when there was some error the Status LED will flash

in red color and the menu stays at A. In this case please make sure you‘ve connected the receiver correctly and try again!

Single-Line receiver (Status LED off, purple or red at menu point A)

When at menu point Bpress and hold the button for 2 seconds to load the default function assignment that has been preset

for the detected radio system. Alternatively you may program a different function assignment manually in case the default

assignment does not match to your transmitter‘s function layout. How this works in detail you can read from the detailed

instruction manual which you can get at wiki.beastx.com.

Preset function assignment for the different single-line receiver protocols (indicated by Status LED color at A):

Press and hold button Press briefly

To enter RECEIVER MENU MICROBEAST PLUS must be switched off completely. Push and hold the button before and while

powering on. The menu LEDs will start to cycle from Ato N. Now you can release the button.

Release button

Menu LEDs cycling

Switch on

transmitter

THR AIL ELE RUD GER PIT AX2 AX3

Throttle [CH5] Aileron Elevator Rudder Gyro gain Pitch Aux [CH6] Governor*

Spektrum® DSM2/DSMX or JR RJ-01 DMSS remote satelite

12345678

Pitch Aileron Elevator Rudder Aux [CH6] Throttle [CH5] Gyro gain Governor*

PPM serial signal (SPPM)

To initiate bind procedure on a single Spektrum® remote satellite connect the Spektrum bind plug to [SYS] port. When

using a DSM2 remote satellite, push and hold the button and turn on power while still holding the button down. The LED on

the satellite will ash together with Menu LED Non the MICROBEAST PLUS. When binding a DSMX remote satellite do not

touch the button but only power on the device. The LED on the satellite will ash together with Menu LED H. Initiate the bind

procedure on the transmitter. Power o and remove the bind plug when nished successfully.

To bind the JR® RJ01 remote satellite initiate the bind procedure on the transmitter and power on the MICROBEAST PLUS.

The remote satellite will bind instantly. Connecting a bind plug or similar is not necessary.

* Governor channel is used to set headspeed for governor function with nitro or gas driven helicopters

Receiver with „Standard“ 5-wire layout (Status LED blue at menu point A)

Here the function assignment is simply determined by the order of physical connection of the wires to the receiver outputs. Assignment

by software is not provided and will not appear when choosing this type of receiver. When a „Standard“ receiver (Status LED blue at

menu point A) was detected the receiver setup is finished and the system will reboot immediately. Menu point Bwill not appear!

WARNING: At menu point Nthe throttle output CH5 is active, when using a electric helicopter the motor

may start to run! Move the throttle to the desired failsafe position which will be set in case the receiver connection is

interupted oder gets disconnected.

When pushing the button after setting throttle failsafe position all the receiver settings will be stored. Then all menu

LEDs will flash repeatedly and the system will reboot after 3 seconds.

12345678

Pitch Aileron Elevator Rudder Aux [CH6] Throttle [CH5] Gyro gain Governor*

Graupner®SUMD

THR AIL ELE RUD GER PIT AX2 AX3

Throttle [CH5] Aileron Elevator Rudder Gyro gain Pitch Aux [CH6] Governor*

Spektrum® SRXL

Then enter SETUP MENU for making the basic adjustments

Setup menu point A- Device orientation (Menu LED A solid lit up)

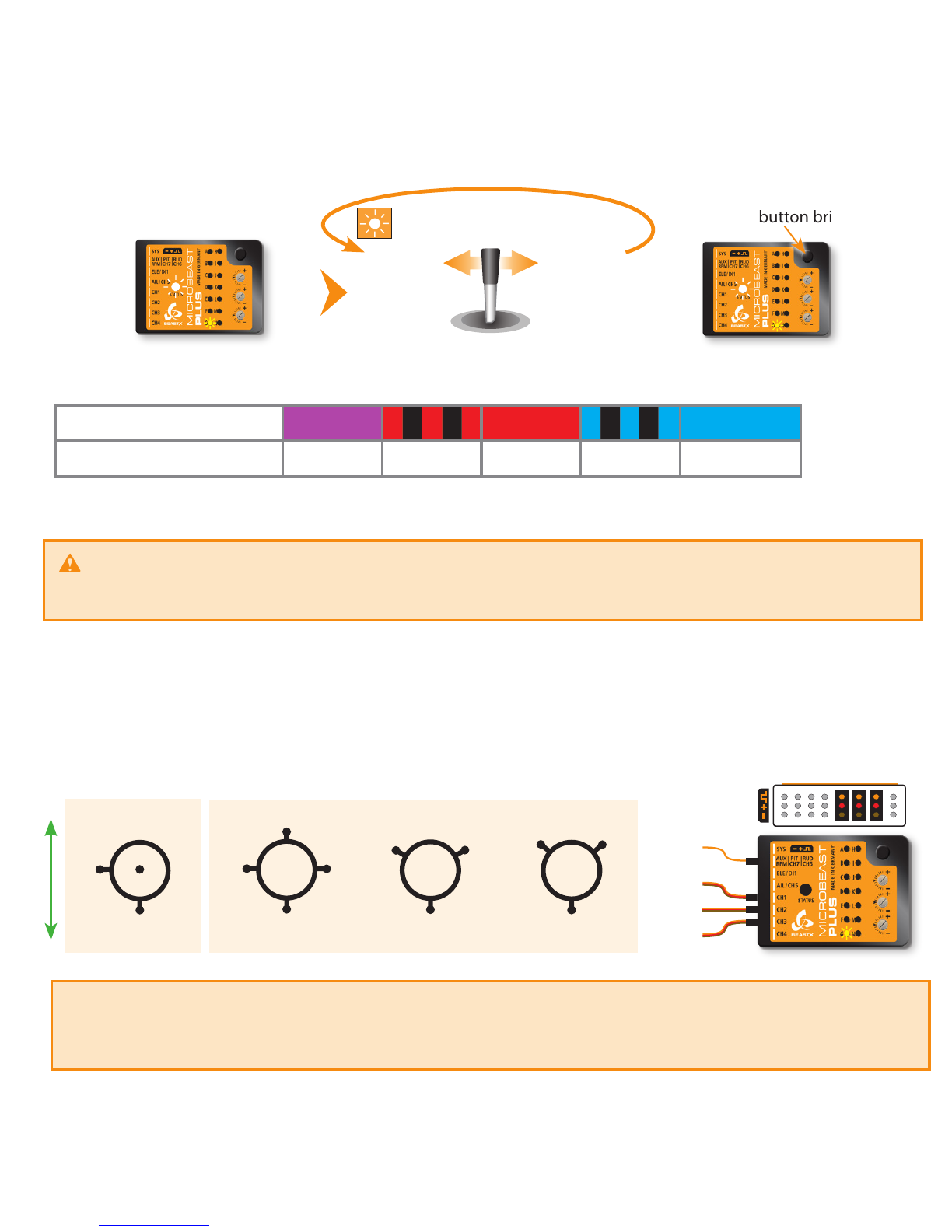

Check the selected device orientation and change it if necessary by (repeatedly) moving the rudder stick into one direction

until the Status LED color corresponds to the real device orientation. Then briefly push the button to save the setting and

to proceed to the next menu point.

12345678

Aileron Elevator Throttle [CH5] Rudder Gyro gain Pitch Aux [CH6] Governor*

Futaba® SBus/SBus2 or BEASTX FASST compatible receiver

12345678

Aileron Elevator Rudder Pitch Throttle [CH5] Gyro gain Aux [CH6] Governor*

Multiplex®SRXL v1 and v2, JR®XBUS Mode B, JETI®UDI 12 + 16ch

Menu LED Bflashes

Status LED is solid blue

Press and hold button

for 2 seconds Release button

Menu LED Nflashes

Status LED flashes red/blue

Press briefly

Make sure throttle is

in motor stop/failsafe

position

When pushing the button after setting throttle failsafe position all the receiver settings will be stored. Then all menu

LEDs will flash repeatedly and the system will reboot after 3 seconds.

Move rudder stick

left or right

5. BASIC HELI SETUP (SETUP MENU)

Status LED lights up

blue or purple

Operation mode

Then enter SETUP MENU for making the basic adjustments

Setup menu point A- Device orientation (Menu LED A solid lit up)

Check the selected device orientation and change it if necessary by (repeatedly) moving the rudder stick into one direction

until the Status LED color corresponds to the real device orientation. Then briefly push the button to save the setting and

to proceed to the next menu point.

Operation mode

(Status LED blue or purple)

Press and hold (!) button

Menu LED Aflashes

(= PARAMETER MENU A)

Keep button pressed

for 2 seconds

Menu LED Alights solid

(= SETUP MENU A)

Release button when

LED Astops flashing

Status LED shows currently

selected device orientation Status LED shows currently

selected device orientation Menu LED Bsolid

(= SETUP MENU B)

Press button briefly

Status LED changes color/state

(= Changing device orientation)

Calibration of

radio channels

Do not move sticks on

the radio!

Calibration of sensor

rest positions

Do not move the

helicopter!

Firmware version: 5.0.x

After power up or finishing RECEIVER MENU adjustment wait until the system has initialized

Status LED off* Status LED

flashing purple Status LED purple Status LED

flashing red

Large socket points

to nose of the heli

Status LED red Status LED

flashing blue Status LED blue Status LED flashing

red/blue

Large socket points

to tail of the heli

Status LED shows current

swashplate update frequency SETUP MENU C

Press button briefly

Status LED shows current

swashplate servo frame rate

Status LED purple ashing red red ashing blue blue

BSwashplate update rate 50 Hz* 65 Hz 120 Hz 120 Hz 200 Hz

CRudder servo pulse width 760 µs - 960 µs - 1520 µs*

DRudder update rate 50 Hz* 120 Hz 270 Hz 333 Hz (560 Hz)

If you don‘t know the which update rate is best for your servos never use more than 50Hz.

The higher the update rate the better it is for the flight performance of MICROBEAST PLUS but you must check the servo specifications

before increasing the update rate. Otherwise the servos may get damaged! For a list with parameter examples for most common servo

types see WIKI.BEASTX.COM.

Always use 1520 µs rudder servo pulse width except you‘re using a very special type of rudder servo with reduced pulse width (only these

servo can be used with an increased update rate of 560 Hz!). Check the servo data sheet!

...

Move rudder stick

left or right

Status LED changes color/state

(Changing swash servo frame rate)

Flight direction

Setup menu points B, Cand D

Adjust swashplate update rate (B), rudder servo pulse width (C) and rudder update rate (D) again by moving the rudder

stick to one or another direction until the Status LED lights in the correct color necessary for the servos used in your helicopter.

Briefly pressing the button will store the selected option and skip to the next menu point.

Menu LED Esolid

Status LED off Use rudder stick to move the servo to

the maximum allowed deflection Release rudder stick Status LED

blue or red

Use rudder stick to move the servo to the

minimum allowed deflection Release rudder stick Status LED

purple

Press button briefly

Menu LED Fsolid

(= SETUP MENU F)

Setup menu point E- Rudder servo limit

Plug the rudder servo connector into [CH4] output of MICROBEAST PLUS. Put the servo arm on the servo so that it forms

roughly an angle of 90 degrees with the rudder linkage rod and adjust the length of the linkage rod as described in the

helicopter manual.

Push and hold the rudder stick into one direction to move the rudder servo and release the stick when the servo reaches the

maximum or mimimum allowed servo throw. Using the rudder stick you can reposition the servo at any time to adjust the

exact servo limit. If you do not touch the rudder stick for several seconds the current servo position will be saved as maximum

or minimum (the Status LED will flash and then light up solid in blue or red color). Then move the servo to the opposite

direction, adjust as described above and wait until also this position gets stored (now Status LED becomes purple).

Setup menu point F- Rudder direction

1. Move the rudder stick and check the rudder direction on the helicopter

Correct Wrong

Rudder stick to the right

Tail rotor pushes tail left, so heli turns to right. Tail rotor pushes tail right, so heli turns to left.

If the stick is moving the servo into the wrong direction use

the servo reverse function of your transmitter and reverse

the rudder channel to change stick control direction.

2. Now set the rudder direction of the MICROBEAST PLUS gyro

When you move the rudder stick to the right, the Status LED must light up or flash in blue color. When you move the rudder stick to the

left, the Status LED must light up or flash in red color. When the display is inverted (red = right and blue = left) reverse the display (internal

control direction) by tapping the aileron(!) stick once.

Status LED blue

Rudder stick to the right

Correct

Status LED red

Wrong

Tap aileron stick to

swap colors

3. Optional: When you move the rudder stick to full deflection, the Status LED should light solid, not just flash. If this is not the case, increase

the servo throw/endpoint of the rudder channel in the transmitter just as far so that the Status LED changes from flashing to solid

when the rudder stick reaches the end position. Note: Do not increase the endpoint too much in the transmitter. We need an exact

match of full stick position and stick end position, the Status LED should just change from flashing to solid when reaching the end position.

Always set servo direction in the transmitter rst, then check the display on the MICROBEAST PLUS or in the software and change the

internal control direction if it does not match the real direction. Do not change the internal direction in order to change the servo

direction! This is only used for telling the gyro in which direction it must move the servo. Be very conscientious when doing this

setup step, as wrong gyro direction will cause loss of control during takeo and you probably crash the helicopter!

For ALIGN ®T-Rex helicopters you can keep the default setting of 120 degrees electronic swash mixing (Status LED solid red).

Setup menu point F- Rudder direction

1. Move the rudder stick and check the rudder direction on the helicopter

Press button briey

Status LED changes color/state

(= changing mixing type)

Move rudder stick

left or right Status LED shows currently

selected mixing type

Status LED purple ashing red red ashing blue blue

G Swashplate mixing type mechanical 90° 120° 140° 135°/140° (1:1)

Setup menu point G- Swashplate mixing type

Status LED shows currently

selected mixing type

For ALIGN ®T-Rex helicopters you can keep the default setting of 120 degrees electronic swash mixing (Status LED solid red).

Never use any swashplate mixing in your transmitter even when electronic mixing is required!

Deactivate the swashplate mixing in your transmitter or set it to mechanical mixing (which is often called “normal“, “H1“ or ”1 servo“

mixing), so that each stick function only moves one receiver output channel. The swashplate mixing is all done by MICROBEAST PLUS!

In the following connect the servos to the outputs marked with CH1 to CH3 (CH7) as shown below. With electronic swashplate

mixing the two aileron servos have to be connected to CH2 (=left) and CH3 (=right). With a mechanical mixed head (H1) the

aileron servo connects to CH2 and collective pitch servo to CH3. Plug the the elevator servo into CH1 port. When using a scale

helicopter with 90 degrees eCCPM you can connect a second elevator servo to CH7 output on the MICROBEAST PLUS. Note

that CH7 only is a signal output, so you must power the servo from elsewhere, i.e. by getting power from the SYS-port or CH5

using a Y-adapter (for + and - only!).

CH1

120°

CH1

CH2CH3

140°

CH1

CH2CH3

Flight direction

90°

CH1

CH H3

2C

H3CH

mCCPM eCCPM

Servo 1

Elevator

Servo 2

Aileron

Servo 3

Aileron 2/Pitch (mCCPM)

top

(CH7)

CH2

Servo 4

Elevator 2

(90° eCCPM)

When you route the wire leads in your model make sure that there is no tension passed to the MICROBEAST PLUS. Make sure that MICROBEAST PLUS

is able to move freely, so no vibrations get passed onto the unit by the wire leads. Do not use any shrink tubing or fabric hose to bundle or encase the

wiring in close proximity to the point at which the cables are plugged into the MICROBEAST PLUS. This makes the cables stiff and inflexible and can cause

vibrations being transmitted to MICROBEAST PLUS.

When you‘ve perfectly adjusted the servos now

adjust the linkage rods going from servos to

the swashplate and from the swashplate to the

blade grips. The swashplate must be leveled and

centered on the main shaft and the bladegrips

should be set to 0° of pitch.

Anti-rotation guide leveled

horizontally and twisted

correctly

Swashplate leveled horizontally

0° pitch

Swashplate centered

vertically on main shaft

Status LED o

(= no servo active)

Choose one of the servos connected at

CH1 - CH3 (CH7)

Tap aileron stick

left or right

to choose servo

Move rudder stick to adjust servo

center position

If necessary adjust the swashplate anti-rotation

guide so that the swashplate phasing is not

shifted (only applies to 2-blade rotorheads).

Linkage balls of swashplate

outer ring and blade grips

must be on one line

Setup menu point H- Swashplate servo trim

At SETUP MENU point H we trim the servo center positions so that each servo horn forms an exact 90 degrees angle with the

adjustment linkage. This is necessary as usually you will not be able to attach the servo horns in exact center position to the

servo. After all servos have been trimmed do not proceed to the next menu point yet. With active trimming adjust the linkage

rods according to your helicopter‘s manual.

Initially when the trimming is 0 on all servos the Status LED will be o. Attach the servo horns in center position as good as

possible. By tapping the aileron stick you can select one servo after another. Every color of the Status-LED is corresponding to

a specic servo channel that is indicating its selection by a short up and down move. Use the rudder stick to change the servo

trimming/adjust the center position. You can switch back and forth between the servos as often as you need.

Hint: To reset the servo trims push and hold the button for at least 10 seconds.

CH1

CH2CH3

Setup menu point I- Swashplate servo directions

Move the thrust stick and check whether all servos push the swashplate up and down simultaneously. If this is not the case by

tapping the aileron stick you can select one servo after another. Every color of the Status-LED is corresponding to a specic

servo channel that is indicating its selection by a short up and down move. Tap the rudder stick once to change the servo

direction. You can switch back and forth between the servos as often as you need.

After adjusting servo directions make sure that the pitch direction is correct! You can either do this by setting the servo

directions correctly right from the beginning or by changing the direction of the pitch channel in the transmitter later.

Please note: It‘s not possible to reverse the servos with the servo reverse function of your transmitter! The transmitter only controls the

functions of MICROBEAST PLUS, not the servos! Reversing a channel in the transmitter will reverse the control function in total, not the

direction of a single servo (except when using mCCPM swashplate mixing).

Setup menu point H- Swashplate servo trim

At SETUP MENU point H we trim the servo center positions so that each servo horn forms an exact 90 degrees angle with the

adjustment linkage. This is necessary as usually you will not be able to attach the servo horns in exact center position to the

servo. After all servos have been trimmed do not proceed to the next menu point yet. With active trimming adjust the linkage

rods according to your helicopter‘s manual.

Initially when the trimming is 0 on all servos the Status LED will be o. Attach the servo horns in center position as good as

possible. By tapping the aileron stick you can select one servo after another. Every color of the Status-LED is corresponding to

a specic servo channel that is indicating its selection by a short up and down move. Use the rudder stick to change the servo

trimming/adjust the center position. You can switch back and forth between the servos as often as you need.

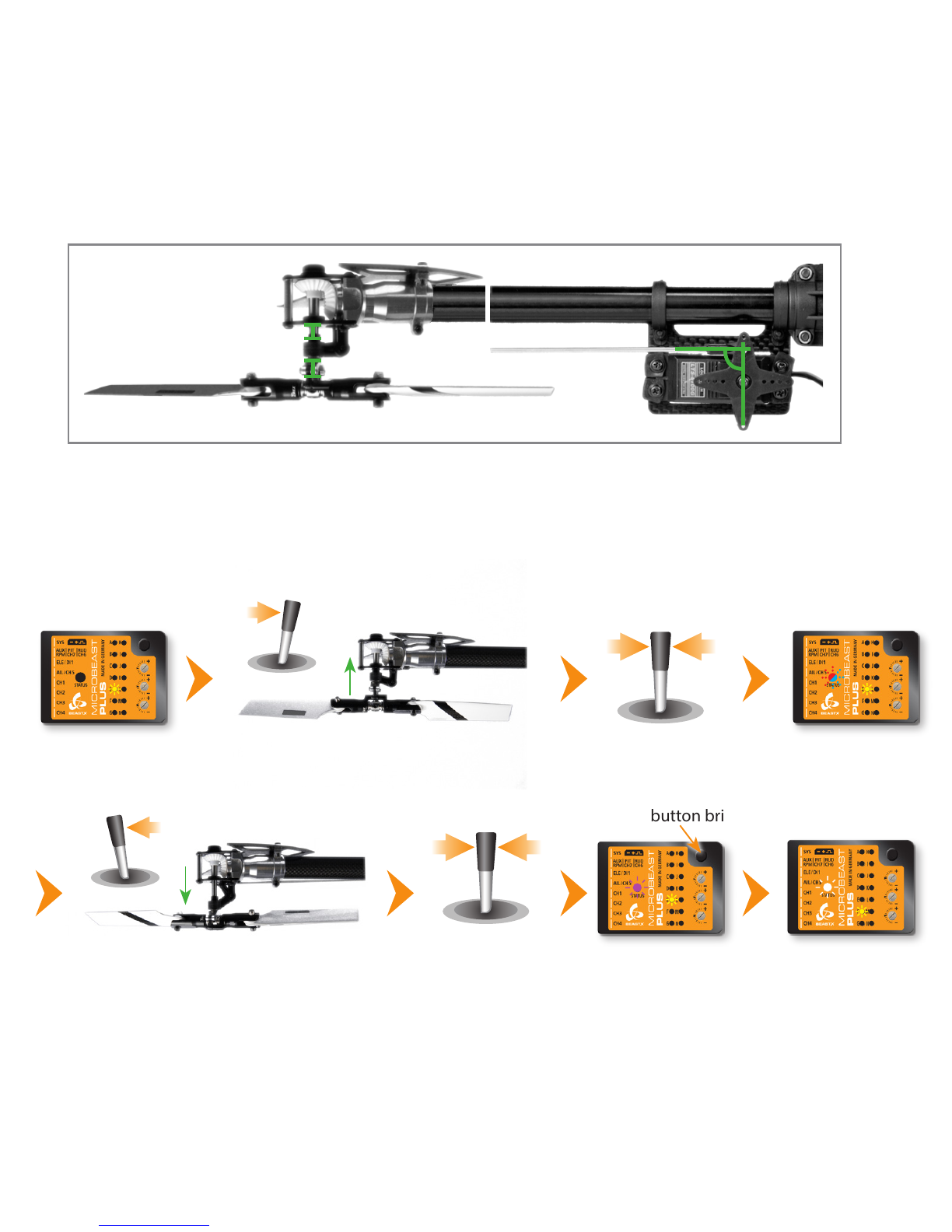

Setup menu point J- Swashplate servo throw

At SETUP MENU point J we adjust the internal servo throw so that MICROBEAST PLUS has a reference on how far it must move

the servos when controlling the helicopter. To set the throw you have to align one rotorblade on the longitudinal axis (in

parallel to the tail boom) and measure the cyclic pitch with a digital pitch gauge on this rotorblade.

Hint: To reset the servo trims push and hold the button for at least 10 seconds.

Move thrust stick

up and down

Tap aileron stick

left or right

to choose servo

Correct Wrong

Tap rudder stick

left or right

to reverse servo

CH1

CH2CH3

Tap aileron stick to

switch to measure

position

Menu LED Jsolid

Status LED o

Status LED should be solid blue

(see instruction manual for

further details on the LED colors)

Setup menu point K- Collective pitch

3. Now use rudder stick to

adjust maximum positive

collective pitch (i. e. +12°)

0°

+12°

Move thrust stick to

maximum positive pitch

and let it stay there

6°

Use rudder stick to adjust

blade pitch to exact

exact +6 or -6 degrees

Status LED blue

Correct

Status LED red

Wrong

Tap aileron stick

once to swap colors

2. The Status LED must light solid, not just flash. If this is not the case, increase the

servo throw/endpoint of the pitch channel in the transmitter just as far so that

the Status LED changes from flashing to solid when the rudder stick reaches

the end position. But do not increase the endpoint too much in the transmitter!

We need an exact match of full stick position and stick end position, the Status LED

should just change from flashing to solid when reaching the end position.

1. Set internal control direction

4. Finally move thrust stick to

full negative position and

repeat steps 2. and 3. for the

negative pitch.

Do not change control

direction anymore!

Setup menu point M- Swashplate control directions

Menu LED Lsolid Move thrust, aileron and

elevator sticks carefully to

maximum deection!

Use rudder stick to

adjust the servo limit

Status LED should be solid

blue (see instruction

manual for further details)

Setup menu point L- Swashplate servo limit

You can remove the pitch gauge now! Simultaneously move the sticks for thrust, aileron and elevator to the maximum

deection and check if the servos, swashplate or linkages get jammed in a certain position. By pushing and holding the

rudder stick left or right you can increase or decrease the limit for the servos! Adjust the limit so that the servos just don‘t get

jammed in any possible stick position but don‘t limit the servos more than necessary.

Elevator forward

Aileron to the right Status LED blue

Correct

Status LED red

Wrong

Tap rudder stick

until color is correct Status LED purple

Wrong

There are four possible options, only one is correct!

1. If not already done, move the stick(s) for aileron and elevator on the radio and check whether the swashplate is moved in the correct

directions on the helicopter.The swashplate must follow the stick movement: pushing elevator forward will tilt the swashplate forwards,

adding aileron to the right will move the swash to the right and so on. If the stick is moving the swashplate into the wrong direction

use the reverse function of your transmitter and reverse the aileron and/or elevator channel to set stick control direction correctly.

2. Now set the internal control direction of the MICROBEAST PLUS gyro

When you‘re using the Headspeed Governor of MICROBEAST PLUS now connect the RPM sensor (i. e. magnetical, optical or

brushless phase sensor) or the wire for RPM signal of your ESC to the white sensorport on the long side. For this you may need

the optional available BXA76401 adapter.

Setup menu point N- Internal Headspeed Governor

This menu point is only accessible if you‘re not using a Standard type receiver! Otherwise pressing the button at menu point

Mwill exit the menu and lead back to operation mode.

Enable the Headspeed Governor function by choosing the type of drive system of your helicopter. If you‘re using the governor

function of the ESC or an external governor or if you want to y without headspeed governing at all, choose „Governor o“.

Status LED shows current RPM

Governor mode

Press button briey

Status LED changes color

(= changing RPM Governor mode)

Move rudder stick

left or right Status LED shows current RPM

Governor mode

Status LED o red blue

N Internal Governor Governor o* electric heli nitro/gas heli

ESC

Speed controller

connected to CH5

Throttle servo

connected to CH5

Magnetical sensor

mounted close to

clutch bell of motor

Other manuals for MICROBEAST PLUS

2

This manual suits for next models

4

Table of contents

Other Beastx Accessories manuals