BECKWITH ELECTRIC M-0420 User manual

i

TABLE OF CONTENTS

TABLE OF CONTENTS

M-0420 Multifunction Relay

Instruction Book

Chapter 1 Introduction

1.1 Foreword ................................................................................................ 1–1

1.2 Before You Begin ................................................................................... 1–2

1.3 Configuration As Shipped ...................................................................... 1–2

1.4 Description ............................................................................................. 1–3

1.5 Design Considerations........................................................................... 1–5

1.6 User Considerations .............................................................................. 1–7

1.7 Options ................................................................................................... 1–8

1.8 Accessories ............................................................................................ 1–9

1.9 References ............................................................................................. 1–9

Chapter 2 Application

2.1 Protective Applications .......................................................................... 2–1

Islanding Protection (81U, 81O, 27, 59) ............................................... 2–1

Ferroresonance Protection (59I) ........................................................... 2–1

Utility-Side Ground Fault Protection and Phase Voltage

Unbalance Protection (27N, 59N) ......................................................... 2–2

Phase Fault Protection (51V, 67) .......................................................... 2–2

Directional Power (32F, 32R) ................................................................ 2–2

Anti-Motoring Protection (32R) .............................................................. 2–2

Ground Fault Protection (59N, 51N, 50N) ............................................ 2–2

Negative Sequence Overcurrent Protection (46) ................................. 2–3

Backup Phase Fault Protection (51VC/VR) .......................................... 2–3

VT Fuse-Loss Protection (60FL) ........................................................... 2–3

Power OK Status ................................................................................... 2–3

2.2 Trip Configuration vs. Applications ....................................................... 2–3

2.3 Intertie Protection ................................................................................... 2–4

2.4 Generator Protection.............................................................................. 2–7

2.5 Setpoints............................................................................................... 2–11

2.6 Functions .............................................................................................. 2–12

81O/81U Over Frequency/Under Frequency ................................... 2–12

59/27 Overvoltage/Undervoltage ...................................................... 2–13

59I Peak Overvoltage........................................................................ 2–14

ii

M-0420 Instruction Book

59N/27N Overvoltage/Undervoltage,

Neutral Circuit or Zero Sequence ....................................................... 2–15

Ground Fault Detection Using 59N and Broken-Delta VTs ............... 2–16

Ground Fault Detection Using 27N and 59N with One VT ................ 2–17

51V Inverse Time Overcurrent, Three-Phase

with Voltage Control or Voltage Restraint........................................... 2–18

51N Inverse Time Overcurrent, Neutral Circuit................................ 2–24

50/50N Instantaneous Overcurrent,

Three-Phase and Neutral Circuits ....................................................... 2–25

46 Negative Sequence Overcurrent ................................................. 2–26

32 Directional Power, Three-Phase.................................................. 2–28

67 Phase Directional Overcurrent Option ........................................ 2–30

79 Reconnect Time Delay................................................................. 2–32

60FL VT Fuse-Loss Detection .......................................................... 2–33

2.7 Fault Recorder ..................................................................................... 2–33

Chapter 3 Front Panel Controls

3.1 Introduction............................................................................................. 3–1

3.2 Target/Status Indicators and Controls .................................................. 3–3

3.3 Serial Interfaces (COM1 and COM2).................................................... 3–3

Chapter 4 Operation

4.1 Introduction............................................................................................. 4–1

4.2 Software Flow ........................................................................................ 4–1

Power-On Self-Test and Status Screens .............................................. 4–1

Default Message Screens ..................................................................... 4–1

Access Screens ..................................................................................... 4–5

Menu Flow .............................................................................................. 4–5

4.3 Moving Between Menus ........................................................................ 4–5

4.4 Entering Values ...................................................................................... 4–5

4.5 Access Codes ........................................................................................ 4–8

4.6 Enabling and Disabling Relay Functions .............................................. 4–8

Chapter 5 Menu Reference

5.1 Introduction............................................................................................. 5–1

5.2 Relay Functions ..................................................................................... 5–1

5.3 Review Setpoints ................................................................................... 5–2

5.4 Monitor Status ........................................................................................ 5–2

5.5 Configure Relays.................................................................................... 5–3

5.6 View Target History ............................................................................... 5–4

5.7 Fault Recorder ....................................................................................... 5–4

5.8 Read Counter ......................................................................................... 5–5

iii

TABLE OF CONTENTS

5.9 Communication ...................................................................................... 5–5

5.10 Setup Unit............................................................................................... 5–6

5.11 Exit Local Mode ..................................................................................... 5–7

5.12 Menus ..................................................................................................... 5–8

Chapter 6 Installation

6.1 Initial Setup Procedure .......................................................................... 6–1

6.2 Commissioning Checkout ...................................................................... 6–2

6.3 DIP Switches .......................................................................................... 6–4

6.4 Mechanical/Physical Dimensions .......................................................... 6–6

6.5 Suggested VT Connections ................................................................. 6–10

6.6 UL-Listed Terminal Block Connections ............................................... 6–10

Chapter 7 Test Procedures

7.1 Introduction............................................................................................. 7–1

7.2 Unit Setup............................................................................................... 7–1

7.3 Equipment Required .............................................................................. 7–2

7.4 Test and Equipment Setup .................................................................... 7–2

7.5 Diagnostic Test Procedures .................................................................. 7–5

Output Test ............................................................................................ 7–5

Input Test ............................................................................................... 7–6

LED Test ................................................................................................ 7–7

Button Test ............................................................................................. 7–7

Display Test ........................................................................................... 7–8

Backlight Test......................................................................................... 7–8

COM1 Test ............................................................................................. 7–9

COM2 Test ............................................................................................. 7–9

Other Diagnostic Mode Commands .................................................... 7–10

Power-On Self-Test ............................................................................. 7–11

59 RMS Overvoltage, 3-Phase ......................................................... 7–12

59N RMS Overvoltage, Neutral Circuit or Zero Sequence.............. 7–14

59I Peak Overvoltage........................................................................ 7–16

27 RMS Undervoltage, 3-Phase ....................................................... 7–18

27N RMS Undervoltage, Neutral Circuit or Zero Sequence............ 7–20

60 FL V.T. Fuse Loss Detection ....................................................... 7–22

81O Over Frequency ......................................................................... 7–23

81U Under Frequency ....................................................................... 7–24

50 Instantaneous Overcurrent, 3-Phase .......................................... 7–25

50N Instantaneous Overcurrent, Neutral ........................................ 7–26

51 Inverse Time Overcurrent, 3-Phase ............................................ 7–28

51VC Inverse Time Overcurrent with Voltage Control, 3-Phase ... 7–30

51VR Inverse Time Overcurrent with Voltage Restraint, 3-Phase 7–32

51N Inverse Time Overcurrent, Neutral ........................................... 7–34

46 Negative Sequence Overcurrent ................................................. 7–35

67 Phase Directional Overcurrent .................................................... 7–36

32F Directional Power, Forward Power, 3-Phase............................ 7–38

iv

M-0420 Instruction Book

32R Directional Power, Reverse Power, 3-Phase ........................... 7–40

79 Reconnect Time Delay................................................................. 7–42

7.6 Self-Calibration Procedure................................................................... 7–43

Test Equipment .................................................................................... 7–43

Test Setup ............................................................................................ 7–43

Calibration Procedure .......................................................................... 7–44

Chapter 8 Design Changes

8.1 Introduction............................................................................................. 8–1

8.2 Host Processor Software Versions ....................................................... 8–1

Appendix A Theory of Operation

A.1 Introduction............................................................................................. A–1

A.2 System Block Diagram .......................................................................... A–2

A.3 Discrete Fourier Transform ................................................................... A–3

Estimation of RMS Value of the Signal................................................. A–4

Instantaneous Peak Voltage.................................................................. A–5

Estimation of the Fundamental Frequency ........................................... A–5

Calculation of Sequence Components .................................................. A–6

Calculation of Power/Power Factor ....................................................... A–6

Implementation of Inverse Time Overcurrent Relay Curves................ A–7

A.4 Acknowledgments .................................................................................. A–7

A.5 References ............................................................................................. A–7

Appendix B Self-Test Error Codes

Appendix C Communications

C.1 Introduction............................................................................................. C–1

C.2 The BECOCOM®Protocol..................................................................... C–1

C.3 Communication Ports............................................................................. C–1

C.4 Direct Terminal Communications via COM1......................................... C–2

Procedure for Terminal Communications via COM1............................ C–2

Appendix D Printed Circuit Board Interconnections

Appendix E Configuration Record Forms

v

TABLE OF CONTENTS

Figures Page

Chapter 1 Introduction

1-1 Traditional Relaying vs the M-0420 Multifunction Relay ...................... 1–4

1-2 M-0420 Block Diagram .......................................................................... 1–6

1-3 M-0420 Functional Diagram .................................................................. 1–6

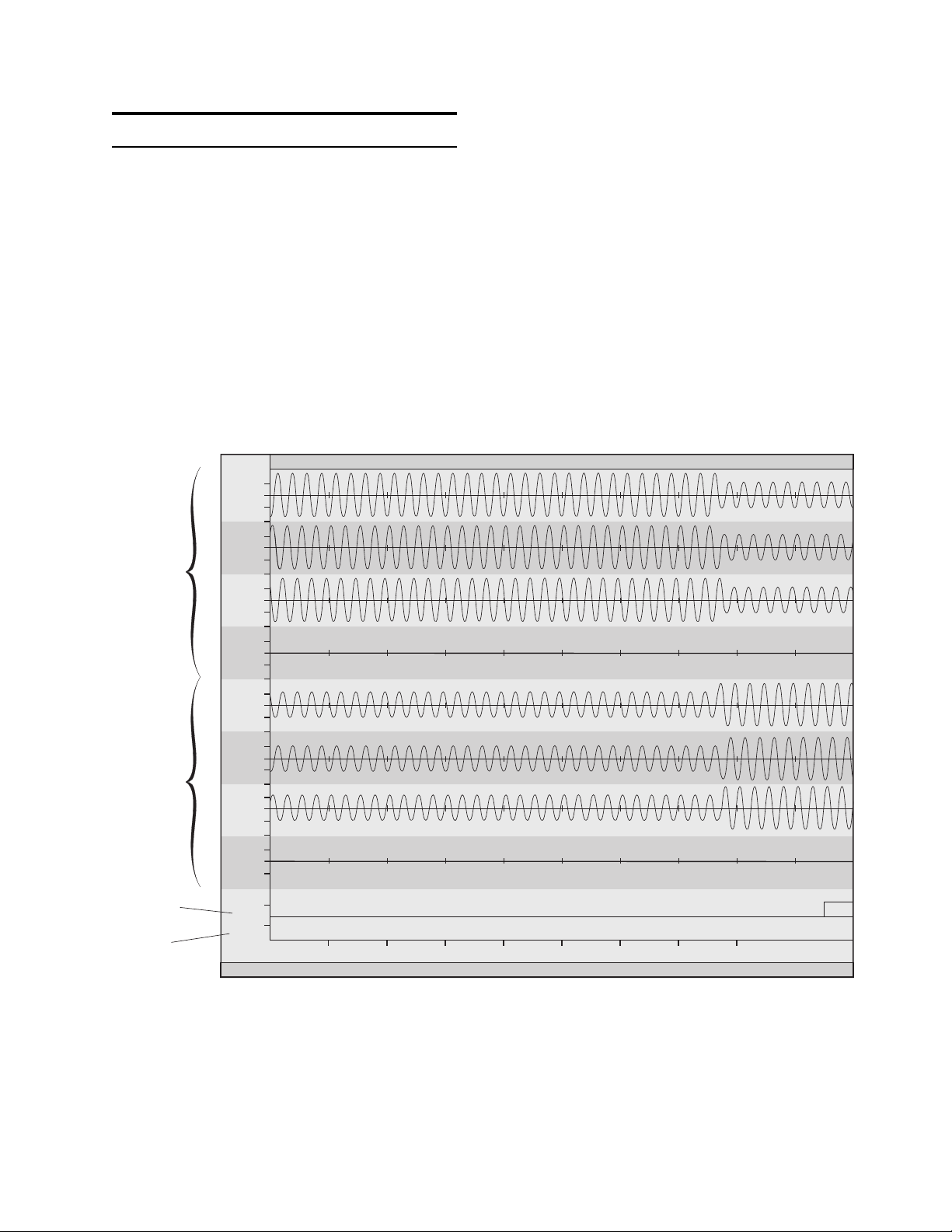

1-4 M-0428A BECOPLOT™ Fault Data Analysis Software Output ........... 1–8

Chapter 2 Application

2-1 Intertie Protection – Typical One-Line Diagram ................................... 2–4

2-2 Intertie Protection – Typical Three-Line Diagram................................. 2–5

2-3 Intertie Protection – Trip Logic .............................................................. 2–6

2-4 Generator Protection – Typical One-Line Diagram .............................. 2–7

2-5 Generator Protection – Typical Three-Line Diagram ........................... 2–8

2-6 Generator Protection – Trip Logic ......................................................... 2–9

2-7 Example of Trip Characteristics: Over and Under Frequency ........... 2–11

2-8 Ground Fault Detection Using 59N and Broken-Delta VTs ............... 2–16

2-9 Ground Fault Detection Using 27N and 59N with One VT ................ 2–17

2-10 Voltage Restraint (51VR) Characteristic ............................................. 2–18

2-11 Definite Time Overcurrent Curve ........................................................ 2–20

2-12 Inverse Time Overcurrent Curve......................................................... 2–21

2-13 Very Inverse Time Overcurrent Curve ................................................ 2–22

2-14 Extremely Inverse Time Overcurrent Curve ....................................... 2–23

2-15 Negative Sequence Overcurrent Inverse Time Characteristic .......... 2–27

2-16 Phase Directional Overcurrent (67) Trip Characteristics ................... 2–31

Chapter 3 Front Panel Controls

3-1 M-0420 Front Panel ............................................................................... 3–2

Chapter 4 Operation

4-1 Software Flow ........................................................................................ 4–2

4-2 Power-on Self-Test and Status Screens............................................... 4–3

4-3 Default Message Screens ..................................................................... 4–4

4-4 Access Screens ..................................................................................... 4–6

4-5 Front Panel Operation ........................................................................... 4–7

vi

M-0420 Instruction Book

Chapter 5 Menu Reference

5-1 M-0420 Menu Flow, Version 4.01 Software ......................................... 5–8

5-2 Voltage Relay: RMS Overvoltage, 3-Phase (59) .................................. 5–9

5-3 Voltage Relay: Peak Overvoltage, 3-Phase (59I) .............................. 5–10

5-4 Voltage Relay: RMS Undervoltage, 3-Phase (27) .............................. 5–11

5-5 Voltage Relay: RMS Overvoltage Neutral Circuit or

Zero Sequence..................................................................................... 5–12

5-6 Voltage Relay: RMS Undervoltage, Neutral Circuit or

Zero Sequence (27N) .......................................................................... 5–13

5-7 Frequency Relay: Overfrequency (81O) ............................................. 5–14

5-8 Frequency Relay: Underfrequency (81U) ........................................... 5–15

5-9 Current Relay: Inverse Time Overcurrent, 3-Phase (51V) ................ 5–16

5-10 Current Relay: Phase Directional Overcurrent, 3-Phase (67) ........... 5–17

5-11 Current Relay: Inverse Time Overcurrent, Neutral (51N),

Instantaneous Overcurrent, Neutral (50N) ......................................... 5–18

5-12 Current Relay: Negative Sequence Overcurrent (46) ........................ 5–19

5-13 Power Relay: Forward Overpower (32F) ............................................ 5–20

5-14 Power Relay: Reverse Overpower (32R) ........................................... 5–21

5-15 Reonnect Relay (79) ............................................................................ 5–22

5-16 Review Setpoints ................................................................................. 5–23

5-17 Configuration of Phase Overcurrent Relay-67 Enabled ..................... 5–24

5-18 Example of Target History Screens .................................................... 5–27

Chapter 6 Installation

6-1 Internal Configuration DIP Switch–60 Hz ............................................. 6–5

6-2 Mounting Dimensions for GE L-2 Cabinet ............................................ 6–6

6-3 Mounting Dimensions for Westinghouse FT-41 Cabinet...................... 6–7

6-4 M-0420 Side View .................................................................................. 6–8

6-5 External Connections ............................................................................. 6–9

6-6 Connections for Wye-Wye Connected VTs ........................................ 6–10

6-7 Connections for Open-Delta Connected VTs ..................................... 6–10

6-8 Connections for Delta-Wye Connected VTs ....................................... 6–10

6-9 Wire Terminations for External Connection as Required

for UL Listing ........................................................................................ 6–10

vii

TABLE OF CONTENTS

Chapter 7 Test Procedures

7-1 Voltage Input Configuration ................................................................... 7–4

7-2 Current Input Configuration ................................................................... 7–4

7-3 Single-Phase Voltage Input Configuration for Calibration.................. 7–43

7-4 Single-Phase Current Input Configuration for Calibration .................. 7–43

Appendix A

A-1 System Block Diagram .......................................................................... A–2

A-2 Frequency Response of the DFT Algorithm ......................................... A–4

A-3 Phasor Diagram ..................................................................................... A–6

Appendix C

C-1 Null Modem Cable: M-0420 COM1 to PC (9-pin)................................. C–3

C-2 Null Modem Cable: M-0420 COM2 to PC (25-pin)............................... C–3

Appendix D

D-1 M-0420 Board Interconnections ............................................................ D–1

Appendix E Configuration Record Forms

E-1 Functional Configuration Record ........................................................... E–2

E-2 Voltage Relay Setpoint Configuration Record ...................................... E–3

E-3 Frequency Relay Setpoint Configuration Record ................................. E–4

E-4 Current Relay Setpoint Configuration Record ...................................... E–5

E-5 Power and Reconnect Relay Setpoint Configuration Record .............. E–6

E-6 Internal DIP Switch Configuration Record ............................................ E–7

viii

M-0420 Instruction Book

Tables Page

Chapter 1 Introduction

1-1 M-0420 Device Functions ...................................................................... 1–3

Chapter 2 Application

2-1 Current Transformer Placement Considerations for

Generator Phase-to-Phase Fault Protection....................................... 2–10

2-2 Over (81O) and Under (81U) Frequency Setpoint Ranges ............... 2–12

2-3 Overvoltage (59) and Undervoltage (27) Setpoint Ranges................ 2–13

2-4 Peak Overvoltage (59I) Setpoint Ranges ........................................... 2–14

2-5 Overvoltage (59N) and Undervoltage (27N) Setpoint Ranges .......... 2–15

2-6 Delta/Wye Transformer Voltage-Current Pairs ................................... 2–19

2-7 Inverse Time Overcurrent with Voltage Control/

Voltage Restraint (51VC/VR) Setpoint Ranges .................................. 2–19

2-8 Inverse Time Overcurrent Neutral (51N) Setpoint Ranges................ 2–24

2-9 Instantaneous Overcurrent (50) and Instantaneous Overcurrent

(50N) Neutral Setpoint Ranges ........................................................... 2–25

2-10 Negative Sequence Overcurrent (46) Setpoint Range....................... 2–26

2-11 Directional Power (32) Setpoint Ranges............................................. 2–29

2-12 Phase Directional Overcurrent (67) Setpoint Ranges ........................ 2–30

2-13 Reconnect Time Delay (79) Setpoint Ranges .................................... 2–32

Chapter 6 Installation

6-1 Internal Configuration DIP Switch ......................................................... 6–4

Chapter 7 Test Procedures

7-1 Initial Settings ......................................................................................... 7–3

7-2 Output Test Terminal Contacts ............................................................. 7–5

7-3 Input Test Terminal Contacts ................................................................ 7–6

7-4 LED Designations .................................................................................. 7–7

Appendix B Error Codes

B-1 Self-Test Error Codes ............................................................................ B–1

Appendix C Communications

C-1 Communication Port Signals ................................................................. C–2

C-2 Terminal Commands .............................................................................. C–2

800-0420-IB-05 04/01

1–1

Introduction – 1

1Introduction

1.1 Foreword ....................................................................................1–1

1.2 Before You Begin .......................................................................1–2

1.3 Configuration As Shipped ..........................................................1–2

1.4 Description .................................................................................1–3

1.5 Design Considerations...............................................................1–5

1.6 User Considerations ..................................................................1–7

1.7 Options .......................................................................................1–8

1.8 Accessories ................................................................................1–9

1.9 References .................................................................................1–9

1.1 Foreword

Beckwith Electric's multifunction protective relays

such as the M-0420 and M-0430 offer a number

of advantages to electric utilities seeking to opti-

mize their protective systems:

Self-Diagnostics –The relay is constantly

checking its own operation. If not functioning

correctly, it alerts the operator through an output

contact. In contrast, single-function electro-

mechanical relays must be tested periodically by

station maintenance personnel.

Fault Recording –The digital electronics in the

relay continuously record the waveform of the

voltage and current inputs, along with the status

contact inputs. When the breaker opens, as

indicated by the 52b contact, the waveform data

is stored in memory for later review when

investigating the cause of the trip.

Compact Size –The relay occupies a panel

space less than 8 inches wide and 21 inches high,

yet can operate fourteen protective functions.

Operation –All settings can be established or

changed using the front panel controls and

alphanumeric display.

Communication –Through a computer connec-

tion, all functions can be monitored and setpoints

changed by a PC-compatible computer, or by a

laptop PC plugged into the front panel.

Functions –The functions respond in the same

manner as do electromechanical relays, includ-

ing time delays, and the nomenclature is the same.

This Instruction Book provides details of the

installation and operation of the relay. Our team

of applications engineers stands ready to assist

you in applying this equipment to your electric

system. Please don't hesitate to call us at (727)

544-2326.

1–2

M-0420 Instruction Book

1.2 Before You Begin

The Beckwith Electric M-0420 Multifunction Re-

lay is a sophisticated relay applicable to a wide

variety of applications. While it has been careful-

ly designed to be easy to install and configure, if

you're a first-time user, we suggest that you ac-

quaint yourself with its operation in the following

manner:

•Read this Introduction for a general over-

view of the relay.

•Read Chapter 2, Application, for informa-

tion on using the relay to protect genera-

tors and to initiate appropriate breaker

commands in response to faults and abnor-

mal conditions.

•Refer to Chapters 3, Front Panel Controls

and 4, Operation, to familiarize yourself with

the layout and operation of the front-panel

controls.

•Refer to Chapter 5, Menu Reference, for

detailed information on the functions you will

be using in your application.

•Read Chapter 6, Installation, for mounting

dimensions, external connections, initial set-

up, and verification routines.

•Refer to Appendix E, Configuration Record

Forms for forms on which to record your

relay configuration and DIP switch settings.

•Refer to publication M-0429A BECOCOM®/

M-0428A BECOPLOT®User’s Guide for

information on configuring and interrogating

the relay via a personal computer running

the optional BECOCOM communications

software package, and for information on

plotting downloaded fault data via the optional

BECOPLOT software package.

The M-0420 Multifunction Relay Instruction Book

has been organized to address the needs of dif-

ferent parts of your organization. If you are re-

sponsible for verifying that the relay conforms to

specifications as received, please turn to Chap-

ter 6, Installation for initial setup, and to Chap-

ter 7, Test Procedures.

If you are responsible for the operation of the

relay in a specific application, please turn to Chap-

ter 2, Application, for information on enabling

specific functions and entering setpoints. If you

are responsible for the mechanical and electrical

installation of the relay, please refer to Chapter

6, Installation.

If you are interested in a description of the re-

lay's capabilities, please read this Introduction

thoroughly, and refer to Appendix A, Theory of

Operation, for more detailed information.

Please don't hesitate to call your local sales

representative or Beckwith's application engineers

(727-544-2326) for assistance in resolving any

problems.

1.3 Configuration As Shipped

You can become familiar with the basic opera-

tion of the relay before it is installed by connect-

ing it to the appropriate power input and setting

it up on a bench or desktop. Even without any

test voltages connected, you will be able to step

through the various menus and note the indica-

tions on the liquid crystal display (LCD) and the

various light-emitting diodes (LEDs). The formal

initial setup information is presented in Chapter

6, Installation, which includes Figure 6-5 show-

ing the external connections.

As shipped, the relay is in the following configu-

ration:

•the clock has been disabled

•the second setpoints on various functions

have been disabled, and do not appear on

the display

•the DIP switch (at bottom of inside case)

has been set as below; setting is also de-

tailed on the yellow or pink tag attached to

the equipment. (The yellow tag is for 60 Hz;

the pink tag is for 50 Hz.)

1)noitcelesresurofton(FFO

2)noitarbilacnahtrehtar,noitarepolamron(NO

3)edomcitsongaidnahtrehtar,noitarepolamron(NO

4)esahpynanodesnestnerruc/rewopesrever(NO

5)enil-ot-enilroftesstupniTV(NO

6)caV021siegatlovyradnocesTV(FFO

7)gatwolley-zH06siycneuqerfmetsys(FFO

)gatknip-ZH05siycneuqerfmetsys(NO

8)ylnotnenopmoclatnemadnufyb,SMR(FFO

1–3

Introduction – 1

•the 51 voltage control and voltage restraint

functions are disabled

•the access code feature is disabled

•options supplied with the equipment are noted

on the yellow or pink (50 Hz) tag. These

are:

phase directional overcurrent function

(device 67)

input voltage (120 V ac, 125 V dc,

48 V dc, 24 V dc)

neutral current input (nominal 5 A or

1 A)

•a set of replacement fuses is attached to

one of the handles. These fuses are mounted

on the internal PC board.

1.4 Description

The M-0420 Multifunction Relay is a

microprocessor-based unit that uses digital signal

processing technology to provide 14 different

protective relaying functions (see Table 1-1) in

one compact unit. The M-0420 is designed to

provide these functions in two basic applications:

generation, and generator/system interties. Within

these basic applications, the various devices in

the M-0420 can provide protection in cases of

islanding, ferroresonance, ground or phase faults,

generator motoring, and other abnormal operating

conditions. Internal relay functions are listed in

Table 1-1. The nomenclature follows the standards

of ANSI/IEEE Std. C37.2-1979, Standard Electric

Power Systems Device Function Numbers.

noitcnuF noitpircseD

72 esahp-3,egatlovrednUSMR

N72ecneuqeSoreZrotiucriClartueN,egatlovrednUSMR

23 dna)F23(drawroF,esahp-3,yaleRrewoPlanoitceriD

)R23(esreveR

64esahp-3,yaleRtnerrucrevOecneuqeSevitageN

05 esahp-3,yaleRtnerrucrevOsuoenatnatsnI

N05lartueN,yaleRtnerrucrevOsuoenatnatsnI

N15 lartueN,yaleRtnerrucrevOemiTesrevnI

V15 htiw,esahp-3,yaleRtnerrucrevOemiTesrevnI

tniartseRegatloVrolortnoCegatloV

95 esahp-3,yaleRegatlovrevOSMR

N95 oreZrotiucriClartueN,yaleRegatlovrevOSMR

ecneuqeS

I95 esahp-3,yaleRegatlovrevOkaeP

*76esahp-3,yaleRtnerrucrevOlanoitceriDesahP

97 yaleDemiTtcennoceR

O18ycneuqerfrevO

U18 ycneuqerfrednU

LF06noitceteDssoLesuF.T.V

lanoitpO*

Table 1-1 M-0420 Device Functions

1–4

M-0420 Instruction Book

Since all functions are incorporated into one pack-

age, much less panel space and panel wiring is

required than for individual relays, as illustrated

in Figure 1-1. You can set and examine all func-

tions via a menu-driven, 2-line by 24-character

LCD display or via remote communication access.

Once you reprogram a value, the new value is

placed in nonvolatile memory where it is unaf-

fected by a loss of power or other system distur-

bance.

The M-0420 Multifunction Relay includes multi-

ple output and status input contacts. It can be

powered by 24, 48, or 125 V dc, or by 120 V ac,

50/60 Hz power, and is rated according to ANSI/

IEEE C37.90 and C37.90.1. The relay includes

self-test diagnostics, internal calibration correc-

tion, communication capability via two RS-232C

ports, real-time display of system parameters, trip

targets, and capture of fault data that occur dur-

ing a system disturbance.

Figure 1-1 Traditional Relaying vs the M-0420 Multifunction Relay

AF

50/

51V

BF

BFCF

CF

Phase Voltage

Relay Functions

Phase Current

Relay Functions

81

O/U

32

3F

46

Directional Power

Relay Function

Reconnect Time

Delay

Relay Function

79

59I

50/51

N27/59

NPeak

Overvoltage

Relay Function

Negative Sequence

Current Unbalance

Relay Function

59I

Neutral

Voltage Current Relay

Functions

Over/Under

Frequency

Relay Function

AF

67

BF

67

CF

67

27/

59

AF

A B C

F

50/

51V 50/

51V

27/

59 27/

59

PRIDE

M0420

MULTIFUNCTIO

N

TARGETS

POWER

59

OVERVOLTAGE

27N

UNDERVOLTAGE

59N

OVERVOLTAGE

27

UNDERVOLTAGE

81O

OVERFREQUENCY

81U

UNDERFREQUENCY

Made in U.S.A.

50

INSTANTANEOUS

OVERCURRENT

51/67

OVERCURRENT

51N

OVERCURRENT

50N

INSTANTANEOUS

OVERCURRENT

32

DIRECTIONAL

OVERPOWER

46

NEGATIVESEQUENCE

OVERCURRENT

TARGETRESET/

LAMPTEST

SERIALINTERFACE

COM1

ENTER

SETPOINT

SELECT

FUNCTION

RELAYOK

ENTER

EXIT

PHASE ELEMENTS

NEUTRALELEMENTS

®

VOLTAGE RELAY

VOLT freq curr

FAULT

RECORDED BREAKER

CLOSED

CO.INC.

BECKWITH

ELECTRIC

➞

1–5

Introduction –1

1.5 Design Considerations

There are basically two approaches in the de-

sign of digital relays. In the first approach, the

microprocessor simply replaces the relay logic

and does not process the voltage and current

signals. The performance of these relays depends

on the accuracy of the analog components used,

and is subject to dc offsets and gain drift with

temperature, supply voltage changes, or aging.

In the second approach, the microprocessor both

processes the signals and performs the logic,

providing a simpler design and offering perfor-

mance advantages. The advent of low-cost digi-

tal signal processors (DSPs), microprocessors

designed especially for the efficient numerical

procedures required, paved the way for the de-

sign of a digital relay using state-of-the-art digital

signal processing techniques, thereby eliminat-

ing the problems inherent with analog hardware.

The Beckwith Electric M-0420 Multifunction Relay

follows this second approach: analog signal-

processing hardware is replaced with a DSP.

Various parameters of the input signals are

estimated using digital signal-processing

algorithms. The voltage and current input signals

of the relay are modeled as sinusoidal signals

corrupted by dc offset and harmonic components.

These signals can be characterized by various

parameters such as rms value, peak value, rms

value/phase angle, and frequency of the

fundamental component.

However, while DSPs are highly effective for signal-

processing applications, they are not very effi-

cient for general purpose applications and have

limited memory space. Therefore, the relay uses

a dual-processor architecture. The DSP executes

all the signal-processing algorithms, while a gen-

eral-purpose (host) processor manages input/

output and other overhead functions, monitors the

keyboard for operator requests, updates memo-

ries for setpoint values, facilitates operator inter-

action via the alphanumeric display, establishes

two-way communication using the RS-232C se-

rial ports, analyzes the data from the DSP, and

issues the trip commands.

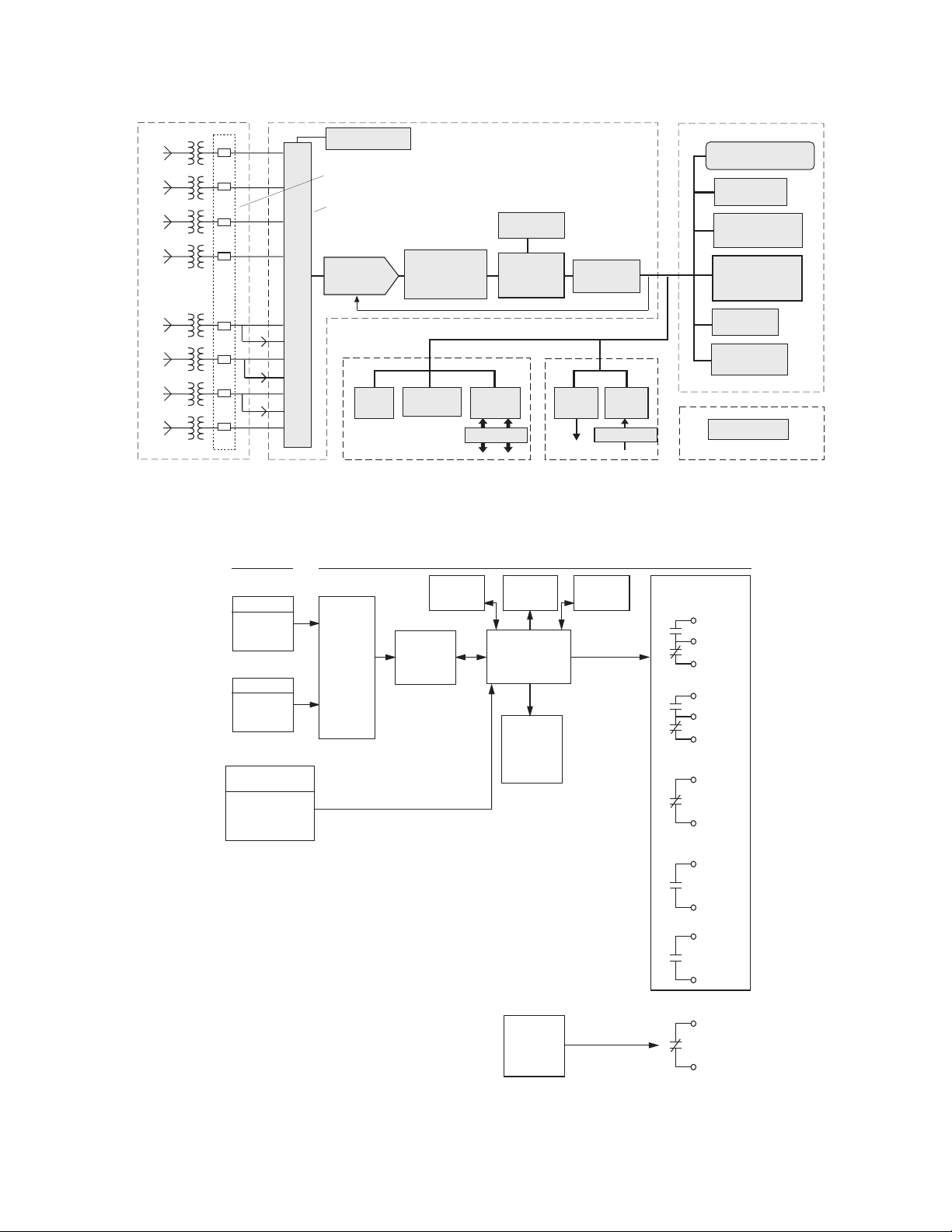

Figures 1-2 and 1-3 present a general overview

of the hardware design and functional operation

of the relay. As shown in these diagrams, the

inputs to the relay, filtered to remove higher or-

der harmonics, are multiplexed and then passed

through an Analog-to-Digital Converter (ADC) to

the DSP, which performs a discrete Fourier trans-

form (DFT) 16 times per cycle for each of the

inputs. The host processor performs all input/output

and overhead functions, including monitoring of

the status inputs, and ultimately analyzes the data

from the DSP to determine the need for a trip

command.

One significant design feature of the relay is

automatic correction of the sensing transformer

error caused by ambient temperature excursions.

Voltage transformers exhibit enough internal

resistance so that the internal regulation of the

transformer results in a significant error due to

changes in temperature. The relay includes a

temperature sensor mounted in the enclosure to

measure directly and accurately the internal

temperature of the relay. This temperature signal

is coupled through the ADC to the DSP, which

processes the information to determine the

appropriate factor required to correct the sensing

transformer error.

The relay uses an algorithm based on the DFT

to compute the frequency and to determine the

phase angle for real/reactive power measurements.

The algorithm uses voltage phasor estimates ob-

tained from the DFT to compute reliable estimates

of frequency unaffected by dc and harmonic com-

ponents in the signal. Additionally, deriving the

positive sequence voltage phasor from the DFT

means that the frequency function will continue

to operate should any single- or two-phase fault

occur.

1–6

M-0420 Instruction Book

Figure 1-2 M-0420 Block Diagram

VTs & CTs

2K byte

Dual-Ported

RAM

Digital Signal

Processor

(DSP)

TMS 32015

8K byte

ROM

12-bit

Analog-to-Digital

Converter

(ADC)

i

va

b

c

n

a

b

c

n

Programmable

Gain Amplifier

DSP Processor Board

Input Board

Host Processor Board

MUX

Address/Data Bus

128K byte Flash-

Programmable

ROM

Host Processor

10 MHz 64180

Front Panel Board

LED

Targets

Front-Panel

Controls RS 232

Serial I/O

Analog Multiplexer

Anti-Aliasing Low-Pass Filters (LPF)

Output Board

Relay

Outputs Contact

Inputs

2-Line by 24-Character

Liquid Crystal Display

32K byte RAM

EEPROM

RAM, Clock

10 Year

Lithium Battery

Power Supply Board

Power Supply

i

i

i

v

v

v

i'

a

b

c

i'

i'

Opto-Isolation Opto-Isolation

Temperature

Sensor

COM1 COM2

Figure 1-3 M-0420 Functional Diagram

ANALOG

INPUTS M–0420 MULTIFUNCTION RELAY

1. FILTERS

2. MUX

3. PGA

4. ADC

DIGITAL

SIGNAL

PROCESSOR

SERIAL

INTERFACE TARGETS USER

INTERFACE

HOST

PROCESSOR

RELAY

SETTINGS

IN

NON-

VOLATILE

MEMORY

OUTPUT

RELAYS

1.TRIP

2. RECON ENABLE

3. SELF TEST

ALARM

4.TRIP ANNUN

5. VT FUSE LOSS

POWER

SUPPLY

AC OR

DC

VO LTAGE

3-PHASES

1-NEUTRAL

CURRENT

3-PHASES

1-NEUTRAL

STATUS

INPUT

1. BREAKER

STATUS 52b

2. VT FUSE LOSS

6. PWR OK STAT

1–7

Introduction –1

1.6 User Considerations

In the design of the M-0420 Multifunction Relay,

careful consideration was given to making its use

as similar as possible to that of the traditional

protective relays that are still found throughout

typical power systems.

Ease of Use and Compatibility

In order to provide maximum compatibility with

existing equipment, care was taken that traditional

electromechanical nomenclature was used for

setpoint values and trip characteristics. For

example, the inverse time overcurrent functions

(devices 51 and 51N) use industry-accepted time-

curve families (Definite Time, Inverse, Very Inverse,

and Extremely Inverse) based on the ABB (formerly

Westinghouse) CO and COV curves. Within each

family, the operator selects the tap setting and

time dial setting just as though doing so on an

electromechanical relay.

The user-friendly controls and display provide easy

access to the various functions. The software is

completely menu driven through a liquid crystal

alphanumeric display (LCD). All functions and

values can easily be set using the front panel

buttons and the rotary knob.

Communication Capabilities

One of the important features of the relay is its

capability for remote communications. The relay

provides two RS-232C serial ports for communi-

cation via modem or direct serial connection. In

a typical communications application, the rear-

panel communication port is permanently con-

nected to a modem, while the front-panel port is

kept free for on-site programming via a laptop

computer.

Fault Recording and Analysis

The multifunction relay provides up to 96 cycles

of fault waveform data with selectable distribu-

tion of the time before and after the breaker trip.

This data can be downloaded via an MS-DOS

computer running the M-0429A BECOCOM®Com-

munications Software. Once downloaded, the data

can be analyzed using the associated M-0428A

BECOPLOT®Fault Data Analysis Software pack-

age.

The fault data analysis software runs on an

MS-DOS computer, enabling the user to plot fault

data, specifying which waveforms and inputs are

displayed, and at what scale. (The sample plot

shown in Figure 1-4 displays all waveforms.) A

marking feature enables the user to mark any

time span and zoom instantly to display it at full

screen, and specific points on the waveform may

be tagged in order to read actual waveform values.

Displayed plots can be printed using the DOS

Print Screen command.

Self-Diagnostics

To ensure confidence in the relay’s operation,

the system software provides many hardware and

software diagnostic checks, some of which are

performed continuously, and others on processor

reset. Should a failure occur, an output relay is

activated, and processing stops in order to prevent

mis-operation. Likewise, if system power fails, an

output contact closes.

Internal Calibration Correction

One of the most important and novel advantages

of the relay is its capability for correcting its

calibration through internal software. Most existing

static and microprocessor relays are designed

with a number of trim pots to trim the signal offsets,

and gain and phase inaccuracies. This can be a

time-consuming process, during both factory

calibration and routine calibration by the customer.

The relay does away entirely with trim pots for

calibration. The gain and phase angle errors are

computed using calibration coefficients stored in

nonvolatile memory. When the calibration mode

is selected, the relay display prompts the operator

to connect the voltage inputs to 120 V and the

current inputs to 5 A with zero phase angle between

the signals. Then, the relay computes the gain

and phase angle errors and stores the appropriate

correction coefficients for use by the relay software.

1–8

M-0420 Instruction Book

1.7 Options

In addition to the selectable power inputs of 24,

48, or 125 V dc/120 V ac (50 or 60 Hz), the relay

can provide the following optional functions:

67 Phase Directional Overcurrent

The relay is available with the phase directional

overcurrent function (67). In addition to the definite

time delay provided on the 67 function, the

directional element of the 67 function can be used

to provide directional control of the 51V function,

thereby realizing a directional inverse time

overcurrent function.

Neutral Current Input

The relay is available with a nominal neutral current

input of 5 A (standard) or 1 A (optional). When

the 1 A input option is chosen, the relay internally

scales the current by a factor of 5 and the settings

and status display work as though the 5 A nominal

neutral current is selected. With the 1 A neutral

current input, the current-related settings and status

display values should be divided by 5 to obtain

the actual current values.

H:Help X:Zmin x:Zmout Y:Zmin y:Zmout ->:Next <-:Prev C:Cursor R:Read Q:Quit

File: F ULT.D T Time Tag: 11/15/91 10:13:32

52b

1.2 pu

0.6

Va

0.6

1.2 pu

0.6

Vb

0.6

0.1 pu

0.05

Vn

0.05

4 pu

2

Ia

2

4 pu

2

Ic

2

0.4 pu

0.2

In

0.2

60FL

t me

(ms)

1 pu

0.5

Vc

0.5

1004.2 1058 1111.9 1165.7 1219.6 1273.4 1327.3 1381.1 1435 1488.9

4 pu

2

Ib

2

52b Breaker

Input Status

Fuse Loss

Currents

Voltages

Figure 1-4 M-0428A BECOPLOT®Fault Data Analysis Software Output

1–9

Introduction –1

1.8 Accessories

M-0319 Dropping Regulator

The M-0319 Dropping Regulator is a resistor/zener-

diode regulating device used to produce 125 V

dc from a 250 V dc battery source. The regulator

can be used to allow an M-0420 Multifunction

Relay with the 120 V ac/125 V dc power supply

option to operate from a 250 V dc source.

M-0421 PRIDE®Test Adapter

The M-0421 Test Adapter makes bench testing

the relay an easy process. The adapter provides

a complete set of rear terminals for testing the

unit after it has been removed from its draw-out

case.

M-0429A BECOCOM®Communications

Software Package

The BECOCOM communications software runs

on an MS-DOS computer, providing remote ac-

cess to the relay via either direct serial connec-

tion or modem. BECOCOM provides the following

communication functions:

•Setpoint interrogation and modification

•Line status real-time monitoring

•Downloading recorded fault data

BECOCOM also provides remote access to the

Beckwith Electric M-0430 Multifunction Relay.

M-0428A BECOPLOT®Fault Data Analysis

Software Package

The M-0428A BECOPLOT Fault Data Analysis

Software runs on any MS-DOS computer, enabling

you to plot and print fault data downloaded (us-

ing the BECOCOM communications software

package) from the M-0420 and M-0430 relays.

Figure 1-4 illustrates typical data output.

M-0422/M-0423 Serial Communications

Cables

The M-0422 cable is a 10 foot straight-through

RS-232 cable for use between the relay's rear-

panel (COM2) port and a modem. This cable has

DB25 (25-pin) connectors at each end.

The M-0423 cable is a 10 foot null-modem RS-232

cable for direct connection between a PC and

the M-0420 front-panel (COM1) port. This cable

has DB9 (9-pin) connectors at each end.

1.9 References

The references that follow provide additional in-

formation about the use of digital technology in

protective relaying. References 12 and 13 present

more detailed information about the design and

relay applications, and are available upon request

from Beckwith Electric Co., Inc.

[1]

Grid Interconnection Performance Require-

ments and Current Practice

. Gas Research

Institute, Topical Report 87-0117, 1986.

[2]

IEEE Guide for Interfacing Dispersed Stor-

age and Generation Facilities with Electric

Utility Systems

. ANSI/IEEE Std. 1001-1988.

[3]

Intertie Protection of Consumer-Owned

Sources of Generation

, 3 MVA or Less. IEEE

Publication 88TH0224-6-PWR.

[4] ANSI/IEEE C37.102-1987 “

IEEE Guide for

AC Generator Protection

.”

[5] M.S. Sachdev (Coordinator),

Microproces-

sor Relays and Protection Systems

. IEEE

Tutorial Text, 88EH0269-1-PWR.

[6] W.E. Feero, W.B. Gish, and C.L. Wagner,

“

Overvoltages on Distribution System Gen-

eration Separated from the Power Systems

,”

Final Report ERM-8701-07, April 1987, Elec-

tric Research and Management, Inc., State

College, PA, 16804.

[7] A.G. Phadke, J.S. Thorp, and M.G. Adami-

ak, “

A New Measurement Technique for

Tracking Voltage Phasors, Local System

Frequency, and Rate-of-Change of Frequen-

cy

.”IEEE Transactions on PAS, vol. PAS-

102, No. 5, May 1983, pp. 1025-1038.

[8] David M. Denison, “

Application of Digital Fault

Recorders on the Tampa Electric Company

System

,”44th Annual Protective Relaying

Conference, Georgia Institute of Technolo-

gy, Atlanta, Georgia, May 2-4, 1990.

[9]

Electric Utility Systems and Practices

, 4th

Edition, Homer M. Rustebakke, John Wiley

& Sons, 1983.

[10]

Protective Relaying, Principles and

Applications

, J. Lewis Blackburn, Marcel

Dekker, Inc., 1987.

1–10

M-0420 Instruction Book

[11] C.F. Henville, “

Relay Replacement and Up-

grading Projects

,”Canadian Electrical As-

sociation 1991 Spring Meeting, Toronto,

Ontario, May, 1991.

[12] Murty V. V. S. Yalla, Donald L. Hornak, “

A

Digital Multifunction Relay for Intertie and

Generator Protection

,”Canadian Electrical

Association 1992 Spring Meeting, Vancou-

ver, B.C., March 1992.

[13] Murty V. V. S. Yalla, “

A Digital Multifunction

Protective Relay

,”IEEE Transactions on

Power Delivery, Vol. 7, No. 1, January 1992,

pp. 193-201.

2–1

Application –2

2Application

2.1 Protective Applications ..............................................................2–1

2.2 Trip Configuration vs Applications ............................................2–3

2.3 Intertie Protection .......................................................................2–4

2.4 Generator Protection..................................................................2–7

2.5 Setpoints...................................................................................2–11

2.6 Function ....................................................................................2–12

81O/81U Overfrequency/Underfrequency...............................2–12

59/27 Overvoltage/Undervoltage.............................................2–13

59I Peak Overvoltage ..............................................................2–14

59N/27N Overvoltage/Undervoltage, Neutral Circuit

or Zero Sequence ....................................................................2–15

Ground Fault Detection Using 59N and Broken-Delta VTs ...2–16

Ground Fault Detection Using 27N and 59N with One VT ....2–17

51V Inverse Time Overcurrent, 3-Phase, with

Voltage Control and Voltage Restraint....................................2–18

51N Inverse Time Overcurrent, Neutral Circuit ......................2–24

50/50N Instantaneous Overcurrent, 3-Phase

and Neutral Circuit ...................................................................2–25

46 Negative Sequence Overcurrent ........................................2–26

32 Directional Power, 3-Phase................................................2–28

67 Phase Directional Overcurrent Option ...............................2–30

79 Reconnect Time Delay .......................................................2–32

60FL VT Fuse Loss Detection.................................................2–33

2.7 Fault Recorder .........................................................................2–33

2.1 Protective Applications

The sections that follow discuss briefly the principal

applications of the M-0420 Multifunction Relay in

intertie or generator protection. Section 2.6,

Functions, discusses the individual functions in

detail, presenting setpoint ranges, increments, and

the initial default settings.

Islanding Protection (81U, 81O, 27, 59)

When a dispersed source of generation (DSG) is

suddenly islanded, the frequency will quickly shift

from 60.0 Hz (except for the improbable case of

an exact generation and load match), making the

measurement of frequency an excellent means

of detecting the island condition. The relay provides

both under frequency (81U) and over frequency

(81O) functions. The relay also provides both rms

undervoltage (27) and rms overvoltage (59)

functions that can be useful in detecting islanding.

Each has two setpoints with time delays from 1

to 8160 cycles, and magnitude range settings from

10 to 200 V.

Ferroresonance Protection (59I)

Lightly loaded islanded systems can experience

ferroresonance, where the system is in resonance

but the inductance is highly nonlinear as the

transformer core cycles in and out of magnetic

saturation. Under these conditions, the voltage

waveform will be distorted to the extent that the

peak voltage of the non-sinusoidal wave can be

dangerously high. Since the peak overvoltage (59I)

2–2

M-0420 Instruction Book

function of the relay detects the value of the

instantaneously sampled wave, it can act in

situations where a relay reacting to rms voltage

would not. The setpoint range is from 1.05 to 1.50

per unit, with a time delay variable from 1 to 8160

cycles.

Utility-Side Ground Fault Protection and

Phase Voltage Unbalance Protection (27N,

59N)

The relay provides both rms undervoltage and

rms overvoltage functions for the neutral circuit

(27N and 59N). Used together with one VT con-

nected from any one phase to ground, the 27N

and 59N devices are an effective means of de-

tecting the most common line-to-ground fault. A

fault on the phase that includes the VT will pull

that phase voltage low and initiate operation of

the 27N function. A fault on either phase without

the VT will result in S3 x normal voltage appear-

ing at the VT, initiating operation of the 59N.

The 59N may also be used to detect system phase

voltage unbalance conditions in conjunction with

three VTs. To do so, the VT secondaries are con-

nected in broken delta and the 59N device in-

serted. In this case, voltage at the 59N will be

zero so long as the three-phase voltages are

balanced, but will rise above zero with any un-

balanced condition, as will occur with a utility line

or ground fault.

Implementation of the 27N and 59N functions pro-

vides two setpoints each with a range setting of

10 to 200 V and a time delay of 1 to 8160 cycles.

Phase Fault Protection (51V, 67)

Time overcurrent relays (51), one per phase, are

basic to any protection scheme. This is the main

device used to trip circuits selectively and time-

coordinate them with other up- or downstream

devices. Four complete series of inverse time trip-

ping characteristics from Definite Time to Extremely

Inverse (based on the ABB CO and COV curves)

are included in the relay.

For intertie protection applications, the optional

phase directional overcurrent function (67) allows

greater selectivity for utility system faults, since

the directional element can be set to look toward

the utility system. As a generator protection re-

lay, the 67 function, looking into the generator,

can provide protection against accidental energi-

zation of the generator on turning gear. When

line-side CT inputs are used, this function can

also provide high-speed protection against gen-

erator winding faults. However, with line-side CTs,

the protection against winding faults during off-

line operation (when the breaker is open) is not

available from the 51V, 50, 46, or 67 functions.

Calculation of the current used for tripping is a

unique feature of this relay. The current is derived

from an RMS calculation, but (by user selection)

can also be computed based on either including

or not including the contribution of harmonics to

the value. Since it is not well established by the

industry whether the calculation should be based

simply upon the fundamental frequency component

or a broader frequency range, a simple switch

setting allows the operator to select either one.

Directional Power (32F, 32R)

Implementation of the directional power function

is straightforward, issuing a trip command when

the magnitude of the power flow (in either direc-

tion as selected) exceeds the setpoint for the pre-

scribed time. However, as opposed to reverse

power relays that rely on zero crossings for phase

angle information, the relay power calculation uses

the fundamental frequency phasor measurements

obtained from the DFT, and thus is immune to

harmonics in voltage and current signals. The

setpoints for either direction range from 0.02 to

3.0 pu, with time delays from 1 to 8160 cycles.

Anti-Motoring Protection (32R)

When the energy supply to the prime mover is

cut off while the generator is still on line, the gen-

erator will act as a synchronous motor driving

the prime mover. A reverse power relay is used

to detect this motoring. Because the power re-

quired to motor is a function of the type of prime

mover, the required sensitivity of the reverse power

relay can vary widely for different applications.

The reverse power function provides 2% sensi-

tivity, making it applicable to many anti-motoring

situations. A time delay of up to 8160 cycles can

be set to avoid tripping during power swings.

Ground Fault Protection (59N, 51N, 50N)

Detection of ground faults in a high-impedance-

grounded unit generator can be accomplished by

an overvoltage relay in the generator neutral. For

good fault sensitivity, the pickup of the relay should

be about 10 to 16 V. However, because the third

harmonics which normally flow in the system and

Table of contents

Other BECKWITH ELECTRIC Relay manuals

BECKWITH ELECTRIC

BECKWITH ELECTRIC SYNCROCLOSER M-0188A User manual

BECKWITH ELECTRIC

BECKWITH ELECTRIC M-0245C User manual

BECKWITH ELECTRIC

BECKWITH ELECTRIC M-3520 User manual

BECKWITH ELECTRIC

BECKWITH ELECTRIC Syncrocloser M-3410A User manual

BECKWITH ELECTRIC

BECKWITH ELECTRIC M-0127A User manual

BECKWITH ELECTRIC

BECKWITH ELECTRIC Syncroclosure M-0193B User manual

BECKWITH ELECTRIC

BECKWITH ELECTRIC M?3311A User manual

BECKWITH ELECTRIC

BECKWITH ELECTRIC M-0236B User manual

BECKWITH ELECTRIC

BECKWITH ELECTRIC M-3425A User manual