–1–

1.0 Introduction

The Beckwith Electric M-0245C is a solid-state device

specifically designed to respond to changes in the

phase angle between two input voltages. When the

line voltage input is within the UPPER and LOWER

VOLTAGE LIMIT dial settings, and the phase angle

between the line voltage and the motor bus voltage is

less than that set on the PHASE ANGLE LIMIT dial,

the device will permit breaker closing. If the phase

angle exceeds the control setting, the device will

block closing within one cycle; i.e., if the limit is 30°,

the unit will inhibit closing within one cycle of the time

when the phase angle exceeds 30°. If the phase

angle returns within the 30° limit, the unit will enable

closing within one cycle.

Using advanced, state of the art semiconductors and

circuits, the Beckwith Electric M-0245C achieves an

overall stability and resolution unattainable with other

techniques. Modern hybrid and monolithic

semiconductors are used to gain temperature stability

without critical compensation or trimming. Unique,

patented circuitry allows precise phase measurement

over a wide range of frequency, voltage and

temperature; while operating within ±1% of the

theoretical speed limit for phase measurement.

2.0 Theory of Operation

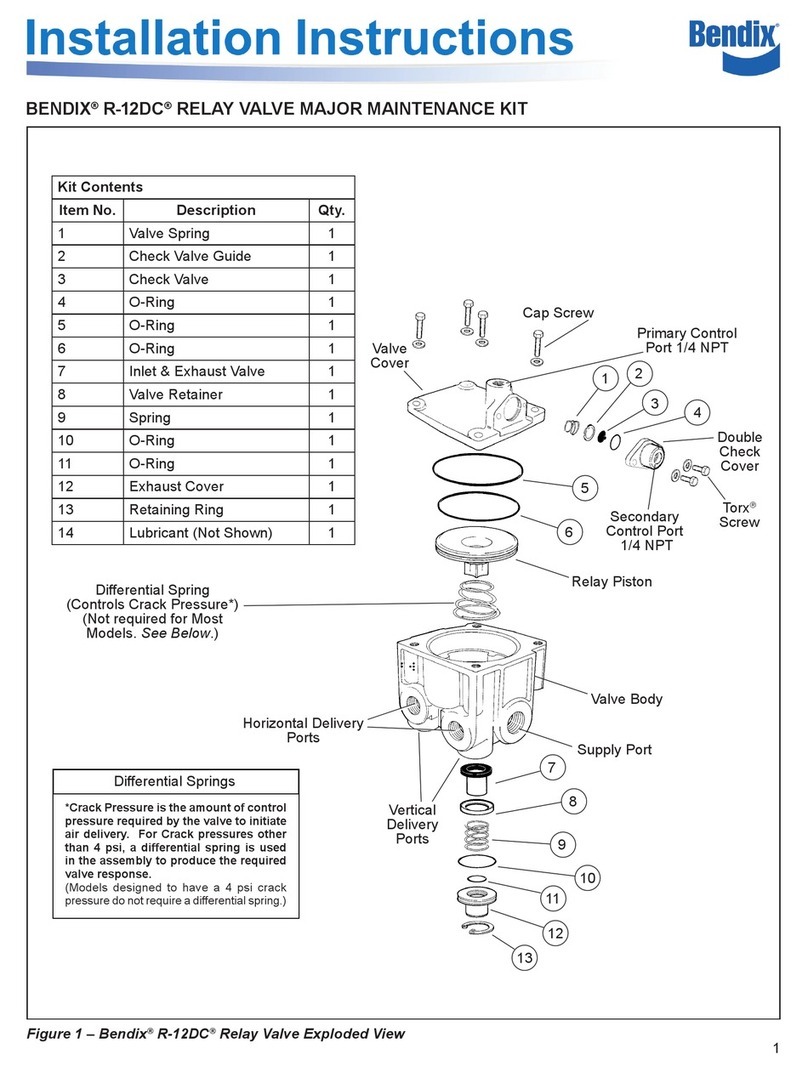

Refer to Figure 1, Block Diagram. Each input (Motor

Bus, Line) is passed through a transformer and scaled

down from 120 V ac to 6 V ac. If variable speed motor

control is used on the motor bus, the variable speed

motor application option should be specified, which

places a dual channel low pass active filter after each

input transformer. This eliminates false zero crossing

triggering due to commutated bus voltage waveforms.

The scaled down voltages are converted into dc

voltages by the Ac to Dc Converters. These converters

are active full-wave rectifiers and filters that eliminate

the diode drop typical of conventional full-wave

rectifiers, which are highly temperature-dependent.

Full-wave rectification was chosen over half-wave

rectification because the filter response time is much

faster for a given ripple voltage. This is due to the fact

that full-wave rectification contains no fundamental

frequency components, only harmonics. The Upper

and Lower Voltage Comparitors compare the output

of the Ac to Dc Converter to a portion of a highly

stable hybrid 10 V reference. LEDs located on the

front panel indicate the condition of the Line voltage

with reference to the UPPER and LOWER VOLTAGE

LIMIT settings.

Two Zero-Crossing Detectors generate rectangular

waveforms at the zero crossing of each input. A logic

gate provides a pulse width that is proportional to the

phase difference between each input, which is then

integrated and sampled each half cycle of the highest

frequency input. This sampled voltage is an accurate

measure of the phase difference and is updated

once every 8.3 ms. The sampled voltage varies from

0 to +10 V for a phase difference change of 0 to

±180°. The sampled phase voltage is compared to

the extremely stable hybrid voltage reference. The

compared signal is an indication of the phase

difference with reference to the front panel PHASE

ANGLE LIMIT setting. Rear terminal TB1-5 allows

external monitoring of the phase difference sampled

voltage, referenced as “Phase Angle Analog Output.”

Power is provided by the Power Supply, which

supplies ±24 V dc, ±15 V dc and the precision 10 V

reference used for comparison. The supply is

designed to operate from 108 V ac to 132 V ac input

and is electrically isolated from all other inputs and

outputs. The Logic Network monitors all functions

including power supply voltages. Upon receiving a

logic “1” from the enable input and the appropriate

logic conditions from the Phase Angle, Upper Voltage,

and Lower Voltage Comparitors; the Logic Network

outputs a breaker close signal to the Breaker Close

Network. Terminals A and B are electrically shorted

by the Breaker Close Network until one of the

controlling logic conditions is false or logic “1.”

Motor Bus Undervoltage Monitor

The Motor Bus Undervoltage Detector will disable

the relay if the voltage decays below 25% during a

bus transfer sequence. This will ensure that the phase

measurement circuitry does not misoperate during a

low voltage condition.

Input Loss Protection

The M-0245C has been designed with an Input Loss

Detector circuit to minimize the possibility of the output

contacts closing due to sudden loss of the VT input

sources. The M-0245C output contact is forced to

the normally open state for any of the following

conditions:

1. Sudden drop in the line V.T. voltage

magnitude.

2. Sudden drop in the bus V.T. voltage

magnitude.

3. Bus V.T. voltage less than 0.25%.

4. Rate of change of phase, as detected by

the M-0245C circuitry, is greater than

2900°/sec. (8 Hz frequency difference).