Manual

DRHS55

Version: 01

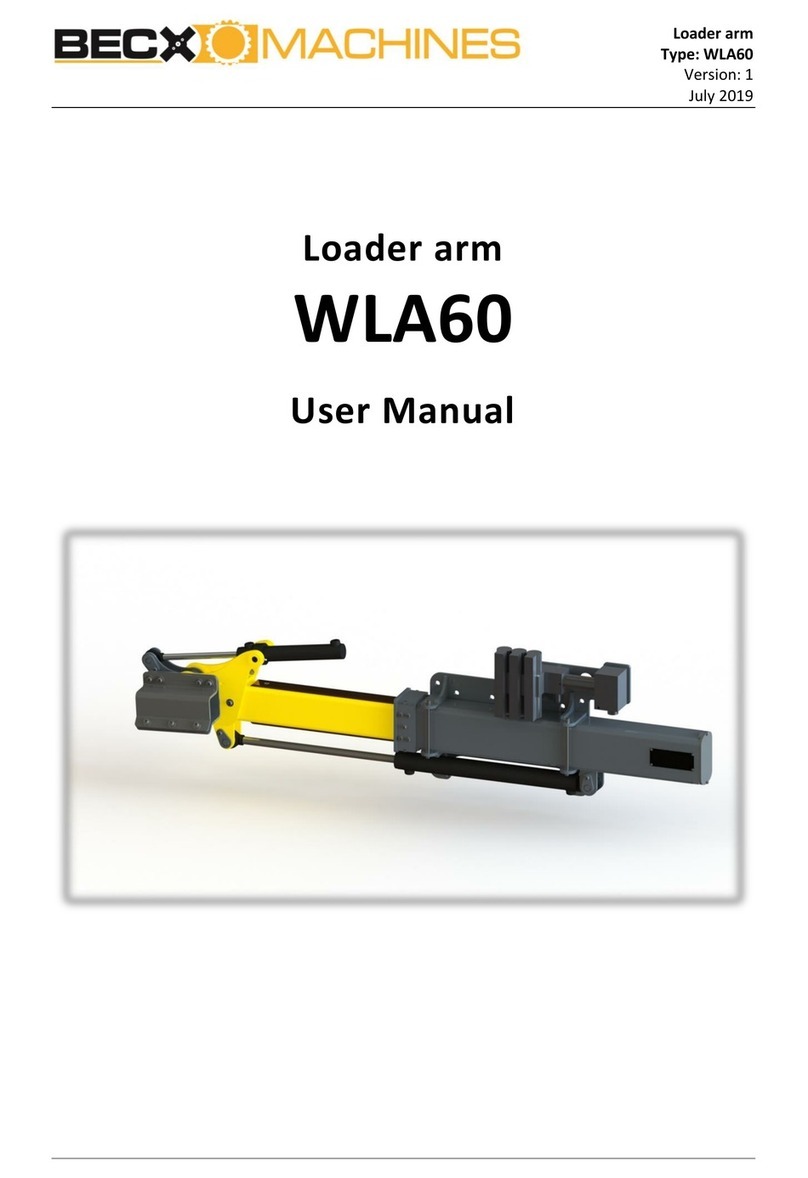

July 2019

Page 4 of 21

Table of contents

FOREWORD.................................................................................................................................. 3

TABLE OF CONTENTS .................................................................................................................... 4

DECLARATION OF CONFORMITY (IIA) (COPY)................................................................................. 5

OVERVIEW OF SYMBOLS............................................................................................................... 6

PICTOGRAMS ........................................................................................................................................... 7

1. TECHNICAL SPECIFICATIONS................................................................................................... 8

2. SAFETY .................................................................................................................................. 9

3. DESCRIPTION OF COMPONENTS........................................................................................... 11

3.1. TOOL NESTING PLACE ................................................................................................................... 11

3.2. SUPPORT ARM COMPONENTS ........................................................................................................ 12

4. OPERATION ......................................................................................................................... 13

4.1. MAKE THE SUPPORT ARM READY FOR USE........................................................................................ 13

4.2. CARRY OUT THE WORK ACTIVITIES................................................................................................... 14

5. MAINTENANCE .................................................................................................................... 15

6. MALFUNCTION ANALYSIS..................................................................................................... 16

7. DISPOSAL ............................................................................................................................ 17

8. LOGBOOK............................................................................................................................ 18

8.1. MAINTENANCE WORK .................................................................................................................. 18

8.2. REPAIRS /REPLACEMENTS............................................................................................................. 19

8.3. MALFUNCTIONS .......................................................................................................................... 20

8.4. INSPECTIONS............................................................................................................................... 21