Becx Machines WLA60 User manual

Loader arm

Type: WLA60

Version: 1

July 2019

Loader arm

WLA60

User Manual

Loader arm

Type: WLA60

Version: 1

July 2019

Page 2 van 23

Manufacturer Becx Machines B.V.

De Sonman 35

5066 GJ Moergestel

Tel: +31 (0)13-207 07 60

http://www.becxmachines.com

© Copyright 2019

Nothing in this publication may be reproduced and/or made public in any form by print, photocopy,

microfilm, recording tape, electronically or by any other means without prior written permission

from Becx Machines B.V.

Becx Machines B.V. reserves the right to modify parts of the system, including the contents of this

manual, at any moment, without prior or direct notification to the buyer.

Although Becx Machines B.V. has taken the greatest care to make sure that individual parts have

been described correctly and in full where necessary, it accepts no liability for damage as a result of

inaccuracies or incompleteness of this manual.

Loader arm

Type: WLA60

Version: 1

July 2019

Page 3 van 23

Preface

From now on, you can get your loader even wider deployed using the WLA60.

This hydraulic arm makes it possible to mount a Becx hedge cutter to your loader. The WLA60 is

designed to fit onto almost any loader. If your loader does not have the two required double-acting

hydraulic valves, Becx can offer you valves + a control box-set as an option. The WLA60 is 60cm

extensible and offers a 105 degrees tilt. The arm can be used left or right and can be mounted to the

front or rear of your machine. Combined with the lift of your wheel loader this allows you cut nearly

every hedge. The WLA60 can carry our HS130HR and HS150HR hedge cutters, and even our new

HS131HR hedge cutter.

Carefully read this manual before using the loader arm. Always

follow the safety instructions set out in chapter 3.

One copy of this manual must be kept with the loader arm and must

be available to the user. All important servicing sessions and any

comments must be recorded and retained by the servicing company.

The user is responsible for selecting a suitable tool carrier for the

loader arm and its tools and for ensuring that the loader arm and

tool is properly attached and connected.

Loader arm

Type: WLA60

Version: 1

July 2019

Page 4 van 23

Table of contents

PREFACE ...................................................................................................................................... 3

TABLE OF CONTENTS .................................................................................................................... 4

FIGURES....................................................................................................................................... 4

CERTIFICATE OF CONFORMITY (IIA) (COPY) ................................................................................... 5

LIST OF SYMBOLS ......................................................................................................................... 6

1. TECHNICAL DATA................................................................................................................... 7

2. SAFETY .................................................................................................................................. 8

2.1. GENERAL...................................................................................................................................... 8

2.2. IN USE ......................................................................................................................................... 8

2.3. OPERATING PERSONNEL.................................................................................................................. 9

2.4. SAFETY SYMBOLS ON THE MACHINE .................................................................................................. 9

3. COMPONENT DESCRIPTION ................................................................................................. 10

3.1. ATTACHMENT ............................................................................................................................. 11

3.2. MECHANICAL COMPONENTS.......................................................................................................... 12

3.3. WEAR-AND GREASE PARTS LOADER ARM......................................................................................... 13

4. HYDRAULIC SCHEMES .......................................................................................................... 14

5. OPERATIONS ....................................................................................................................... 15

5.1. ASSEMBLY AND ADJUSTMENT OF THE LOADER ARM ........................................................................... 15

5.2. CARRY OUT THE WORKS................................................................................................................ 16

6. MAINTENANCE .................................................................................................................... 17

7. FAILURE ANALYSES .............................................................................................................. 18

8. REMOVAL............................................................................................................................ 19

9. LOGBOOK............................................................................................................................ 20

9.1. MAINTENANCE SERVICING,REPAIRS/REPLACEMENTS,FAULTS AND INSPECTIONS .................................... 20

Figures

FIGURE 1: OVERVIEW ................................................................................................................................. 10

FIGURE 2: ATTACHMENT PLATE .................................................................................................................... 11

FIGURE 3: GENERAL OVERVIEW OF THE MECHANICAL COMPONENTS................................................................... 12

FIGURE 4: OVERVIEW WEAR-AND GREASE PARTS LOADER ARM ......................................................................... 13

FIGURE 5: HYDRAULIC SCHEME –WITHOUT VALVE BLOCK ................................................................................. 14

FIGURE 6: HYDRAULIC SCHEME –WITH VALVE BLOCK....................................................................................... 14

FIGURE 7: MAXIMUM FORCES ARM AND TOOL ................................................................................................ 15

Loader arm

Type: WLA60

Version: 1

July 2019

Page 5 van 23

Certificate of conformity (IIa) (copy)

We:

Becx Machines B.V.

De Sonman 35

5066 GJ Moergestel

declare entirely under our sole responsibility, that this product:

Description : Loader arm

Type : BECX WLA60

Serial number : .....................

to which this declaration applies, complies with the provisions of the Directives:

Machinery Directive 2006/42/EC

Complies with the following standards:

NEN-EN-12100-1 Safety of machinery. Basic definitions, general design principles.

Part 1: Basic terminology, methodology

NEN-EN-12100-2 Safety of machinery. General design principles. Part 2: Technical

principles and descriptions

NEN-EN 982 Safety of machines –Safety requirements for hydraulic and

pneumatic systems and their components: Hydraulics

NEN-EN 14121-1 Safety of machines –Risk assessment –Part 1: Principles

Director; Erwin Hommen

Netherlands, Moergestel,

Date: .........................

Loader arm

Type: WLA60

Version: 1

July 2019

Page 6 van 23

List of symbols

This manual uses the following symbols for all actions and situations where the safety of the operator or

technician is at stake and where it is necessary to act with caution:

Warning!

Explanation.

Loader arm

Type: WLA60

Version: 1

July 2019

Page 7 van 23

1. Technical data

Description

Value

Unit

General

Noise pressure

See tool carrier

dB(A)

Vibration level in normal use

n/a

Hydraulic oil filtering requirements

10

microns

Oil for the drive

HV-46 or equivalent

Grease for greasing cutting heads

NLGI 2

Dimensions and weights

Length in*

1.315

mm

Length out*

1915

mm

Width *

320

mm

Height without/ with valves

400 / 460

mm

Own weight without/ with valves *

90 / 100

kg

Attachment information

Type

Screwable adapter plate

-

Attachment information

Standard attachment tube

80*80

mm

Available mounting width

250

mm

Force on attachment point (see Figure 7)

2700

N

Hanging moment (see Figure 7)

1300

Nm

Connection data

Maximum operating pressure

210

bar

Connection without valves

Connection pressure / drains single acting (1x) ***

1/2"

Connection pressure / drains double action (2x)

3/8”

Drain line connection ***

3/8”

Connection with valves

Connection pressure / drains single acting

1/2"

Drain line connection

3/8”

Valve-control (2x)

12

V

Fuse

10

A

Electrical connection to loader

12V-connector

* Exclusive tool and wheel loader

** Depending on the number of hydraulic control functions the loader features

*** For use with Becx hedge trimmer

Loader arm

Type: WLA60

Version: 1

July 2019

Page 8 van 23

2. Safety

2.1. General

No modifications must be made to the loader arm.

The user is responsible for making sure that the correct loader and adapter

are used (see chapter Fout! Verwijzingsbron niet gevonden.). The following

re important points in this regard:

The maximum pressure and number of revolutions (oil flow) must not be

exceeded. Excess pressure and excess revving can damage the machine and

cause injury.

The tool carrier must be strong and stable enough to absorb the forces and

moments exerted by the loader arm safely and under all circumstances.

2.2. In use

Consult the tool carrier manual for the noise rating. Because this is

considerably louder than the loader arm itself, the noise load of the tool

carrier determines the rating.

The machinery must only be used for the activities for which it is designed.

Persons or animals who are present in or who approach the danger zone must

be stopped immediately and the weed brush must be switched off.

If passers by disrupt the work too much, the operator can consider

temporarily cordoning off the site.

If the loader arm starts to make a different sound and/or starts to vibrate,

work must stop immediately and the weed brush has to be switched off. Work

can only continue after the source of the noise has been identified and

resolved.

Always complete inspection and maintenance jobs.

The machinery must not be used for any other purposes during inspection and

maintenance.

The hydraulic feed to the loader arm must be disconnected during inspection,

maintenance or cleaning to prevent accidental operation.

Always comply with local work regulations and safety rules.

If the machinery is used in the dark, use sufficient lighting (approx. 50 lux at

the work site).

Loader arm

Type: WLA60

Version: 1

July 2019

Page 9 van 23

2.3. Operating personnel

Operating personnel must be over 18.

Only persons who have received permission from the owner are allowed to

operate the system.

Persons must only carry out jobs for which they are trained. This applies to

both maintenance work and normal operations.

Personnel who operate equipment must be familiar with all possible

situations that could arise.

The owner or person in charge must be told if personnel operating machinery

identify faults or hazards or do not agree with safety measures.

2.4. Safety symbols on the machine

1.

Read the manual before use!

2.

Safety zone

Loader arm

Type: WLA60

Version: 1

July 2019

Page 10 van 23

2

1

3

3. Component description

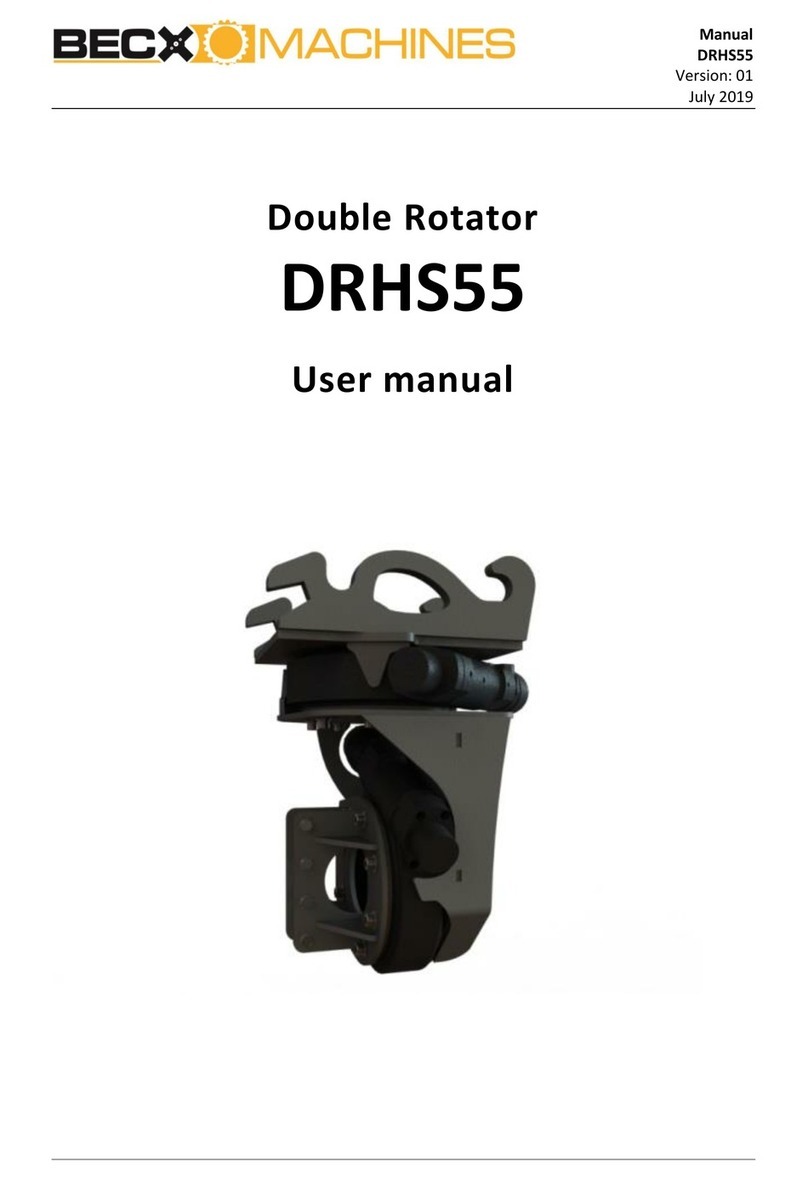

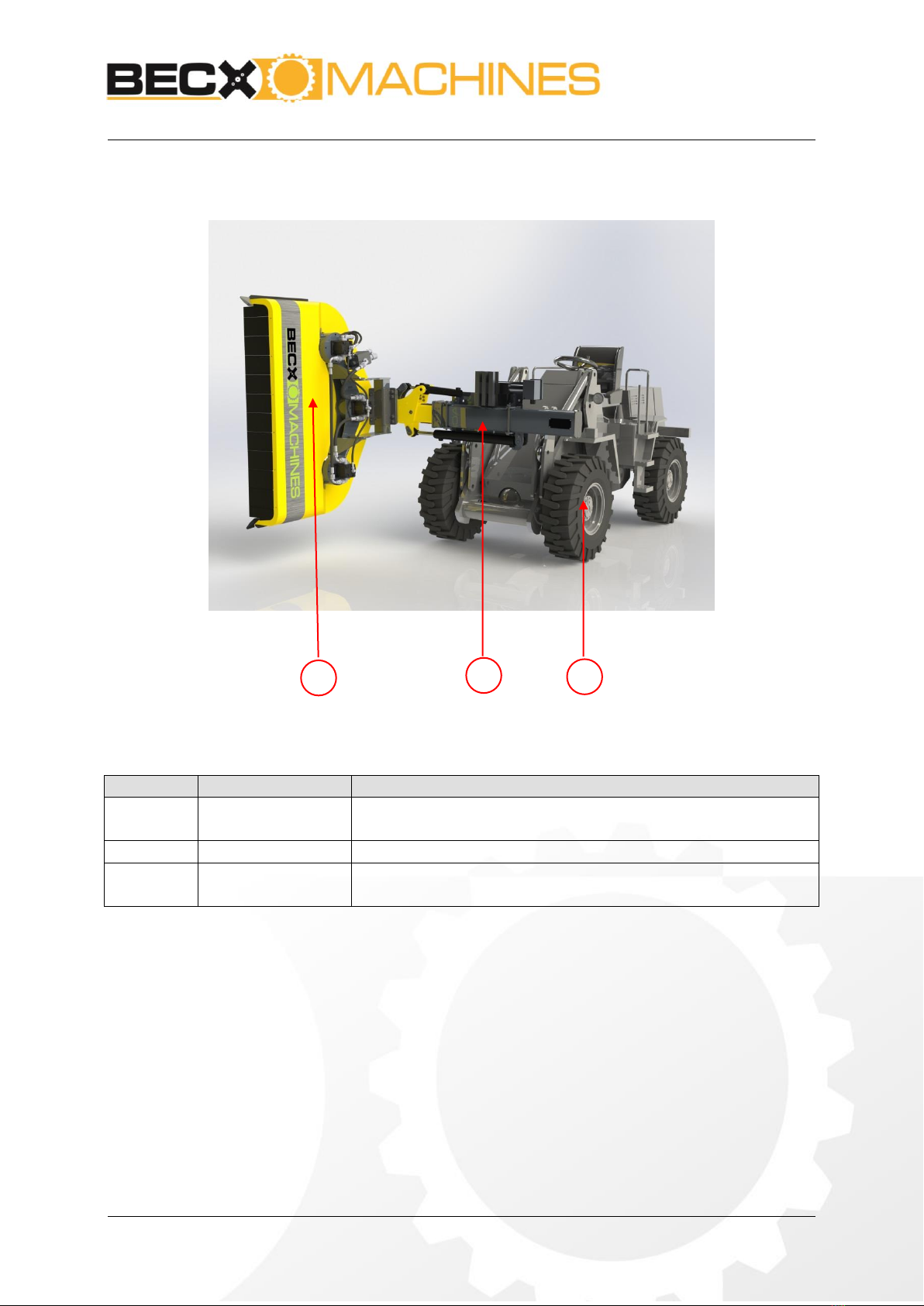

Figure 1: Overview

Figure 1

Part

explanation

1

Loader

The loader is not supplied. The user is responsible for using a

tool carrier that is suitable for the loader.

2

Loader arm

The loader arm couples the tool to the loader.

3

Tool

The tool is not supplied. The user is responsible for using a

tool that is suitable for the loader arm and loader.

Loader arm

Type: WLA60

Version: 1

July 2019

Page 11 van 23

1

2

3

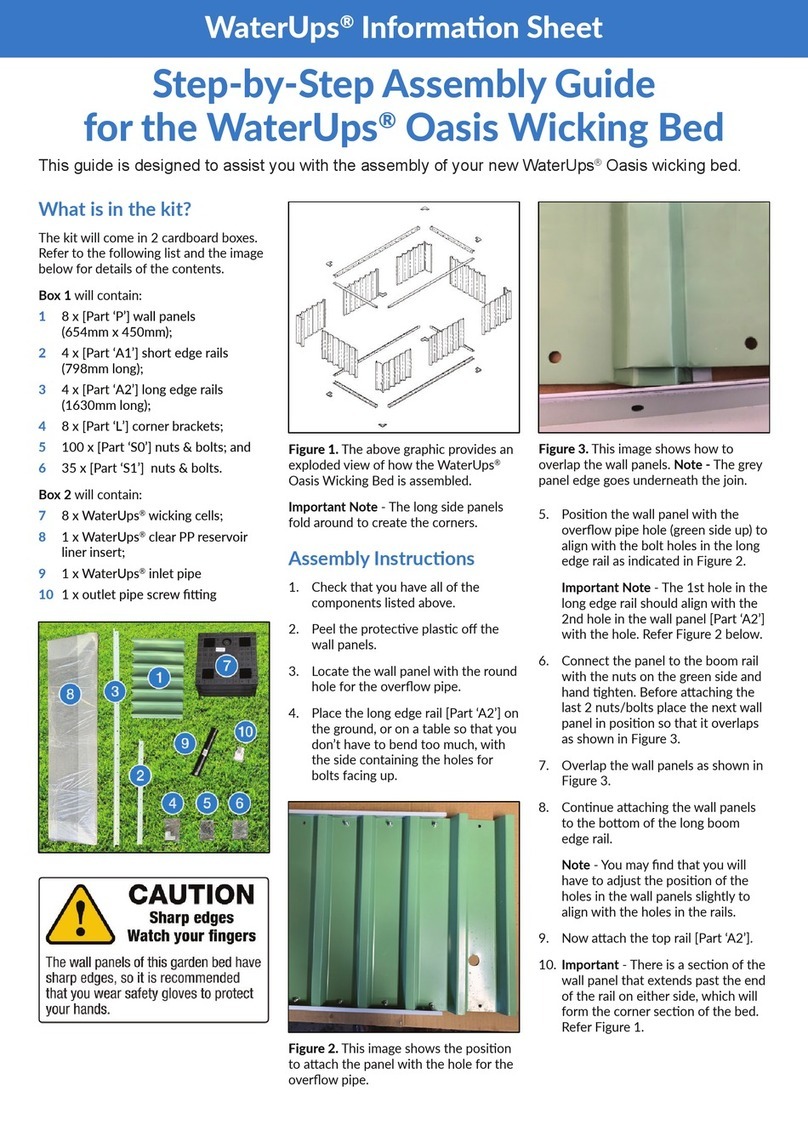

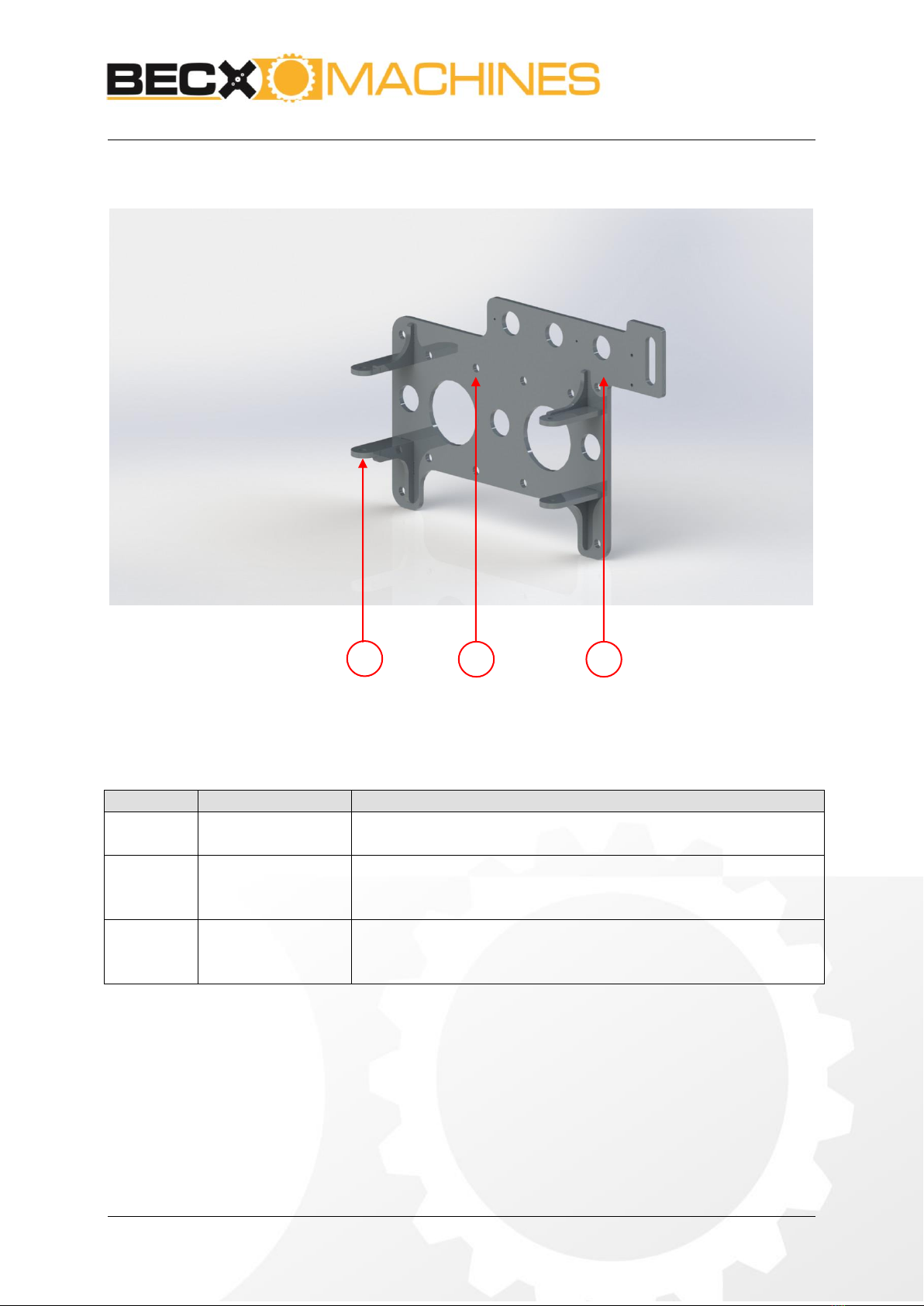

3.1. Attachment

Figure 2: Attachment plate

Figure 2

Part

Explanation

1

Arm clamp

The actual support arm is attached by means of clamps on the

adapter plate. This is done with the two mounting bolts

2

Adapter plate

Using a minimum of 4 of the 12 fixing holes WLA60 can be

attached to almost any loader. It is preferred to us the holes

on the sides of the plate

3

Valve block

connection

If the version including control valve is provided, this is

located at the appropriate position. In the version without

valve block this section on the adapter plate is not present.

Loader arm

Type: WLA60

Version: 1

July 2019

Page 12 van 23

7

1

2

3

4

5

6

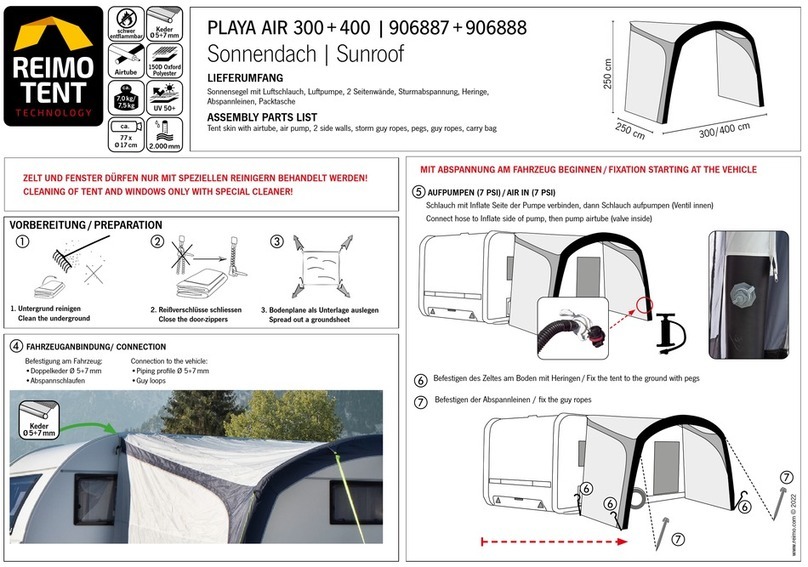

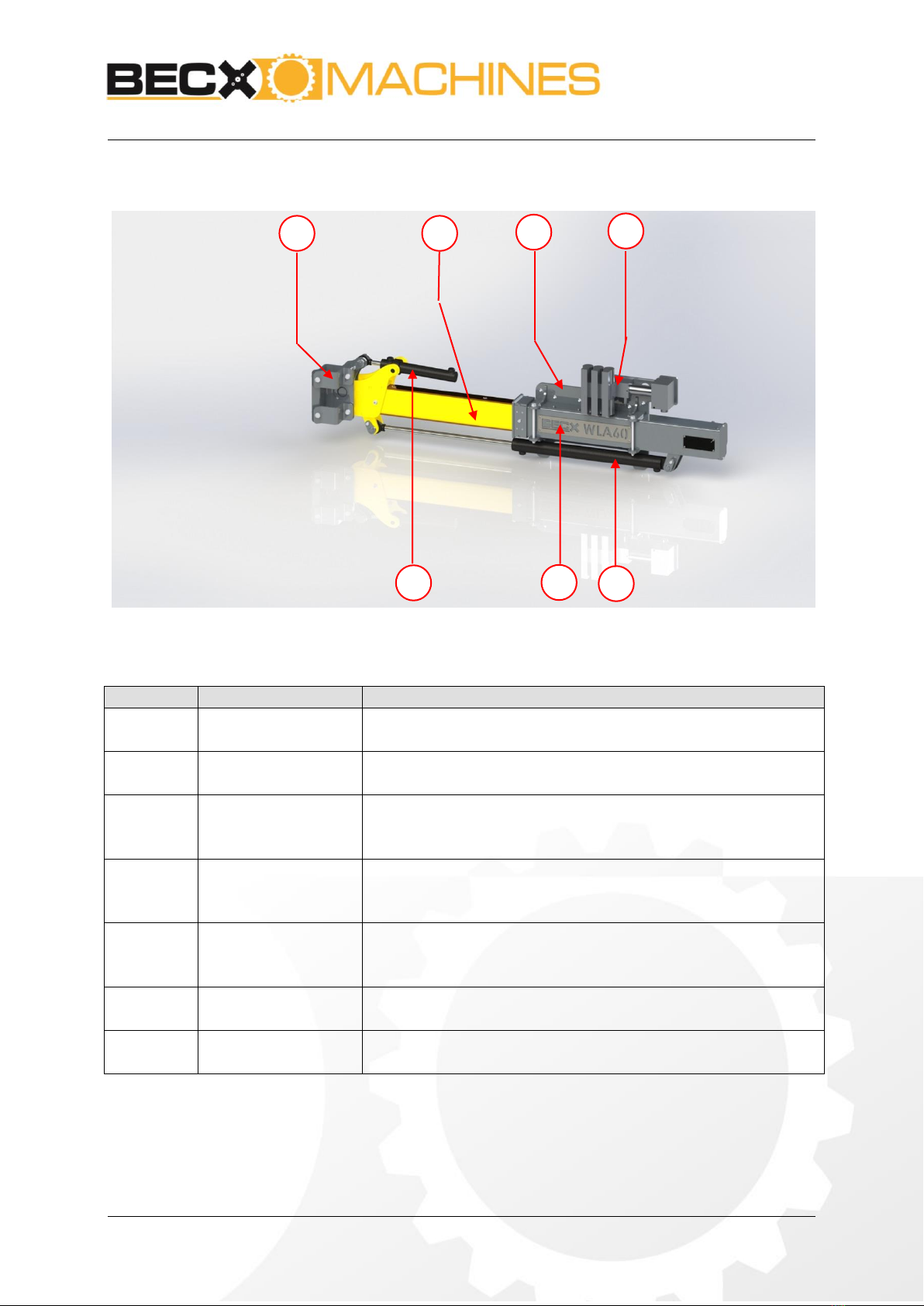

3.2. Mechanical components

Figure 3: General overview of the mechanical components

Figure 3

Part

Explanation

1

Clamp

With this clamp, the tool, for example a Becx hedge cutter,

can be coupled to the arm

2

Side-shift

By side-shifting this part, the tool can moved to the left or

right.

3

Adapter plate

Using a minimum of 4 of the 12 fixing holes WLA60 can be

attached to almost any loader. It is preferred to us the holes

on the sides of the plate

4

Valve block

Optionally, the control valve can be supplied. This converts

to one single-acting hydraulic function to two double-acting

functions and a single-action function.

5

Cylinder to rotate

By using this cylinder the tool will be rotated up to 110

degrees. This can be used to switch between the cutting on

top, or on the side of the hedge.

6

Base

This section is the base of the arm. This connects all the

components together.

7

Side-shift cylinder

By using this cylinder, the tool can be side-shifted up to

60cm to the left or right

Loader arm

Type: WLA60

Version: 1

July 2019

Page 13 van 23

1

1

1

2

2

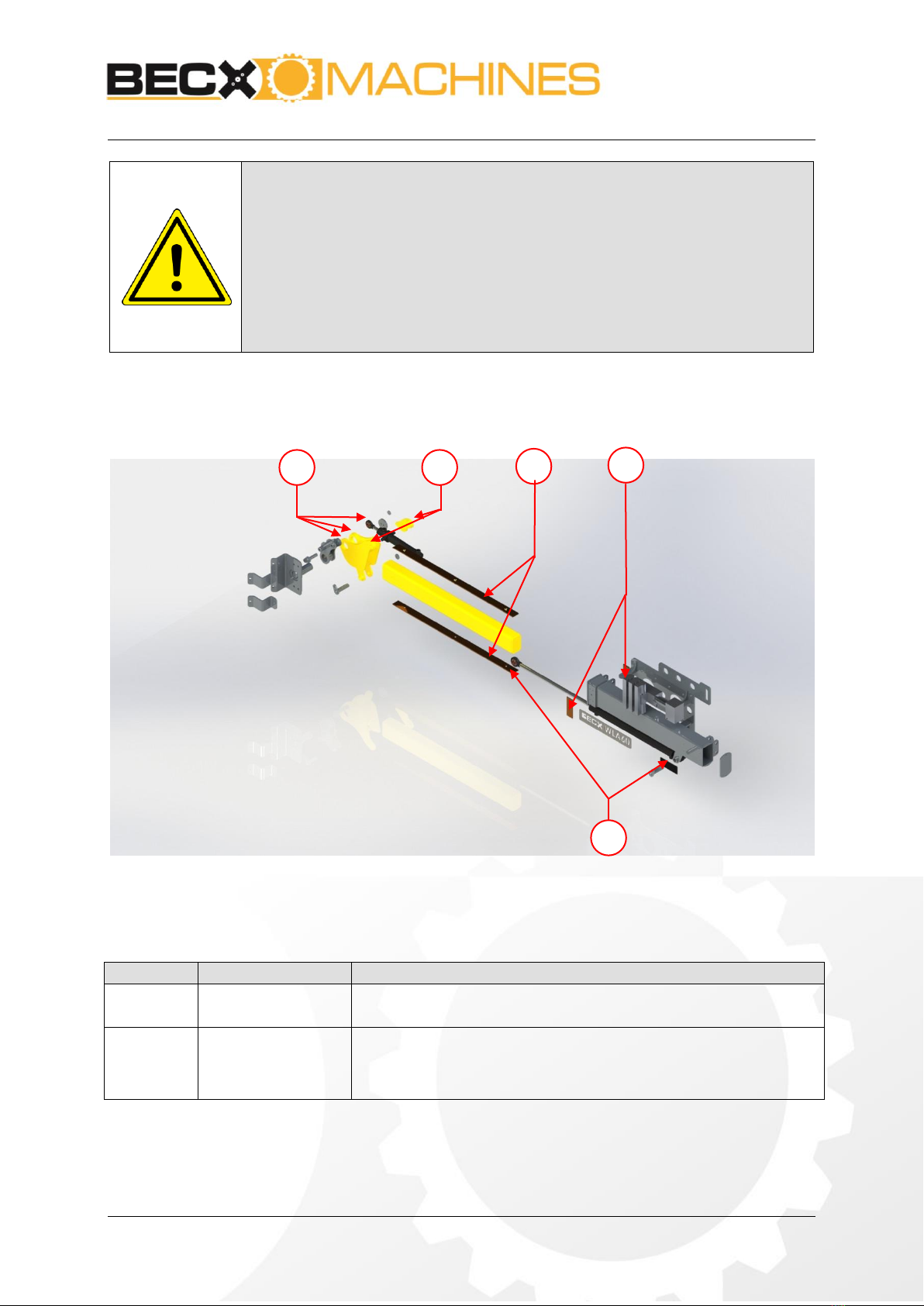

ATTENTION!

Depending on the loader, this arm can be delivered with two double-

acting electric functions. By default, the machine is delivered without

valve block, but with the necessary hydraulic fittings and hoses supplied.

See the supplied electrical and hydraulic diagrams for your model.

It is the responsibility of the user to link the machine in the right manner

to the tool and loader.

3.3. Wear- and grease parts loader arm

Figure 4: Overview wear- and grease parts loader arm

Figure 3

Part

Explanation

1

Grease points

Squeeze grease into the grease nipples on the cutting heads.

See Chapter 1: Technical data or the grease specification

2

Wear strips

During use, these parts will wear out. When the strips are

worn onto the screw heads, these parts should be replaced

per set (4 strips)

Loader arm

Type: WLA60

Version: 1

July 2019

Page 14 van 23

4. Hydraulic schemes

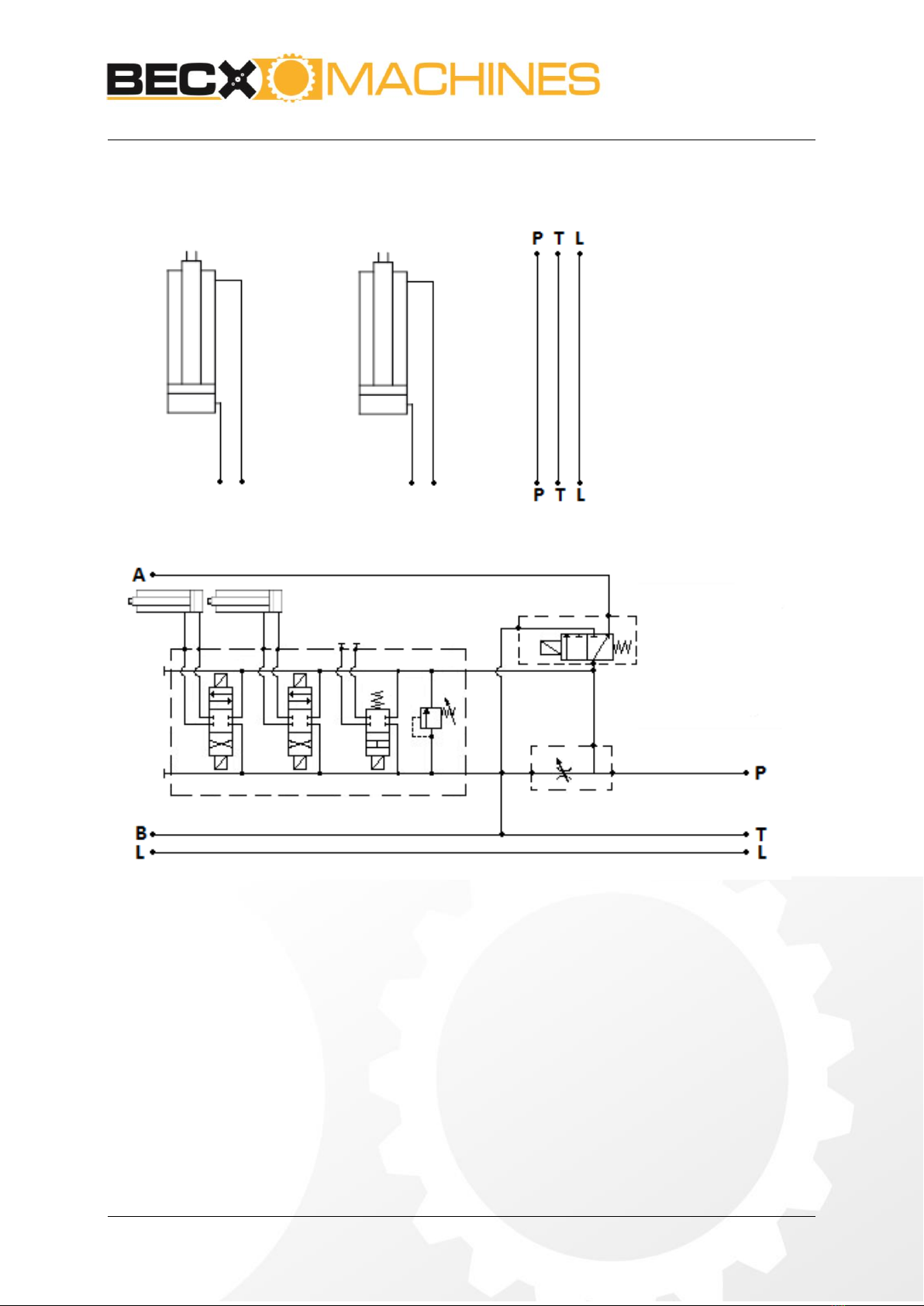

Figure 5: Hydraulic scheme –without valve block

Figure 6: Hydraulic scheme –with valve block

Loader arm

Type: WLA60

Version: 1

July 2019

Page 15 van 23

5. Operations

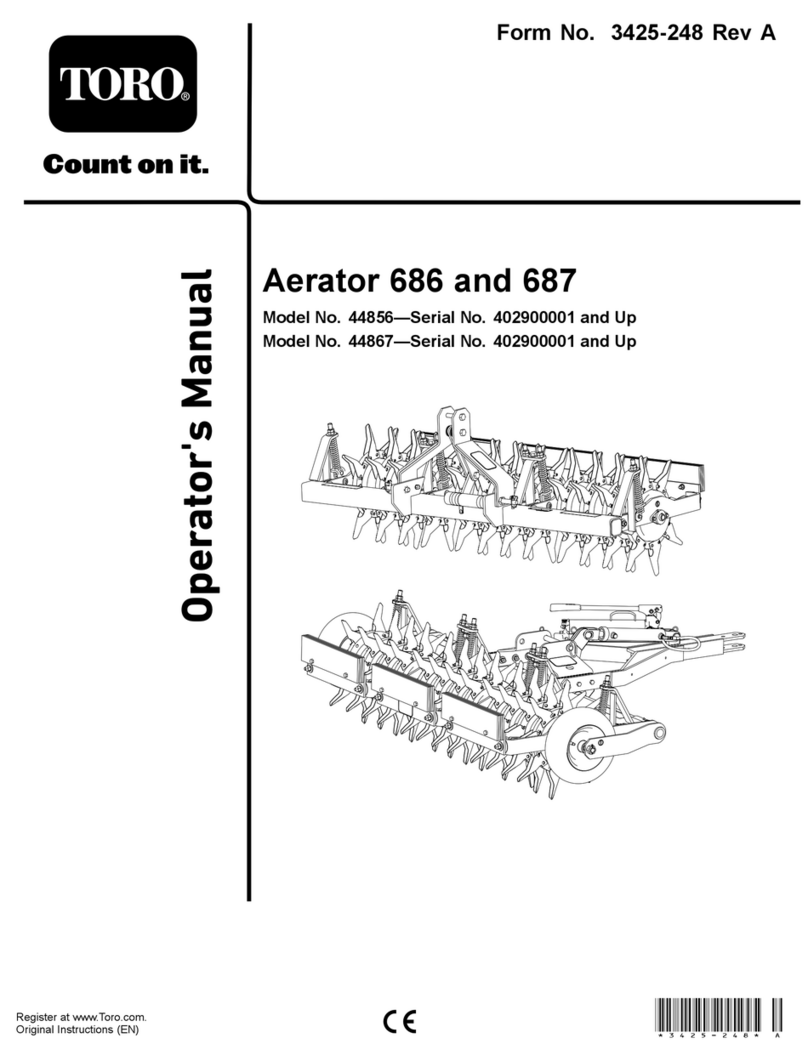

5.1. Assembly and adjustment of the loader arm

Figure 7: maximum forces arm and tool

No.

What to do

Action

Result

1

Select the correct tool

carrier and lifting arm

Make sure that the tool carrier and lifting

arm are sufficiently strong and stable for

the weed brush (see chapter 1: Technical

data for the load when lifting and the

exerted moment of the lifting).

Make sure that the maximum pressure

and number of revolutions (oil flow) are

not exceeded.

Make sure that the correct rapid

attachment connections are installed.

Make sure that the correct clasp is used.

Ignoring the stated

values can result in

damage to

equipment and

injury to persons.

2

Connect the loader

arm to the loader

mechanically

Make sure the base is vertical

Connect the adapter plate (Figure

3:3) with at least 4 of the provided 12

connection holes to the loader.

Place the base (Figure 3:6) on the

desired position on the adapter plate.

Depending on the preference of the

user, it can be mounted on different

positions.

Lock the base properly

Moment tool

Vertical force tool

Loader arm

Type: WLA60

Version: 1

July 2019

Page 16 van 23

2

Connect the hoses

Connect the rapid attachment

connections for the feed line, return

line and drain line.

3

Adjust the hydraulic

system

Adjust the setting of the hydraulic

aggregate so that the maximum

pressure and number of revolutions

cannot be exceeded.

This will depend on the type of tool

carrier that is used. Please refer to

the manual of the tool carrier.

5.2. Carry out the works.

Observe the safety-instructions in chapter Fout! Verwijzingsbron niet

evonden..

Observe the manual of the loader for the correct operation of the control

functions.

Observe the manual of the loader the right safety-instructions.

Loader arm

Type: WLA60

Version: 1

July 2019

Page 17 van 23

6. Maintenance

Only components supplied or approved by the manufacturer must be used for

replacement or repair of parts.

Always disconnect the loader arm from the feed lines when work is carried

out on the machinery. This is done by disconnecting the rapid attachments.

Only persons who can show that they have adequate knowledge of

mechanical and hydraulic machinery through their training and experience are

allowed to carry out maintenance work.

The installation can be cleansed with a high pressure cleanser, never point

directly at hydraulic components.

Weekly maintenance

No.

What to do

Action

Result

1

Tightening bolts

Check and tighten all bolts

2

Visual check

Visually check the construction and hydraulic

aggregate for damage and cracks.

Check cylinder-rods for damages and dirt.

3

Wear strip check

Check if the strips are worn onto the bolt

heads (see chapter 3.3), if so, replace all 4

strips.

4

Grease

Squeeze grease into the grease nipples. These

are located at all pivot points.

See 1 Technical data for type

Annual maintenance

No.

What to do

Action

Result

1

Inspect

Check following parts for damage, cracks and

looseness:

Connections.

Hoses.

Couplings.

Pivot points.

Wear strips.

Loader arm

Type: WLA60

Version: 1

July 2019

Page 18 van 23

7. Failure analyses

Breakdown

Remedy

1

Not enough hydraulic power

available

Check the hydraulic hoses.

2

After switching on, the tool

does not run

Check that the hydraulic hoses are correctly connected.

3

Switching between hydraulic

functions doesn’t work

Check the electrical circuit.

Check the operation of the control valve.

If the fault cannot be solved by following the above recommendations, consult your dealer or

maintenance department.

Loader arm

Type: WLA60

Version: 1

July 2019

Page 19 van 23

8. Removal

When replacing parts or at the end of the part's lifecycle, please ensure that all materials are

disposed of, destroyed or recycled in a legal and environmentally friendly way.

Loader arm

Type: WLA60

Version: 1

July 2019

Page 20 van 23

9. Logbook

9.1. Maintenance servicing, repairs/replacements, faults and

inspections

The following must be recorded in this logbook:

All annual maintenance services (sheet 1)

All repairs/replacements (sheet 2)

Faults (sheet 3)

Inspections (sheet 4)

Maintenance servicing

Date

Passed by:

Description

Table of contents

Other Becx Machines Lawn And Garden Equipment manuals

Popular Lawn And Garden Equipment manuals by other brands

New England Arbors

New England Arbors Athens Assembly instructions

Blumfeldt

Blumfeldt Solid Sky Expand manual

Westfalia

Westfalia 946960 manual

Truvox International

Truvox International R48HD Cimex HD user manual

Dancover

Dancover Garden Storage Box Regular A manual

Coleman

Coleman Moscuito Deleto Instructions for use