Beech Ovens Page 3 2/09/2019 (C)

E-Series Manual (R4) Confidential and Proprietary

Contents

CRITICAL ISSUES TO BE CONSIDERED ...............................................2

Section 1 - Installation ..................................................................6

Important Information .............................................................................7

WARNING:................................................................................................................7

For your safety..........................................................................................................7

Disposal of ashes......................................................................................................7

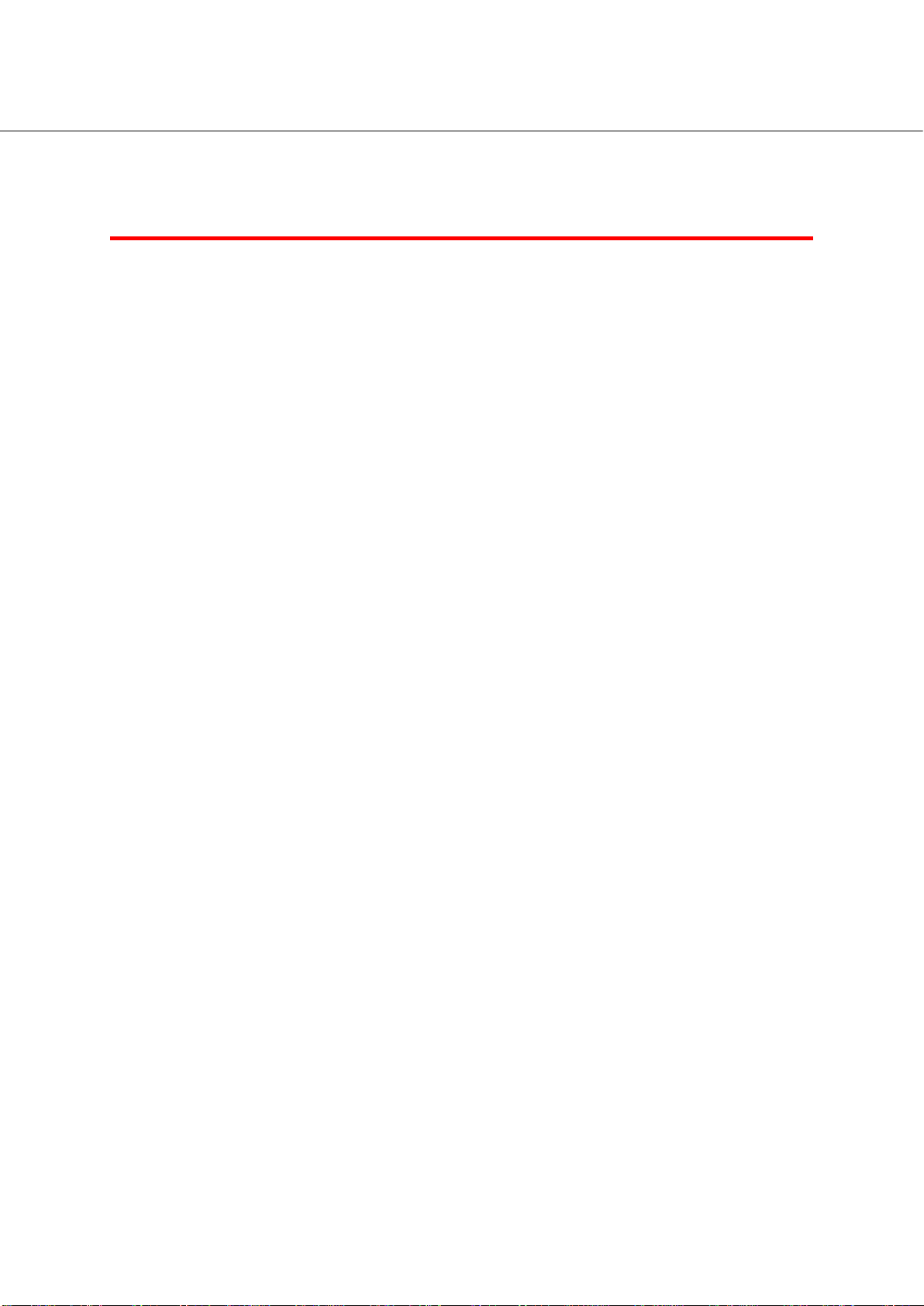

Oven Overview.........................................................................................8

Preliminary checks..................................................................................9

Site Preparation ........................................................................................................10

Protection of Combustible floors ...............................................................................11

Oven Installation Procedure...................................................................12

Removing the oven from the crate............................................................................12

Lifting Positions.........................................................................................................12

Transportation...........................................................................................................14

Leg Fastening ...........................................................................................................14

Exhaust Requirements............................................................................15

Flue Material .............................................................................................................15

Recommended Flue size ..........................................................................................15

Nominal airflow required ...........................................................................................15

Exhaust Canopy/Hood Design..................................................................................16

Recommended Exhaust Canopy/Hood Positioning...................................................17

General Information on Flues.................................................................18

Flue Fires..................................................................................................................18

Ventilation Requirement .........................................................................19

Gas Systems overview..............................................................................................20

Gas Control System..................................................................................................20

Firing Systems.........................................................................................21

Wood ONLY............................................................................................................21

Display burner.........................................................................................................21

Electric....................................................................................................................21

Pilot/ Igniter Assembly...............................................................................................21

Digital Display and Thermocouple.............................................................................22

System Connection.................................................................................24

Contractors Responsibility.........................................................................................24

Gas Train ..................................................................................................................24

Gas Connection Procedures.....................................................................................25

Electrical Connection ................................................................................................26

Final Checks .............................................................................................................26

Installation Checklist...............................................................................27

Section 2 - Commissioning ..........................................................28

Commissioning........................................................................................29

Setting High and Low Flame Pressure...................................................31

Flame Calibration ....................................................................................32