Beechcfaft D9*5A User manual

A

LIST

OF

EFFECTIVE

PAGES

TOTAL

NUMBER

OF

PAGES

IN

11i

IS

BOOK

IS

132

*Tide

*List

of

Effective

Pages

i through vi

*I-9 through I-IOB

1-ll

through

J-2I

2-1 through 2-2

*2-3 through 2-4A

3-1 through 3-6

4-1 through 4-2

*4-3 through 4-4

4-5 through

4-I8

5-1

through 5-13

6-I

through 6-23

7-1 through 7-4

*7-5 through 7-6A

7-7 through 7-9

*7-10

7-11 through 7-15

*7-16

7-17 through 7-30

AI

AI

Al

AI

AI

Al

A1

Al

August

3,

1964

August

3,

1964

Original

August

3,

1964

Original

Original

August

3,

1964

Original

Original

August

3,

1964

Original

Original

Original

Original

August

3,

1964

Original

August

3, 1964

Original

August

3,

1964

Original

*The asterisk indicates pages revised, added

or

deleted

br

the current revision.

Revised

August 3, 1964

THANK YOU

...

for displaying confidence in

us

by

selecting a BEECHCRAFT airplane. Our

design engineers, assemblers and inspectors have utilized their skills and years

of experience

to

ensure

that

the

new BEECHCRAFT meets the high

standards

of

quality and performance for which BEECHCRAFT airplanes

have become famous

throughout

the

world.

IMPORTANT NOTICE

This manual should be read carefully

in

order

to

become familiar with

the

operation

of

the

airplane. Suggestions and recommendations have been made

within it

to

aid

in

obtaining maximum performance

without

sacrificing

economy.

Be

familiar with and operate the airplane

in

accordance with

the

Owner's Manual and FAA Approved Airplane Flight Manual

and/or

placards

which are located in

the

airplane.

As

a further reminder,

the

owner and operator should also be familiar with

the

Federal

Aviation

Regulations applicable

to

the

operation and

maintenance

of

the

airplane, and FAR Part

91

General Operating and Flight

Rules. Further,

the

airplane

must

be operated and maintained in accordance

with FAA Airworthiness Directives which may be issued against it.

The Federal Aviation Regulations place

the

responsibility for the

maintenance

of

this airplane on

the

owner and

the

operator,

who

should

make certain

that

all

maintenance

is

done by qualified mechanics

in

conformity with all airworthiness requirements established for this airplane.

All

limits,

procedures,

safety practices, time limits, servicing, and

ma

i

ntena

nee

requirements contained

in

this manual are considered

mandatory for continued airworthiness

to

maintain

the

airplane

in

a

condition equal

to

that

of

its original manufacture.

Authorized BEECHCRAFT Parts and Service Outlets

will

have recommended

modification, service, and operating procedures issued by both FAA and

Beech Aircraft Corporation, which are designed

to

get maximum utility and

safety from

the

airplane.

Table

ol

Contents

SECTION I

Descriptive

Information

____________

}.}

lCF>

SECTION

II

Operating

Check

Lists ----------------2-l

'SF>

SECTION

III

Performance

Specifications

and

Limitations

--------------------------3-l

SECTION

IV

Flying

Your

BEECHCRAFT

......4-1 lSE>

SECTION V

Unusual

Operating

Conditions

....

5-l

'ETt•

SECTION

VI

Operational

Data

----------·······-···---6·1

SECTION

VII

Servicing

and

Maintenance

........

7-l

iii

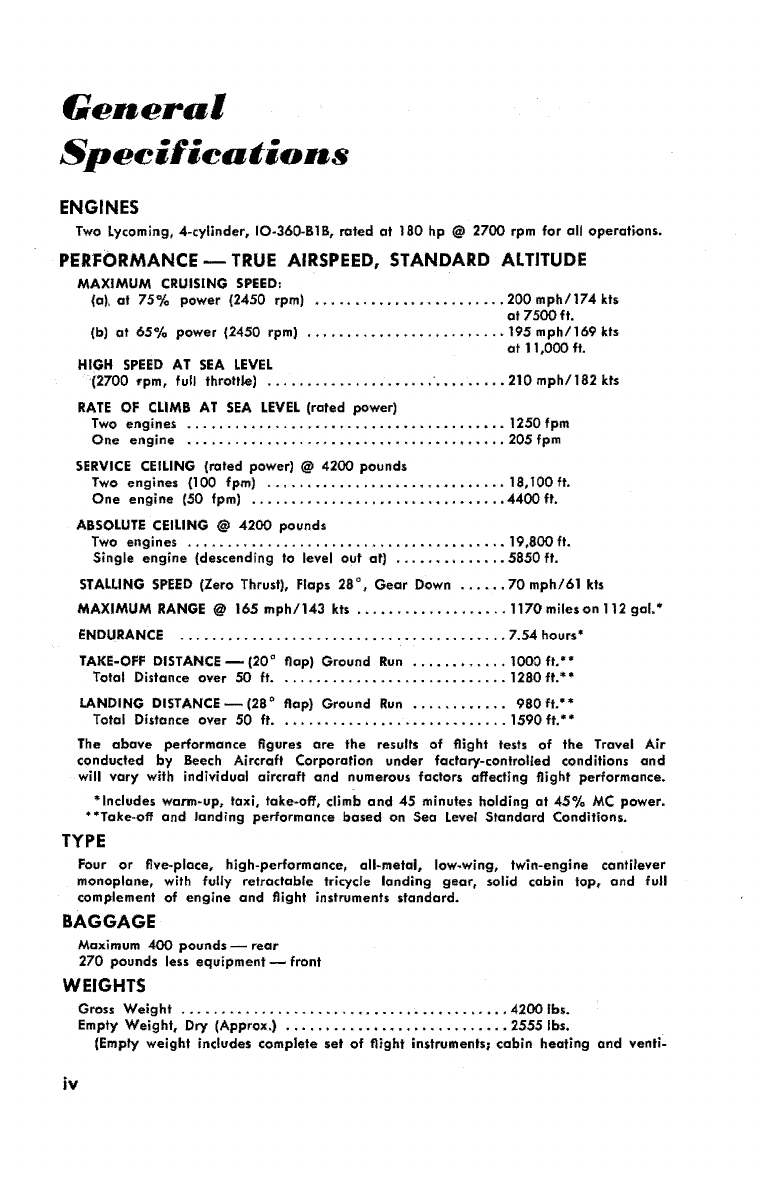

G@n@ral

Sp@cilications

ENGINES

Two

Lycoming, 4-cylinder, I0-360-B1B, rated

ot

180

hp

@l

2700 rpm

for

all

operations.

PERfORMANCE-

TRUE

AIRSPEED,

STANDARD

ALTITUDE

MAXIMUM

CRUISING

SPEED:

{a),

at

75%

power

{2450 rpm)

........................

200

mph/174

kts

at7500

ft.

{b)

at

65%

power

(2450 rpm)

.........................

195

mph/169

kts

ot

11,000 ft.

HIGH

SPEED

AT

SEA

LEVEL

(2700

rpm,

full throttle)

..............................

210

mph/182

kts

RATE

OF

CLIMB AT

SEA

LEVEL

{rated power)

Two

engines

•..•...•••••.••••.••.••..••••••.•..•••.•

1250 fpm

One engine

•.•.....•.......••••.•••.•••••••••••••••

205 fpm

SERVICE

CEILING {rated power)

@l

4200 pounds

Two engines {100 fpm)

..............................

18,100ft.

One engine {50 fpm)

..••••••....••..••.••••••.••••••

4400

fl.

ABSOLUTE

CEILING

@l

4200 pounds

Two engines

.....•..•..•.....•.•...•.••••••.••••.•••

19,800

ft.

Single engine (descending to level out at)

.•.••••..•••••

5850

fl.

STALLING

SPEED

{Zero Thrust), Flaps

28°,

Gear Down

•.•••.

70

mph/61

kts

MAXIMUM

RANGE

@l

165

mph/143

kts

.•.••..•..•••••••..

1170miles on 112 gal.•

ENDURANCE

.•.••.•••..•••••••..•.•••...•.•••..•••..•

7.54 hours•

TAKE-OFF

DISTANCE-

{20° flap) Ground

Run

............

1000 ft.

••

Total Distance over 50

ft

.............................

1280 ft.

..

LANDING

DISTANCE-

(28• flap) Ground

Run

•.•...••..••

980ft.

• •

Total Distance over 50

ft

.............................

1590 ft.

••

The above performance figures are the results

of

flight

tests

of

the Travel

Air

conducted

by

Beech

Aircraft

Corporation under factory-controlled conditions

and

will

vary

with

individual

aircraft

and numerous factors affecting

flight

performance.

*Includes warm-up, taxi, lake-off, climb

and

45 minutes

holding

at

45%

MC power.

• *Take-off and

landing

performance based on

Sea

Level Standard Conditions.

TYPE

Four

or

five-place, high-performance, all-metal,

low-wing,

twin-engine cantilever

monoplane, with

fully

retractable tricycle

landing

gear, solid cabin

top,

and

full

complement

of

engine

and

flight

instruments standard.

BAGGAGE

Maximum 400

pounds-

rear

270 pounds

less

equipment-

front

WEIGHTS

Gross

Weight

.••••••••.•••••.••••••••••.••••••••••••••

4200 lbs.

Empty

Weight,

Dry {Approx.)

•....•••.•••••.•••......••••

2555 lbs.

(Empty

weight

includes complete set

of

flight

instruments1 cabin heating and venti-

iv

lating system with windshield defrosters; soundproofing;

navigation,

cabin,

instrument

and

landing

lights.)

Useful

load

(Approx.)

........•.••...........•••..••••.•

16451bs.

WING

AREA

AND LOADINGS

Wing

Area

.....••...............•................•..•

199.2 sq. ft.

Wing

loading,

at

gross

weight

..•...•.•..••.............

20.6

lb>.lsq.

fl.

Power Loading,

at

gross

weight

.........•••..............

11.4

lbs./

hp

DIMENSIONS

Wing

Span

.......•.•....••.......•.••....••••........

37ft.

10 in.

length

....................•..........................

25

fl.

11

in.

Height

........•......•••.........•.......•...........

9 ft. 6 in.

CABIN DIMENSIONS

Cabin

length

......................••...•.............

8

fl.

6 in.

Cabin

Width

..•..........•.....•.•.•..•..•••.••.•....

3 ft. 6 in.

Cabin

Height

.................•.......•...••...••.....

4ft.

2 in.

Passenger

Door size

...•••..•...••.••..•••.....••....•.

36

in. x

37

in.

Baggage

Door size,

rear

•....•.......•..••...•.•...•••.

18.5 in. x 22.5 in.

Baggage

Compartment size,

rear

......•..................

33.5 cubic ft.

Baggage

Compartment size, front . . . . . . . . . • • . .

...••...•.

12 cubic fl.

Accessory Shelf, nose cone

.•...•••••••...•...•.••....•.

7 cubic ft.

PROPELLER

AND EQUIPMENT

Propeller-

constant

speed,

full

feathering,

diameter

72",

with hydraulic governor.

ENGINE EQUIPMENT !Per Engine)

Starter

Generator

Voltage Regulator

Auxiliary

fuel

Pump

Induction Air Filler

Exhaust Manifolds (stainless >!eel)

Vacuum Pump

FUEL

AND

OIL

CAPACITY

fuel

Capacity

in

standard

wing tanks

......•.•••..••••...

80

gal.(usable)

fuel

Capacity with optional

auxiliary

wing tanks

...•.••...•

112

gal.

(usable)

Oil

Capacity

. . . . . . . . . . . • . . . . . . . . . . . . . . . . . . . • . • . . •. . • . • 16

quarts

LANDING

GEAR

Tricycle type with swiveling

steerable

nose wheel

equipped

witn shimmy

dampener.

Beech air-oil struts

on

all wneels

designed

for

smooth

taxiing

and

to wilnstand

the

shock

created

by

landing

with a vertical

descent

component

of

over

600

feet

per

minute. Main tires

7.00"

x

6"

size; nose wheel tire 5.00" x

5"

size. Wheels

Beech with ring-disc hydraulic

brakes.

ELECTRICAL

EQUIPMENT

(24

Volt

System)

One

17-ampere-hour

battery,

standard

(two

24-ampere-hour

batteries,

optional);

electric motors

far

operating

flaps

and

landing

gear;

electrically

operated

cowl flaps

(optional); two 25-am

pere

generators,

standard

(two

40-ampere

generators,

optional).

v

25.94

vi

SECTI01V

I

Descriptive

Information

Your new BEECHCRAFT Travel

Air

is a

four

or

five-place, low wing I

monoplane.

The

all-metal, semimonocoque

airframe

structure is

of

aluminum, magnesium

and

alloy riveted

and

spotwelded

for

•

maximum strength. Careful workmanship

and

inspection make certain

that structural components will withstand flight loads

in

excess

of

the

FAA requirements

for

a

"Normal"

category,

under

which the Model

D95A is licensed.

To develop a good flying technique, you must first have a general

working knowledge

of

the several systems

and

accessories

of

your

aircraft.

Although

they

are

closely interdependent

in

fact, these

systems have been

broken

down

arbitrarily

in

this section

for

ease

of

presentation.

1-1

FLIGHT CONTROLS

Primary

movable control surfaces

of

the Travel

Air

are

operated

through

push-pull rods

and

conventional closed-circuit cable systems

terminating

in

bell cranks.

The

pre-formed, extra-flexible steel cables

run

over phenolic pulleys with sealed

ball

bearings which

ordinarjly

require

no

lubrication

and

insure smooth, free action

and

long

cable

life.

Standard

equipment provides a throw-over type control wheel

arm

for elevator

and

aileron control which may

be

locked in posi-

tion on either the pilot or copilot side

and

pilot's

rudder

pedals

adjustable

fore

and

aft

to fit individual requirements.

The

right

hand

rudder

pedals (optional) rnay be laid flat against the floorboards

when not

in

use.

Trim

tabs on the elevator

and

rudder

control sur-

faces

are

adjustable from the control console through closed-circuit

cable systems which drive jackscrew type actuators. Position indicators

for each

of

the

trim

tabs

are

located

near

the respective controls.

Aileron trim is accomplished by actuating the aileron

trimmer

on

the control column hub.

The

trimmer

displaces the aileron surfaces

themselves to compensate for uneven loading. The displacement

1s

maintained

by

cable loads imposed

by

the aileron trimmer.

Single, slot-type wing flaps

are

operated

through

a system

of

flexible

shafts

and

jackscrew actuators driven

by

a reversible electric

motor

located

under

the front seat. The flap position lights on the left side

of

the control console show green for the up position

and

red

for

the full down

(28°)

landing

position. Intermediate flap positions

of

10°

and

20°,

as

marked on the leading edge

of

the left flap, may

be selected by moving the three position control switch on the left

side of the console to

"OFF"

when the desired flap setting

mark

lines

up with the wing

trailing

edge. Limit switches automatically shut

off the flap motor when the full

up

or

down position is reached.

LANDING GEAR

The

Travel

Air's

extra

strong, electrically operated tricycle

landing

gear incorporates all

of

the advantages provided by this type gear.

The ease

of

ground

operation is assisted

by

the increased visibility,

more positive directional control for

parking

or

operation

under

high

surface wind conditions, decreased stopping distance and longer

brake

and

tire

life;

these

are

but

a few

of

the advantages.

1-2

The

gear

is

operated

through

push-pull

tubes

by

a

reversible

electric

motor

and

actuator

gear

box

under

the

front

seat.

The

motor

is

controlled

by

a two-position

landing

gear

switch

located

on

the

right

hand

side

of

the

control console.

Limit

switches

and

a

dynamic

braking

system

automatically

stop

the

retract

mechanism

when

the

gear

reaches

its

full

up

or

full

down

position.

With

the

landing

gear

in

the

up

position,

the

wheels

are

completely

enclosed

by

fairing

doors

which

are

operated

mechanically

by

the

retraction

and

extension

of

the

gear.

After

the

gear

is

lowered,

the

main

gear

inboard

fairing

doors

automatically

close,

producing

extra

lift

and

reduced

drag

for take-off

and

landing.

Individual

uplocks

actuated

by

the

retraction

system

lock

the

main

gear

positively

in

the

up

position.

No

downlocks

are

necessary

since

the

over-center

pivot

of

the

linkage

forms

a

geometric

positive

lock

when

the

gear

is

fully

extended.

The

linkage

is

also

spring

loaded

to

the

over-center

position.

Landing

gear

position

lights,

located

above

the

landing

gear

switch,

indicate

the

position

of

the

gear,

either

up

or

down,

coming

on

only

when

the

gear

reaches

its

fully

extended

or

retracted

position.

In

addition,

a

mechanical

indicator

beneath

the

control console shows

the

position

of

the

nose

gear

at

all

times.

To

prevent

accidental

gear

retraction

on

the

ground,

a

safety

switch

on

the

left

main

strut

breaks

the

control

circuit

whenever

the

strut

is

compressed

by

the

weight

of

the

airplane

and

completes

the

circuit

so

the

gear

may

be

retracted,

when

the

strut

extends.

Never

rely

on

the

safety

switch

to

keep

the

gear

down

while

taxiing

or

on

take-of}

or

landing

roll.

Always

check

the

position

of

the

switch

handle.

With

the

gear

retracted,

if

either

or

both

throttles

are

retarded

below

an

engine

setting

sufficient to

sustain

flight, a

warning

horn

will

sound

an

intermittent

note.

During

single-engine

operation

the

horn

may

be

silenced

by

advancing

the

throttle

of

the

inoperative

engine

enough

to

open

the

landing

gear

warning

horn

switch.

The

nose wheel assembly is

made

steerable

through

spring

loaded

linkage,

connected

to

the

rudder

pedals

for

greater

maneuverability

during

taxi

operation.

The

retraction

of

the

gear

relieves

the

rudder

pedals

of

their

nose

steering

load

and

centers

the

wheel,

by

a

roller

1-3

and

slot arrangement, to insure

proper

retraction into the wheel well.

A hydraulic dampener

on

the

nose wheel

strut

compensates for the

inherent shimmy tendency

of

a pivoted nose wheel.

Wheels

are

carried

by heat treated

tubular

steel trusses

and

use

Beech air-oil type shock struts. Since the shock struts are filled with

both compressed

air

and

hydraulic fluid, their correct inflation should

be checked

prior

to each flight. Even

brief

taxiing with a deflated

strut

can cause severe damage.

For

manual operation of the landing gear (lowering only) a handcrank

is located behind the front seats. The crank, when engaged, drives the

normal gear actuation system.

Main landing

gear

wheels

are

equipped with BEECHCRAFT ring-disc,

self-adjusting, self-energizing hydraulic brakes actuated by individual

master cylinders connected to the

rudder

pedals

and

operated as toe

brakes.

The

hydraulic

brake

fluid reservoir is accessible from the

forward baggage compartment

and

should be checked occasionally

for specified fluid level.

The

parking

brake

is set

by

a push-pull control

with a center-button lock

and

is located

just

to the left

and

slightly

below the control console. Setting the control does not pressurize the

brake

system,

but

simply closes a valve

in

the lines

so

that

pressure

built

up

by pumping the toe pedals is retained

and

the brakes

remain

set.

Pushing

the control in opens the valve

and

releases the brakes.

POWER PLANTS

Your

Travel

Air

is powered

by

two Lycoming I0-360-BIB engines

rated

at

180 horsepower each,

at

2700 rpm, for take-off

and

maximum

continuous operation.

The

four-cylinder, opposed, aircooled engines

have direct propeller drives

and

a compression ratio of 8.5:I. Pres·

sure

type cowlings

are

used; cooling is controlled by a gill-type flap

on

the

lower trailing edge of each cowling. Fuel distribution is accom-

plished with a constant-flow fuel injection system which incorporates

a special aerated nozzle at the intake

port

of each cylinder. Filtered

induction system

air

is obtained through a filtered airscoop on the

lower front of the engine

and

directed to the

air

throttle valve. A

spring

loaded door

on

the bottom

of

the

air

box opens automatically

if the airscoop is blocked

by

impact ice

or

dirt. Manual controls on

the control console may

he

used to select either filtered

or

alternate

air.

Full dual ignition systems

are

used, with

an

ignition vibrator

1-4

supplying

starting

voltage.

The

electrical system uses Delco-Remy

starters, generators,

and

voltage regulators.

Fuel

injection pumps,

vacuum pumps,

and

constant-speed propellers

are

standard

equip-

ment.

Other

features include sodium-cooled rotator-type valves, chrome

piston

rings

and

a nitrided crankshaft.

Constant-speed, two-bladed, hydraulic, full feathering propellers use

pressure from a feathering

spring

and

centrifugal force

from

the blade

shank

counterweights to increase pitch. oil

under

governor-

boosted pressure decreases pitch.

Propeller

feathering is accomplished by

pulling

the

propeller

control

back past the detent to the

limit

of travel.

Unfeathering

and

restarting

is achieved by moving the propeller control well into the governing

range

and

following the

normal

starting

procedure.

On

airplanes

with the optional unfeathering accumulator, momentary use of the

starter

to initiate rotation is necessary only

at

low airspeeds. lmme-

<Iiately

after

the engine starts, the throttle

and

propeller controls should

be

adjusted

to prevent

an

engine over-speed condition.

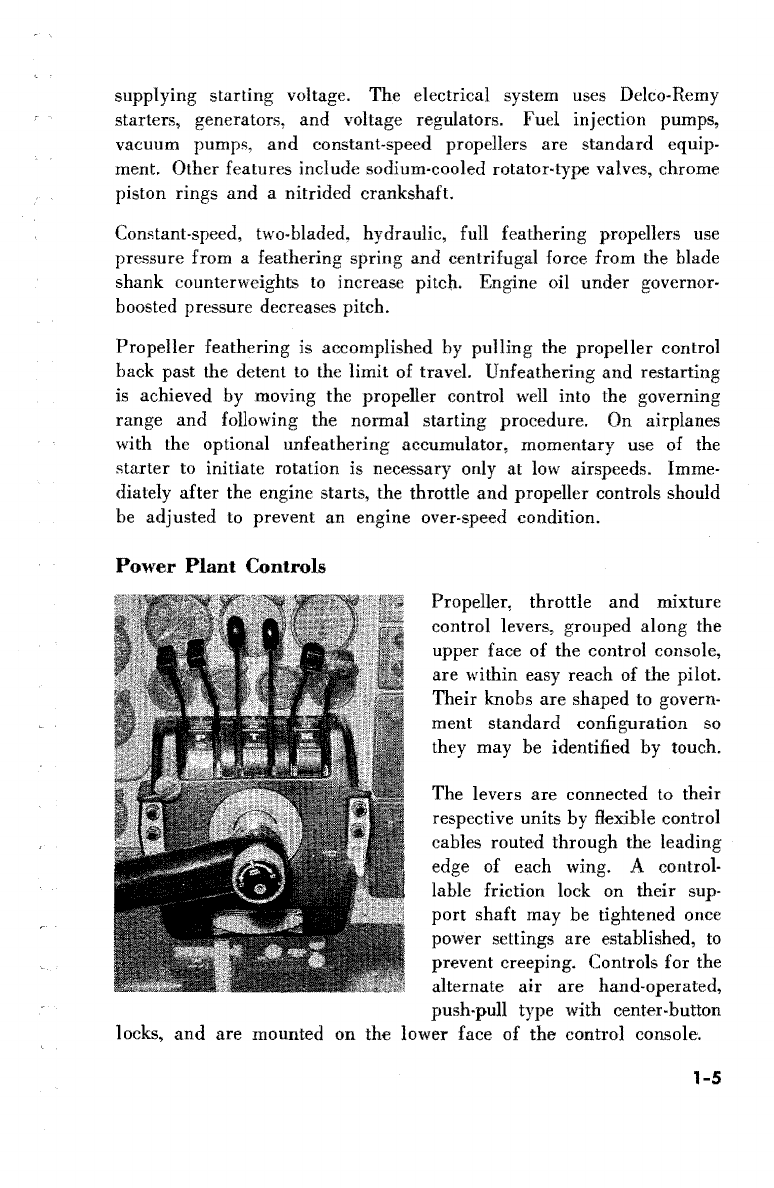

Power

Plant

Controls

Propeller,

throttle

and

mixture

control levers, grouped

along

the

upper face

of

the control console,

are

within easy reach of the pilot.

Their

knobs

are

shaped to govern-

ment

standard

configuration so

they may be identified

by

touch.

The levers

are

connected to their

respective units by flexible control

cables routed

through

the

leading

edge of each wing. A control-

lable friction lock on

their

sup-

port

shaft

may be tightened once

power settings

arc

established,

to

prevent creeping. Controls for the

alternate

air

are

hand-operated,

push-pull type with center-button

locks,

and

are

mounted

on

the

lower face

of

the

control console.

1-5

Direct-cranking electric starters

are

relay-controlled

and

are

energized

by

spring

loaded, combination magneto-starter switches, located on

the ignition paneL These

spring

loaded switches

return

to the

"BOTH"

position when released. The push-pull, button-lock type controls

that

operate the engine cowl flaps are located aft of each fuel selector valve

handle. The optional electrically operated cowl flaps

are

controlled

by switches on .the electrical panel located to the left

of

the control

console.

An

indicator light

adja~ent

to the switches comes

on

whenever

the electric cowl flaps

are

not fully closed.

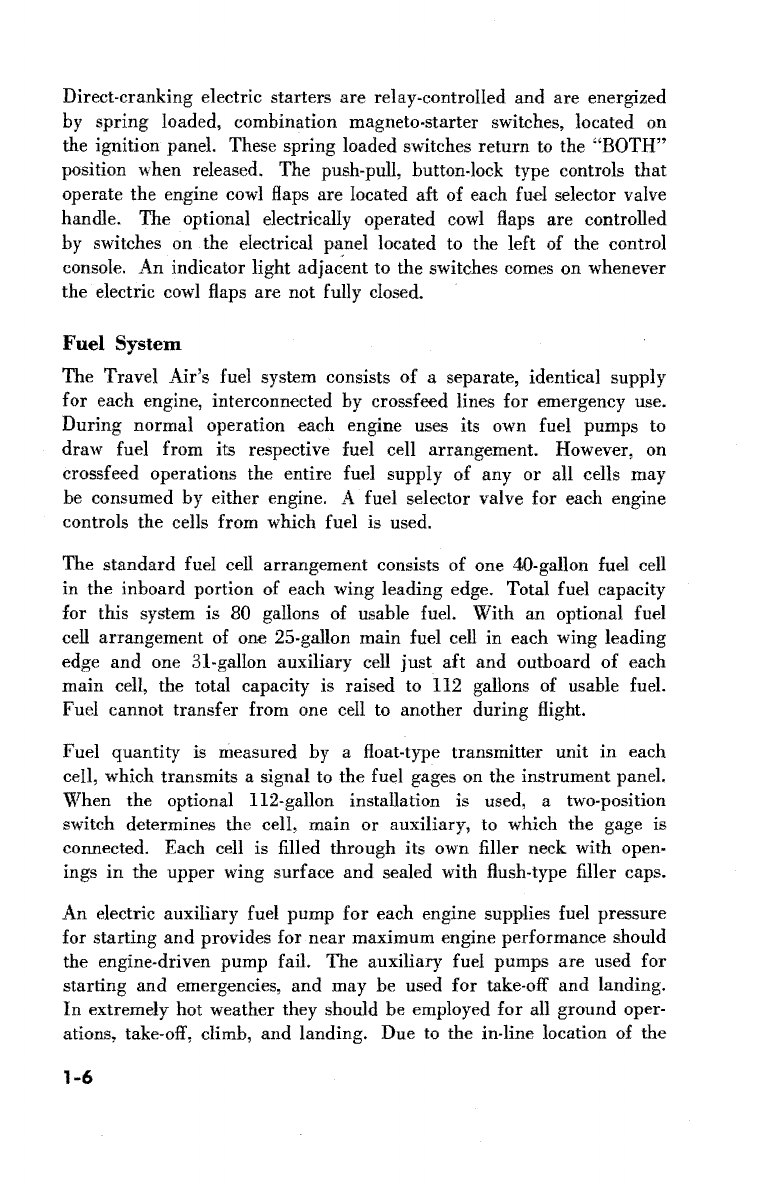

Fuel

System

The

Travel

Air's

fuel system consists

of

a separate, identical supply

for

each engine, interconnected by crossfeed lines

for

emergency use.

During

normal

operation each engine uses its own fuel pumps to

draw

fuel from its respective fuel cell arrangement. However, on

crossfeed operations the entire fuel supply

of

any

or

all cells may

be consumed

by

either engine. A fuel selector valve

for

each engine

controls the cells from which fuel is used.

The

standard

fuel cell arrangement consists

of

one 40-gallon fuel cell

in the inboard portion of each wing leading edge. Total fuel capacity

for

this system is 80 gallons of usable fuel.

With

an optional fuel

cell

arrangement

of one 25-gallon main fuel cell in each wing leading

edge

and

one 31-gallon auxiliary cell

just

aft

and

outboard

of

each

main

cell, the total capacity is raised to

ll2

gallons of usable fuel.

Fuel cannot

transfer

from one cell to another

during

flight.

Fuel quantity is measured by a float-type transmitter unit

in

each

cell, which transmits a signal to the fuel gages on the instrument panel.

When the optional

ll2-gallon

installation is used, a two-position

switch determines the cell, main

or

auxiliary, to which the gage is

connected. Each cell is filled through

its

own filler neck with open-

ings

in

the upper wing

surface

and

sealed with flush-type filler caps.

An

electric auxiliary fuel

pump

for

each engine supplies fuel pressure

for

starting

and

provides for

near

maximum engine performance should

the engine-driven

pump

fail. The auxiliary fuel pumps

are

used

for

starting

and

emergencies,

and

may be used

for

take-off

and

landing.

In

extremely hot weather they should be employed

for

all ground oper-

ations, take-off, climb,

and

landing. Due to the in-line location of the

1-6

-

I

.....

AUXILIARY

ENGINE

SUPPlY

OUTLET

L.

H.

SElECTOR

VAlVE

DRAIN

INLET

I•

TO

ENGINE

•I

ENGINE

SUPPlY

OUTlET

R.

H.

SElECTOR

VALVE

DRAIN

"TT

c:

m

r-

..,..

-<

..,..

......

m

~

..,..

n

:t:

m

~

~

n

auxiliary fuel pumps, between the cells

and

metering unit, fuel

may

be

drawn

from

any

cell within the system

by

the auxiliary

pump

for

the

operating

engine. The fuel system is drained at eight different

locations (including

the

two optional auxiliary cell sumps) as shown

in

the fuel system schematic

and

the servicing

diagram.

Fuel system

strainers

are

located on

the

wing main

spar

in each wheel well

and

at

the inlet to the fuel control units. Regular checking of the strainers

is

of

utmost importance to preventive maintenance, since lowered fuel

pressure may often

be

traced to contaminants clogging the system.

A fuel

flow

indicator

on

the instrument panel is calibrated

in

gallons

per

hour,

based

on system pressure

at

the fuel manifold valve of the fuel

injection unit.

The

instrument also indicates fuel pressure

for

starting.

Oil System

The

engine oil system is

of

the

full-pressure, wet-sump type

and

has

an

8-quart

capacity.

For

safe engine operation, the absolute minimum

amount

of

oil

required

in

the

sump

is 2 quarts. Oil

operating

temperatures

are

controlled by

an

automatic thermostat by-pass control

incorporated

in

the

engine oil passage

of

each system. The automatic

by-pass control will prevent oil flow

through

the cooler when

operating

temperatures

are

below normal.

It

also will by-pass

if

the

radiator

is

blocked. System servicing

and

draining

points

are

shown on the

servicing diagram. The determining factor

for

choosing the correct

grade

of

oil is the oil inlet temperature which is observed

during

flight;

inlet

temperatures consistently

near

the maximum allowable

would indicate a heavier oil is needed.

Straight

petroleum base, aviation

grade, nondetergent oil

of

the

lightest weight

that

will provide

adequate

cooling should

be

used. Certain additive type aviation

grade

oils

are

also

approved

by

the engine manufacturer,

but

they should

be

used with

caution. (See servicing information

and

Consumable Materials Chart

in

Section

VII.)

Condensed moisture

in

the oil sump

may

be

drained

by

occasionally opening

the

oil

drain

valve

and

allowing a small amount of

oil to escape; ideally, this

draining

should be done when the engines

have been stopped overnight or approximately 12 hours. This procedure

should

be followed

more

closely

during

cold weather

or

when a

series of

short

flights

of

less

than

30 minutes

duration

have been

made and the engines allowed to cool completely between such flights.

INSTRUMENTS

All flight

and

engine instruments

are

positioned on the instrument panel

1-8

for maximum utility

and

convenience. Instrument markings

are

matte

white on a black background

and

where practicable, the normal oper-

ating

limits

are

indicated.

The

flight instruments

are

located on a hinged floating panel directly

in

front

o£

the pilot's seat.

Standard

flight instrumentation includes atti-

tude

and

directional gyros, airspeed, altimeter, rate-of-climb, electric

turn-and-bank,

and

a clock.

The

airspeed indicator is marked with a

special blue line range

for

single-engine operation. An outside

au

temperature thermometer

and

magnetic compass

are

mounted on the

windshield divider.

The

standard

engine instruments consist

of

the dual manifold pressure

gage

and

individual tachometers with engine

hour

recorders

at

the top

center of the instrument panel, the dual fuel flow indicator on the lower

STANDARD EQUIPMENT OPTIONAL EQUIPMENT

1.

Clock

2.

Airspeed

Indicator

3. Turn-and-Bank

Indicator

4.

Attitude

Gyro

5.

Directional

Gyro

6.

Altimeter

7. Vertical Speed

Indicator

8. Tachometer

9. Fuel

Quantity

Gages

10.

Magnetic

Compass

11. Dual

Manifold

Pressure

Gage

Revised August 3, 1964

12. Dual Fuel Flow

Indicator

13. Ammeters

14. Suction

Gage

15. Dual

Oil

Pressure

Gage

16. Dual

Cylinder

Head

Temperature

Gage

17. Dual

Oil

Temperature

Gage

18. Landing

Gear

Position Switch

19. Flap Position Switch

20. Electrical Panel

21.

Ignition

Panel

and

Generator

or

Alternator

Switches

A. ADF

Indicator

B.

Dual Tachometer

C.

Propeller

Anti-

leer Fluid

Gage

D.

VOR

Indicator

E.

VOR

Indicator

with

Glide

Slope

F.

DME

Indicator

G.

DME

Control

1-9

left

hand

side

of

the panel,

and

the

dual

oil temperature, oil pressure,

and

cylinder

head

temperature gages plus a suction gage on the

right

hand

side of the panel. When the optional dual tachometer is installed,

the fuel flow indicator is mounted

adjacent

to

the manifold pressure

gage in the top center portion of the panel. Fuel

quantity

is

shown by

two separate gages, each gage serving both the

standard

and

the optional

fuel

tank

in each wing.

The

gages·

are

mounted with the ammeters

just

above the control console.

Impact

air

pressure and atmospheric

air

pressure

for

the airspeed

indicator, ;dtimeter,

and

vertical speed

indicator

are

supplied

by

the

pitot

and

static

air

systems. Since the accuracy

of

these instruments

depends

on

accurate pickup

of

the two pressures, the systems have

been developed carefully

and

tested in flight with highly accurate

special equipment. To insure the

proper

operation

of

these instru-

ments,

drain

the

systems

regularly

and

keep the static

ports

clear

of obstructions.

ELECTRICAL SYSTEM

The Travel

Air's

direct-current electrical power system uses either, one

17-ampere-hour 24-volt battery,

or

two 25-ampere-hour 12-volt batteries,

in

any

standard

or

optional combination with two 25-ampere 12-volt

generators,

or

two 50-ampere

alternator

rectifiers.

Either

battery

in-

stallation is mounted

in

the lower portion of

the

nose section;

both

generator installations

are

belt driven from the engine crankshaft.

In

general,

the

aircraft's

circuitry

is the single-wire, ground-return type

with

the

aircraft

structure itself

being

used as the

ground

return.

On

the

standard

generator installation, each generator's electrical out-put

is automatically controlled

by

its respective voltage regulator

and

the

system's common generator paralleling relay. This paralleling relay

equalizes the out-put

or

load for each generator. The system electrical

reading

is then indicated on the direct

reading

type (not the charge-

diseharge type) ammeters located on the instrument panel

just

above

the

control console. These ammeters indicate individual generator

out-put

and

also serve as system load-meters, i.e.,

an

ammeter indication will

increase

or

decrease

in

direct proportion to the electrical load applied.

On

the optional,

or

alternator

installation,

both

alternators

are

con-

trolled

by

two fully transistorized electronic voltage regulators, however,

1-10

Revised

August

3,

1964

only one.

regulator

is

operable

in

the

system

at

a

time;

the

remammg

regulator

being

used as

an

alternate

or

standby.

Either

of

these regu-

lators

when

switched

into

the

circuit

will

automatically

adjust

alternator

out-put to

the

required

electrical load,

including

battery

recharging.

These

electronic voltage

regulators

provide

usable

current

out-put

at

low

engine

rpm.

Each

alternator

will

produce

approximately

20

amperes

at

1100

engine

rpm.

Selection

of

a

regulator

is

made

by

a

select

switch

placarded

l

and

2, located

on

the

ignition

switch

panel.

System

protection

against

overvoltage is

provided

by

an

overvoltage

relay

which

disconnects

the

alternators

from

the

aircraft

bus

should

an

overvoltage

condition

occur. A press-to-test overvoltage

warning

light

located on

the

instrument

panel

illuminates

whenever

the

alter-

nator

is

disconnected

from

the

aircraft

bus

by

the

overvoltag·e relay.

Should

an

overvoltage

condition

occur

(illumination

of

overvoltage

warning

light),

switch

to

the

standby

voltage

regulator,

either

l

or

2 as

necessary.

Should

the

condition

persist, pull

the

alternator

field

circuit

breaker

(

5-ampere)

and

correct

the

discrepancy

prior

to

the

next

flight.

Illumination

of

this

light

provides

a

warning

that

electrical

current

consumption

should

be

minimized

since only

battery

power

is

available

with

the

alternators

shut-off.

The

circuit

is also designed so

that

the

alternators

are

automatically

shutoff

whenever

the

battery

master

switch

is

OFF.

CAUTION

To

protect

the

alternators

from

overheating,

do

not

use

more

than

45

amperes

from

either

alternator

while

operating

on

the

ground

at

temperatures

above

100°

F

(38°

C)

or

in

flight

at

altitudes

above

14,000 feet

with

outside

air

temperature

above

45°

F

(70°

C).

A

panel

containing

the

magneto,

starter,

battery,

and

generator

switches

is located below

the

pilot's

storm

window.

On

aircraft

equipped

with

alternator

generators,

this panel is modified

by

replacing

the

generator

switches

with

alternator

control switches

and

the

addition

of a

regulator

l

and

2

switch

and

a

5-ampere

alternator

field

circuit

breaker.

Placards

indicate

the

particular

circuit

controlled

by

the

electrical switches

and

individual

circuit

breakers

in

the

panel

to

the

left

of

the

control com-ole.

Refer

to

Section

VII

for

alternator

servicing

and

maintenance

in-

formation.

Revised

August

3,

1964

1-lOA

Table of contents