Beijer Electronics X2 marine 15 User manual

Foreword

Installation manual for X2 marine 15 - B2 HBSC

Foreword

All operator panels are developed to satisfy the demands of human-machine

communication. Built-in functions such as displaying and controlling text,

dynamic indication, time channels, alarm and recipe handling are included.

The operator panel works primarily in an object-oriented way, making it easy to

understand and use. Configuration is carried out on a PC using iX Developer

software. The project can then be transferred and stored in the operator panel

itself.

Various types of automation equipment such as PLCs, servos or drives can be

connected to the operator panels. In this manual, the term “the controller” refers

to the connected equipment.

This manual explains how to install the operator panel. Please refer to the

iX Developer reference manual for further information.

Order no: MAEN229

Copyright © 2021-11 Beijer Electronics AB. All rights reserved.

The information in this document is subject to changewithoutnoticeandisprovidedasavailableatthe

time of printing. Beijer Electronics AB, including all its group companies, reserves the right to change any

information without updating this publication. Beijer Electronics AB, including all its group companies,

assumesnoresponsibilityforanyerrorsthatmayappearinthisdocument. Readtheentireinstallation

manual prior to installing and using this equipment. Only qualified personnel may install, operate or repair

this equipment. Beijer Electronics AB, including all its group companies, are not responsible for modified,

altered or renovated equipment. Because the equipment has a wide range of applications, users must acquire

the appropriate knowledge to use the equipment properly in their specific applications. Persons responsible

for the application and the equipment must themselves ensure that each application is in compliance with

all relevant requirements, standards and legislationinrespecttoconfigurationandsafety. Onlypartsand

accessories manufactured according to specifications set by Beijer Electronics AB, including all its group

companies, may be used.

BEIJER ELECTRONICS AB, INCLUDING ALL ITS GROUP

COMPANIES, SHALL NOT BE LIABLE TO ANYONE FOR ANY

DIRECT, INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL

DAMAGES RESULTING FROM THE INSTALLATION, USE OR

REPAIR OF THIS EQUIPMENT, WHETHER ARISING IN TORT,

CONTRACT, OR OTHERWISE. BUYER'S SOLE REMEDY SHALL

BE THE REPAIR, REPLACEMENT, OR REFUND OF PURCHASE

PRICE, AND THE CHOICE OF THE APPLICABLE REMEDY SHALL

BE AT THE SOLE DISCRETION OF BEIJER ELECTRONICS AB,

INCLUDING ALL ITS GROUP COMPANIES.

Beij er Electronics, MAEN229

Contents

Contents

1 SafetyPrecautions ....................................................... 4

1.1 General ........................................................... 4

1.2 Hazardous Materials ............................................. 4

1.3 DisposalRequirementsUnderWEEERegulations ........... 5

1.4 UL and cUL Installation ......................................... 5

1.5 DuringInstallation .............................................. 6

1.6 DuringUse ....................................................... 7

1.7 Service and Maintenance ........................................ 7

1.7.1 CleaningtheDisplay ............................................ 7

1.8 Dismantling and Scrapping ..................................... 8

1.9 Appearance of Air in Touch Screen ............................. 8

2 NamingConvention .................................................... 9

3 Installation ............................................................... 10

3.1 SpaceRequirements ............................................. 10

3.2 InstallationProcess .............................................. 10

3.2.1 ConnectionstotheController ..................................12

3.2.2 OtherConnectionsandPeripherals .............................13

4 TechnicalData ........................................................... 14

4.1 CompassSafeDistance .......................................... 15

5 ChemicalResistance .................................................... 16

5.1 MetalCasing ..................................................... 16

5.2 Touch Screen and Overlay Material ............................ 16

5.2.1 ProtectiveFilm ...................................................16

5.2.2 TouchScreenSurface ............................................18

5.2.3 TouchScreenProtector ..........................................18

6 OperatorPanelDrawings .............................................. 19

6.1 Connectors ....................................................... 19

6.1.1 CommunicationPorts ...........................................19

6.1.2 DigitalOutputs ..................................................20

6.2 X2marine15-B2HBSCOutline ............................. 21

7 Additional Installation Tips ............................................ 22

7.1 Grounding the operator panel .................................. 22

7.2 EthernetConnectionintheOperatorPanel ................... 23

7.3 To Achieve Better EMC Protection ............................. 24

7.4 AmbientTemperature ........................................... 25

7.5 Safety ............................................................. 27

7.6 GalvanicIsolation ................................................ 28

7.7 Cable and Bus Termination RS-485 ............................ 30

7.8 CANInterface ................................................... 30

7.8.1 CableRecommendations ........................................30

7.8.2 Termination .....................................................30

7.8.3 RestrictionsandRecommendations ............................31

7.9 USBMemorystick ............................................... 31

7.10 ImageSticking ................................................... 31

Beij er Electronics, MAEN229

Safety Precautions

1SafetyPrecautions

Both the installer and the owner and/or operator of the operator panel must read

and understand this installation manual.

1.1 General

•Read the safety precautions carefully.

•Check the delivery for transportation damage. If damage is found, notify the

supplier as soon as possible.

•Do not use the operator panel in an environment with high explosive hazards.

•The supplier is not responsible for modified, altered or reconstructed

equipment.

•Use only parts and accessories manufactured according to specifications of

the supplier.

•Read the installation and operating instructions carefully before installing,

using or repairing the operator panel.

•Neverallowfluids,metalfilingsorwiringdebristoenteranyopeningsinthe

operator panel. This may cause fire or electrical shock.

•Only qualified personnel may operate the operator panel.

•Storing the operator panel where the temperature is lower/higher than

recommended in this manual can cause the LCD display liquid to

congeal/become isotropic.

•The LCD display liquid contains a powerful irritant. In case of skin contact,

wash immediately with plenty of water. In case of eye contact, hold the eye

open,flushwithplentyofwaterandgetmedicalattention.

•Thefiguresinthismanualserveanillustrativepurpose. Becauseofthemany

variables associated with any particular installation, the supplier cannot

assume responsibility for actual use based on the figures.

•The supplier neither guarantees that the operator panel is suitable for your

particular application, nor assumes responsibility for your product design,

installation or operation.

•It is recommended to turn on and shut down the operator panel at least once

before installing any components/cards or before connecting the operator

panel to external devices; for example serial devices.

•For Marine panels only:

–The operator panel must be installed and operated as described in this

document to meet this certification.

–Observe precautions for handling electrostatic discharge sensitive devices

1.2 HazardousMaterials

Toxic and hazardousmaterialsor elements

有毒和有害的材料或元素

Part description

零件描述

Pb Hg Cd Cr6+ PBB PBDE

PCBand elect ronic

component s

PCB和电子元件

XOO O O O

O: Indicat es t hat t he concent rat ion of t he hazardoussubst ance in all homogeneous

materialsinthepartsisbelowtherelevant t hreshold of t he GB/ T 26572-2011

Beij er Electronics, MAEN229 4

Safety Precautions

st andard.

O:表示该有害物质在该部件所有均质材料中的含量均在 GB/ T 26572-2011 规定的限

量要求以下。

X: Indicat est hat t he concent rat ion of t he hazardoussubst ance of at least one of

allhomogeneousmaterialsinthepartsisabove t he relevant t hreshold of t he GB/ T

26572-2011 standard. But st ill complieswit h t he EU RoHSDirect ive 2011/ 65/ EU.

X: 表明该有害物质至少在部件的某一均质材料中的含量超出GB/ T 26572-2011规定

的限量要求。但仍然符合EURoHS指令2011/ 65/ EU。

1.3 Disposal RequirementsUnder

WEEERegulations

For professional users in the European Union: If you wish to discard electrical

and electronic equipment (EEE), please contact your dealer or supplier for further

information.

For disposal in countries outside of the European Union: If you wish to discard

this product please contact your local authorities or dealer and ask for the correct

method of disposal.

1.4 ULandcULInstallation

Caution:

Thissect ion isonly valid for ULlabeled X2 panels.

•This equipment is suitable for use in Class 2 non-hazardous locations only.

[combinations of equipment in your system are subject to investigation by the

local authority having jurisdiction at the time of installation].

•All devices have to be supplied by a Class 2 power supply.

Warning:

Only UL and cUL approved expansion unit sare allowed t o be connect ed t o

t he port designat ed “ EXPANSION” . At t he moment t here are no such unit s

evaluat ed or allowed.

SEULESLESUNITÉSD'EXTENSION CERTIFIÉESUL ET

cUL PEUVENT ÊTRERACCORDÉESAU PORT DÉSIGNÉ« EXPANSION ».

ÀL'HEUREACTUELLE, AUCUNEUNITÉDECETYPEN'AÉTÉTESTÉE

OU AUTORISÉE

Warning:

Explosion hazard! Subst it ut ion of component smay inpair suit abilit y f or Class

I, Division 2.

RISQUED’ EXPLOSION! LASUBSTITUTIONDECOMPOSANTSPEUT NUIREÁLA

CONFORMITÉDECLASSEI, DIVISION 2.

Beij er Electronics, MAEN229 5

Safety Precautions

Warning:

Bat t ery may explode if mist reat ed. Do not recharge, disassemble or dispose

of in fire.

LABATTERIEPEUT EXPLOSERENCASDEMAUVAISEMANIPULATION.

NELARECHARGEZ PAS, NELADÉMONTEZ PASET NELAJETEZ

PAS DANSLE FEU.

•This product contains a battery; this must only be changed in an area known

to be non-hazardous.

•Replace the battery with a BR 2032 battery. Use of another type of battery

may present a risk of fire or explosion.

•For use on a flat surface of a type 4X enclosure indoor use only.

•Use minimum 75°C copper conductors only.

•To make wiring connections to the power supply connector, follow the table

with cable and torque specifications below:

Terminal Block Connector Wire Size AWG Torque (Lb. In. )

X1/ X100 Phoenix connect ors AWG30 –12 5 –7

X1/ X100 Anyt ek connect ors AWG24 –12 3.5

X1/ X100 DECA connect ors AWG24 –12 7

•ThesedevicesareClass2suppliedprogrammablecontrollers(industrialPCs)

for the use in industrial control equipment and are intended to be (front)

panel mounted (Type 12 and 4x for indoor use only).

Caution:

Theenclosureprovidesadegreeof protectionofat least IP20, but wheninstalledinan

apparat us, it should meet IP65.

LEBOÎTIEROFFREUNDEGRÉDEPROTECTIOND'AUMOINSIP20, MAIS

LORSQU'IL EST INSTALLÉDANSUNAPPAREIL, IL DOIT ÊTREDECLASSEIP65.

1.5 DuringInstallation

•The operator panel is designed for stationary installation on a planar surface,

where the following conditions are fulfilled:

–no high explosive risks

–no strong magnetic fields

–no direct sunlight

–no large, sudden temperature changes

•Install the operator panel according to the accompanying installation

instructions.

•Ground the operator panel according to the accompanying installation

instructions.

•Only qualified personnel may install the operator panel.

•Separate the high voltage, signal, and supply cables.

•Make sure that the voltage and polarity of the power source is correct before

connecting the operator panel to the power outlet.

•Peripheral equipment must be appropriate for the application and location.

Beij er Electronics, MAEN229 6

Safety Precautions

1.6 DuringUse

•Keep the operator panel clean.

•Emergency stop and other safety functions may not be controlled from the

operator panel.

•Do not use excessive force or sharp objects when operating the touch screen.

1.7 Service and Maintenance

•Only qualified personnel should carry out repairs.

•The agreed warranty applies.

•Before carrying out any cleaning or maintenance operations, disconnect the

equipment from the electrical supply.

•Clean the display and surrounding front cover with a soft cloth and mild

detergent.

•Replacing the battery incorrectly may result in explosion. Only use batteries

recommended by the supplier. During the warranty period, the battery needs

to be replaced by an authorized Beijer Electronics service center.

Warning:

On versionswit h Codesys runt ime included don’ t replace t he bat t ery bef ore

a backup of t he Codesysret ain variablesand cont ent hasbeen made!

For more inf ormat ion cont act our l ocal support t eam or look in hel ponline.

1.7.1 Cleaningthe Display

We recommend using a dry, clean cloth to wipe off dust regularly. Use alcohol or

ammonia-based cleaning agent for cleaning only when necessary. When other

solvents or cleaning agents are used, be sure to follow manufacturers’ instructions.

The agent should be applied to a clean cloth and should not be sprayed directly

onto the panel surface. After cleaning the agent should be removed.

Ammonia based glass cleaners (typically 5-10% ammonia) or 75% alcohol can be

used to clean the surface of PCAP and resistive touch panels.

When you clean the surface of your touch panel, please follow these steps:

1. Apply cleaning agent (alcohol, bleach, or glass cleaner) to a clean cloth. Make

sure the cloth is well saturated.

2. Wipe touch panel in a “Z” motion on the touch panel surface.

3. Dry the panel thoroughly with a dry cloth, removing as much of the cleaning

solution as possible.

4. Do not mix bleach and ammonia because this will produce a dangerous

chemical reaction.

5. Please do not spray cleaning solution directly onto the touch panel surface.

Beij er Electronics, MAEN229 7

Safety Precautions

Note:

•Cleaning solut ionscont aining bl each, alcohol, and ammonia are corrosive t o

t ouch panel surf ace coat ingsand ITOfil m. So, you should not leave t he solut ion on

t he t ouch panel surf ace f or more t han 2 minut es. Make sure t o remove all residue

when finished cleaning.

•Do not use sharp t oolst o clean t he surf ace of t he t ouchscreen.

•Do not use air guns, wat er j et s, or st eam, to clean t he surface of t ouchscreensas

t hey may damage t ouchscreen funct ionalit y.

•If condiment s, food, or drinksare spilled on t he surf ace of t he t ouchscreen, please

remove t hem immediat ely.

•Ensure moist ure doesnot seep t hrough t he cable connect ion area f rom t he edges

during cleaning.

1.8 Dismantlingand Scrapping

•The operator panel or parts thereof shall be recycled according to local

regulations.

•The following components contain substances that might be hazardous to

health and the environment: lithium battery, electrolytic capacitor, and

display.

1.9 Appearance of Air in Touch Screen

The layer structure of the touch screen contains air. In rare cases, the appearance

of bubbles can arise. This is purely cosmetic and does not affect the functionality

of the operator panel. The appearance can occur under certain environmental

conditions such as temperature, humidity, and atmospheric pressure.

Beij er Electronics, MAEN229 8

Naming Convention

2 NamingConvention

The name of each panel is based on its properties according to the table below.

X2 family Size (inches)

Genera-

tion/ Version Variant

base

pro

marine (= wit h

BL)

cont rol (= wit h

SC)

mot ion (= wit h

SM)

ext reme

4

5

7

10

12

15

21

v2 SC

SM

HB

HP

BL

12V

SL

RO

CO

web

Soft Cont rol

Sof t Mot ion

High Bright ness

High Performance

Black

12 Volt

Sealed

Rugged Only

Cert ificat ion Only

Examples:

•X2 base 5 v2

•X2 pro 7

•X2 control 10

•X2 marine 12 SC

•X2 marine 15 HB SC

•X2 extreme 7 12V*

•X2 extreme 12 HP SC*

•X2 extreme 7 SL HP*

•X2 extreme 12 SL HP SC*

•X2 extreme 7 CO*

•X2 extreme 12 SL HP RO

Note:

Not al l combinat ionsare available.

Note:

* indicat esvariant sincluding IECEx\ ATEXand C1D2 accredit at ion.

Beij er Electronics, MAEN229 9

Installation

3Installation

3.1 Space Requirements

•Maximum installation plate thickness: 8 mm .

The following drawings show the space requirements in millimeters when

installing the operator panel. The drawings are only illustrative and may be out of

proportion.

410 mm

286 mm

100 mm

50 mm 50 mm 100 mm

100 mm 53 mm

3.2 Installation Process

The following is needed:

•A Phillips/slot screwdriver

Do the following:

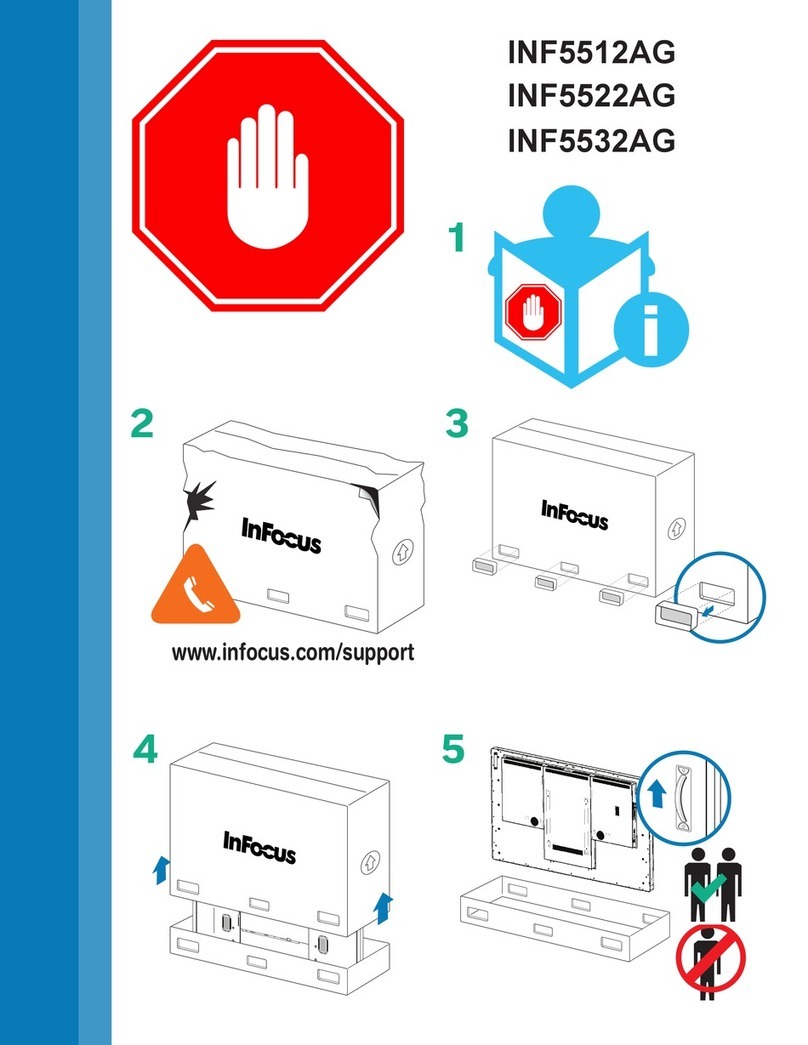

1. Unpack and check the delivery. If damage is found, notify the supplier.

Note:

Place t he operat or panel on a st able surf ace during inst allat ion.

Dropping t he operat or panel or l et t ing it f all may cause damage.

2. To cut a correct opening for the operator panel, use the cut out dimensions

in the outline drawing. A separate cut out drawing is available for download

from the Beijer Electronics web site. For more information, see sections

Operator Panel Drawings and Technical Data.

Beij er Electronics, MAEN229 10

Installation

3. Make sure that the mounting surface of the cutout is smooth and cleaned from

any burrs or debris.

4. Install the operator panel into the cutout.

5. Secure the operator panel in position by screwing the slotted thumb screw

clockwise, allowing the built-in brackettoflipoutandtightenagainstthe

cabinet as shown.

Tighten the screws to 0.7 Nm ± 0.2 Nm.

6. In cases where the front panel seal (IP54 or greater, NEMA-4X) is critical,

use a torque wrench to ensure all screws are torqued within the specification

above.

Beij er Electronics, MAEN229 11

Installation

7. Connect the cables in the specified order, according to the drawing and steps

below.

Caution:

•The operat or panel must be brought t o ambient t emperat ure bef ore it isst art ed

up. If condensat ion f orms, ensure t hat t he operat or panel is dry bef ore connect ing

it t o t he power out let .

•Ensure t hat t he operat or panel and t he cont roller syst em have t he same el ect rical

grounding (ref erence volt age level), ot herwise errorsin communicat ion may

occur.

•Ensure t hat the voltage and polarit y of t he power source iscorrect .

•Separat e high volt age cablesfrom signal and supply cables.

•Shielded communicat ion cablesare recommended.

24V DC

RS232/

RS422/

RS485

24V DC

A

D

Controller

Power

B

Ethernet

C

The image is illustrative only and may differ slightly from the actual panel.

–Connect cable A.

–Connect cable B, using 14-20 AWG (2.08–0.52 mm2), 180–220 N-cm

torque.

–Connect cable C.

–Connect cable D. The recommended cross-section of the cable is 1.5

mm2.

8. Carefully remove the protective film over the operator panel display, take care

to avoid static electricity that could damage the panel.

3.2.1 Connectionsto the Controller

For information about the cables to be used when connecting the operator panel to

the controller, please refer to the help file for the driver in question.

Beij er Electronics, MAEN229 12

Installation

3.2.2 Other Connectionsand Peripherals

Cables, peripheral equipment and accessories must be suitable for the application

and its environment. For further details or recommendations, please refer to the

supplier.

Beij er Electronics, MAEN229 13

Technical Data

4TechnicalData

Parameter X2marine15-B2HBSC

Front panel,W×H×D 410×286×8mm

Cut out dimensions,

W×H

394 × 270 mm

Mount ing dept h 53 mm (153 mm including clearance)

Standalonemounting VESA75×75Note: Maximum screw length for VESA

mount ing is 4mm. Usage of longer screwsmay lead t o

damage.

Front panel seal IP65

Rear panel seal IP 20

Touch screen

material

Polyest er on glass, ITOfilm, resist ive

Frame overlay Autoflex EBA 180L

Touch screen

operat ions

1 million finger t ouch operat ions

Reverse side

material

Pow der - coat ed al um inum

Frame mat erial Powder-coat ed al uminum

Weight 3.85 kg

CPU i.MX6Quad

Quad ARMCort ex-A9 Core

1.0 GHz

1MBL2cache

Serial port s St andard D-sub (9 Pin, f emal e)

COM1: RS-232 wit h RTS/ CTS

COM2: RS-422/ RS-485

COM3: RS-485

1×RS-232 Rx/ Tx wit h RTS/ CTSand 1×RS-422 or 2×RS-485 or

1x CAN2.0B.

Et hernet LAN A 10/ 100 Mbit Base-T (shielded RJ45 wit h LEDs)

Et hernet LAN B 10/ 100 Mbit Base-T (shielded RJ45 wit h LEDs)

USB 2 × USBHost 2. 0, max out put current 500 mA

Support sup t o USB2. 0 High Speed

DIO (out put s,

pot ential free)

Ye s

Opto-MOSrelay, 2x SPST. Normally open.

Ext ernal st orage

media

1×SDcard

Flash memory

(applicat ion

memory)

1 GBSSD(eMMC)

Memory RAM 2 GBDDR3

NVRAM 128 kB

LED 1 × Mult i color

Real t ime clock Yes

Beij er Electronics, MAEN229 14

Technical Data

Parameter X2marine15-B2HBSC

Bat t ery BR2032 lit hium bat t ery

replaceable

Power consumpt ion

at rat ed volt age

31.2 W

Fuse InternalDCfuse,4AT,5×20mm

Power supply +24 VDC(18–32 VDC)

CE: The power supply must conform wit h t he requirement s

according t o EN/ IEC60950 and EN/ IEC61558-2-4.

UL and cUL: The power supply must conform wit h t he

requirement sfor class2 power supplies.

Display TFT-LCDwit h LEDbackl ight

1280 × 800 pixels, 262k colors

Act ive area of display 15. 4” diagonal

Pixel errors ClassI (ISO9241-307)

Backlight bright ness 450 Cd/ m2

Backlight lif et ime 50, 000 hours

Operating

t emperat ure

-10° Ct o +60° C

St orage t emperat ure -20° Ct o +70° C

Rel at ive humidit y in

operat ion

5%–85%non-condensat ion

Vibrat ion 1g, according t o EN/ IEC60068-2-6, Test Fc

Mechanical shock 15g, half -sine, 11msaccording t o EN/ IEC60068-2-27

Approvalsand

cert ificat ions

CE/ FCC/ KCC

Inf ormat ion isavailable on www.beij erelect ronics.com

UL approval Inf ormat ion isavailabl e on ht t p:/ / www.beij erelect ron-

ics.com and/ or ht t ps:/ / UL.com

Marine cert ificat es Inf ormat ion isavailable on www.beij erel ect ronics. com

4.1 CompassSafe Distance

Variant Condit ion St andard

Compass

St eering

Compass

X2 marine 15 HBSC Non-energized

Non-energizedafter

magnet izat ion

Energized and operat ing

40 cm

60 cm

45 cm

20 cm

45 cm

20 cm

Beij er Electronics, MAEN229 15

Chemical Resistance

5 Chemical Resistance

5.1 Metal Casing

The frame and casing material is powder-coated aluminum. This powder paint

withstands exposure to the following chemicals without visible change:

Acet ic acid 10% Phosphoric acid 4%

Citric acid 10% Phosphoric acid 10%

Diesel Sea wat er

Dist illed wat er Sodium chl oride 2%

Edible oil Sodium chloride 20%

Fuel oil Sulphuric acid 20%

Hydrogen peroxide 3% Tap wat er

The powder paint shows limited resistance to the following chemicals at room

temperature:

But anol Nit ric acid 3%

Hydrochloric acid 5% Nit ric acid 10%

Isopropyl alcohol Phosphoric acid 43%

Sodium hypochlorit e 10% Turpent ine

Note:

If exposure t o any of t he above chemicalsisdemanded, it isrecommended t o first t est

t he chemical in a hidden spot of t he met al casing.

Thepowderpaintshowslittleornoresistancetothefollowingchemicalsatroom

temperature:

Acet ic acid, conc. Met hyl -et hyl ket one Toluene

Acet one Nit ric acid 30% Trichloret hyl ene

Ammonia 5% Phenol Xylene

Ammonia, conc. Sodium hydroxide 5% 97 oct ane unleaded pet rol

Et hyl acet at e Sodium hydroxide 30% 98 oct ane leaded pet rol

5.2 Touch Screen and Overlay Material

5.2.1 Protective Film

Autoflex EBA 180L covers the overlay surrounding the screen.

Beij er Electronics, MAEN229 16

Chemical Resistance

Solvent Resistance

The protective film withstands exposure of more than 24 hours duration under

DIN42115Part2tothefollowingchemicalswithoutvisiblechange:

Acet onit rile Diesel Pet roleum spirit (1)

Aj ax / Vim in solut ion Downy / Lenor(1) Phosphoric acid (<30%)

Alkalicarbonat e

solut ion(1) Et hanol Pot assium f erricyanide

Ammonia (<40%)(1) Glycerine Pot assium hydroxide (<30%)

Acet ic acid (<50%) Gl ycol Pure Turpent ine

Ariel powder in

solut ion(1) Gumpt ion(1) SBP60/ 95(1)

Bleach(1) Hydrochloric acid (<36%) Sulfuric acid (<10%)

Cast or oil Linseed oil Tomat o ket chup

Caust ic soda (<40%)(1) Met hanol Trichloroacet ic acid (<50%)

Cut t ing oil Nit ric acid (<10%) Whit e Spirit

Cyclohexanol Paraffinoil Windex(1)

Diacet one alcohol Persil powder in solut ion(1) Wisk

(1) Ext remely f aint glossing of t he t ext ure wasnot ed.

The Autoflex protective film withstands DIN 42 115 Part 2 exposure of up to 1

hour duration to glacial acetic acid without visible change.

The Autoflex protective film is not resistant to high pressure steam at over 100

°C or the following chemicals:

Concent rat ed mineral acids Benzyl alcohol

Concent rat ed caust ic solut ion Met hyl ene chloride

Beij er Electronics, MAEN229 17

Chemical Resistance

5.2.2 Touch Screen Surface

The touch screen surface on the operator panel withstands exposure to the

following solvents without visible change:

Solvents Time

Acet one 10 minut es

Isopropanol 10 minut es

To l u e n e 5 h o u r s

Thetouchscreensurfaceontheoperatorpanelismadeofpolyesterwithahard

coat to resist scratches and withstand exposure to many solvents without visible

change.

5.2.3 Touch Screen Protector

For harsh environments and exposure to outdoor conditions, it is recommended

to use a protective film to guard the touch screen from damage. This optional part

can be ordered from Beijer Electronics.

Beij er Electronics, MAEN229 18

Operator Panel Drawings

6 Operator Panel Drawings

6.1 Connectors

1234

56

Pos. Connector Description

1 Power supply +24 V DC(18–32 V DC)

2 Digital out Opt o-MOSrelay, 2x SPST. Normally open, isolat ed.

3 USB USBHost 2. 0, max out put current 500 mA

4 LANA 10/ 100 Base-T (shielded RJ45)

5 LANB 10/ 100 Base-T (shielded RJ45)

6 COM Serial communicat ion port

6.1.1 Communication Ports

Serial port, 9-pin female

Pin

COM1 COM2 COM3 CAN1 CAN2

1- RS-422 Tx+

RS-485 Tx+/ Rx+ -CAN1-H-

2 RS-232 RxD - - - -

3RS-232TxD - - - -

4 - RS-422 Rx+ RS-485

Tx+/ Rx+ -CAN2-H

5 GND GND GND GND GND

6- RS-422 Tx-

RS-485 Tx-/ Rx- -CAN1-L-

7 RS-232 RTS - - - -

8RS-232CTS - - - -

9 - RS-422 Rx- RS-485

Tx-/ Rx- -CAN2-L

The connector supports up to three independent communication channels and

can be configured for RS-232 and RS-422 or 2xRS-485 or 2x CAN.

Beij er Electronics, MAEN229 19

Operator Panel Drawings

Note:

In order t o ut ilize t wo communicat ion port s, t he Y-split cable CAB109 must be used.

In order to ut ilize t hree communicat ion port st he split cable CAB150 must be used.

To use RS-232 and RS-422, use CAB109.

To use RS-232 and RS-485, use CAB150.

6.1.2 Digital Outputs

Rat ings

Maximum suppl y volt age 32. 0 V (DC) / 22 VRMS(AC)

Maximum load current 0.5 A(DC) / 0.5 ARMS(AC)

Isolation

ChanneltoChannel 1000V(DC)/ 550V

RMS(AC)

ChanneltoSystem 1000V(DC)/ 550V

RMS(AC)

Beij er Electronics, MAEN229 20

This manual suits for next models

1

Table of contents

Other Beijer Electronics Touchscreen manuals