6

When connected to a suitable system and correctly

mounted in a panel enclosure complying with the

requirements for Type of protection 'n', the panel

enclosure containing the BA377NE may be installed

in:

Zone 2 explosive gas air mixture not

likely to occur, and if it does

will only exist for a short time.

Be used with gases in groups:

Group A propane

Group B ethylene

Group C hydrogen

In gases that may safely be used with equipment

having a temperature classification of:

T1 450oC

T2 300oC

T3 200oC

T4 135oC

T5 100oC

At ambient temperatures between -40 and +60oC.

This allows use with all commonly used industrial

gases except carbon disulphide CS2.

2.3 Special conditions for safe use

Special conditions for safe use are specified by the

Ex nA certificate indicated by the certificate

number's 'X' suffix. These state that the BA377NE

Timer or Clock should be:

a. Mounted such that the instrument terminals

are protected by at least an IP54 enclosure

compliant with IEC 60079-0 & IEC 60079-15.

b. Be supplied from limited energy circuits with

output parameters in normal operation equal

to, or less than the instruments input

parameters.

These special conditions for safe use can be

satisfied by mounting the BA377NE in an Ex n, Ex e

or Ex p panel enclosure. For ATEX Category 3

installations in Zone 2, self or third party certified

Ex n, Ex e or Ex p panel enclosures may be used.

Additional requirement apply for non-metallic panel

enclosures.

2.4 Power supply

The input safety parameters for the power supply

terminals 1 and 2 are:

Ui = 30V dc

Ii = 100mA

This allows the BA377NE to be powered from any

dc supply which in normal operation has an output

voltage of less than 30V. See section 3.1 for power

supply recommendations.

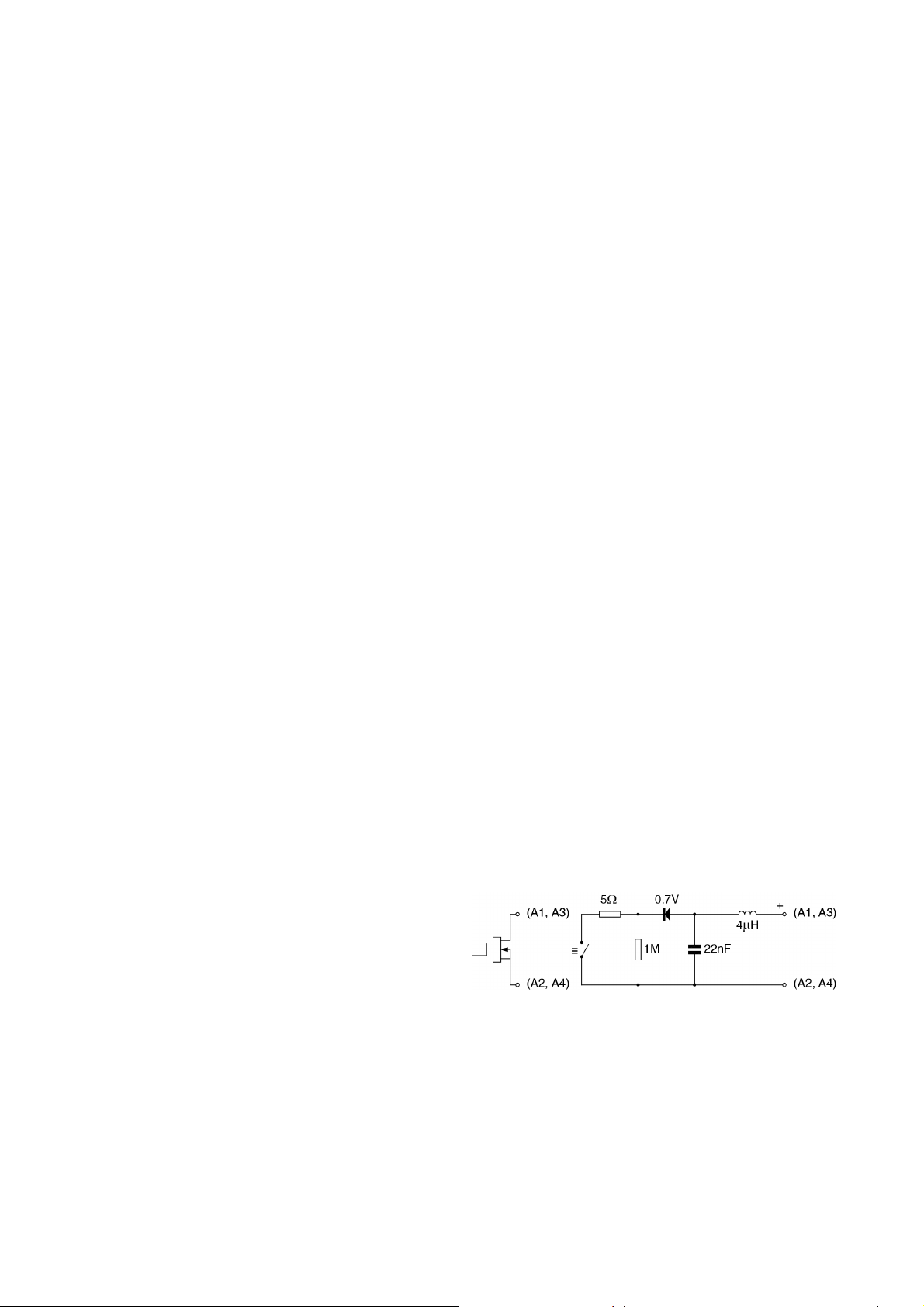

2.5 Input terminals

The BA377NE Timer or Clock has a single pair of

pulse input terminals 5 and 6 that may be configured

for use with different types of sensor.

For sensors that require energising to determine

their state, such as switch contacts or a 2-wire

proximity detector, an external link between

terminals 3 & 4 of the BA377NE connects an internal

7V, 6mA supply to the input terminals. Energising is

not required when the Timer or Clock input is

connected to a voltage pulse source.

Fitting an external link between terminals 3 & 4

changes the Timer or Clock's pulse input safety

parameters as shown below. This table also shows

the types of sensor requiring energising (link fitting).

Safety parameters

Input Output

Type of input Link 3 & 4 Ui Uo Io

Switch contact Yes 15V 10.5V 9.2mA

Proximity detector Yes 15V 10.5V 9.2mA

Open collector Yes 15V 10.5V 9.2mA

Magnetic pick-off No 30V 1.1V 0.5mA

Voltage input (low) No 30V 1.1V 0.5mA

Voltage input (high) No 30V 1.1V 0.5mA

2.6 Remote reset terminals

The BA377NE total display my be reset to zero by

connecting the external reset terminals RS1 and

RS2 together for more than one second. The two

reset terminals have the following safety parameters

in normal operation:

Ui = 30V

Uo = 3.8V

Io = 1mA

2.7 Control outputs - optional

Each of the two optional control outputs is a

separate galvanically isolated Ex nA circuit with the

following input parameters:

Ui = 30V dc

Ii = 200mA

This allows each control output to switch any dc

circuit providing that in normal operation the

maximum supply voltage is not greater than 30V dc

and the switched current is not greater than 200mA.

Providing that the BA377NE Timer or Clock is

correctly installed in a panel enclosure located in

Zone 2 complying with the requirements for Ex n

protection, the two control outputs may be used to

switch suitably protected equipment located in Zone

1 or 2 of a hazardous area, or equipment located in

a safe area.