Belimo WRF04 User manual

1

V1.1 02.2012 · Subject to modification

Room Operating Panel WRF04

Types available

Type code Type Description

Product overview

The room operating panel is designed for temperature detection and

integrated manual control of HVAC applications (change set point,

occupancy, fan speed).

The operating functions can be used very flexibly depending on the room

requirements. Thus, different types with various numbers of function keys

are available.

The universal room operating panel has a wiring clamp, where the sensor

or the operating element (potentiometer, rotary switch, pushbutton, ...) is

wired up.

The device disposes of the following features

- Different function keys depending on the device type, e.g. for set point

or occupancy or fan speed

- LED for status indication

- Integrated temperature sensor

- For wall mounting, mounting on standard installation box is possible

EXT-TN-1070408 WRF04 Ni1000 Ni1000

EXT-TN-1066579 WRF04 PT1000 PT1000

EXT-TN-1070415 WRF04 NTC10k NTC10k

EXT-TN-1072600 WRF04 NTC10kPRE NTC10k Precon

EXT-TN-1072617 WRF04 NTC10kPRE11k NTC10k Precon 11k

EXT-TN-1066586 WRF04 NTC20k NTC20k

EXT-TN-1070712 WRF04 TRA MultiRange 4...20mA

EXT-TN-1070736 WRF04 TRA3 4...20mA

EXT-TN-1070750 WRF04 TRV MultiRange 0...10V

EXT-TN-1070774 WRF04 TRV3 0...10V

EXT-TN-1072655 WRF04P PT1000 PT1000, 1k Potentiometer

EXT-TN-1072631 WRF04P NTC10k NTC10k, 1k Potentiometer

EXT-TN-1072648 WRF04P NTC10kPRE NTC10k Precon, 1k Potentiometer

EXT-TN-1070484 WRF04P Ni1000 Ni1000, 10k Potentiometer

EXT-TN-1070538 WRF04P PT1000 PT1000, 10k Potentiometer

EXT-TN-1070507 WRF04P NTC20k NTC20k, 10k Potentiometer

EXT-TN-1070569 WRF04PS Ni1000 Ni1000, 10k Potentiometer, fan speed

EXT-TN-1070613 WRF04PS PT1000 PT1000, 10k Potentiometer, fan speed

EXT-TN-1070583 WRF04PS NTC20k NTC20k, 10k Potentiometer, fan speed

EXT-TN-1072686 WRF04T PT1000 PT1000, pushbutton

EXT-TN-1072662 WRF04T NTC10k NTC10k, pushbutton

EXT-TN-1072679 WRF04T NTC10kPRE NTC10k Precon, pushbutton

EXT-TN-1072716 WRF04TD PT1000 PT1000, pushbutton, LED

EXT-TN-1072693 WRF04TD NTC10k NTC10k, pushbutton, LED

EXT-TN-1072709 WRF04TD NTC10kPRE NTC10k Precon, pushbuton, LED

-

0

+

II I I I

-

0

+

II I I I

DTP40FRWP40FRW

-

0

+

I

II

AUTO 0

III

II I I I

WRF04PST

(P) Setpoint (P) Setpoint

(T) Pushbutton

(D) Status LED

(S) Fanspeed

WRF04 (P) Setpoint

(T) Pushbutton

WRF04 sensor Room operating panel, temperature sensor

WRF04 TRA Room operating panel, 4...20mA temperature output

WRF04 TRV Room operating panel, 0...10V temperature output

WRF04P sensor Room operating panel, potentiometer, temperature sensor

WRF04PS sensor Room operating panel, potentiometer, fan speed, temperature sensor

WRF04T sensor Room operating panel, pushbutton, temperature sensor

WRF04TD sensor Room operating panel, pushbutton, LED, temperature sensor

2

V1.1 02.2012 · Subject to modification

Room Operating Panel WRF04

Technical data

Security advice !

Mounting advice

Standards CE conformity

EN conformity

2004/108/EEC EMC directive

- EN60730-1(2000) Interference resistance

- EN60730-1(2000) Emitted interference

The installation and assembly of electrical equipment may only be performed by a skilled electrician.

The modules must not be used with equipment that supports, directly or indirectly, human health or life or with applications that can result in

danger for people or animals.

The devices are supplied in an operational status. Installation is made by means of rawl plugs and screws (accessory) to the smooth wall

surface. For wiring, the snap-on lid must be separated from the base plate.

Installation must be made on representative places for the room temperature, to avoid a falsification of the measuring result. Solar radiation

and draught should be avoided. If the device is mounted on standard flush box, the end of the installation tube in the flush box must be sealed,

so as to avoid any draught in the tube falsifying the measuring result.

Power supply

Power consumption

Measuring range

Output

Accuracy@21°C

Potentiometer (P)

Rotary switch (S)

Presence key (T)

Status LED (D)

Clamps

Enclosure

Protection

Cable entry

Ambient temperature

Transport

Weight

- TRV : DC 15-24V(±10%) / AC 24V(±10%)

- TRA : DC 15-24V(±10%)

- TRV : max. 12mA / DC 24V

- TRA : max. 20mA / DC 24V

Adjustable at the transducer

- TRA1 : -50°C...+50°C

- TRA3 : 0°C...+50°C

- TRA8 : -15°C...+35°C

- TRV1 : -50°C...+50°C

- TRV3 : 0°C...+50°C

- TRV8 : -15°C...+35°C

- Sensor : depending on sensor used

- TRV : 0...10V, min. load 5kΩ

- TRA : 4...20mA, max. load 700Ω / DC 24V

- Sensor : depending on sensor used

- TRV/TRA : 1% of full scale

Output resistance 1kΩ or 10kΩ, 3 wire, max.

load 0.25W

5 stages (Auto,0,I,II,III), max. load 5VA

Close contact, max. load 600mW

Colour green, supply voltage DC 15-24V /

AC 24V

Terminal screws, max. 1.5mm²

For wall mounting, material ASA,

colour pure white, similar to RAL9010

IP30 according to EN60529

From behind or side-mounted entry from top /

below

-35...70°C

-35...70°C / max. 85% RH, non-condensing

50g

General Data

1.

2.

Open cover here

Base plate

3

V1.1 02.2012 · Subject to modification

Room Operating Panel WRF04

Electrical connection

Location and accuracy of room sensor

Surface and flush mounting

Build up of self heating by electrical dissipated power

Terminal connection plan

The devices are constructed for the operation of protective low voltage (SELV). For the electrical connection, the technical data of the

corresponding device is valid. With regard to passive sensors (e.g. PT100 etc.) in 2 wire conductor versions, the wire resistance of the supply

wire has to be considered. It is likely that the same has to be compensated by the following electronics. Due to the self heating, the wire current

affects the accuracy of the measurement. Therefore it should not exceed 1mA.

Sensing devices with transducers should in principle be operated in the middle of the measuring range to avoid deviations at the measuring

end points. The ambient temperature of the transducer electronics should be kept constant.

The transducers must be operated at constant supply voltage. The adjustment of the measuring ranges is made by changing the bonding

jumpers (see terminal connection diagram). The output value in the new measuring range is available after approximately 2 seconds.

Besides a suitable representative mounting place, corresponding to the room temperature, the accuracy of the temperature measurement also

depends directly on the temperature dynamics of the wall. It is important that the flush socket is completely closed at the wall side, so that the

circulation of air may take place through the gaps in the cover. Otherwise, deviations in temperature measurement will occur due to uncon-

trolled air circulation. Furthermore, the temperature sensor should not be covered by furnitures, etc. A mounting place next to doors (occurring

draught) or windows (colder outside wall) should be avoided.

Room temperature sensors with electronic components always have a dissipated power, which affects the temperature measurement of the

ambient air. The dissipation in active temperature sensors shows a linear increase with rising operating voltage. This dissipated power has to

be considered when measuring temperature. In case of a fixed operating voltage, this is normally done by adding or reducing a constant offset

value. As transducers (TRA or TRV) work with a variable operating voltage, only one operating voltage can be taken into consideration, for

reasons of production engineering. Transducers 0-10V / 4-20mA have a standard setting at a operating voltage of DC 24V. Therefore at this

voltage, the expected measuring error of the output signal will be the least. As for other operating voltages, the offset error will be increased or

lowered by a changing power loss of the sensor electronics. If a re-cablibration should become necessary later directly on the sensor, this can

be done by means of a trimming potentiometer on the sensor board (For sensors with LON-interface, a re-calibration can be done via

corresponding software variable SNVT).

Remark: Occurred draft leads to a better carrying-off of dissipated power at the sensor. Thus, temporal limited fluctuations might occur upon

temperature measurement.

The temperature dynamics of the wall influence the measurement result of the sensor. Various wall types (brick, concrete, dividing and hollow

brickwork) have different behaviour with regard to thermal variations. A solid concrete wall responds to thermal fluctuations within a room in a

much slower way than a light-weight structure wall. Room temperature sensors installed in flush boxes, have a longer response time to thermal

variations. In an extreme case, they detect the radiant heat of the wall even if the air temperature in the room is lower. The quicker the dynam-

ics of the wall (temperature acceptance of the wall) or the longer the selected inquiry interval of the temperature sensor, the smaller are the

deviations limited in time.

WRF04 Sensor

WRF04 TRV

WRF04 TRA

12

11

10

9

1

Sensor

(1) 3

(2) 4

(2) 5

(1) 2

4-wire

(2) 4

(1) 3

Sensor

2-wire

(1) 3

(2) 4

(2) 5

Sensor

3-wire

WRF04 P Sensor (Sensor, Potentiometer)

WRF04 PTD Sensor (Sensor, Potentiometer, Pushbutton, Status LED)

12

11

10

9

8

7

6

5

4

3

2

1

Notice:

Depending on respective design, the device has a dierent conguration of terminals. The

connection plan attached to each device is valid!

!

Measuring range adjustment

-50°C....+50°C

-10°C....+120°C

0°C....+50°C

0°C....+160°C

0°C....+250°C

-15°C....+35°C

T T

UB

15-24V=

24V~

OUT GND UB

DC 15-24V

GND/OUT

4-20mA

Oset adjustment

-3K +3K

0K

TRV TRA

4

V1.1 02.2012 · Subject to modification

Room Operating Panel WRF04

Dimensions (mm)

Other Belimo Control Panel manuals

Popular Control Panel manuals by other brands

Aprilaire

Aprilaire Zoned Comfort Control 6203 Safety & installation instructions

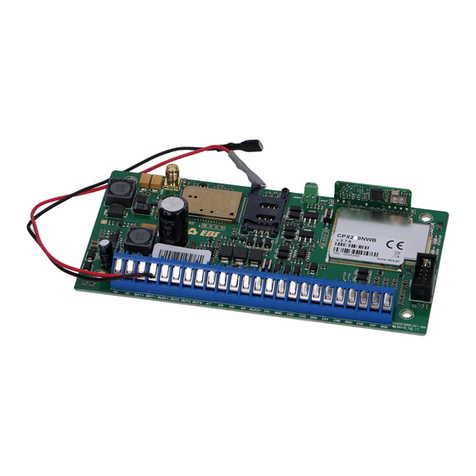

EBS

EBS CPX230NWB Installation and programming manual

Skov

Skov DOL 234 Panel Technical user guide

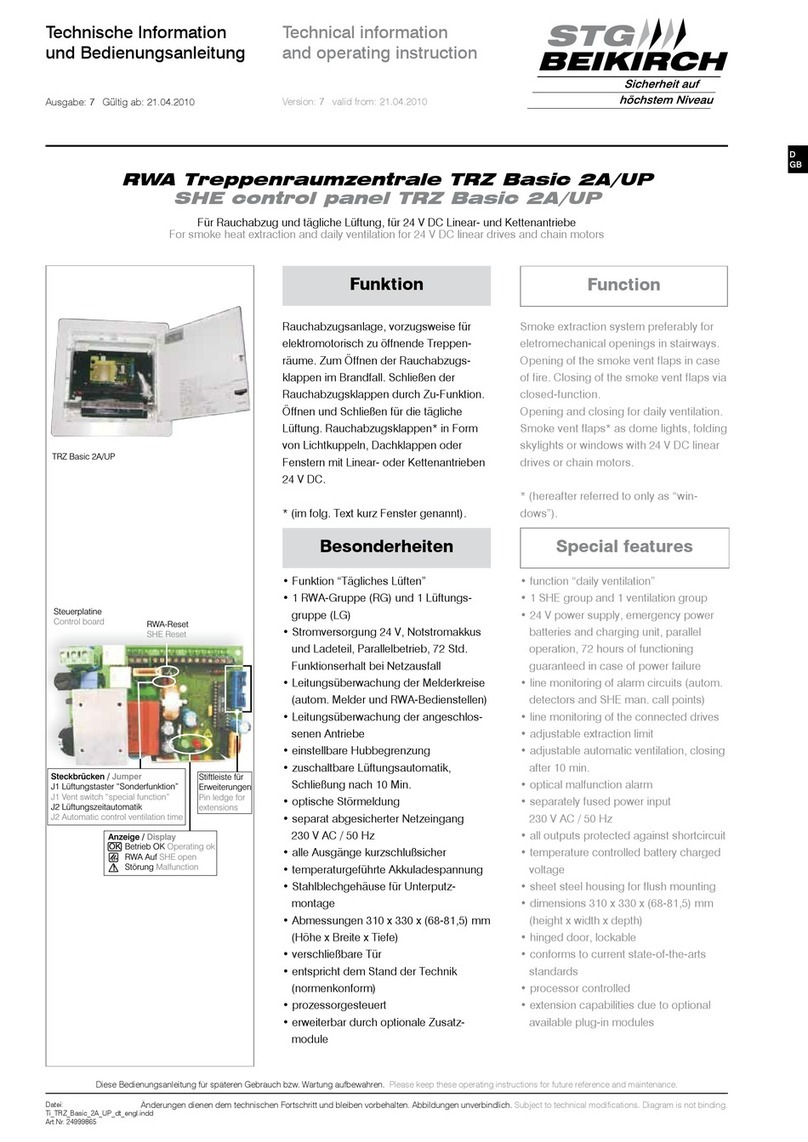

STG-BEIKIRCH

STG-BEIKIRCH TRZ Basic 2A/UP Technical information and operating instruction

STG-BEIKIRCH

STG-BEIKIRCH TRZ Basic 8HM Technical information and operating instruction

AirTech

AirTech ADVISOR CD 7212 installation manual