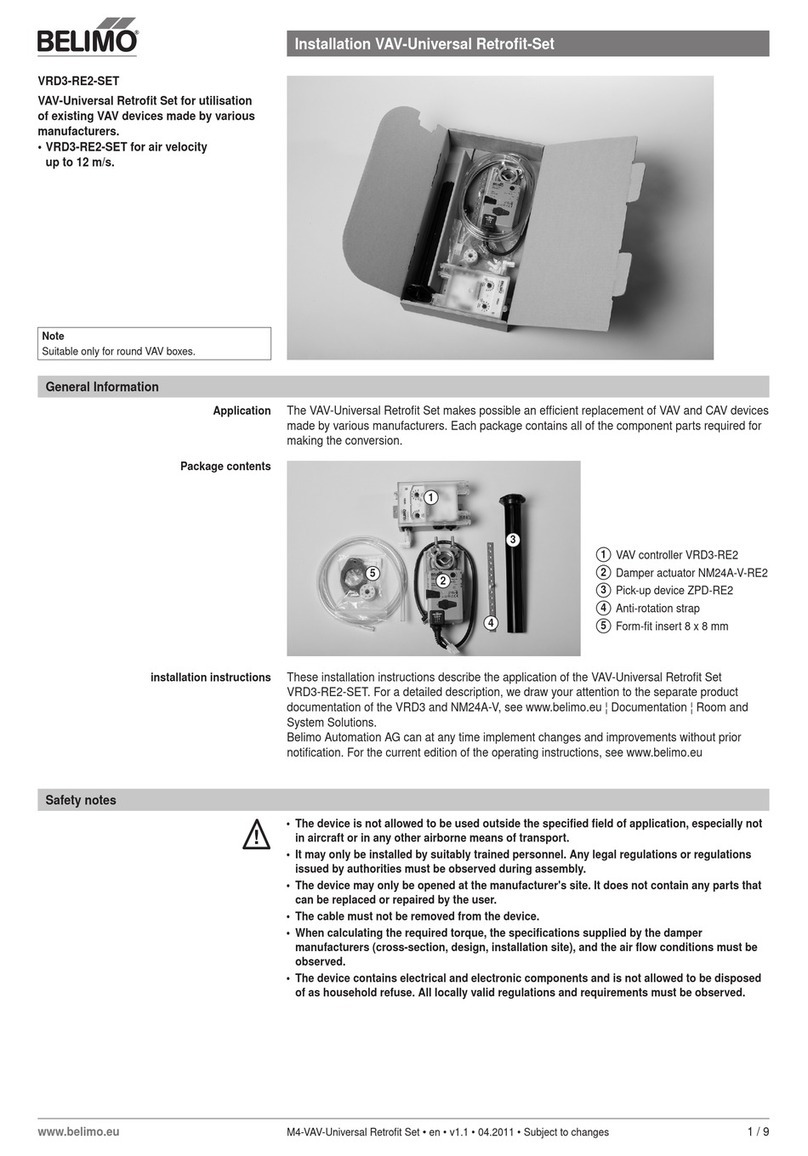

Belimo FS Series Use and care manual

Replacement of Old Gear Train Motors with Belimo FSxx Series

See www.belimo.us/firesmoke Retrofits for more replacement instructions.

Contents

UL®................................................................................................................... 2

Code and Standard Issues............................................................................... 2

NFPA 80 (Fire) & NFPA 105 (Smoke).............................................................. 3

Local Code Approval........................................................................................ 4

Cross Reference.............................................................................................. 5

Examples of various gear train motors and mounting....................................... 8

Linkage Mounting........................................................................................... 11

FSLF.............................................................................................................. 16

FSTF mounting .............................................................................................. 17

FSTF linkage kit mounting.............................................................................. 18

Direct Coupling............................................................................................... 19

Wiring............................................................................................................. 23

Contacts:

Chris Sheehan 203 749-3112 Larry Felker 775 355-2461 (775 250-4160 Cell)

Mike Knipple 203 749-3170 Laure Pomianowski 775 355-2466

800 543-9038

WARNING!

Installer must be trained and experienced with repair

of fire and smoke dampers and actuators.

WARNING!

Before replacing actuator, damper must be inspected and

determined to be fully functional. See NFPA 80 &/or NFPA 105 for

recommended check list.

Gear Train Motors and Linkages - Replacements with Belimo March 2018 1

UL®

Code and Standard Issues

In general, the administrative section of codes state that all mechanical and electrical

systems must be kept in working order and an individual section may state that all life safety

devices and systems must be operable. NFPA 80 (Fire) & NFPA 105 (Smoke) require

periodic testing and repair of dampers as soon as possible after any deficiency is

uncovered.

Chapter 7 IBC & IFC "Containment” Dampers

Commissioning

End of first year

Every 4 years except in hospitals every 6 years

Chapter 9 IFC "Smoke Control System” Dampers

Dedicated

Non-dedicated

Commissioning Commissioning

Semi-annually Annually

Chapter 9 IBC & IFC

Fire detection & Smoke control systems

Dedicated

Non-dedicated

Weekly self-test Not required

Fire & smoke dampers are appliances and field replacement of components is required

when failure of any component occurs.

The Authority Having Jurisdiction (local Fire Marshal and/or Building Official) must be

consulted if any blade or auxiliary switches are employed and are connected to the fire

alarm system or to a Fire Fighters Smoke Control System (FSCS) panel. Retesting is

required. A permit and inspection may be required since connections to an alarm system

have been touched.

In the “Marking & Application Guide, Dampers for Fire Barrier and Smoke Applications &

Ceiling Dampers” April 2013 by Underwriters Laboratories Inc.®, page 6 they state:

DAMPER ACTUATORS

“… field mounting or substitution of actuators is not covered within the scope of the UL

certification of the product. However, this does not necessarily preclude replacement of

actuators in the field. Like any appliance, field servicing of these products is not covered

under the scope of the UL certification and factory follow-up service program. As with any

part of the damper, it is expected that replacement of actuators in the field be done in

d ith th d f t ’ l fi ld i i ”

Gear Train Motors and Linkages - Replacements with Belimo March 2018 2

NFPA 80 (Fire) & NFPA 105 (Smoke)

See NFPA 80 & NFPA 105 for details. The damper cleaning and examination

check list here is based on them.

Damper installation shall meet code requirements. Fire stopping and drywall integrity shall be

confirmed. Damper blades shall be in plane of wall. Duct shall be fall away with no fasteners

connected to damper sleeve.

a. Dampers and ducts shall be cleaned of all foreign debris and dust build-up.

b. All exposed moving parts of the damper shall be dry lubricated as required by the

manufacturer. Do not use oil as it draws dirt.

c. Damper shall be examined without defective old motor or new actuator to determine:

i. The damper shall fully close from the open position.

ii. Damper shall fully open from the closed position.

iii. There are no obstructions to the operation of the damper. The damper shall not be

blocked from closure in any way due to rusted, bent, misaligned, or damaged

frame or blades. The damper shall not have defective hinges, side &/or blade

seals, or other moving parts. The damper frame shall not be penetrated by any

foreign objects that would affect operation.

d. If the damper is equipped with a fusible link, the link shall be removed for testing to

ensure full closure and lock-in-place if so equipped. If the link is damaged or painted, it

shall be replaced with a link of the same size, temperature, and load rating.

e. The fusible link shall be reinstalled after testing is complete.

After installation and wiring of new actuator it shall be tested.

a. The checklist may be customized using material here and in NFPA Standards. Multiple

geometric configurations of springs, fusible link, thermal sensor(s), and actuation are

possible. Confirm with AHJ if any additional requirements exist.

b. Electric thermal sensors, if present, must be tested and replaced if defective.

c. The test shall be conducted with normal HVAC airflow.

d. When equipped with smoke detection activation, the smoke detector shall be activated and

damper operation observed.

For the Air Movement and Control Association damper maintainance manual go to:

http://www.amca.org/publications/damper_maintenance.aspx

NFPA requires damper inspection and repair of dampers.

See www.nfpa.org. for Standards. Details not covered here.

Test voltage input to actuators and repair as necessary if voltage is not correct.

Old breakers often deliver below 115V and failed actuators may be due to power

supply problems.

Gear Train Motors and Linkages - Replacements with Belimo March 2018 3

Local Code Approval

While it is not detailed in codes, the following rules should be followed for selecting Belimo

actuators for replacement:

Check the technical specifications to ensure an “equal or better” actuator is used.

•Temperature – the replacement actuator shall have been UL555S tested at the same

or better temperature as the original actuator. 250˚F or 350˚F are standard.

•Time – the replacement actuator shall drive open and spring closed at a speed equal

or faster than presently required by codes. (The AHJ may grant an exception and

“grandfather” slower actuators where the original actuator was slower.)

•Torque – replacement actuator shall have equal or greater torque than the failed

actuator.

•Voltage – replacement actuator shall have the same voltage rating as the original.

•Amperage – the replacement actuator(s) shall not draw more amperage than the

original(s) and cause the total connected amp draw on a circuit breaker to be greater

than allowed by electrical code.

•Final Testing – actuated damper and associated devices shall be tested for proper

operation. See Acceptance testing details below.

(Mnemonic device: TTT-VAT)

WARNING!

In all cases, installation must comply with any and all local electrical

and life safety codes. Operation of the system after installation must

be performed to verify proper damper cycling. Final checkout requires

verifying correct function.

WARNING!

Note that where any fire alarm wiring is touched, the fire department

must be informed.

Gear Train Motors and Linkages - Replacements with Belimo March 2018 4

Cross Reference

Siebe/Barber

Coleman

Power

Torque

Aux

Switches

Belimo

Notes

MA220

120 VAC

30

FSLF120 US

1, 2, 4

MA221

240 VAC

30

FSLF230 US

1, 2, 4

MA223

24 VAC

30

FSLF24 US

1, 2, 4

MA230

120 VAC

50

FSNF120 US

1, 2, 3

MA231

240 VAC

50

FSNF230 US

1, 2, 3

MA233

24 VAC

50

FSNF24 US

1, 2, 3

MA240

120 VAC

50

5,6

MA250

120 VAC

50

FSNF120 US

1, 2, 3, 4

MA251

230 VAC

50

FSNF230 US

1, 2, 3, 4

MA253

24 VAC

50

FSNF24 US

1, 2, 3, 4

MA-318

24 VAC

60

FSNF24 US

1, 3

MA-318-500

24 VAC

60

1

FSNF24 -S

US

1, 3

MA-418

120 VAC

60

FSNF120 US

1, 3

MA-418-500

120 VAC

60

1

FSNF120-S

US

1, 3

1

Direct couple the Belimo where shaft is available.

Some were direct coupled.

2

FSTF <1.5 sq.ft. FSLF <4

sq.ft.

3

FSNF <12 sq.ft. FSAF*A <18 sq.ft.

4

For Pottorff with shaft spring see:

https://www.belimo.us/mam/americas/technical_documents/pdf-

web/fire_and_smoke_doc/pottorff-ma2xx_to_belimo.pdf

5

Motor was not 90 degree and pulley and cable were usually

used. Some geometric changes are necessary to simplify.

6

Provide photos. Motor, linkage, blades, fusible link, McCabe ©

Link, Typically direct couple to damper shaft if available.

Otherwise, investigation necessary.

Other Honeywell replacements are available.

M8xxx

24 VAC

Modulating

60

FSAFB24-SR

M8xxx w/ Switch

24 VAC

Modulating

60

FSAFB24-SR-S

See https://www.belimo.us/mam/americas/technical_documents/pdf-

web/fire_and_smoke_doc/fire_smoke_competitive_replacement_data_reference.pdf for greater detail.

Gear Train Motors and Linkages - Replacements with Belimo March 2018 5

Honeywell

Voltage

Control

Torque

Aux

Replacement

ML4105A1000

120 VAC

On/Off

30

FSLF120 US

*

ML4105B1009

120 VAC

On/Off

30

FSLF120 US

*

ML4105C1008

230 VAC

On/Off

30

FSLF230 US

*

ML4105D1007

230 VAC

On/Off

30

FSLF230 US

*

ML4115A1009

120 VAC

On/Off

30

FSLF120 US

*

ML4115A1017

120 VAC

On/Off

30

FSLF120 US

*

ML4115B1008

120 VAC

On/Off

30

FSLF120 US

*

ML4115B1016

120 VAC

On/Off

30

FSLF120 US

*

ML4115C1007

230 VAC

On/Off

30

FSLF230 US

*

ML4115C1015

230 VAC

On/Off

30

FSLF230 US

*

ML4115D1006

230 VAC

On/Off

30

FSLF230 US

*

ML4115D1014

230 VAC

On/Off

30

FSLF230 US

*

ML4115H1002

120 VAC

On/Off

30

FSLF120 US

*

ML4115J1019

120 VAC

On/Off

30

FSLF120 US

*

ML4202F1000

120 VAC

On/Off

20

FSLF120 US

*

ML4202F1000

120VAC

On/Off

20

FSLF120 US

*

ML4302F1008

120 VAC

On/Off

20

FSLF120 US

*

ML8105A1006

24 VAC

On/Off

30

FSLF24 US

*

ML8105B1005

24 VAC

On/Off

30

FSLF24 US

*

ML8115A1005

24 VAC

On/Off

30

FSLF24 US

*

ML8115A1013

24 VAC

On/Off

30

FSLF24 US

*

ML8115B1004

24 VAC

On/Off

30

FSLF24 US

*

ML8115B1012

24 VAC

On/Off

30

FSLF24 US

*

ML8115H

24 VAC

On/Off

30

FSLF24 US

*

ML8115J

24 VAC

On/Off

30

FSLF24 US

*

ML8202

24 VAC

On/Off

20

FSLF24 US

*

ML8302

24 VAC

On/Off

20

FSLF24 US

*

MS4104F1010

120 VAC

On/Off

30

FSLF120 US

*

MS4104F1210

120 VAC

On/Off

30

2

FSLF120-S US

*

MS4109F1010

120 VAC

On/Off

80

FSNF120 US

MS4109F1210

120 VAC

On/Off

80

2

FSNF120-S

MS4120F1006

120 VAC

On/Off

175

FSAFA120

MS4120F1204

120 VAC

On/Off

175

2

FSAF120A-S

MS4209F1007

120 VAC

On/Off

80

FSNF120 US

MS4309F1005

120 VAC

On/Off

80

FSNF120 US

Gear Train Motors and Linkages - Replacements with Belimo March 2018 6

MS4604F1010

230 VAC

On/Off

30

FSLF230

*

MS4604F1210

230 VAC

On/Off

30

2

FSLF230-S

*

MS4609F1010

230 VAC

On/Off

80

FSNF230

MS4609F1210

230 VAC

On/Off

80

2

FSNF230-S

MS4620F1005

230 VAC

On/Off

175

FSAF230A

MS4620F1203

230 VAC

On/Off

175

2

FSAF230A-S

MS4709F1014

230 VAC

On/Off

80

FSNF230 US

MS4809F1012

230 VAC

On/Off

80

FSNF230 US

MS7520A2015

24 VAC

2-10V, 4-20mA

175

FSAFB24-SR US

MS8104F1010

24 VAC

On/Off

30

FSLF24

*

MS8104F1210

24 VAC

On/Off

30

FSLF24

*

MS8109F1010

24 VAC

On/Off

80

FSNF24

MS8109F1210

24 VAC

On/Off

80

2

FSNF24-S

MS8120F1002

24 VAC

On/Off

175

FSAF24A

MS8120F1200

24 VAC

On/Off

175

2

FSAF24A-S

MS8209F1003

24 VAC

On/Off

80

FSNF24 US

MS8309F1001

24 VAC

On/Off

80

FSNF24 US

S20230-F

230 VAC

On/Off

175

FSAF230A

S20230-F-SW2

230 VAC

On/Off

175

2

FSAF230A-S

S2024-F

24 VAC

On/Off

175

FSAF24A

S2024-F-SW2

24 VAC

On/Off

175

2

FSAF24A-S

SPH2 Aux Switch

**

32003532-002 Aux Switch

**

* Use FSNF series if damper is > 4 sq.ft.

** Use -S model of proper voltage.

Nominal sq.ft. per UL555S testing.

Temp

Actuator

<4

350°F

FSLF

36” w x 24” h also.

<12 350°F FSNF Multisections also.

<16 250°F FSNF Multisections also.

<18 350°F FSAF*A Multisections also.

The FSTF series actuators were introduced in 2013. They are 18 in-lb and designed for

under 1.5 sq.ft. of fire and smoke damper. Use on larger dampers only when replacing

an existing FSTF on a fire and smoke damper.

The FSLF is recommended for small dampers.

Belimo actuators pass

UL555S at the same damper

sizes as the Honeywell.

NOTE. Although an actuator may operate a larger sized damper

use the UL listed sizing. Call for assistance.

Gear Train Motors and Linkages - Replacements with Belimo March 2018 7

Siemens

Make & Model

Power

Belimo Replacement

GGD121

24

FSAF24

FSNF24

GGD221

120

FSAF120

FSNF120

GGD321

230

FSAF230

FSNF230

GND12x.1x

24V

FSLF24

GND22x.1x

120V

FSLF120

GND32x.1x

230V

FSLF230

Electronic Fuse Link (24 Vac)

ASK79.165 165°F (74°C)

BAE165 US

ASK79.212 212°F (100°F)

None. Call if needed.

ASK79.250 250°F (121°C)

None. Call if needed.

ASK79.350 350°F (177°C)

None. Call if needed.

Optional

Two Auxiliary Switches Fixed 5° and 85°

For more manufacturer specific instructions see Retrofit or Documentation Tabs in

middle of page:

https://www.belimo.us/firesmoke

Belimo linkage kits:

https://www.belimo.com/pim/mam

/americas/technical_documents/d

ata_sheets/man-air-

acc/Mechanical_Accessories.pdf

Mounting Methods Guide:

https://www.belimo.us/mam/americ

as/technical_documents/pdf-

web/guides/mounting_methods.pdf

Gear Train Motors and Linkages - Replacements with Belimo March 2018 8

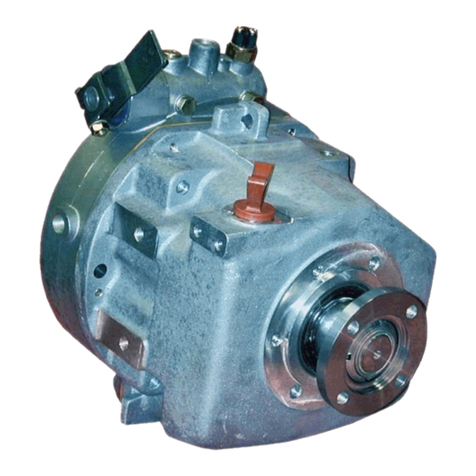

Examples of various gear train motors and mounting

In general, oil-filled spring return motors like the MA418 are

straightforward replacements. In this case, the Belimo FSNF or FSAF

may be direct coupled. The shaft spring should be examined and

exercised to prove it is still operational. The fusible link cannot be seen,

however it should release the shaft spring.

Gear Train Motors and Linkages - Replacements with Belimo March 2018 9

The above applications will need linkages due to space constraints or accessibility

ZG-AF US kit. This contains parts for several different ways to linkage the FSAF and

FSNF series of actuators.

Gear Train Motors and Linkages - Replacements with Belimo March 2018 10

Linkage Mounting

Apply the most appropriate linkage mounting method for the geometric

arrangement

WARNING!

USE CAUTION!

Springs are under high torsion and may cause serious injury! If any external

springs are present, exercise caution – wear face and hand protection.

Gear Train Motors and Linkages - Replacements with Belimo March 2018 11

Use of ZG-106 bracket with crank arm and ball joints to

connect to two damper arms.

With no space to direct couple, the ZG-AF Leg kit has

been used. Note the legs between actuator and duct

Above are some ways in which Belimo linkages are used. The lower right

picture is of an FSTF with ZG-TF112. This actuator is not generally used

for retrofits as it is only 18 in-lb of torque, but in special circumstances, it is

quite useful.

MA418 that was formerly

linkaged, now direct

coupled

These are very easy to

replace. Simply remove

the old motor and

linkages. Then mount

Belimo FSNF over shaft.

Do not remove any

bearings.

Gear Train Motors and Linkages - Replacements with Belimo March 2018 12

The FSAF*A and FSNF series may be mounted using the ZG-102 (left).

However, it is recommended that they be mounted on the ends of the

jackshaft (right). Derate torque to 80% of the combination of multiple

actuators.

NO.

Use of the ZG-102 for mounting 2 FSNF is not recommended in general. The

fast speed and high torque loads will damage gears if actuators are cycled

more than once a day.

YES.

Mounting FSNFs on the ends of the same

jackshaft is preferred. Alternately, the

jackshaft can be cut and the one actuator,

one damper section approach taken.

Example of linkage that can be replaced by direct coupling

The motor to the right can

be replaced by direct

coupling over the shaft.

Use of linkages is not

needed.

Gear Train Motors and Linkages - Replacements with Belimo March 2018 13

Belimo linkage kits:

https://www.belimo.com/pim/mam

/americas/technical_documents/d

ata_sheets/man-air-

acc/Mechanical_Accessories.pdf

Mounting Methods Guide:

https://www.belimo.us/mam/americ

as/technical_documents/pdf-

web/guides/mounting_methods.pdf

Gear Train Motors and Linkages - Replacements with Belimo March 2018 14

Gear Train Motors and Linkages - Replacements with Belimo March 2018 15

FSLF

The FSLF has no linkages except for a custom one supplied in a kit by Ruskin.

Ruskin makes a kit with a shaft

adaptor, hold down, and Belimo

FSLF120 actuator.

Fusible rods are no longer

available from Ruskin.

Where springs are defective, ball

joints, rod, and a BAE 165 or

Ruskin EFL are necessary.

Rewiring is necessary.

Gear Train Motors and Linkages - Replacements with Belimo March 2018 16

FSTF mounting

Given the typical space constraints of installed dampers, it is likely that all the actuator

and linkage parts will need to be assembled as much as possible and then installed as

an assembly.

Possible alternate arrangements for damper clip. (FSNF, FSAF actuators shown.)

Gear Train Motors and Linkages - Replacements with Belimo March 2018 17

FSTF linkage kit mounting

The crank arm material is Duroplast Vyncolit® (phenolic compound similar to Bakelite).

Smoldering temp is 500°F; auto-ignition temp is 900°F.

The ZG-TF112 Crank Arm Adaptor Kit includes:

1 ZG-113 Mounting Bracket

1 KH-TF-1 Crank arm with Retaining Clip

2 Bolts with Nuts

Ball joints and 5/16” Rod not included

The ZG-TF2 Crank Arm Adaptor Kit includes:

1 Mounting Bracket

1 KH-TF-1 Crank Arm with Retaining Clip

3 Bolts with Nuts

Ball joints and 5/16” Rod not included

It is assumed that the bracket here will be installed on an existing sleeve or the Prefco

mounting plate shown in the full damper pictures below. Belimo brackets and parts are

shown in our Mechanical Accessories Guide:

https://www.belimo.com/pim/mam/americas/technical_documents/data_sheets/m

an-air-acc/Mechanical_Accessories.pdf

Gear Train Motors and Linkages - Replacements with Belimo March 2018 18

Direct Coupling

This is the preferred method for mounting -

FSLF

Note that actuator floats freely. Clamp cold welds

when teeth dig into the damper shaft and the anti-

rotation strap stud allows the actuator to move if

shaft is not perfectly concentric. Rigid mounting by

jamming the stud into the U-slot of actuator is NOT

usually best.

FSLF mounted on the

damper shaft. Two

sheet metal screws hold

the anti-rotation strap.

Two nuts secure cold-

weld clamp onto shaft.

Gear Train Motors and Linkages - Replacements with Belimo March 2018 19

FSNF & FSAF

For short shaft mounting, the ZG-

LMSA-1/2-5 can be used.

Alternately, the clamp can be

installed between the actuator and

sheet metal.

Clamp

The geometry of linkages changes the torque translation between the actuator and the

damper. See Belimo’s Mounting Methods Guide for a description of the mathematics.

As long as it is mechanically

solid, the anti-rotation strap

may be bent to fit height.

-

FSNF mounted on the

damper shaft. Two

screws hold the anti-

rotation strap. Two nuts

secure cold-weld clamp

onto shaft.

FSAF mounts the same.

Side view

Gear Train Motors and Linkages - Replacements with Belimo March 2018 20

Other manuals for FS Series

4

Table of contents

Other Belimo Engine manuals

Popular Engine manuals by other brands

PEUGEOT

PEUGEOT Elyseo 50cc Workshop manual

YS

YS 140 LIMITED Operator's manual

Foley Engines

Foley Engines ZF 45 C - Walter Repair manual

Lutz

Lutz B1 Translation of the original instructions

Westerbeke

Westerbeke 55B-FOUR Service manual

Hatz Diesel

Hatz Diesel 2G 40 H Translation of the Original Instruction Book

Nice

Nice Era Star P Series Instructions and warnings for installation and use

CHERUBINI

CHERUBINI Tronic RX instructions

WITTUR

WITTUR WSG-S2.4 Series operating instructions

Flux

Flux F 416 EX Original attachment

Newport Vessels

Newport Vessels NK-180S user manual

IAME

IAME Parilla Norswift 60cc Assembly instructions and user's manual