Type of Erase and Bias: Iligh Frequency (A. C. ) 60KC.

Tube Complement: 1-12AY7 or ECC-83, l-12AX7,

1-6C4, l-6V6cT, 1-6X5cT.

Controls: 1. Speed Change, On-Off Control.

2. Run-Stop Control.

3. Record Push.Button.

4. Tone and push button rewind.

5. Volume and push button fast forward.

OPERATI NG INSTRUCTIONS

Preparing The Bell For Recording-

1. Place the recorder on a flat surface and

remove the eover. Make certain that the "Run-Stop"

control is in the "Stop" position and that the "Speed"

control is in the "Off" position.

2. Insert the A. C. power cord plug into a con-

venient 110-120 volt, 60 cycle A. C. outlet.

Threading The Tape-

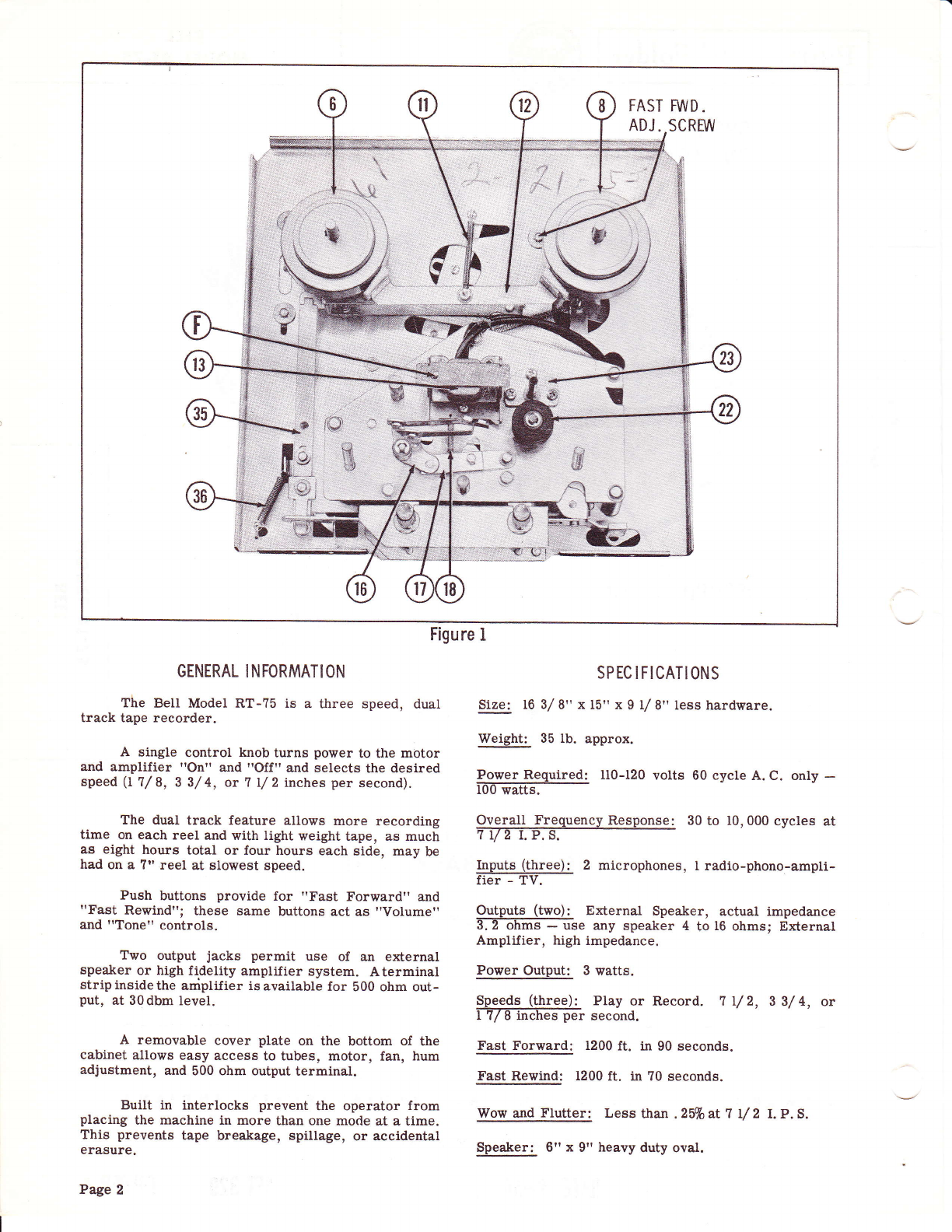

1. Place a reel of rtA, wind tape on the supply

reelsupport (6) and an empty reel of the same size on

the taleup reel support (8).

2. Unwindabout two feet of tape. Hold a section

oftapestraightwith both hands and insert the tape into

the tape slot. Insert the free end of the tape into one

of the radialslots in the hub of the empty reel. Rotate

reel counter clockwise three of four turns to secure

and take up all slack between reels.

To Record From Microphone-

1. Turn recorder on by placing speed control

knob (1) in t}te speed position desired. Allow approxi-

mately 30 seconds for the unit to warm up. Insert the

microphone plug into the Mic. I input jack. Use Mic.

2 input jack only when using two microphones or when

mixing with Radio, Phono., or TV programs. If

microphone is set on a hard surface, place sponge

rubber or several thicknesses of cloth underneath it

to absorb any vibrations, Set record level before

recording by depressing the red record button and

observing the flash of the neon record level indicator.

While sound source is striking microphone, carefully

adjustthe volume control so thatthe levellamp flashes

on peak passages.

NOTE: Correct recording volume is very important.

If the neon level lamp flashes all the time,

the recordingwill be overloaded and distorted

on playback. If level lamp does not flash at

all, playback will be weak and contain high

background noise.

2. After level adjustment has been set, turn the

run-stop control (2) to "Run". Thetape is now moving

and any sound entering the microphone will be re-

corded on the tape. When recording is finished, turn

control (2) to "Stop".

To Record From Radio. Phono. Or TV-

Recordings can be made from a radio or tele-

vision reeeiver by placing the microphone near the

loudspeaker, howeverthis type of recording is usually

not satisfactory beeause of background noises picked

up by the microphone and lack of good quality. A

better recording can be made by connecting the "Radio"

inputof the recorderto the radio or TV voice coil ter-

minals, In the case of an AM-FM Tuner, connect to

the tuner output.

Dual Track Operation-

NOTE: Recordings are made on half the width of the

tape at one time. Since it is impossible to edit

and splice one "track" without affecting the

other, recordings which are to be edited should

be limited to one track.

l. After a reel of tape has been recorded, a

second track may be recorded on the same reel (without

rewinding) by removing the full reel from the right hand

spindle, turning it over, t}ten placing on the left hand

spindle. Placethe emptyreel onthe right hand spindle.

2. Rethreadthe tape andproceedwiththe record-

ing as previously described.

3. Afterthesecondtrack has been recorded, the

first track is ready to be played without rewinding, by

changing reels as described in Step #1 above.

To Rewind-

After a recording is made, tape maybe rewound

by pushing "Rewindrrknob downpositively. Itwill lock

in position Fo it is unnecessary to hold down. When

desired portion of tape is rewound, push down and

release I'Fast Forwardrr knob. This will stop ttre tape.

When rewinding a complete or large portion of a reel,

it is better to take tape out of slot and run straight

across from reel to reel. Thissaves wearonthe head

and is somewhat faster since it eliminates the drag

set up by the tape running through the head slot.

To Play A Recording-

l. To play back recordings, place reels on reel

supports and tlread as previously described. Turn

the speed control pointer (1) to the correct speed; this

alsosupplies power tothe motor and amplifier. Plaee

the run- stop pointer (2) in the "Run" position and adjust

the "Volume" and "Tone" controls for desired listening

level. If speed of tape is unknown, the speed control

pointer (l) can beturned afterthe unitis playing. After

the recordings have been played, return the run-stop

pointer (2) to the "Stop" position. This releases the

pressure roller (22) from the capstan and stops t}e

tape.

2. After the first track has been played, the

second track may be played, without rewinding, by turn-

ing the reels over and placing them on opposite reel

platforms. This may be done at any time during

playback.

NOTE: When recordings are played back thru the

built-in speaker, remove anyphone plug which

may be inserted in either the External Speaker

or High-Z output jacks. These jacks, when

used, disconnect the built-in speaker.

Fast Forward-

In playback, it is sometimes desirable to skip

portions of tape to a particular spot. To do this, push

down and hold "Fast Forward" knob until tape arrives

i

\=/ =o

Hr

FrlF

nF

{

I

\

lrr

Page 3