Bell&Howell 013300 User manual

Disclaimer

This scanned document is provided as a courtesy. We make

no representation for its accuracy. It is for use by qualified

personnel only. There are high voltage and mechanical

hazards present in this equipment. Do not attempt repair

unless you are fully aware of the safety precautions to be

taken. Use this information at your own risk.

www.paulivester.com

SERVICE

INSTRUCTIONS

LAMP

SUPPLY

UNITS

50

Hz

—

Part

No.

013300

60

Hz

—Part

No.

013

310

PHOTO

PRODUCTs GROUP

BELL

s

HOWELL

GENERAL

SERVICE

DEPT.

7100

McCORMICK

ROAD

CHICAGO,

ILLINOIS

60645

PART

NO.

70472-2

REVISED

PRINTED

IN

U.S

.A.

JANUARY

1971

SERVICE

INSTRUCTIONS

Lamp

Supply

Unit

for

Marc

300

Projection

Lamp

TABLE

OF

SPECIFICATIONS

Bell

&

Howell

Part

Number:

50

-Hz

Unit

013300

60

-Hz

Unit

013310

Overall

Dimensions:.

.

3.75

in.

h

by

9.08

in.

w

by

13.25

in.

lg

120

volts

AC

±10%

(60

Hz)

Input

Voltage:

115

volts

AC

±10%

(50

Hz)

Input

Power:

384

watts

Input

Current:

9

amperes

AC

Load

Current:

7.75

amperes

DC

±

5%

Load

Voltage:

Pulse

9KV

Peak

Back

Up

Run

330

volts

DC

37.5

volts

DC

Thermal

Specifications:

(see

Page

7)

Thermal

Protection:

Two

automatic

resetting

thermal

protectors

interrupt

power

if

the

internal

temperature

of

the

power

supply

exceeds

105

°

C

(220°F.)

LAMP

SUPPLY

UNITS

FACTORY

SERVICE

ADDRESSES

PRODUCT

ONLY

CHICAGO

General

Service

Department

2200

Brummel

Place

Evanston,

Illinois

60202

Area

Code:

312-673-3300

NEW

YORK

General

Service

Department

200

Smith

Street

E.

Farmingdale,

L.I.,

New

York

11735

Area

Code:

516-293-8910

GLENDALE

General

Service

Department

623

Rodier

Drive

Glendale,

California

91201

Area

Code:

213-245-6631

PARTS

ORDERS

AND

SERVICE

INFORMATION

General

Service

Department

7100

McCormick

Road

Chicago,

Illinois

60645

Area

Code:

312-673-3300

TABLE

OF

CONTENTS

INTRODUCTION

Page

General

2

Principles

of

Operation

2

Circuit

Description

2

Code

Date

Information

3

ELECTRICAL

TEST

PROCEDURES

Special

Test

Equipment

Required

4

Commercial

Test

Equipment

Required

4

Hi

-Potential

Test

5

General

Electrical

Inspections

5

Test

Equipment

Set

-Up

5

Inrush

Current

Test

5

Ripple

Current

Test

5

D.C.

Output

and

A.C.

Input

Current

Tests

5

Pulse

Voltage

and

Relay

Cycle

Time

Tests

6

Open

Circuit

Voltage

Test

6

TROUBLE

SHOOTING

Trouble

Shooting

for

Overheating

in

Lamp

Supply

Unit

7.

Trouble

Shooting

for

Faulty

Lamp

Operation

7

-

8

Trouble

Shooting

with

Test

Equipment

9-10

Illustrations

—

Figures

1

through

8

11

-

24

1

SERVICE

INSTRUCTIONS

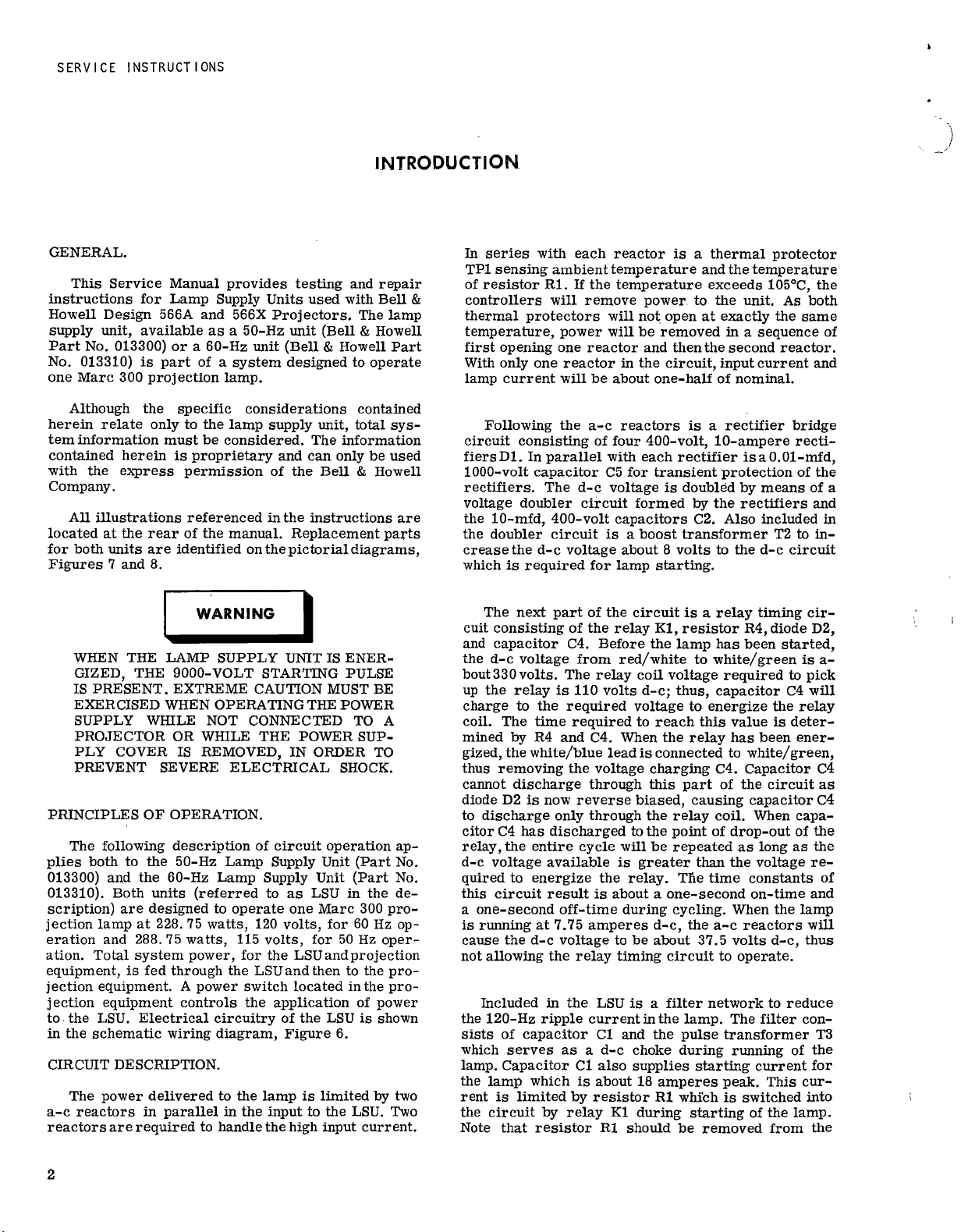

INTRODUCTION

GENERAL.

This

Service

Manual

provides

testing

and

repair

instructions

for

Lamp

Supply

Units

used

with

Bell

&

Howell

Design

566A

and

566X

Projectors.

The

lamp

supply

unit,

available

as

a

50

-Hz

unit

(Bell

&

Howell

Part

No.

013300)

or

a

60

-Hz

unit

(Bell

&

Howell

Part

No.

013310)

is

part

of

a

system

designed

to

operate

one

Marc

300

projection

lamp.

Although

the

specific

considerations

contained

herein

relate

only

to

the

lamp

supply

unit,

total

sys-

tem

information

must

be

considered.

The

information

contained

herein

is

proprietary

and

can

only

be

used

with

the

express

permission

of

the

Bell

&

Howell

Company.

All

illustrations

referenced

in

the

instructions

are

located

at

the

rear

of

the

manual.

Replacement

parts

for

both

units

are

identified

on

the

pictorial

diagrams,

Figures

7

and

8.

WARNING

WHEN

THE

LAMP

SUPPLY

UNIT

IS

ENER-

GIZED,

THE

9000

-VOLT

STARTING

PULSE

IS

PRESENT.

EXTREME

CAUTION

MUST

BE

EXERCISED

WHEN

OPERATING

THE

POWER

SUPPLY

WHILE

NOT

CONNECTED

TO

A

PROJECTOR

OR

WHILE

THE

POWER

SUP-

PLY

COVER

IS

REMOVED,

IN

ORDER

TO

PREVENT

SEVERE

ELECTRICAL

SHOCK.

PRINCIPLES

OF

OPERATION.

The

following

description

of

circuit

operation

ap-

plies

both

to

the

50

-Hz

Lamp

Supply

Unit

(Part

No.

013300)

and

the

60

-Hz

Lamp

Supply

Unit

(Part

No.

013310).

Both

units

(referred

to

as

LSU

in

the

de-

scription)

are

designed

to

operate

one

Marc

300

pro-

jection

lamp

at

228.75

watts,

120

volts,

for

60

Hz

op-

eration

and

288.

75

watts,

115

volts,

for

50

Hz

oper-

ation.

Total

system

power,

for

the

LSUandprojection

equipment,

is

fed

through

the

LSU

and

then

to

the

pro-

jection

equipment.

A

power

switch

located

in

the

pro-

jection

equipment

controls

the

application

of

power

to

the

LSU.

Electrical

circuitry

of

the

LSU

is

shown

in

the

schematic

wiring

diagram,

Figure

6.

CIRCUIT

DESCRIPTION.

The

power

delivered

to

the

lamp

is

limited

by

two

a

-c

reactors

in

parallel

in

the

input

to

the

LSU.

Two

reactors

are

required

to

handle

the

high

input

current.

In

series

with

each

reactor

is

a

thermal

protector

TP1

sensing

ambient

temperature

and

the

temperature

of

resistor

Rl.

If

the

temperature

exceeds

105°C,

the

controllers

will

remove

power

to

the

unit.

As

both

thermal

protectors

will

not

open

at

exactly

the

same

temperature,

power

will

be

removed

in

a

sequence

of

first

opening

one

reactor

and

then

the

second

reactor.

With

only

one

reactor

in

the

circuit,

input

current

and

lamp

current

will

be

about

one-half

of

nominal.

Following

the

a

-c

reactors

is

a

rectifier

bridge

circuit

consisting

of

four

400

-volt,

10

-ampere

recti-

fiers

Dl.

In

parallel

with

each

rectifier

is

a

0.01-mfd,

1000

-volt

capacitor

C5

for

transient

protection

of

the

rectifiers.

The

d

-c

voltage

is

doubled

by

means

of

a

voltage

doubler

circuit

formed

by

the

rectifiers

and

the

10-mfd,

400

-volt

capacitors

C2.

Also

included

in

the

doubler

circuit

is

a

boost

transformer

T2

to

in-

crease

the

d

-c

voltage

about

8

volts

to

the

d

-c

circuit

which

is

required

for

lamp

starting.

The

next

part

of

the

circuit

is

a

relay

timing

cir-

cuit

consisting

of

the

relay

Kl,

resistor

R4,

diode

D2,

and

capacitor

C4.

Before

the

lamp

has

been

started,

the

d

-c

voltage

from

red/white

to

white/green

is

a-

bout

330

volts.

The

relay

coil

voltage

required

to

pick

up

the

relay

is

110

volts

d

-c;

thus,

capacitor

C4

will

charge

to

the

required

voltage

to

energize

the

relay

coil.

The

time

required

to

reach

this

value

is

deter-

mined

by

R4

and

C4.

When

the

relay

has

been

ener-

gized,

the

white/blue

lead

is

connected

to

white/green,

thus

removing

the

voltage

charging

C4.

Capacitor

C4

cannot

discharge

through

this

part

of

the

circuit

as

diode

D2

is

now

reverse

biased,

causing

capacitor

C4

to

discharge

only

through

the

relay

coil.

When

capa-

citor

C4

has

discharged

to

the

point

of

drop

-out

of

the

relay,

the

entire

cycle

will

be

repeated

as

long

as

the

d

-c

voltage

available

is

greater

than

the

voltage

re-

quired

to

energize

the

relay.

The

time

constants

of

this

circuit

result

is

about

a

one

-second

on

-time

and

a

one

-second

off

-time

during

cycling.

When

the

lamp

is

running

at

7.75

amperes

d

-c,

the

a

-c

reactors

will

cause

the

d

-c

voltage

to

be

about

37.5

volts

d

-c,

thus

not

allowing

the

relay

timing

circuit

to

operate.

Included

in

the

LSU

is

a

filter

network

to

reduce

the

120

-Hz

ripple

current

in

the

lamp.

The

filter

con-

sists

of

capacitor

Cl

and

the

pulse

transformer

T3

which

serves

as

a

d

-c

choke

during

running

of

the

lamp.

Capacitor

Cl

also

supplies

starting

current

for

the

lamp

which

is

about

18

amperes

peak.

This

cur-

rent

is

limited

by

resistor

R1

which

is

switched

into

the

circuit

by

relay

K1

during

starting

of

the

lamp.

Note

that

resistor

R1

should

be

removed

from

the

2

LAMP

SUPPLY

UNITS

circuit

if

the

lamp

starts,

as

the

relay

will

return

to

the

non

-energized

condition.

If

resistor

R1

is

not

re-

moved,

it

will

overheat

and

cause

the

power

to

be

re-

moved

by

means

of

the

thermal

protector

TP1.

Approximately

8KV

peak

is

required

to

initially

ionize

the

lamp.

This

is

generated

in

the

LSU

with

the

pulse

transformer

T3,

capacitor

C3

and

resistor

R3.

With

the

relay

in

the

non

-energized

position,

capaci-

tor

C3

will

charge

to

the

d

-c

voltage

available

through

the

C3,

R3

path.

When

the

relay

is

picked

up,

capa-

citor

C3

is

placed

across

aportion

of

the

pulse

trans-

former

which

generates

the

high

pulse

voltage

for

starting

the

lamp.

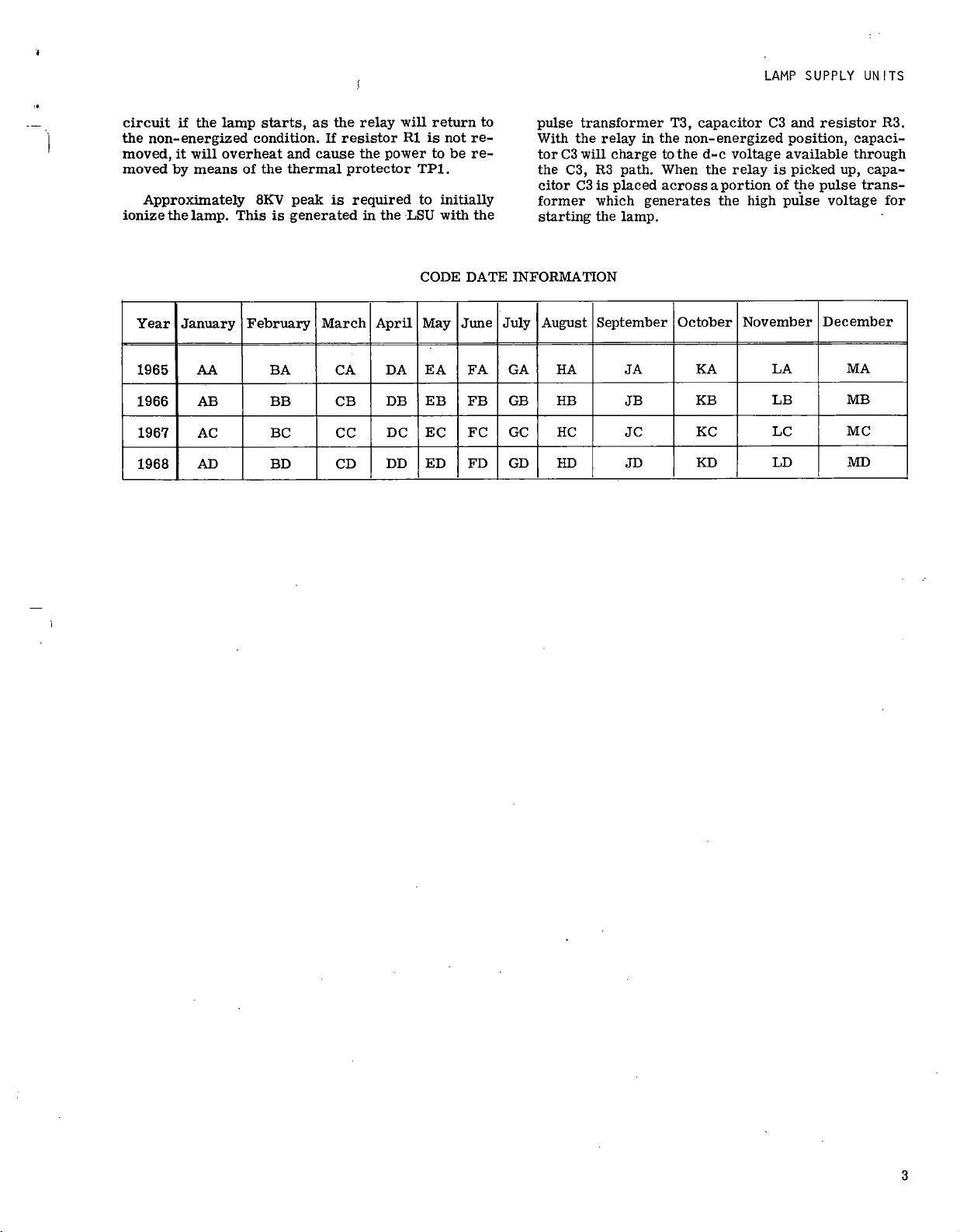

CODE

DATE

INFORMATION

Year

January

February

March

April

May

June

July

August

September

October

November

December

1965

AA

BA

CA

DA

EA

FA

GA

HA

JA

KA

LA

MA

1966

AB

BB

CB

DB

EB

FB

GB

HB

JB

KB

LB

MB

1967

AC

BC

CC

DC

EC

FC

GC

HC

JC

KC

LC

MC

1968

AD

BD

CD

DD

ED

FD

GD

HD

JD

KD

LD

MD

3

SERVICE

INSTRUCTIONS

ELECT_RICAL

TEST

PROCEDURES

SPECIAL

TEST

EQUIPMENT

REQUIRED.

Accurate

testing

of

the

Lamp

Supply

Unit

requires

the

following

special

test

equipment,

as

well

as

the

commercially

available

test

equipment

listed

in

Table

II.

Complete

specifications

for

the

special

test

equip-

ment

are

illustrated

and

listed

in

Figures

1,

2

and

3

of

these

instructions.

These

units

are

not

available

from

Bell

&

Howell

and

must

be

assembled

according

to

the

specifications

illustrated.

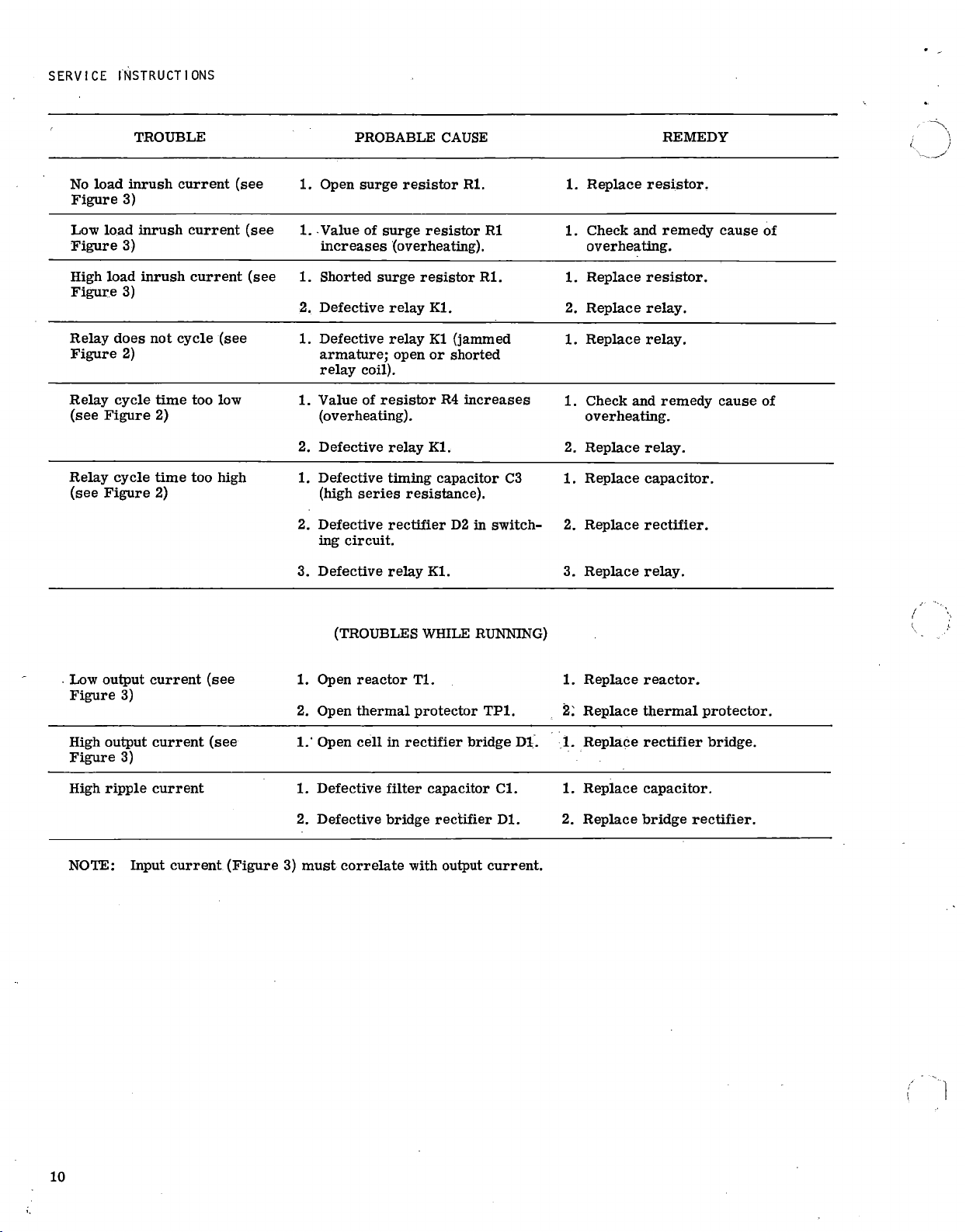

TABLE

I.

SPECIAL

TEST

EQUIPMENT

Description

Fig.

Ref.

B

&

H

Part

No.

Open

Circuit

Starting

1

S

-013000-1-F3

Voltage

Tester

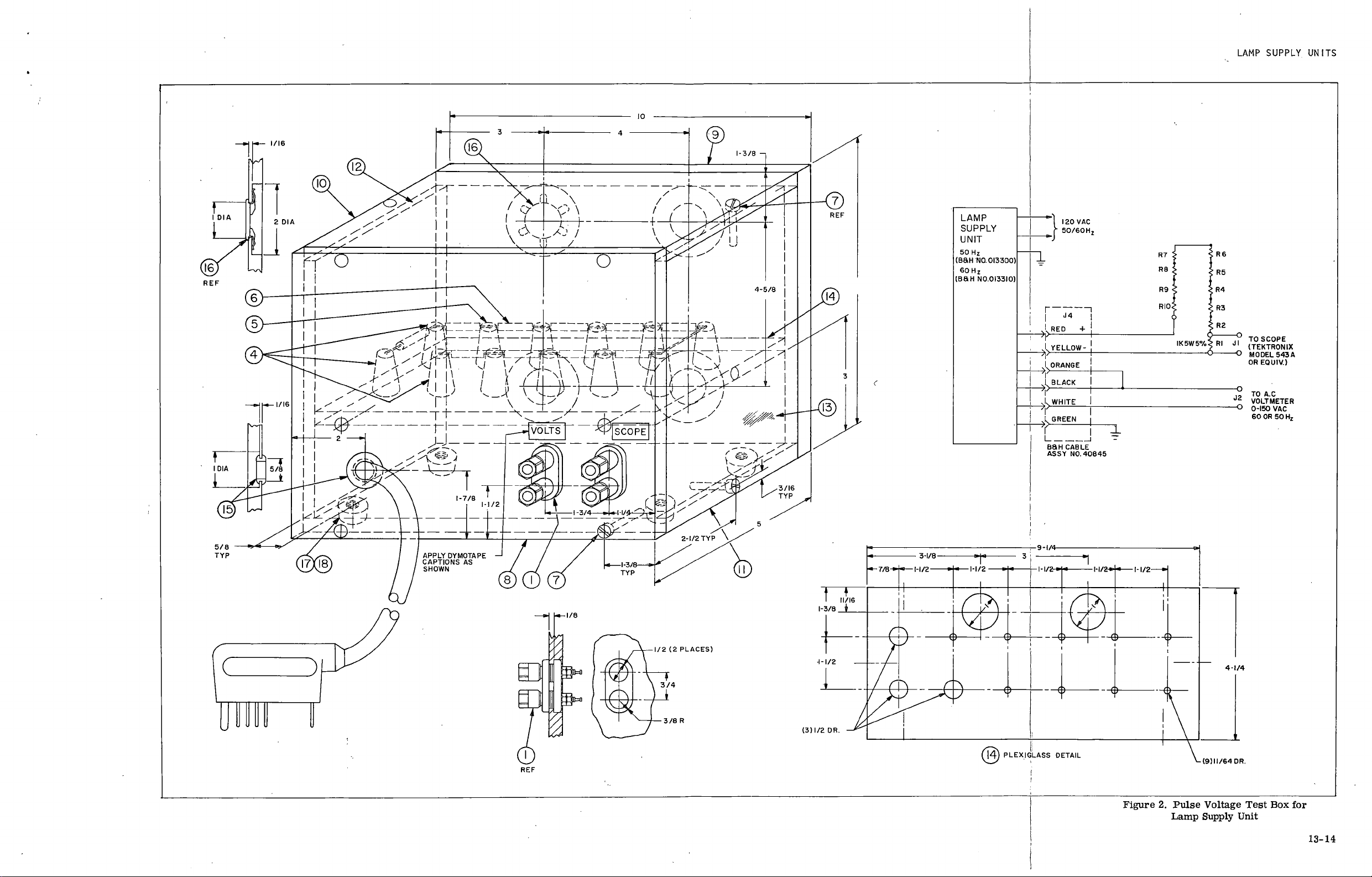

Pulse

Voltage

Test

Box

for

LSU

2

S

-013000-1-F1

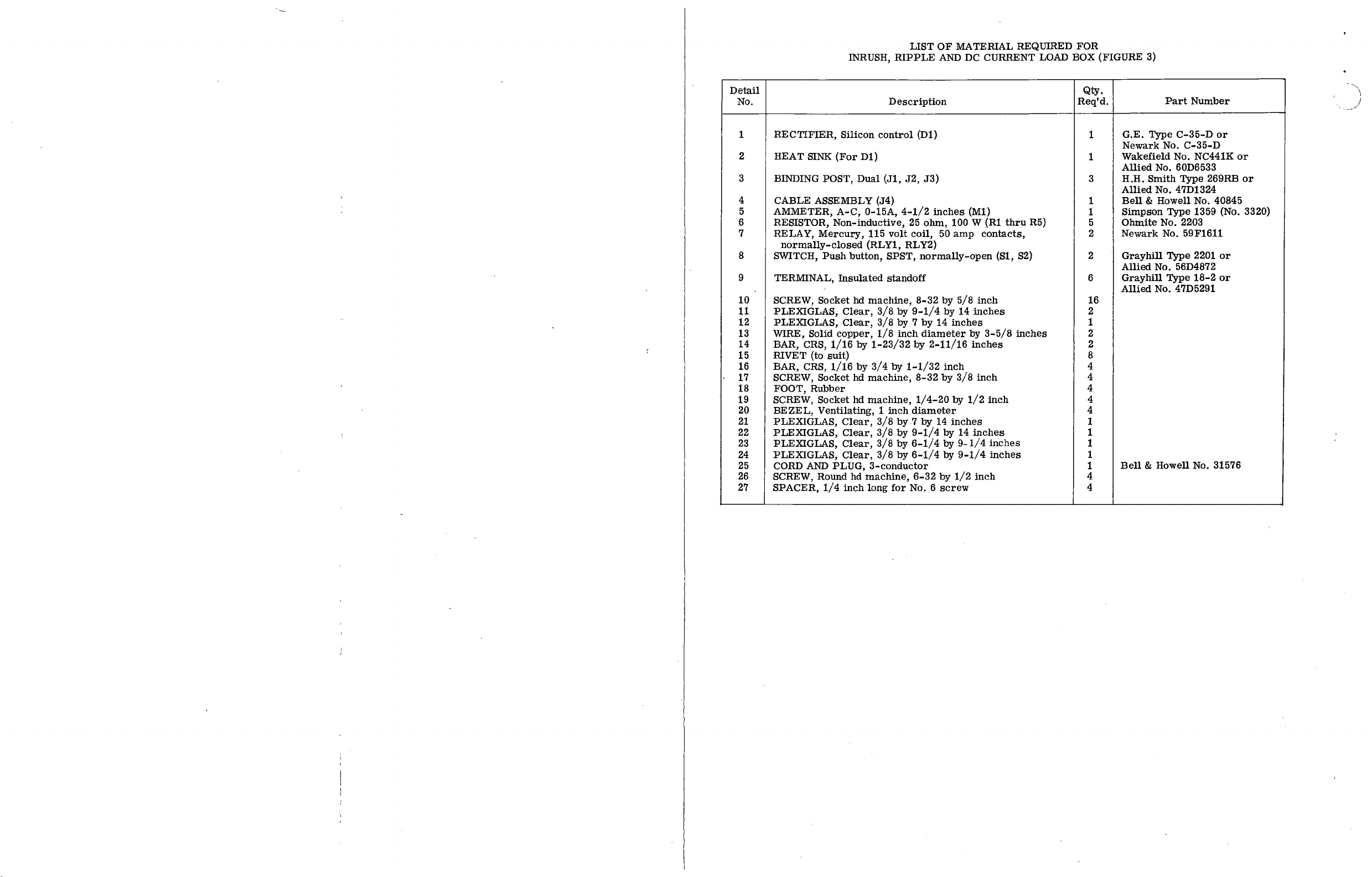

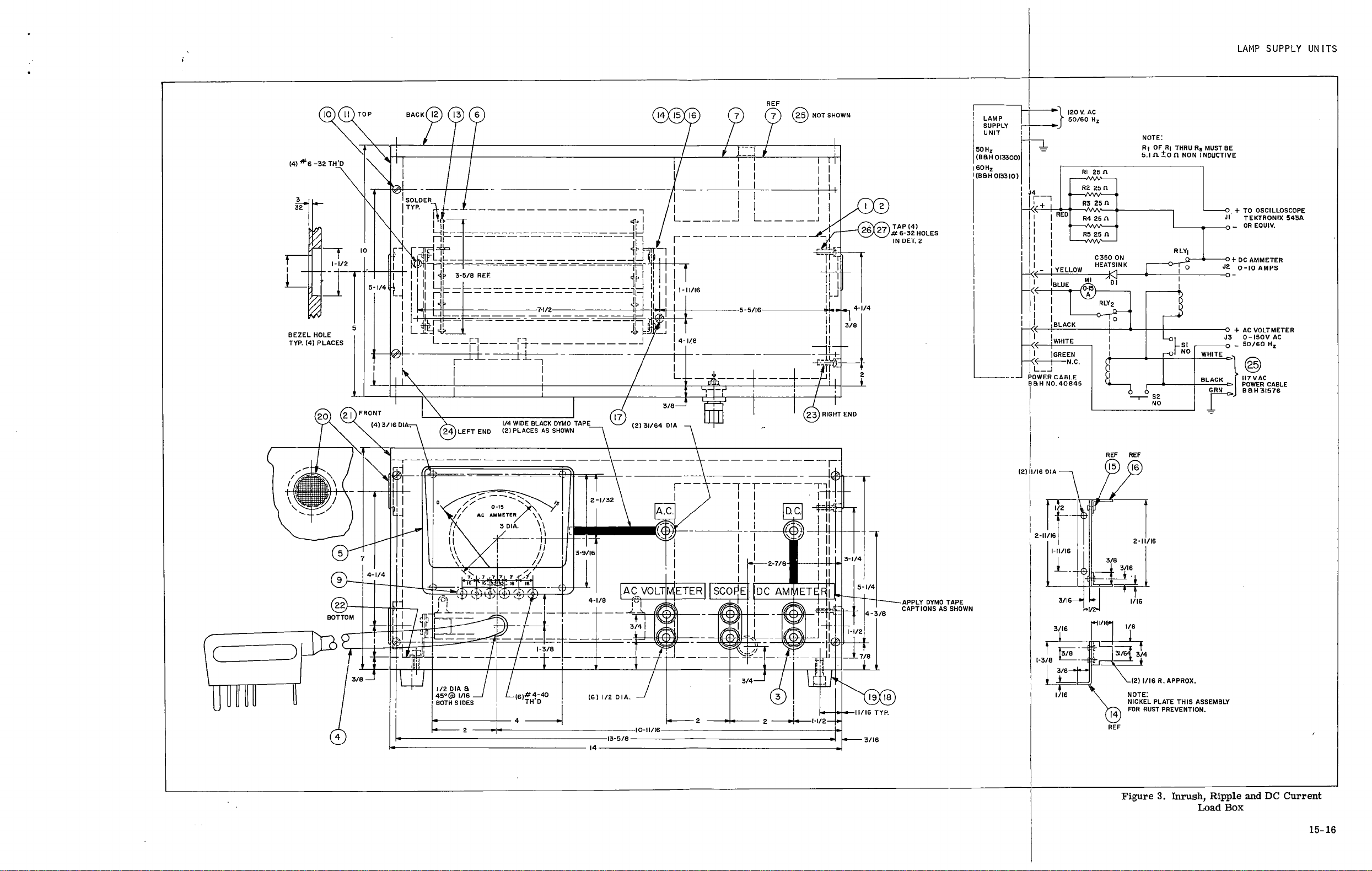

Inrush,

Ripple

and

D

-C

Current

Load

Box

3

S

-013000-1-F4

COMMERCIAL

TEST

EQUIPMENT

REQUIRED.

Table

II

lists

the

commercially

available

test

equip-

ment

required

for

performance

of

test

procedures

outlined

in

these

instructions.

TABLE

II

.

COMMERCIAL

TEST

EQUIPMENT

Test

Equipment

Recommended

Model

(Or

Equivalent)

Oscilloscope

Tektronix

Model

535A

Plug

-In

Unit

Tektronix

Model

53/54CA

10:1

Attennuator

Probe

Tektronix

Model

P6006

Variac

(Monitored)

General

Radio

Type

W20MT3A

(50/60

Hz)

Hi

-Pot

Tester

Associated

Research

Model

411

Thermocouple

Meter

Simpson

Model

388-3L

DC

Voltmeter

Simpson

Model

1327

(0-500

VDC)

DC

Ammeter

Simpson

Model

1327

(0-10

ADC)

TABLE

III.

TEST

LIMITS

Parameter

Input

Voltage

(See

*Note)

Limit

Testing

Conditions

Maximum

Minimum

Starting:

Open

Circuit

105

120

-

350

V

290

V

-

See

Fig.

1

Pulse

Voltage

105

120

—

12.0

KV

Total

(1200V

across

1

K

-ohm)

6.6

KV

Total

(660V

across

1

K

-ohm)

—

See

Fig.

2

Load

Inrush

Current

120

36

amps

(182V

Peak

across

5.1

ohm)

20

amps

(102V

Peak

across

5.1

ohm)

See

Fig.

3

Relay

Cycle

Time

120

44

Cycles

12

Cycles

See

Fig.

2

30

Seconds

30

Seconds

Running:

Output

Current

120

7.9

D.C.

7.4

D.C.

See

Fig.

3

Ripple

Current

120

2.4

A.P

P

(12.2V

P

-P

across

5.1

ohm)

—

See

Fig.

3

Input

Current

120

9.0

A.

AC

—

See

Fig.

3

*NOTE:

Use

50

-Hz

input

voltage

for

50

-Hz

LSU

(Part

No.

013300).

Use

60

-Hz

input

voltage

for

60

-Hz

LSU

(Part

No.

013310).

4

LAMP

SUPPLY

UNITS

WARNING

WHEN

THE

LAMP

SUPPLY

UNIT

IS

ENER-

GIZED,

THE

9000

-VOLT

STARTING

PULSE

IS

PRESENT.

EXTREME

CAUTION

MUST

BE

EXERCISED

WHEN

OPERATING

THE

POWER

SUPPLY

WHILE

NOT

CONNECTED

TO

A

PROJECTOR

OR

WHILE

THE

POWER

SUP-

PLY

COVER

IS

REMOVED,

IN

ORDER

TO

PREVENT

SEVERE

ELECTRICAL

SHOCK.

HI

-POTENTIAL

TEST.

The

Lamp

Supply

Unit

shall

withstand

900

volts

A.C.

for

one

(1)

minute

or

1080

volts

A.C.

for

one

(1)

second

when

this

potential

is

applied

(from

zero)

be-

tween

all

current

-carrying

parts

of

the

primary

of

the

Lamp

Supply

Unit

and

all

dead

metal

parts.

GENERAL

ELECTRICAL

INSPECTIONS.

(1)

Check

both

fuses

for

proper

ampere

ratings

(15A,

250V)

and

make

certain

that

fuses

can

be

re-

moved

and

installed

without

difficulty.

(2)

Use

the

low

resistance

range

of

a

volt

-ohm-

meter

and

check

for

continuity

between

the

ground

pin

of

the

A.C.

receptacle

and

the

metal

chassis

of

the

Lamp

Supply

Unit.

Resistance

should

be

near

zero

ohms.

(NOTE:

When

the

supply

unit

is

removed

from

its

case,

connect

a

juniper

cable

between

the

bottom

chassis

and

the

front

receptacle

panel.)

(3)

The

oscilloscope

mustbe

isolated

from

ground

by

plugging

the

scope

into

an

A.C.

adapter

plug

(3

-

prong

female

to

2

-prong

male);

then

plugging

the

ad-

apter

into

the

A.C.

outlet.

(NOTE:

If

the

chassis

of

the

oscilloscope

is

grounded,

one

side

of

the

Lamp

Supply

Unit

output

terminals

will

be

grounded

and

the

supply

unit

output

terminals

must

be

floating.)

WARNING

THE

OSCILLOSCOPE

ISNOT

GROUNDED.

DO

NOT

TOUCH

BE

TWEEN

OSCILLOSCOPE

AND

OTHER

EQUIPMENT

AS

SERIOUS

SHOCK

HAZARD

EXISTS.

TEST

EQUIPMENT

SET-UP.

(1)

Plug

variac

into

A.C.

outlet.

(2)

Connect

supply

unit

A.C.

line

cord

(Bell

&

Howell

Part

No.

4083'7)

between

supply

unit

and

variac.

(3)

Connect

the

six

-prong

plug

of

the

power

cable

from

the

Inrush,

Ripple

and

DC

Current

Load

Box

(Figure

3)

to

the

Lamp

Supply

Unit.

(4)

Connect

the

D.C.

Ammeter

to

the

Load

Box.

(5)

Connect

oscilloscope

to

the

Load

Box

through

the

10X

multiplier

probe.

INRUSH

CURRENT

TEST.

(1)

Set

the

AC/DC

switch

on

the

oscilloscope

at

the

AC

position.

(2)

Set

the

VOLTS/CM

control

on

the

pre

-amp

plug-in

unit

at

the

5-volt/CM

position.

(3)

Set

the

TIME/CM

control

at

the

200

msec/CM

position.

(4)

Set

the

Multiplier

control

at

NORMAL

and

the

Trigger

Mode

Control

at

AC

(LF

REJECT).

(5)

Set

the

Trigger

Slope

control

at

"+"

INT

posi-

tion.

(6)

Set

the

variac

to

120V

on

the

meter.

(7)

On

50

Hz

Lamp

Supply

Units

only,

check

the

operation

of

the

blower

fan.

(8)

When

the

relay

pulses

(clicks),

measure

the

pulse

on

the

oscilloscope

by

clicking

the

ON

-OFF

switch

on

the

variac.

Pulse

should

be

102

volts

mini-

mum

to

182

volts

maximum.

D.C.

peak

as

measured

across

the

5.1

ohm

load

resistor

(10.2

volts

mini-

mum

to

18.2

volts

maximum

on

scope

with

10X

mul-

tiplier

probe).

RIPPLE

CURRENT

TEST.

(1)

Set

the

VOLTS/CM

control

at

the

0.2

volts/CM

position.

(2)

Set

the

TIME/CM

control

at

the

5

msec/CM

position.

(3)

Set

the

Trigger

Mode

Control

at

AUTO.

(4)

Turn

on

the

variac

and

measure

the

ripple

voltage

on

the

scope

(across

the

5.1

ohm

load

re-

sistor).

Ripple

voltage

should

not

exceed

12

volts

P

-P

maximum

(1.2

volts

P

-P

maximum

on

scope

with

10X

multiplier

probe).

D.C.

OUTPUT

AND

A.C.

INPUT

CURRENT

TESTS.

(1)

Press

and

hold

the

D.C.

current

button

on

the

test

load

box

(Figure

3)

and

note

the

current

reading

on

the

D.C.

Ammeter.

Current

should

read

7.4

to

7.9

amps

D.C.

Release

the

D.C.

current

button.

(2)

Press

and

hold

the

A.C.

current

button

on

the

testload

box

and

note

the

current

reading

on

the

A.C.

Ammeter.

Current

should

not

exceed

9

amps

A

.C

.

Re-

lease

the

A.C.

current

button.

5

SERVICE

INSTRUCTIONS

PULSE

VOLTAGE

AND

RELAY

CYCLE

TIME

TESTS.

(1)

Connect

the

six

-prong

plug

of

the

power

cable

from

the

Pulse

Voltage

Test

Box

(Figure

2)

to

the

Lamp

Supply

Unit.

(2)

Connect

the

oscilloscope

to

the

test

box

through

the

10X

multiplier

probe.

(3)

Set

the

VOLTS/CM

control

at

the

20

volts/CM

position.

(4)

Set

the

TIME/CM

control

at

the

5

microsec-

ond/CM

position.

(5)

Set

the

Trigger

Mode

Control

at

AC

(LF

RE-

JECT)

and

the

Trigger

Slope

Control

at

"+"

INT.

(6)

Switch

the

variac

ON

and

adjust

the

Stability

and

Triggering

Level

controls

(per

manufacturer's

instruction

book)

to

obtain

a

single

pulse.

(7)

Adjust

the

Horizontal

Position

control

to

cen-

ter

the

pulse

on

the

face

of

the

CRT.

(8)

Adjust

the

variac

for

120

volts

A.C.

on

the

me-

ter

and

measure

the

peak

amplitude

of

the

starting

pulse.

The

pulse

should

not

be

greater

than

12,000

volts

(120

volts

on

scope

with

10X

multiplier

probe).

(9)

Using

the

sweep

second

hand

of

a

watch

or

clock,

count

the

number

of

pulses

in

a

30

-second

per-

iod.

There

should

be

between

12

and

44

pulses

in

a

30-

second

period.

(10)

Adjust

the

variac

for

105

volts

A.C.

on

the

meter

and

measure

the

peak

amplitude

of

the

start-

ing

pulse.

The

pulse

should

not

be

less

than

6,600

volts

peak

(66

volts

on

scope

with

10X

multiplier

probe).

OPEN

CIRCUIT

VOLTAGE

TEST.

(1)

Connect

the

six

-prong

plug

of

the

power

cable

from

the

Open

Circuit

Starting

Voltage

Tester

(Fig-

ure

1)

to

the

Lamp

Supply

Unit.

(2)

Switch

the

variac

ON

and

adjust

for

105

volts

on

the

A.C.

meter.

The

D.C.

output

voltage

should

be

greater

than

290

volts

D.C.

on

the

D.C.

meter.

(3)

Adjust

the

variac

for

120

volts

on

the

A.C.

me-

ter.

The

D.C.

output

voltage

should

be

less

than

350

volts

on

the

D.C.

meter.

6

LAMP

SUPPLY

UNITS

TROUBLE

SHOOTING

WARNING

WHEN

THE

LAMP

SUPPLY

UNIT

IS

ENER-

GIZED,

THE

9000

-VOLT

STARTING

PULSE

IS

PRESENT.

EXTREME

CAUTION

MUST

BE

EXERCISED

WHEN

OPERATING

THE

POWER

SUPPLY

WHILE

NOT

CONNECTED

TO

A

PROJECTOR

OR

WHILE

THE

POWER

SUP-

PLY

COVER

IS

REMOVED,

IN

ORDER

TO

PREVENT

SEVERE

ELECTRICAL

SHOCK.

TROUBLESHOOTING

FOR

OVERHEATING

IN

LAMP

SUPPLY

UNIT.

Thermocouple

location

and

identification

for

50

-

Hz

and

60

-Hz

Lamp

Supply

Units

will

be

found

in

Fig-

ures

4

and

5

respectively.

The

termocouple

temper-

ature

readings

in

Table

IV

provided

to

aid

in

locating

an

overheated

component

in

the

Lamp

Supply

Unit.

Readings

should

be

taken

under

the

following

test

conditions.

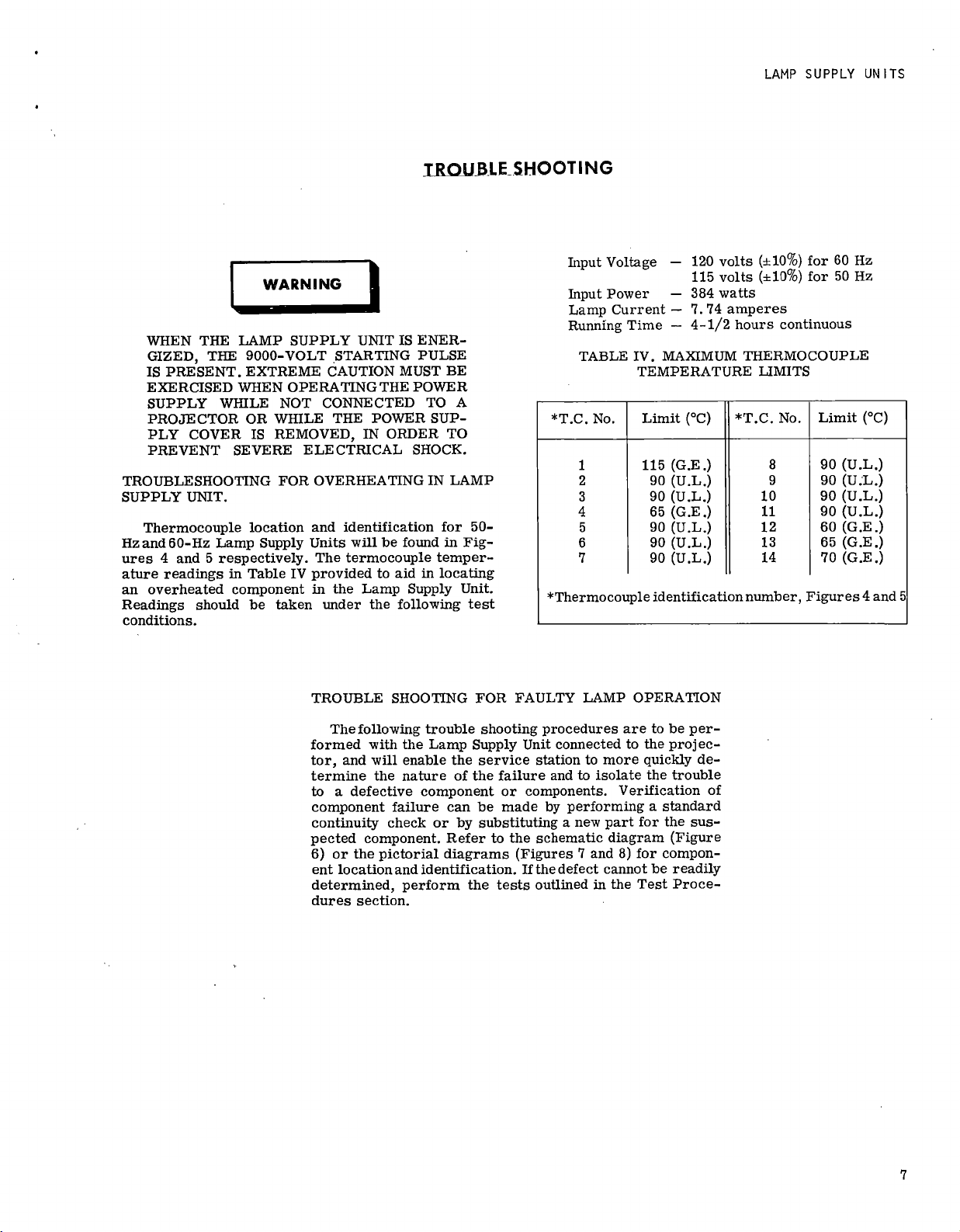

Input

Voltage

—

Input

Power

—

Lamp

Current

—

Running

Time

—

120

volts

(±10%)

for

60

Hz

115

volts

(±10%)

for

50

Hz

384

watts

7.74

amperes

4-1/2

hours

continuous

TABLE

IV.

MAXIMUM

THERMOCOUPLE

TEMPERATURE

LIMITS

*T.C.

No.

Limit

(°C)

*T.C.

No.

Limit

(

°

C)

1

115

(G.E.)

8

90

(U.L.)

2

90

(U.L.)

9

90

(U.L.)

3

90

(U.L.)

10

90

(U.L.)

4

65

(G.E.)

11

90

(U.L.)

5

90

(U.L.)

12

60

(G.E.)

6

90

(U.L.)

13

65

(G.E.)

7

90

(U.L.)

14

70

(G.E.)

*Thermocouple

identification

number,

Figures

4

and

5

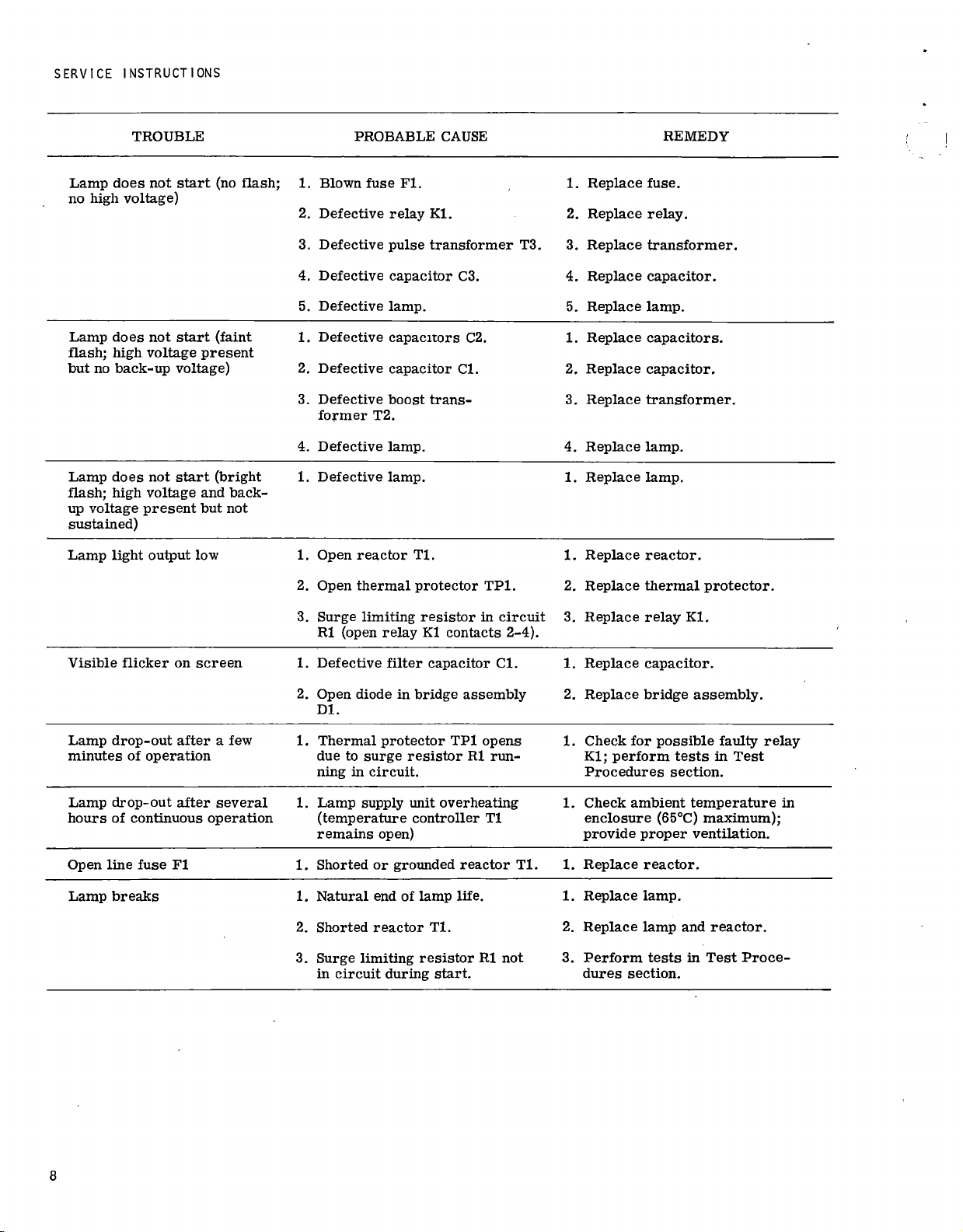

TROUBLE

SHOOTING

FOR

FAULTY

LAMP

OPERATION

The

following

trouble

shooting

procedures

are

to

be

per-

formed

with

the

Lamp

Supply

Unit

connected

to

the

proj

ec-

tor,

and

will

enable

the

service

station

to

more

quickly

de-

termine

the

nature

of

the

failure

and

to

isolate

the

trouble

to

a

defective

component

or

components.

Verification

of

component

failure

can

be

made

by

performing

a

standard

continuity

check

or

by

substituting

a

new

part

for

the

sus-

pected

component.

Refer

to

the

schematic

diagram

(Figure

6)

or

the

pictorial

diagrams

(Figures

7

and

8)

for

compon-

ent

location

and

identification.

If

the

defect

cannot

be

readily

determined,

perform

the

tests

outlined

in

the

Test

Proce-

dures

section.

7

SERVICE

INSTRUCTIONS

TROUBLE

PROBABLE

CAUSE

REMEDY

Lamp

does

not

start

(no

flash;

no

high

voltage)

1.

Blown

fuse

Fl.

2.

Defective

relay

Ki.

3.

Defective

pulse

transformer

4.

Defective

capacitor

C3.

5.

Defective

lamp.

1.

Replace

fuse.

2.

Replace

relay.

T3.

3.

Replace

transformer.

4.

Replace

capacitor.

5.

Replace

lamp.

Lamp

does

not

start

(faint

flash;

high

voltage

present

but

no

back-up

voltage)

1.

Defective

capacitors

C2.

2.

Defective

capacitor

Cl.

3.

Defective

boost

trans-

former

T2.

4.

Defective

lamp.

1.

Replace

capacitors.

2.

Replace

capacitor.

3.

Replace

transformer.

4.

Replace

lamp.

Lamp

does

not

start

(bright

flash;

high

voltage

and

back-

up

voltage

present

but

not

sustained)

1.

Defective

lamp.

1.

Replace

lamp.

Lamp

light

output

low

1.

Open

reactor

Tl.

2.

Open

thermal

protector

TP1.

3.

Surge

limiting

resistor

in

circuit

R1

(open

relay

Ki

contacts

2-4).

1.

Replace

reactor.

2.

Replace

thermal

protector.

3.

Replace

relay

Ki.

Visible

flicker

on

screen

1.

Defective

filter

capacitor

Cl.

2.

Open

diode

in

bridge

assembly

Dl.

1.

Replace

capacitor.

2.

Replace

bridge

assembly.

Lamp

drop

-out

after

a

few

minutes

of

operation

1.

Thermal

protector

TP1

opens

due

to

surge

resistor

R1

run-

ning

in

circuit.

1.

Check

for

possible

faulty

relay

Kl;

perform

tests

in

Test

Procedures

section.

Lamp

drop

-out

after

several

hours

of

continuous

operation

1.

Lamp

supply

unit

overheating

(temperature

controller

Ti

remains

open)

1.

Check

ambient

temperature

in

enclosure

(65°C)

maximum);

provide

proper

ventilation.

Open

line

fuse

Fl

1.

Shorted

or

grounded

reactor

Tl.

1.

Replace

reactor.

Lamp

breaks

1.

Natural

end

of

lamp

life.

2.

Shorted

reactor

Ti.

3.

Surge

limiting

resistor

R1

not

in

circuit

during

start.

1.

Replace

lamp.

2.

Replace

lamp

and

reactor.

3.

Perform

tests

in

Test

Proce-

dures

section.

8

LAMP

SUPPLY

UNITS

TROUBLE

SHOOTING

WITH

TEST

EQUIPMENT.

If

the

results

of

tests

performed

in

the

Electrical

Test

Procedures

section

fail

to

meet

noted

specification

require-

ments,

use

the

following

troubleshooting

guide

to

isolate

and

correct

the

trouble.

Refer

to

the

schematic

wiring

dia-

gram

(Figure

6)

and

the

pictorial

diagrams

(Figures

7

and

8)

for

component

location

and

identification.

WARNING

WHEN

THE

LAMP

SUPPLY

UNIT

IS

ENER-

GIZED,

THE

9000

-VOLT

STARTING

PULSE

IS

PRESENT.

EXTREME

CAUTION

MUST

BE

EXERCISED

WHEN

OPERATING

THE

POWER

SUPPLY

WHILE

NOT

CONNECTED

TO

A

PROJECTOR

OR

WHILE

THE

POWER

SUP-

PLY

COVER

IS

REMOVED,

IN

ORDER

TO

PREVENT

SEVERE

ELECTRICAL

SHOCK.

TROUBLE

PROBABLE

CAUSE

REMEDY

(TROUBLES

DURING

STARTING)

No

open

circuit

voltage

(see

1.

Blown

fuse

Fl.

1.

Replace

fuse.

Figure

1)

2.

Open

connection.

3.

Shorted

boost

transformer

T2.

4.

Shorted

rectifier

bridge

Dl.

2.

Check

circuit

and

correct

condition.

3.

Replace

transformer.

4.

Replace

rectifier

bridge.

Low

open

circuit

voltage

(see

1.

Defective

voltage

doubler

Figure

1

capacitor

C2.

2.

Open

rectifier

bridge

Dl.

3.

Defective

boost

transformer

T2.

4.

Leaky

filter

capacitor

Cl.

5.

Open

leads.

1.

Replace

capacitor.

2.

Replace

rectifier

bridge.

3.

Replace

transformer.

4.

Replace

capacitor.

5.

Perform

continuity

check;

correct

condition.

Variable

open

circuit

voltage

(see

Figure

1)

1.

Open

surge

resistor

R1

(varies

with

relay

cycling).

1.

Replace

resistor.

No

pulse

voltage

(see

Figure

2)

1.

Defective

pulse

transformer

T3.

2.

Relay

K1

not

cycling

(bad

contacts).

1.

Replace

transformer.

2.

Clean

contacts

or

replace

relay.

3.

Open

connection

or

short

circuit.

3.

Check

circuit

and

correct

condition.

4.

Open

surge

resistor

Rl.

4.

Replace

resistor.

5.

Open

or

shorted

filter

capacitor

5.

Replace

capacitor.

Cl.

9

SERVICE

INSTRUCTIONS

TROUBLE

PROBABLE

CAUSE

REMEDY

No

load

inrush

current

(see

Figure

3)

1.

Open

surge

resistor

Rl.

1.

Replace

resistor.

Low

load

inrush

current

(see

1.

Value

of

surge

resistor

R1

Figure

3)

increases

(overheating).

1.

Check

and

remedy

cause

of

overheating.

High

load

inrush

current

(see

Figure

3)

1.

Shorted

surge

resistor

Rl.

2.

Defective

relay

Kl.

1.

Replace

resistor.

2.

Replace

relay.

Relay

does

not

cycle

(see

Figure

2)

1.

Defective

relay

K1

(jammed

armature;

open

or

shorted

relay

coil).

1.

Replace

relay.

Relay

cycle

time

too

low

(see

Figure

2)

1.

Value

of

resistor

R4

increases

(overheating).

2.

Defective

relay

Kl.

1.

Check

and

remedy

cause

of

overheating.

2.

Replace

relay.

Relay

cycle

time

too

high

(see

Figure

2)

1.

Defective

timing

capacitor

C3

(high

series

resistance).

2.

Defective

rectifier

D2

in

switch-

ing

circuit.

3.

Defective

relay

Kl.

1.

Replace

capacitor.

2.

Replace

rectifier.

3.

Replace

relay.

Low

output

current

(see

Figure

3)

(TROUBLES

WHILE

RUNNING)

1.

Open

reactor

Tl.

2.

Open

thermal

protector

TP1.

1.

Replace

reactor.

2:

Replace

thermal

protector.

High

output

current

(see

Figure

3)

1.'

Open

cell

in

rectifier

bridge

Di.

1.

Replace

rectifier

bridge.

High

ripple

current

1.

Defective

filter

capacitor

Cl.

2.

Defective

bridge

rectifier

Dl.

1.

Replace

capacitor.

2.

Replace

bridge

rectifier.

NOTE:

Input

current

(Figure

3)

must

correlate

with

output

current.

10

LIST

OF

MATERIAL

REQUIRED

FOR

OPEN

CIRCUIT

STARTING

VOLTAGE

TESTER

(FIGURE

1)

Detail

No.

Description

Qty.

Req'd.

Part

Number

1

CAPACITOR,

5.0

mfd,

600

vdc

(C1)

1

G.E.

Type

23F1214

or

2

1/32

by

2

by

5-21/32

inch

aluminum

1

Allied

No.

43D0084

3

SCREW,

Round

hd

machine,

8-32NC

by

3/8

inch

2

4

BINDING

POST,

Dual

(J2,

J3)

2

H.H.

Smith

Type

269RB

or

Allied

No.

47D1324

5

6

TERMINAL,

Insulated

stand

off

SCREW,

Socket

hd

machine,

8-32NC

by

1/2

inch

4

16

Grayhill

Type

18-2

or

Allied

No.

47D5291

7

FOOT,

Rubber

4

8

SCREW,

Socket

hd

machine,

1/4-20NC

by

1/2

inch

4

9

PLEXIGLAS,

Clear,

3/8

by

5-1/4

by

8

inches

1

10

PLEXIGLAS,

Clear,

3/8

by

4

by

5-1/4

inches

2

11

PLEXIGLAS,

Clear,

3/8

by

4-3/4

by

8

inches

1

12

PLEXIGLAS,

Clear,

3/8

by

5-1/4

by

8

inches

1

13

PLEXIGLAS,

Clear,

3/8

by

4-3/4

by

8

inches

1

14

CABLE

ASSEMBLY

(J1)

1

Bell

&

Howell

No.

40845

15

LUG,

Solder

(any

suitable

type)

2

LAMP

SUPPLY

UNITS

2

DRILL

a

TAP

NO.8-32

THD

(2)

I

2-19/32

5-I/4

4-1/2

1-7/8

3/8

3/16—+

5-1/4

8

7

5/8

(4)

1/2

DIA

---

v2

3/16-

1/2

DIA

a

1/16)45°

BOTH

SIDES

6

7

_

16

7

16

647

7

1

7

8

-

1

7

4

‘•

2

II

II

7-5/8

2

4

AC

VOLTS

VOLTS

I

(4)3/8

R

AD)

3/8

TYP

z

CD

3/4

1

7/8

1-1/2

11/16

TYP-

0

-1

1-

0

-

7

8

DRILL

a

TAP

NO.4-40

THD

(6)

15

3/16

2-5/32

-1/64

1-5/16

2

REF

(2)

11/64

DIA.

APPLY

DYMOTAPE

CAPTIONS

AS

SHOWN

LAMP

SUPPLY

UNIT

50

Hz (B&H

013300)

60

Hz (B&H

013310)

4-

J-

1

120

VAC

50/60

Hz

JI

<<

+

RED

-Fi

CI

k

-

YELLOW

I

I

600V.

DC

J2

DC

VOLTMETER

0-400V

5.0

MFD

0

I,

BLUE_ORI

ORN

<lc

•

0+

%

I

BLACK

,j3

AC

VOLTMETER

0-150V

<

I

i<

WHITE

0

50/60Hz

i

<1<

GREEN

L

-

CABLE

ASSY

B

a

H

NO.40845

12

o+

I

3/4

,.''V.,,..

11/16

co

Figure 1.

Open

Circuit Starting

Voltage

Tester

11-12

LIST

OF

MATERIAL

REQUIRED

FOR

PULSE

VOLTAGE

TEST

BOX

(FIGURE

2)

Detail

No.

Description

Qty.

Req'd.

Part

Number

1

BINDING

POST,

Dual

(J1,

J2)

2

H.H.

Smith

Type

269RB

or

Allied

No.

47D1324

3

CABLE

ASSEMBLY

(J4)

1

Bell

&

Howell

No.

40845

4

BUSHING,

Insulated,

thru-panel

(TH1,

2

and

3)

3

E.F.

Johnson

Type

135-50

or

Allied

No.

46Z217

5

Insulator,

Cone,

Steatite

(TH4)

9

E.F.

Johnson

Type

135-501

or

Newark

No.

37F064

6

RESISTOR,

Non

-inductive,

1K,

5W

±5%

(R1

thru

R10)

10

Sprague

Type

453E

or

7

SCREW,

Socket

hd

machine,

10-32

by

1

inch

18

Allied

No.

25Z925C

8

PLEXIGLAS,

Clear,

3/8

by

8

by

10

-inches

1

9

PLEXIGLAS,

Clear,

3/8

by

8

by

10

-inches

1

10

PLEXIGLAS,

Clear,

3/8

by

4-1/4

by

10

inches

1

11

PLEXIGLAS,

Clear,

3/8

by

4-1/4

by

10

inches

1

12

PLEXIGLAS,

Clear,

3/8

by

4-1/4

by

7-1/4

inches

1

13

PLEXIGLAS,

Clear,

3/8

by

4-1/4

by

7-1/4

inches

1

14

PLEXIGLAS,

Clear,

3/8

by

4-1/4

by

9-1/4

inches

1

15

GROMMET,

Rubber,

1/2

inch

I.D.

1

16

BEZEL,

Ventilating,

1

-inch

diameter

4

17

FOOT,

Rubber

4

18

SCREW,

Socket

hd

machine,

1/4-20

by

1/2

inch

4

LAMP

SUPPLY

UNITS

10

3

I

DIA

16

REF

I

DIA

1/16

2

DIA

6

4

5/8

TYP

5/8

12

10

16

1-3/8

z

0

-0

/

4-5/8

7

REF

14

,--

,/-

.

-

T A

i-

---

.1-

--i

+ -

-I-

+

--

4--

1-

7---

---

I

,

--=''''

4-

-/

--1-_

-_7-*,_-

\

\II

-r

\

1

k

4-

\--(Y

4-

I

\ I I

I

I

l

i

I

/

1

\

I

...-

..---

,

I

__

)

I,

('

I

)\,

I

`,_

)

1

-\---U

-4

H/

-

_,

__

_

_

_

_

/

__

____>

--

-7

i

--

---

>(....

_/

4

.

k-

z

- -

1

-

1

-

- -

--

__J__,

_,

)

J

---,-7

-

--.7,

--

-.

........

i,

'

A

..,-

-,--

:----

---)

17

18

VOLTS

SCOP4

1-7/8

0

I-1/2

0

0

0 -

1-3/4

I

-I/¢

<

APPLY

DYMOTAPE

-

CAPTIONS

AS

SHOWN

0

REF

7

1/8

1-3/

TYP

2-1/2

TYP

1/2

(2

PLACES)

3/4

3/8

R

3/16

TYP

13

LAMP

SUPPLY

UNIT

50

Hz

(Bali

.

N0.0B300)

60

Hz

(Ba

H

NO.013310)

120

VAC

50/60H

1

J4

I

RED

+

))

ORANGE

R7

R6

R5

R9

R4

RIO

R3

•

R2

•

IK

5W

5%

RI

R8

YELLOW

-

I,

BLACK

I

/

I

WHITE

>

I

>

GREEN

31/8

1

1/2—w-

0

-1

1/2

3

L

_______

Ba

H

CABLE

ASSY

NO.40845

9

1/

4

1

I

1/2-

01,4

---I 1/24."•-1-1/2-1.

1-3/8

-I-I/2

(3)1/2

DR.

JI

TO

SCOPE

(TEKTRONIX

•

MODEL

543A

OR

EQUIV.)

0

J2

TO

A.C

VOLTMETER

0

0-150

VAC

60

OR

50

H

z

4-1/4

0

PLEXIGLASS

DETAIL

(9)11/64

DR.

Figure

2.

Pulse

Voltage

Test

Box

for

Lamp

Supply

Unit

13-14

LIST

OF

MATERIAL

REQUIRED

FOR

INRUSH,

RIPPLE

AND

DC

CURRENT

LOAD

BOX

(FIGURE

3)

Detail

No.

Description

Qty.

Req'd.

Part

Number

1

RECTIFIER,

Silicon

control

(D1)

1

G.E.

Type

C

-35-D

or

Newark

No.

C

-35-D

2

HEAT

SINK

(For

D1)

1

Wakefield

No.

NC441K

or

Allied

No.

60D6533

3

BINDING

POST,

Dual

(J1,

J2,

J3)

3

H.H.

Smith

Type

269RB

or

Allied

No.

47D1324

4

CABLE

ASSEMBLY

(.14)

1

Bell

&

Howell

No.

40845

5

AMMETER,

A

-C,

0-15A,

4-1/2

inches

(M1)

1

Simpson

Type

1359

(No.

3320)

6

RESISTOR,

Non

-inductive,

25

ohm,

100

W

(R1

thru

R5)

5

Ohmite

No.

2203

7

RELAY,

Mercury,

115

volt

coil,

50

amp

contacts,

normally

-closed

(RLY1,

RLY2)

2

Newark

No.

59F1611

8

SWITCH,

Push

button,

SPST,

normally

-open

(S1,

S2)

2

Grayhill

Type

2201

or

Allied

No.

56D4872

9

TERMINAL,

Insulated

standoff

6

Grayhill

Type

18-2

or

Allied

No.

47D5291

10

SCREW,

Socket

hd

machine,

8-32

by

5/8

inch

16

11

PLEXIGLAS,

Clear,

3/8

by

9-1/4

by

14

inches

2

12

PLEXIGLAS,

Clear,

3/8

by

7

by

14

inches

1

13

WIRE,

Solid

copper,

1/8

inch

diameter

by

3-5/8

inches

2

14

BAR,

CRS,

1/16

by

1-23/32

by

2-11/16

inches

2

15

RIVET

(to

suit)

8

16

BAR,

CRS,

1/16

by

3/4

by

1-1/32

inch

4

•

17

SCREW,

Socket

hd

machine,

8-32

by

3/8

inch

4

18

FOOT,

Rubber

4

19

SCREW,

Socket

hd

machine,

1/4-20

by

1/2

inch

4

20

BEZEL,

Ventilating,

1

inch

diameter

4

21

PLEXIGLAS,

Clear,

3/8

by

7

by

14

inches

1

22

PLEXIGLAS,

Clear,

3/8

by

9-1/4

by

14

inches

1

23

PLEXIGLAS,

Clear,

3/8

by

6-1/4

by

9-1/4

inches

1

24

PLEXIGLAS,

Clear,

3/8

by

6-1/4

by

9-1/4

inches

1

25

CORD

AND

PLUG,

3

-conductor

1

Bell

&

Howell

No.

31576

26

SCREW,

Round

hd

machine,

6-32

by

1/2

inch

4

2'7

SPACER,

1/4

inch

long

for

No.

6

screw

4

LAMP

SUPPLY

UNITS

REF

0

(4)

*

6

-32

TH

U

D

3

32

II

I-1/2

TOP

BACK

14

15 16

C)

NOT

SHOWN

10

BEZEL

HOLE

TYP.

(4)

PLACES

20

I

SOLDER

TYP.

-A-

lt

5

1/4

4

'.

1

I

1

--

4

I

L

REF

4-1/8

5

5/16

I

7

26

I

I

3/8

21

FRONT

(4)3/16

DIA.

24

1/4

WIDE

BLACK

DYMO

TAPE

LEFT

END

(2)

PLACES

AS

SHOWN

3/8

(2)

31/64

DIA

I

I

RIGHT

END

(i

)

22

BOTTOM

4-1/4

..---

----

---..."-..

./r

. I

0-15

\

AC

AMMETER

\\

3

DIA.

\

1

\

1

1r

7 7

.

1

6"

:

163r37:

16

"

16

b.(

• (

(0)

•

—

I

I

1-3/8

2-1/32

3-9/16

4-1/8

A.C.

D.C.

AC

VOLTMETER

c.‘

3/4

I

SCOPE

(0)

•

7/8

./

- 7 - 7 -

t

II

I

II

DC

AM

ET

I

2

3-1/4

5

1/4

I-1/2

27

4-3/8

3/8

1/2

DIA

8

45'

1/16

BOTH

S

IDES

2

)0

4

-

40

TH'D

14

10

11/16

3/4

2

3

1

1

1/2

7/8

19

TAP

(4)

#

6-32

HOLES

IN

DET.

2

18

11/16

TYP.

3/16

APPLY

DYMO

TAPE

CAPTIONS

AS

SHOWN

LAMP

SUPPLY

UNIT

50Hz (B&H

013300)

60Hz

(BEM

013310)

1

120

V.

AC

50/60

Hz NOTE

Rt

OF

RI

THRU

Rs

MUST

BE

5.1

IL

±0

fl

NON

INDUCTIVE

RI

25

ft

R2

25

ft

R3

25

0

RED

R4

2511

R5

25

0

C350

ON

YELLOW

HEATSINK

J1

R

Ls('

+

TO

OSCILLOSCOPE

TEKTRONIX

543A

OR

EQUIV.

+

DC

AMMETER

0

J

2

0-10

AMPS

BLUE

MI

DI

0-15

A

RLY2

BLACK

__i(

WHITE

_(

[

<

GREEN

N.C.

POWER

CABLE

B&H

NO.40845

(2)

1/16

DIA

•

+

AC

VOLTMETER

J3

0-150V

AC

SI

•

50/60

Hz NO

WHITE

S2

NO

REF REF

15

16

I

1,2

3/8

3/16

2-11/16

3/16

3/16

1

3/8

1-3/8

3/8

14

REF

(2)

1/16

R.

APPROX.

BLACK

117

VAC

POWER

CABLE

GRN

B&H

31576

NOTE:

NICKEL

PLATE

THIS

ASSEMBLY

FOR

RUST

PREVENTION.

Figure

3.

Inrush,

Ripple

and

DC

Current

Load

Box

15-16

LAMP

SUPPLY

UNITS

THERMOCOUPLE

IDENTIFICATION

(See

Figures

4

and

5)

Item

No.

Description

1

CENTER

—

Bridge

Rectifier

Case

D1

2

COIL

—

A.C.

Reactor

T1

3

CORE

—

A.C.

Reactor

Ti

4

CASE

—

Filter

Capacitor

C1

5

COIL

-

Pulse

Transformer

T3

6

BRACKET

—

Pulse

Transformer

T3

7

COIL

—

Pulse

Transformer

T3

8

COIL

-

Boost

Transformer

T2

9

CORE

—

Boost

Transformer

T2

10

COIL

—

A.C.

Reactor

T1

11

CORE

—

A.C.

Reactor

T1

12

EXPOSED

END

—

Voltage

Doubler

Capacitor

C2

13

AMBIENT

AIR

(Inside

Enclosure)

14

CASE

—

"Klixon"

Thermal

Protector

TP1

-

n

8

-

6Th

m

)

®

l0

c)

-4

O

C)

C)

(11

1

O

C)

C

I

1

-

o

;—

Figure

4.

Thermocouple

Location

and

Identification

for

50

Hz

Unit,

Part

No.

013300

2

C)

O

C)

n

I

di

9

III

I

14

8

0

9

e

10

0

13

e

0

0

O

2

5

-

4

0

0

C)

UI

C)

CM

L

O

1

O

0

C)

cn

0

Figure

5.

Thermocouple

Location

and

Identification

for

60

Hz

Unit,

Part

No.

013310

17-18

This manual suits for next models

1

Table of contents

Popular Projector Accessories manuals by other brands

New Star

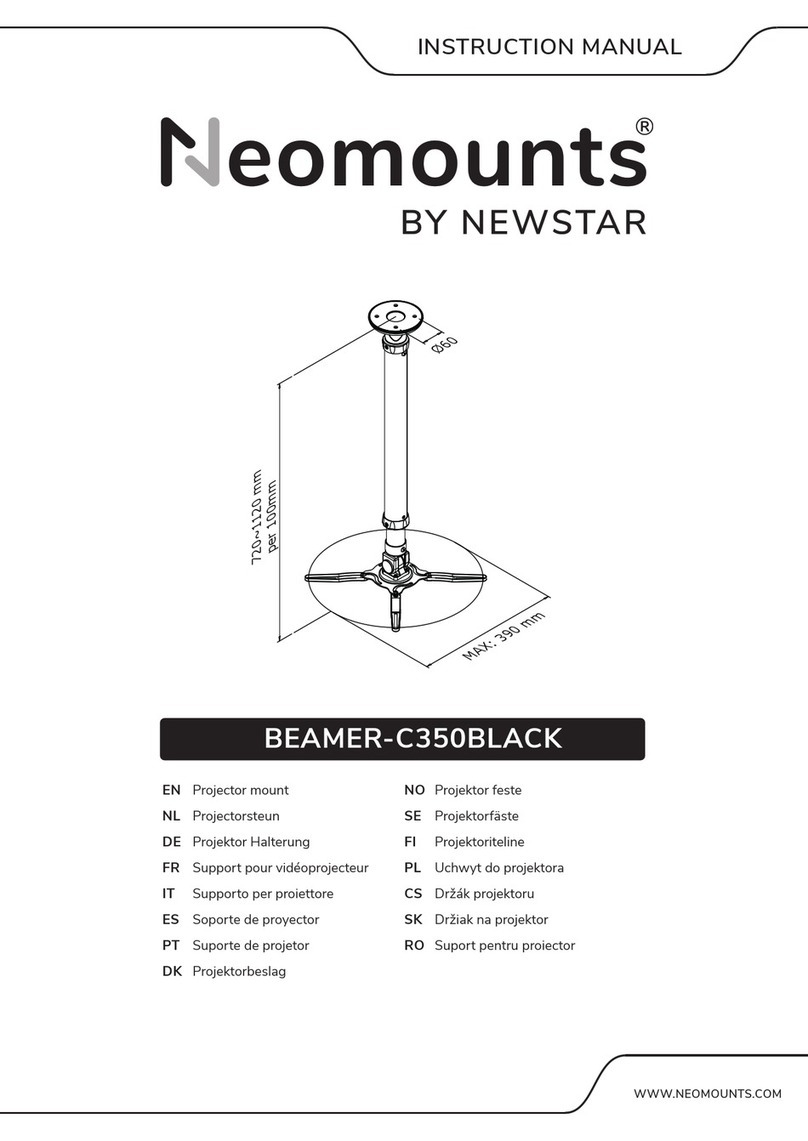

New Star Neomounts BEAMER-C350BLACK instruction manual

Celexon

Celexon Professional Plus operating instructions

Sharp

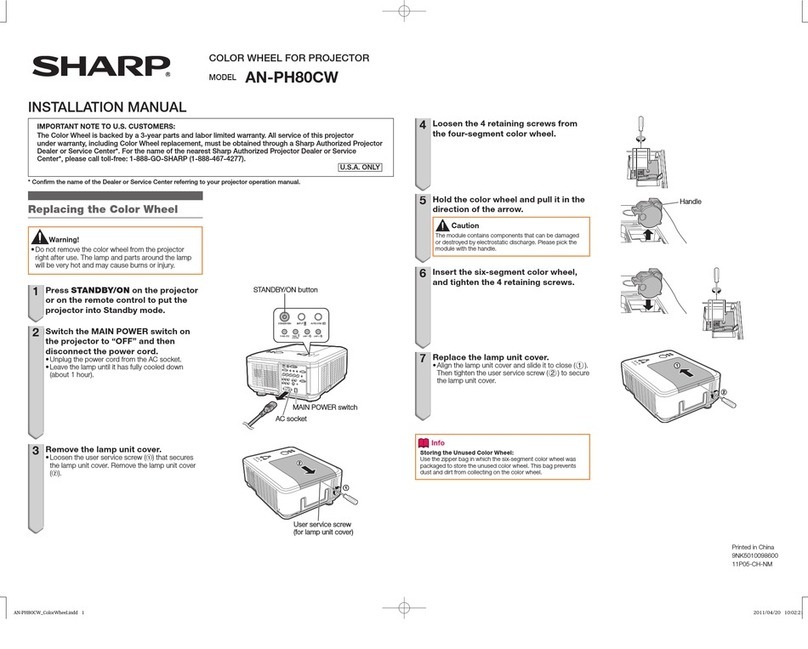

Sharp AN-PH80CW installation manual

Barco

Barco ClickShare Present C Series installation manual

ZeeVee

ZeeVee ZVconnect user manual

Strong International

Strong International X-90 instruction manual