Belle Group BMD 300 User manual

1

- Spare Parts Book

- Pièces détachées

- Libro Despiece

- Lista de Peças

- Onderdelen Boekje

- Reservedele Skrift

- Ersatzteilhandbuch

- Manuale dei ricambi

- Bruksanvisning

- Bruksanvisning

- Varaosaluettelo

- Lista Części Zamiennych

- Запасные части Книга

- Varuosade nimekiri

- Rezerves daļu saraksts

- Atsarginiu daliu sarašas

- Lista Pieselor de Schimb

- Részek Oldalra dől

- Rezervni djelovi Knjiga

- yedek taksimat kitap

Operators Manual

Operators Manual

Manuel De L'Opérateur

Manual del Operador

Manual de Operação

Handleiding

Betjeningsvejledning

Bedienungshandbuch

Manuale Dell'Operatore

Bruksanvisning

Betjene Håndbok

Käyttöohje

Instrukcja Obsługi

Рyкoboдctbo для oпepatopa

Kasutusjuhend

Lietotāja rokasgrāmata

Naudojimo Instrukcija

Manual de Utilizare

Kezelõk Kézi

Uputstvo za rukovatelja

Operatör elle yapılan

GB

F

E

P

NL

DK

D

I

S

US

SF

PL

RUS

EST

LV

LT

6

14

22

30

38

46

54

62

70

78

86

94

102

110

118

126

134

142

174

870/90000/0

HUN

HR

TR

RO

150

158

NO

166

2

Signed by: Managing Director - On behalf of BELLE GROUP (SHEEN) UK.

Signature:

Le Directeur Général - Pour le compte de la SOCIETE BELLE GROUP (SHEEN) UK.

Medido por: Director Gerente - En nombre de BELLE GROUP (SHEEN) UK.

Assinado por: Director-Geral - Em nome de BELLE GROUP (SHEEN) UK.

Getekend door: Algemeen Directeur - Namens BELLE GROUP (SHEEN) UK.

Uunderskrevetaf: Administrerende direktør – På vegne af BELLE GROUP (SHEEN) UK.

PRODUCT TYPE ..................

MODEL .................................

SERIAL No............................

DATE OF MANUFACTURE...

SOUND POWER LEVEL.......

MEASURED

(GUARANTEED):

TYPE DE PRODUIT ..............

MODELE................................

N° DE SERIE ........................

DATE DE FABRICATION.......

NIVEAU DE ..........................

PUISSANCE SONORE

MESUREE (GARANTIE)

TIPO DE PRODUCTO ............

MODELO ................................

Nº DE SERIE ..........................

FECHA DE FABRICACIÓN....

NIVEL DE ...............................

POTENCIA ACÚSTICA

MEDIDO (GARANTIZADO)

TIPO DE PRODUTO: ...........

MODELO:.............................

NO. DE SÉRIE: ....................

DATA DE FABRIC................

NIVEL DE .............................

POTÊNCIA DE SOM

MEDIDO (GARANTIDO)

PRODUCTTYPE.....................

MODEL ..................................

SERIENUMMER ....................

FABRICAGEDATUM .............

GEMETEN ..............................

GELUIDSSTERKTENIVEAU

(GEGARANDEERD)

We, Belle Group Sheen UK, Sheen, Nr. Buxton, Derbyshire, SK17 0EU, GB, hereby certify that if the product described within this certificate is bought from an

authorised Belle Group dealer within the EEC, it conforms to the following EEC directives: 98/37/EC (This directive is a consolidation of the original machinery directive

89/392/EEC), Electromagnetic Compatability Directive 89/336/EEC (as amended by 92/31/EEC & 93/68 EEC). The low voltage directive 73/23/EEC, EN 292 Safety of

machinery and associated harmonised standards, where applicable. Noise emissions conform to directive 2000/14/EC Annex VI, for machines under article 12 the

notified body is AV Technology Limited, AVTECH house, Birdhall Lane, Cheadle Heath, Stockport, Cheshire, SK3 0XU, GB.

O signatário, Belle Group Sheen UK, Sheen, Nr Buxton, Derbyshire, SK 0EU, GB, pelo presente, declara que se o produto descrito neste certificado foi adquirido a

um distribuidor autorizado do Belle Group em qualquer país da UE, está em conformidade com o estabelecido nas seguintes directivas comunitárias: 98/37/EC (esta

directiva é uma consolidação da directiva de maquinaria original 89/392/EEC), Directiva de Compatibilidade Electromagnética 89/336/EEC (conforme corrigido pelas

92/31/EEC & 93/68 EEC). A directiva de baixa voltagem 73/23/EEC, EN 292 Segurança da maquinaria e às normas harmonizadas afins se aplicáveis. As emissões de

ruído respeitam e estão dentro das directivas para máquinas 2000/14/EC Anexo VI, artigo 12, sendo o organismo notificado AV Technology Limited, AVTECH house,

Birdhall Lane, Cheadle Heath, Stockport, Cheshire, SK3 0XU, GB.

Ondergetekende, Belle Group Sheen UK, Sheen, Nr. Buxton, Derbyshire, SK17 OEU, GB, verklaren hierbij dat als het product zoals beschreven in dit certificaat is

gekocht van een erkende Belle Group dealer binnen de EEG, het voldoet aan de volgende EEG richtlijnen: 98/37/EC (Deze richtlijn is een opvolger van de orginele

Machinerichtlijn 89/392/EEG), Electromagnetische Compatability Richtlijn 89/336/EEG ( geamendeerd door 92/31/EEG & 93/68 EEG). De Laagspannings Richtlijn

72/23/EEG, EN 292 Veiligheid van Machines en hieraan gekoppelde geharmoniseerde Standaarden, waar deze van toepassing is. Rumoer emissions passen voor

richtlijn EC Zijgebouw VI , voor toestel onder stuk 12 naar de notified troep zit AV Technology Limited, AVTECH house, Birdhall Lane, Cheadle Heath, Stockport,

Cheshire, SK3 OXU, GB

La Sociedad, Belle Group Sheen UK, Sheen, Nr. Buxton, Derbyshire, SK 17 OEU, GB, por el presente documento certifica que si el producto descrito en este

certificado es comprado a un distribuidor autorizado de Belle Group en la CEE, este es conforme a las siguientes directivas: 98/37/CE de la CEE (Esta directiva

consolida la directiva inicial sobre maquinaria 89/392/CEE), Directiva 89/336 CEE sobre Compatibilidad Electromagnética (según enmiendas 92/31/CEE y 93/68 CEE),

Directiva sobre Bajo Voltaje 73/23/CEE, EN 292 de Seguridad de Maquinaria y Niveles armonizados estándares asociados donde sean aplicables. Emisión de Ruídos

conforme a la Directiva 2000/14/CE Anexo VI para máquinas bajo artículo 12 la mencionada unidad está AV Technology Limited, AVTECH House, Birdhall Lane,

Cheadle Heath, Stockport, Cheshire, SK3 OXU, GB.

Nous soussignons, Belle Group Sheen UK, Sheen, Nr Buxton, Derbyshire, SK17 0EU, GB, certifions que si le produit décrit dans ce certificat est acheté chez un

distributeur autorisé Belle Group au sein de la CEE, il est conforme aux normes CEE ci-après: 98/37/CE (Cette norme est une codification des normes de la machine

d'origine 89/392/CEE), Norme compatible pour l'électromagnisme 89/336/CEE (modifié par 92/31/CEE et 93/68/CEE). Caractéristiques basse tension 73/23/CEE, EN

292, Norme de sécurité des machines et des critères associés et configurés, si applicable. Les émissions de bruit sont conformes à la directive 2000/14/EC Annexe VI

pour machines , article 12, l’objet mentionné est

AV Technology Mimited, AVTECH House, Birhall Lane, Cheadle Heath, Stockport, Cheshire, SK3 0XU, GB.

EC DECLARATION OF CONFORMITY / DECLARATION CE DE CONFORMITE /

DECLARACIÓN DE CONFORMIDAD CE / DECLARAÇÃO CE DE CONFORMIDADE /

EG-VERKLARING VAN OVEREENSTEMMING / EF

OVERENSSTEMMELSESERKLÆRING

Vi, Belle Group Sheen UK, Sheen, Nr. Buxton, Derbyshire, SK17 0EU, GB, erklærer hermed, at hvis det i dette certifikat beskrevne produkt er købt hos en autoriseret

Belle Group forhandler i EU, er det i overensstemmelse med følgende EØF-direktiver: 98/37/EF, 73/23/EØF (som ændret ved 93/68/EØF), 89/336/EØF (som ændret ved

92/31/EØF), 93/68/EØF og tilknyttede, harmoniserede standarder, hvor relevant. Støjniveauet er i overensstemmelse med direktiv 2000/14/EF, bilag VI gældende for

maskiner under paragraf 12. Det bemyndigede organ er AV Technology Limited, AVTECH house, Birdhall Lane, Cheadle Heath, Stockport, Cheshire, SK3 0XU,

Storbritanien.

PRODUKTTYPE..................

MODEL ...............................

SERIENR. ...........................

FREMSTILLINGSDATO......

LYDEFFEKTNIVEAU .........

MÅLT (GARANTERET)

Ray Neilson

3

EGKONFORMITÄTSERKLÄRUNG / DICHIARAZIONE CE DI CONFORMITÁ /

EG-VERKLARING VAN OVEREENSTEMMING /

EC SAMSVARSERKLÆRING / EY-YHDENMUKAISUUSILMOITUS / DEKLARACJA

ZGODNOSCI Z PRZEPISAMI UE

Wir, Belle Group Sheen UK, Sheen, Nr. Buxton, Derbyshire, SK17 0EU, Großbritannien, bestätigen hiermit, dass das in diesem Zertifikat beschriebene Produkt, wenn es

von einem autorisierten Belle Group Händler innerhalb der europäischen Gemeinschaft gekauft wurde, folgenden EG-Richtlinien entspricht: 98/37/EG, 73/23/EG

(geändert durch 93/68/EG), 89/336/EG (geändert durch 92/31/EG), 93/68/EG und, wenn zutreffend, den harmonisierten Normen. Geräuschemissionen entsprechen der

Richtlinie 2000/14/EG, Anhang VI, für Maschinen unter Artikel 12: die benannte Stelle ist AV Technology Limited, AVTECH House, Birdhall Lane, Cheadle Heath,

Stockport, Cheshire, SK3 0XU, GB.

Il Gruppo Belle Sheen UK, Sheen, Nr. Buxton, Derbyshire, SK17 0EU, GB, certifica che il prodotto descritto nel presente certificato è acquistato da un concessionario

autorizzato del gruppo Belle nell'ambito CEE e che è pienamente conforme alle seguenti direttive CEE: 98/37/EC, 73/23/EEC (emendamento 93/68/CEE), 89/336/EEC

(emendamento 92/31/CEE), 93/68/CEE e relativi standard armonizzati. Livelli acustici sono in conformità con la direttiva 2000/14/EC Annex VI per macchine coperte dall’

articolo 12. L’ente di riferimento è AV Technology Limited, AVTECH house, Birdhall Lane, Cheadle Heath, Stockport, Cheshire, SK3 0XU, GB.

Undertecknade, Belle Group Sheen UK, Sheen, Nr Buxton, Derbyshire, SK17 0EU, Storbritannien, intygar härmed att en produkt beskriven i detta certifikat som köps från

en godkänd Belle Group återförsäljare inom EU stämmer överens med följande EG-direktiv: 98/37/EG, 73/23/EG (ändrat genom 93/68/EEC), 89/336/EG (ändrat genom

92/31/EG), 93/68/EG och tillhörande harmoniserade standarder i tillämpliga fall. Buller nivån överensstämmer med Direktiv 2000/14/EC Bilaga VI gällande maskiner

under artikel 12, den aviserade organisationen är AV Technology Limited, AVTECH house, Birdhall Lane, Cheadle Heath, Stockport, Cheshire, SK3 0XU,

Storbritannien.

Vi, Belle Group Sheen UK, Sheen, Nr Buxton, Derbyshire, SK17 0EU, GB, bekrefter med dette at det produktet som står beskrevet i denne erklæringen er kjøpt fra en

autorisert Belle Group forhandler innen EØF, og at det oppfyller følgende direktiver: 98/37/CE dette direktivet er et sammendrag av det opprinnelige maskindirektivet

89/392/EØF), Det elektromagnetisk kompatabiltets-direktivet 89/336/EØF (som endret av 92/31/EØF og 93/68/EØF). Lavspenningsdirektivet 73/23/EØF, EN 292,

Sikkerhet til maskineri og tilhørende harmoniserte standarder, hvor atuelt. Støyemisjon er i samsvar med direktiv 2000/14/EC, vedlegg VI, for maskiner. Organet som skal

informeres under artikkel 12 er

AV Technology Limited, AVTECH House, Birhall Lane, Cheadle Heath, Stockport, Cheshire, SK3 0XU, GB.

NO

Me, Belle Group Sheen UK, Sheen, Nr. Buxton, Derbyshire, SK17 0EU, GB, ilmoitamme täten, että jos tässä todistuksessa kuvattu tuote on ostettu valtuutetulta Belle

Groupin myyjältä ETY:n alueella, se on yhdenmukainen seuraavien ETY-direktiivien kanssa: 98(37/EY (Tämä direktiivi on yhdistelmä alkuperäisestä konedirektiivistä

89/392/ETY, sähkömagneettisen yhteensopivuuden direktiivistä 89/336/ETY, korjauksineen 92/31/ETY ja 93/68/ETY), matalajännitedirektiivistä 73/23/ETY,

koneturvallisuusstandardista EN 292 ja siihen liittyvistä yhdenmukaistetuista standardeista, tapauksen mukaan. Melumittaus mittaus on laadittu direktiivin 2000/14/EC

Kohdan VI artiklan 12 mukaisille koneille mukaan. Mittauksen suorittaja on AV Technology Limited, AVTECH House, Birdhall Lane, Cheadle Heath, Stockport,

Cheshire, SK3 0XU, GB.

SF

PL

PRODUKTTYP ..........................

MODELL....................................

SERIENNR.................................

HERSTELLUNGSDATU............

SCHALLLEISTUNGSPEGEL ...

GEMESSEN (GARANTIERT)

TIPO PRODOTTO......................

MODELLO.................................

SERIE N° ..................................

DATA DI FABBRICAZIONE......

LIVELLO....................................

POTENZA SONORA

MISURATA (GARANTITA)

PRODUKTTYP ..........................

MODELL....................................

SERIENR. .................................

TILLVERKNINGSDATUM.........

LJUDSTYRKA...........................

UPPMÄTT

(GARANTERAD)

PRODUKTTYPE........................

MODELL....................................

SERIENR ..................................

PRODUKSJONSDATO.............

LYDKRAFTNIVÅ........................

MÅLT (GARANTERT)

TUOTETYYPPI....................

MALLI..................................

VALMISTUSNRO................

VALMISTUSPÄIVÄ.............

ÄÄNENVOIMAKKUUDEN

TASO...................

MITATTU (TAATTU)

unterzeichnet vo: Generaldirektor – Im auftrag von BELLE GROUP (SHEEN) UK.

Firmato da: Amministratore Delegato – Per conto di BELLE GROUP (SHEEN) UK.

Undertecknat: V.D. – På vägnar av BELLE GROUP (SHEEN) UK.

Ray Neilson

Emisja hałasu zgodna z dyrektywą 2000/14/EC Aneks VI dla maszyn paragraf 12 jednostką notyfikowaną jest

4

СЕРТИФИКАТ СООТВЕТСТВИЯ / EÜ VASTAVUSDEKLARATSIOON /

ATBILSTĪBAS DEKLARĀCIJA / ES ATITIKTIES DEKLARACIJA /

ДЕКЛАРАЦИЯ ЗА СПАЗВАНЕ НА ИЗИСКВАНИЯ /

ΕΕ ΔΗΛΩΣΗ ΚΑΤΑΛΛΗΛΟΤΗΤΑΣ

RUS

EST

LT

LV

BG

Εμείς, η Belle Group, Sheen UK, Sheen, Nr. Buxton, Derbyshire, SK17 0EU, Μεγάλη Βρετανία, με το παρόν δηλώνουμε ότι εάν το προϊόν που

περιγράφεται στη δήλωση αυτή έχει αγοραστεί μέσω ενός εξουσιοδοτημένου αντιπροσώπου της Belle Group, σε χώρα μέλος της ΕΕ, τότε

συμμορφώνεται με τις ακόλουθες οδηγίες του Ευρωπαϊκού Συμβουλίου: 98/37/ΕΕ (Αυτή η οδηγία είναι μία σύμπτυξη της αρχικής οδηγίας περί

μηχανημάτων 89/392/EEC), την Οδηγία Ηλεκτρομαγνητικής Συμβατότητας 89/336/EEC (όπως τροποποιήθηκε από την 92/31/EEC & 93/68 EE). Την

οδηγία χαμηλής τάσης 73/23/EE, EN 292, Ασφάλεια μηχανημάτων και παρεμφερή εναρμονισμένα πρότυπα, όπου εφαρμόζεται . Οι εκπομπές

θορύβου συμμορφώνονται με την Οδηγία 2000/14/EC Παράρτημα VI, για μηχανήματα που υπάγονται στο άρθρο 12 το σώμα που πρέπει να

ενημερωθεί είναι: AV Technology Limited, AVTECH house, Birdhall Lane, Cheadle Heath, Stockport, Cheshire, SK3 0XU, GB.

GR

Мы, нижеподписавшиеся, от имени Белле Груп Шиин (Великобритания), Sheen, Nr. Buxton, Derbyshire SK17 0EU, Великобритания,

заявляем, что вслучае, если описанная вданном сертификате продукция была приобретена ууполномоченного представителя Белле Груп

вЕС, то она соответствует следующим директивам ЕС: 98/37/ЕЕС (данная директива является продолжением первоначальной директивы

по машиностроению 89/392/ЕЕС), директиве электромагнитной совместимости 89/336/ЕЕС (дополненной 92/31/ЕЕС и93/68/ЕЕС),

директиве вобласти низкого напряжения 73/23/ЕЕС, по применимым параметрам стандарту ЕН 292 «Безопасность машин исвязанные с

этим гармонизированные стандарты». Уровень шума соответствует требованиям директивы 2000/14/EC Приложение VI, для машин,

указанных в статье 12 уполномоченный орган: AV Technology Limited, AVTECH house, Birdhall Lane, Cheadle Heath, Stockport, Cheshire, SK3

0XU, GB.

Mēs, Belle Group Sheen UK, Nr. Buxton, Derbyrshire, SK17 0EU, ar šo apliecinām, ka šajā sertifikātā aprakstītais produkts ir iegādāts no autorizēta Belle

Group piegādātāja Eiropas EEK un tas atbilst šādām EEK direktīvām: 98/37/EC (šī direktīva ir sākotnējās mašīntehnikas direktīvas 89/392/EC

konsolidācija), Elektromagnētiskās savienojamības direktīvai 89/336/EEC (ar grozījumiem 92/31/EEC un 93/68 EEC), Zema sprieguma direktīvai

73/23/EEC, EN 292 mašīntehnikas drošības un saistītie harmonizācijas standarti, kad piemērojami. Trokšņu emisija atbilst direktīvas 2000/14/EK VI

pielikumam, attiecībā uz 12. pantā minētajām mašīnām informējošā institūcija ir AV Technology Limited, AVTECH house, Birdhall Lane, Cheadle Heath,

Stockport, Cheshire, SK3 0XU, LIELBRITĀNIJA.

Τύπος προϊόντος...............

Μοντέλο............................

Αριθμός σειράς.................

ΜΕΤΡΗΜΕΝΗ...................

ΣΤΑΘΜΗ ΘΟΡΥΒΟΥ

ΚΑΤΑ ΤΗΝ.........................

....

ΗΜΕΡΟΜΗΝΙΑ

ΚΑΤΑΣΚΕΥΗΣ

(ΕΓΓΥΗΜΕΝΗ)

ТИП ПРОДУКЦИИ....................

МОДЕЛЬ....................................

СЕРИЙНЫЙ НОМЕР................

ДАТА ВЫПУСКА......................

УРОВЕНЬ ШУМА ЗАМЕР........

ПРОИЗВЕДЕН

(ГАРАНТИРОВАН)

SĒRIJAS NR.

Υπογραφή: Διευθύνων Σύμβουλος – εκ μέρους της BELLE GROUP (SHEEN) Μεγάλη Βρετανία

Подпись: исполнительный директор - от имени БЕЛЛЕ ГРУП ШИИН (ВЕЛИКОБРИТАНИЯ)

Ray Neilson

се подчинява не директива 2000/ 14/ EC, Допълнение VI за машини под член 12 оповестеното тяло е

Шумовата емисия

Müratase on vastavuses direktiiviga

2000/14/EC Lisa VI masinatele kehtiva punktiga 12, teataja

Skleidžiamas triukšmas atitinka Direktyvos 2000/14/EB VI priedo nuostatas įrangai, nurodytai 12 straipsnyje, paskirtoji įstaiga yra AV Technology Limited, AVTECH house, Birdhall Lane,

Cheadle Heath, Stockport, Cheshire, SK3 0XU, GB.

5

ES PROHLÁŠENÍ O SHODĚ / DECLARATIE DE CONFORMITATE CE /

EU MEGFELELŐSÉGI NYILATKOZAT / EC UYUM BİLDİRGESİ /

EC IZJAVA O USKLAĐENOSTI / PREHLÁSENIE O ZHODE

Ray Neilson

My, Belle Group Sheen UK, Sheen, Nr. Buxton, Derbyshire, SK 17 0EU, Velké Británie, tímto prohlašujeme, že pokud byl níže uvedený produkt zakoupen

u autorizovaného prodejce Belle Group v rámci trhu Evropské Unie (EEC) odpovídá následujícím EEC směrnicím: 98/37EC (Tato směrnice sjednocuje originál směrnice

pro strojní zařízení: 89/392/EEC) a směrnici o elektromagnetické kompatibilitě 89/336/EEC (ve znění 92/31/EEC a 93/68 EEC). Na produkt byly aplikováný směrnice

73/23/EEC, EN 292 o bezpepečností strojních zařízení a přidružené harmonizované standardy. Emise hluku jsou v souladu se směrnicí 2000/14/ES, příloha VI, pro

zařízení podle článku 12 je notifikovaným orgánem AV Technology Limited, AVTECH house, Birdhall Lane, Cheadle Heath, Stockport, Cheshire, SK3 0XU, Velká

Británie.

CZ

Noi, Belle Group Sheen UK, Sheen, Nr. Buxton, Derbyshire, SK17 0EU, GB, certificam ca, daca produsul descris in acest certificat, este cumparat de la un distribuitor

autorizat al Belle Group in CEE, este conform cu directivele CEE urmatoare: 98/37/CE ( aceasta directiva este o consolidare a directivei originale referitoare la masini

89/392/CEE), directiva pentru compatibilitate electromagnetica 89/336/CEE (modificata de 92/31/CEE si 93/68/CEE), directiva pentru joasa tensiune 73/23/CEE, EN 292

referitoare la normele de siguranta ale masinilor si standardele asociate armonizate, acolo unde sunt aplicabile. Emisiile de zgomot sunt conforme cu Directiva CE

200/14, Anexa IV, referitoare la mecanismele de la articolul 12, partea informată fiind AV Technology Minimited AVTECH House, Birhall Lane, Cheadle Heath,

Stockport, Chesire, SK3 OXU, GB

RO

Mi, a Belle Group Sheen UK, Sheen, Nr. Buxton, Derbyshire, SK17 0EU, Egyesült Királyság ezennel tanusítjuk, hogy ha az ebben a tanusítványban leírt terméket a Belle

Group meghatalmazott forgalmazójától vásárolták az EU-n belül, a termék megfelel a következő EU irányelveknek: 98/37/EC (ez az irányelv az eredeti, 89/392/EEC gép

irányelv megerősítése), 89/336/EEC elektromágneses kompatibilitási irányelv (a 92/31/EEC és 93/68 EEC kiegészítésekkel együtt), 73/23/EEC kisfeszültség irányelv, EN

292 gépek biztonsága és a kapcsolódó harmonizált szabványok, ahol azok alkalmazandók. A hangkibocsátás megfelel a 2000/14/EC direktíva VI bekezdésében

foglaltaknak a 12 cikkelyben alá tartózó gépekre vonatkozóan: AV Technology Limited, AVTECH house, Birdhall Lane, Cheadle Heath, Stockport, Cheshire, SK3

0XU, Egyesült Királyság.

HUN

Vi, Belle Group Sheen UK, Sheen, Nr. Buxton, Derbyshire, SK17 0EU, GB, erklærer hermed, at hvis det i dette certifikat beskrevne produkt er købt hos en autoriseret

Belle Group forhandler i EU, er det i overensstemmelse med følgende EØF-direktiver: 98/37/EF, 73/23/EØF (som ændret ved 93/68/EØF), 89/336/EØF (som ændret ved

92/31/EØF), 93/68/EØF og tilknyttede, harmoniserede standarder, hvor relevant. Emisie hluku sú v súlade so smernicou 2000/14/ES, príloha VI, pre zariadenia podľa

článku 12 je notifikovaným orgánom AV Technology Limited, AVTECH House, Birdhall Lane, Cheadle Heath, Stockport, Cheshire, SK3 0XU, GB.

SK

Biz, Belle Group Sheen UK, Sheen, Nr. Buxton, Derbyshire, SK17 0EU, GB, Belle Group yetkili bayisinden alınmış olan burada belirtilen ürünün belirtilen EEC

yönergelerine uyduğunu doğrularız. 98/37/EC (Bu yönerge orijinal makine yönergesi olan 89/392/EC yönergesini güçlendiriyor), elektro manyetik uyumluluk yönergesi

89/336/EEC (92/31/EEC & 93/68 EEC ile değiştirilmiştir). Düşük voltaj yönergesi 73/23/EEC, EN 292 makinelerin güvenliği yönergesi, 2000/14/EC Ek VI ile onaylanmış

ses yönergesi; bildirilen kuruluşlar AV Technology Limited, AVTECH house, Birdhall Lane, Cheadle Heath, Stockport, Cheshire, SK3 0XU, GB.

TR

Mi, Belle Group Sheen UK, Sheen, Nr. Buxton, Derbyshire, SK17 0EU, GB, ovime potvrđujemo da ako je proizvod naveden u ovoj izjavi izdan od ovlaštenog Belle Group

prodavača unutar EEC, tada zadovoljava slijedeće EEC direktive: 98/37/EC (Ova direktiva je pročišćena direktiva o originalnim strojevima 89/392/EEC), Direktiva o

elektromagnetskoj usklađenosti 89/336/EEC (dopunjena sa 92/31/EEC & 93/68 EEC). Direktiva o niskoj voltaži 73/23/EEC, EN 292 Sigurnosti strojeva i pridruženi

usklađeni standardi, gdje su primjenjivi. Emisija buke usklađena je sa direktivom 2000/14/EC aneks VI za strojeve pod člankom 12 objavljenom od AV Technology

Limited, AVTECH house, Birdhall Lane, Cheadle Heath, Stockport, Cheshire, SK3 0XU, GB.

HR

TYP PRODUKU.........................

MODEL......................................

SERI ČÍSL .................................

DATUM VÝROBY.......................

NAMĚŘENÁ HL. HLUKU..........

(GARANTOVANÁ)

TIPUL PRODUSULUI................

MODEL......................................

SERIA ........................................

DATA FABRICARII.....................

NIVEL DE ZGOMOT..................

MASURAT (GARANTAT)

A TERMÉK TÍPUSA............

MODELL..............................

GYÁRI SZÁM.......................

GYÁRTÁSI IDŐ....................

A MÉRT (GARANTÁLT)......

HANGERŐSZINT

ÜRÜN TIPI.................................

MODEL......................................

SERI NUMARASI ......................

ÜRETIM TARIHI.........................

SES SEVIYE ÖLÇÜMÜ.............

(GARANTI EDILEN)

TIP PROIZVODA........................

MODEL.......................................

SERIJSKI Br ..............................

DATUM PROIZVODNJE.............

NIVO SNAGE ZVUKA................

IZMJEREN (GARANTIRANO):

TYP PRODUKTU........................

MODEL......................................

SÉRIOVÉ ČÍSLO ......................

DÁTUM VÝROBY ......................

NAMERANÁ HLADINA HLUKU

.....

(GARANTOVANÁ)

Podepsal: Generální ředitel – jménem BELLE GROUP (SHEEN) UK

Semnat de: Director General - in numele BELLE GROUP (SHEEN), UK

Aláírás: Ügyvezető igazgató - A BELLE GROUP (SHEEN) UK nevében

Potpisao: Izvršni Direktor – U ime BELLE GROUP (SHEEN) UK

İmzalayan: Yönetici - BELLE GROUP (SHEEN) UK adına.

Podpísal: Generálny riaditeľ – menom BELLE GROUP (SHEEN) UK

6

How To Use This Manual

GB

The product can be at risk. The machine or yourself can be damaged or injured if procedures are not

carried out in the correct way.

CAUTION

The life of the operator can be at risk.

WARNING

WARNING

GB

Before you operate or carry out any maintenance on this machine YOU MUST READ and STUDY

this manual.

WARNING

Contents

KNOW how to safely use the unit’s controls and what you must do for safe maintenance. (NB Be sure that you know how to switch the

machine off before you switch on, in case you get into difficulty.)

ALWAYS wear or use the proper safety items required for your personal protection. If you have ANY QUESTIONS about the safe use

or maintenance of this unit, ASK YOUR SUPERVISOR OR CONTACT: BELLE GROUP (UK): +44 (0) 1298 84606

GB

How to use this manual.............................................................................................................................................................................6

Warning .....................................................................................................................................................................................................6

Machine Description..................................................................................................................................................................................7

Environment ..............................................................................................................................................................................................7

Technical Data...........................................................................................................................................................................................8

General Safety ..........................................................................................................................................................................................9

Health and Safety......................................................................................................................................................................................9

Pre-Start Checks.....................................................................................................................................................................................10

Start and Stop Procedure........................................................................................................................................................................10

Operating Instructions .............................................................................................................................................................................11

Trouble Shooting Guide ..........................................................................................................................................................................11

Service and Maintenance................................................................................................................................................................ 12 - 13

Warranty ..................................................................................................................................................................................................13

Declaration of Conformity..........................................................................................................................................................................2

Belle Group reserves the right to change machine specification without prior notice or obligation.

This manual has been written to help you operate and service the BMD Minidumper safely.

This manual is intended for dealers and operators of the BMD Minidumper.

Foreword

The ‘Environment’ section gives instructions on how to handle the recycling of discarded apparatus in an environmentally friendly way.

The ‘Machine Description’ section helps you to familiarize yourself with the machine’s layout and controls.

The ‘General Safety’ and ‘Health and Safety’ sections explain how to use the machine to ensure your safety and the safety of the general

public.

The ‘Trouble Shooting’ guide helps you if you have a problem with your machine.

The ‘Servicing’ section is to help you with the general maintenance and servicing of your machine.

The ‘Warranty’ Section details the nature of the warranty cover and the claims procedure.

The ‘Declaration of Conformity’ section shows the standards that the machine has been built to.

Directives with regard to the notations.

Text in this manual to which special attention must be paid are shown in the following way:

7

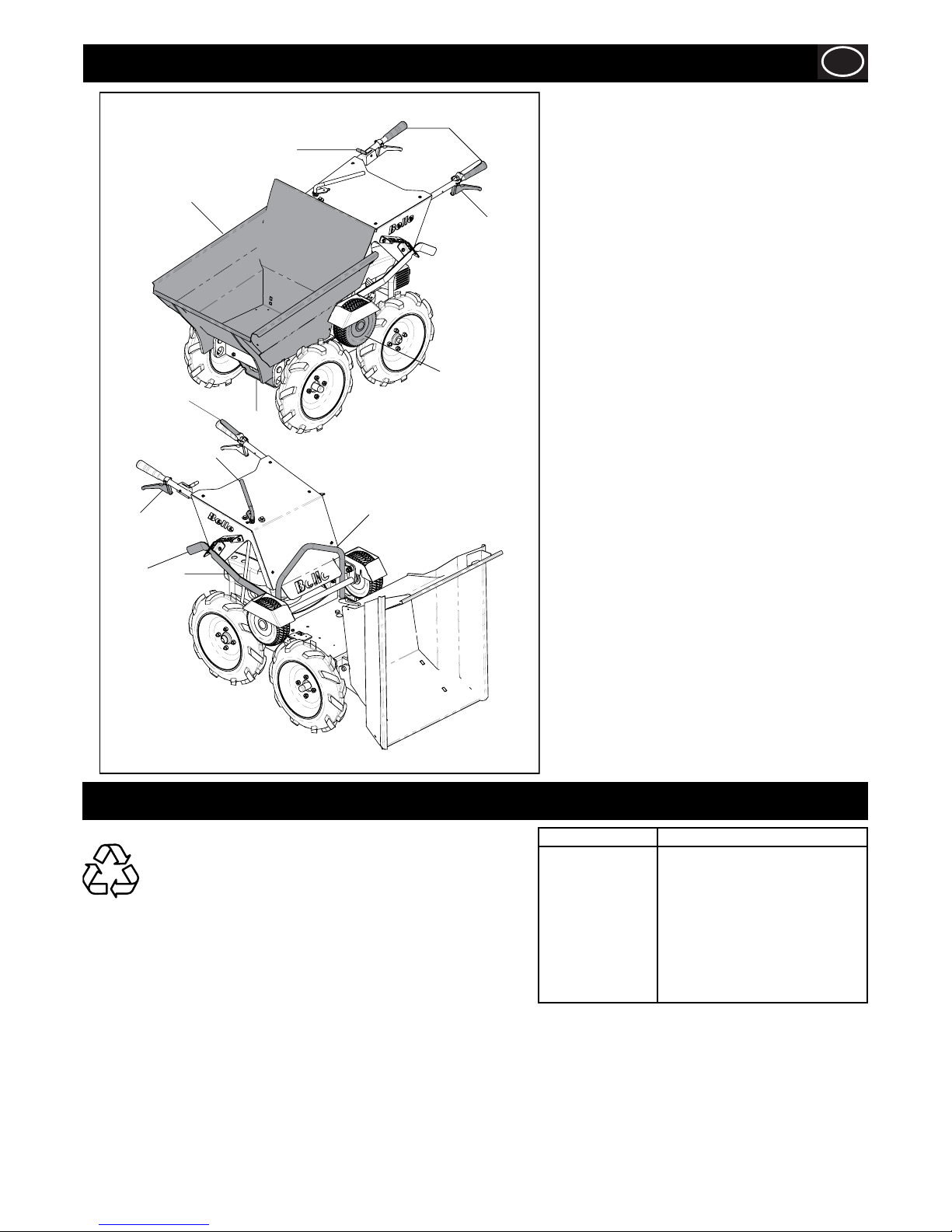

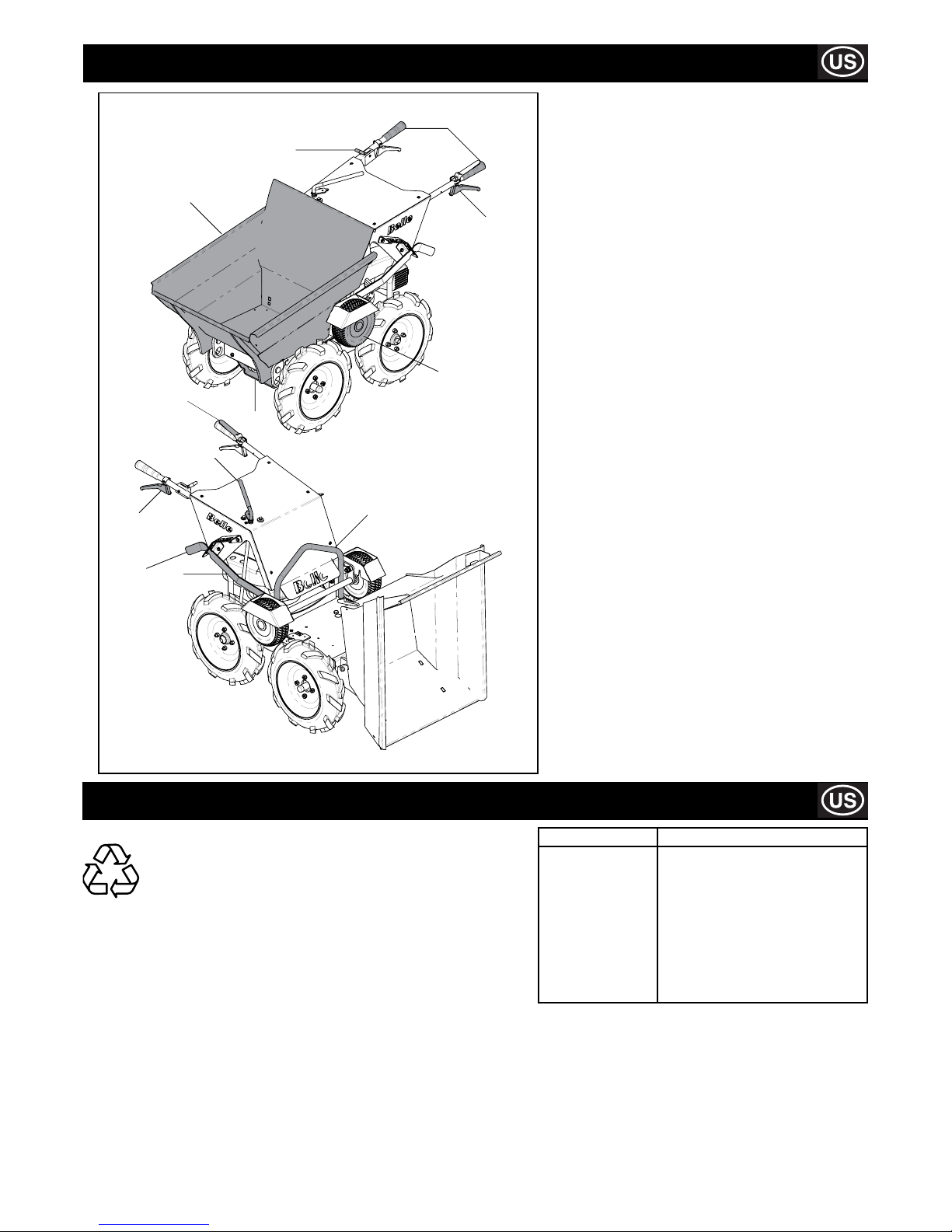

Machine Description

GB

1. Skip / Bucket.

2. Gear Lever.

3. Operating Handles.

4. Drive Lever.

5. Strapping Points.

6. Throttle Lever.

7. 4-Wheel Drive Engagement Levers.

8. Oil Fill and Dipstick.

9. Skip Release Lever.

10. Lifting Eye.

11. Park Brake Lever

12. Friction Wheel (This engages the

4-wheel Drive option)

Safe Disposal.

Instructions for the protection of the environment.

The machine contains valuable materials. Take the discarded

apparatus and accessories to the relevant recycling facilities.

Environment

Component Material.

Handle Steel

Hand Grips Rubber

Chassis Steel

Engine Aluminium and Steel

Gearbox Aluminium, Steel and

Phosphor Bronze

Skip Steel

Various Parts Steel and Rubber

1

3

4

5

6

2

9

78

10

11

12

8

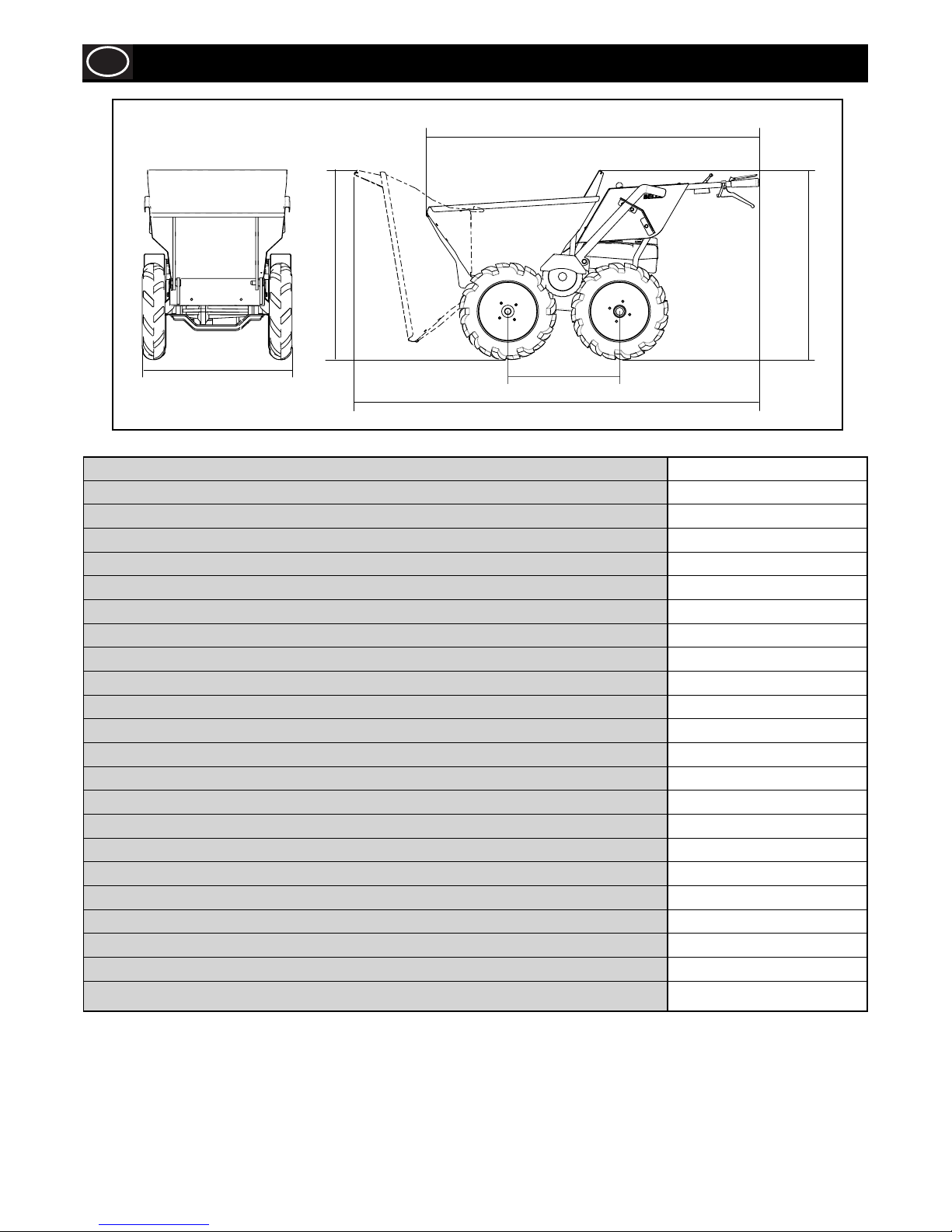

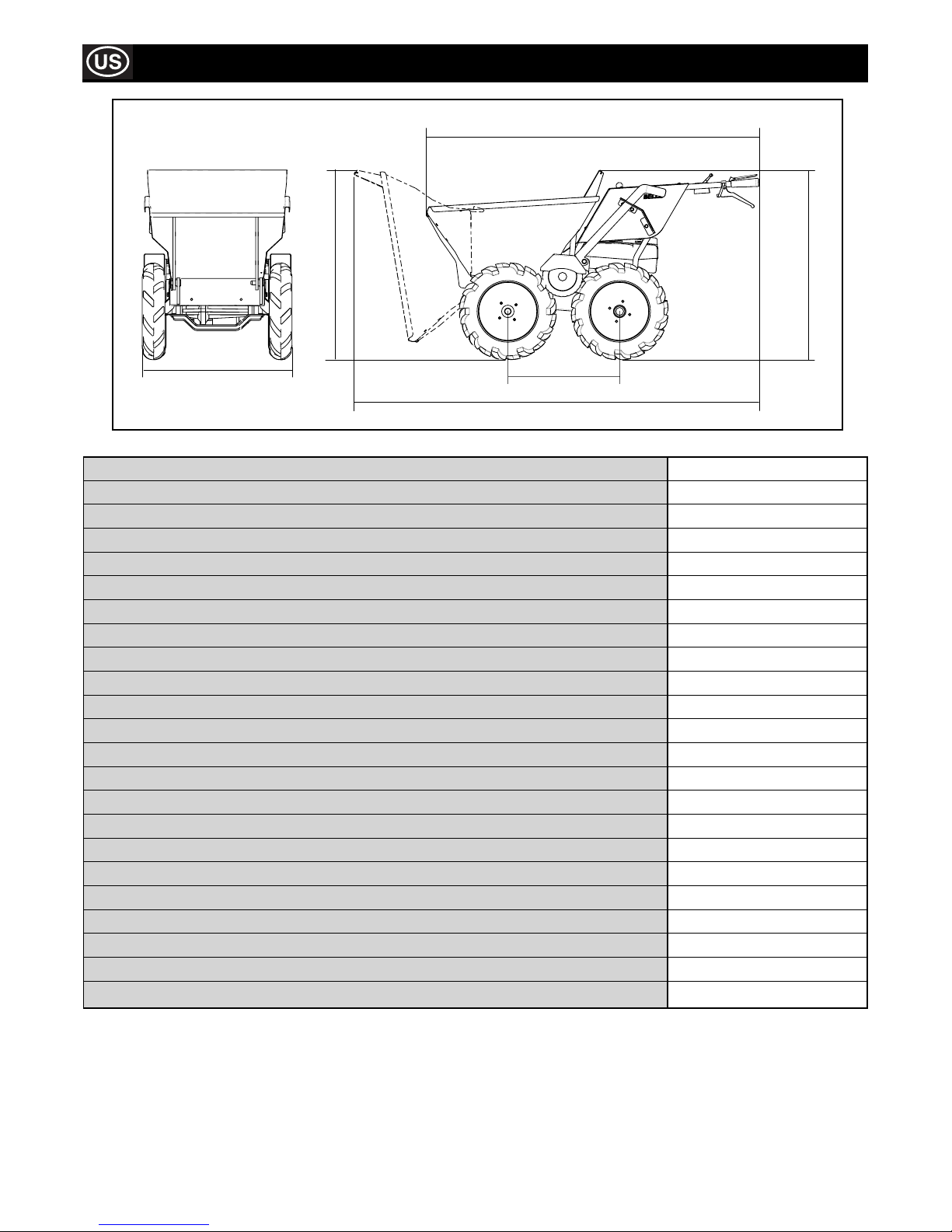

Technical Data

GB

BMD 300

A - Machine Width (mm) 716

B - Machine Length (mm) 1588

C - Machine Length During Tipping (mm) 1957

D - Machine Height (mm) 925

E - Machine Height During Tipping (mm) 859

F - Wheel Base 528

Engine Model Honda GXV160 (5.5Hp)

Engine Type Unleaded Petrol

Maximum Engine RPM 3000

Maximum Travel Speed - Forward (Km/h) 6

Maximum Travel Speed - Reverse (Km/h) 2.6

Skip Capacity - Fill Volume (Ltr) 113

Skip Capacity - Heaped Volume (Ltr) 134

Tyre Pressure (PSI / Bar) 30 / 2.1

Tyre Size (in) 4.00 x 10

Tyre Pressure - Friction Wheel (PSI / Bar) 35 / 2.4

Tyre Size - Friction Wheel (in) 9 x 3.5 -4

Machine Weight (kg) 155

Maximum Axle Weight (kg) 300

Maximum Uphill Gradient 20º

Maximum Downhill Gradient 20º

Noise Level (dB(A)) 101

A

B

F

D

E

C

9

General Safety

GB

• Before refuelling, switch off the engine and allow it to cool.

• When refuelling, DO NOT smoke or allow naked flames in the area.

• Spilt fuel must be made safe immediately, by using sand. If fuel is spilt on your clothes, change them.

• Store petrol in an approved, purpose made container away from heat and ignition sources.

• If fuel is spilt when re-fuelling the tank, wipe off the excess and wait 2 minutes before re-starting.

• This equipment is heavy and must not be lifted single-handedly, GET HELP and use suitable lifting equipment.

• Cordon off the work area and keep members of the public and unauthorized personnel at a safe distance.

• Personal Protective Equipment (PPE) must be worn by the operator when ever this equipment is being used (see Health & Safety).

• Make sure you know how to safely switch this machine OFF before you switch it ON in case you get into difficulty.

• Always switch OFF the engine before transporting, moving it around the site or servicing it.

• During use the engine becomes very hot, allow the engine to cool before touching it. Never leave the engine running and

unattended.

• Never remove or tamper with any guards fitted, they are there for your protection. Always check guards for condition and

security, if any are damaged or missing, DO NOT USE THE BMD MINIDUMPER until the guard has been replaced or repaired.

• Do not operate the machine when you are ill, feeling tired, or when under the influence of alcohol or drugs.

• Do not stand the machine on end with the engine running.

• Do not use the BMD Minidumper to transport people.

• Do not release the brake suddenly when travelling forward at speed with a heavy load as the machine may topple forward.

• When travelling downhill, engage the reverse gear with the clutch lever fully engaged and parking brake lever pressed down

(brake off). Close the throttle if necessary so that engine braking controls the speed.

• Always ensure that when moving downwards on a hill, the machine is travelling in reverse.

Fuel Safety

Petrol is flammable. It may cause injury and property damage. Shut down the engine, extinguish all open

flames and do not smoke while filling the fuel tank. Always wipe up any spilled fuel.

WARNING

Improper maintenance can be hazardous. Read and Understand this section before you perform any

maintenance, service or repairs.

WARNING

For your own personal protection and for the safety of those around you, please read and ensure you fully understand the following

safety information. It is the responsibility of the operator to ensure that he/she fully understands how to operate this equipment safely.

If you are unsure about the safe and correct use of the BMD Minidumper, consult your supervisor or Belle Group.

Health And Safety

GB

Vibration.

Some vibration from the operation is transmitted through the handle to the operator’s hands. DO NOT exceed the maximum usage times.

(See Technical Data section)

PPE (Personal Protective Equipment).

Suitable PPE must be worn when using this equipment i.e. Safety Goggles, Gloves, Ear Defenders, Dust Mask and Steel Toe capped

footwear. Wear clothing suitable for the work you are doing. Tie back long hair and remove any jewellery which may catch in the equip-

ment’s moving parts.

Petrol Machines.

Fuel.

Do not ingest fuel or inhale fuel vapours and avoid contact with your skin. Wash fuel splashes immediately. If you get fuel in your eyes,

irrigate with copious amounts of water and seek medical attention as soon as possible.

Exhaust Fumes

Do not operate the BMD Minidumper indoors or in a confined space, make sure the work area is adequately ventilated.

The exhaust fumes produced by this equipment are highly toxic and can kill!

WARNING

10

Honda GXV 160 Petrol Engine

Starting

1. Turn the fuel shut off valve to the ON position.

2. Move the throttle control to the choke position. Do not use the choke when the engine is warm. Move the throttle control slightly

Maximum RPM (Hare) position.

3. Pull the starter grip lightly until resistance is felt, then pull briskly.

NOTE:- Do not allow the starter grip to snap back against the engine. Return it gently to prevent damage to the starter.

4. If the choke was used to start the engine, move the throttle to the fast (or high) position as soon as the engine warms up enough

to run smoothly without use of the choke.

Throttle Lever

5. Position the throttle control for the desired engine speed. For best engine performance, it is recommended that the engine be

operated with the throttle in the fast (or high) position.

Pre-start Checks

GB

Pre start-up inspection.

The following Pre-start-up inspection must be performed before the start of each work session or after every four hours of use, which-

ever is first. Please refer to the service section for detailed guidance. If any fault is discovered, the BMD Minidumper must not be used

until the fault is rectified.

1. Thoroughly inspect the BMD Minidumper for signs of damage. Check components are present and secure.

2. Check fluid lines, hoses filler openings, drain plugs and any other areas for signs of leakage. Fix any leaks before operating.

3. Check the engine oil level and top up as necessary.

4. Check the engine fuel level and top up as necessary.

5. Check for fuel and oil leaks.

Start and Stop Procedure

GB

For safety reasons, the maximum operating speed must be adjusted with a special tool. Please consult

your authorised Honda dealer for this operation.

CAUTION

6. Using a tachometer, check the engine speed. If you can’t obtain the top no load engine speed specified, consult your

Honda dealer.

Stopping

7. Move the throttle control to the stop position. The fuel cock will automatically turn off.

8. When the engine has stopped, turn the fuel valve to the OFF position if you do not intend to restart the engine soon.

11

Operating Instructions

GB

Gear Selection Options

1st Gear = Climbing steep slopes, steps or ramps.

2nd Gear = Climbing slopes.

3rd Gear = Travelling on level ground when laden.

4th Gear = Travelling on level ground when unladen.

Operating the BMD Minidumper

1. Start the engine.

2. With the engine running, select the gear by turning the Gear Lever (2) to the desired position.

3. Release the brake by pressing the red Park Brake Lever (11) down towards the operating handle and pull the Drive Lever (4)

upwards to engage drive. The machine will now begin to move.

4. Once the machine is moving the throttle can be opened or closed to increase or decrease the speed of the machine.

(If more speed is required, follow steps 2, 3 and 4 but select a higher gear than is currently in use)

NOTE: The gears cannot be altered whilst the machine is in motion.

If it is necessary to travel down a slope of more than 15° when fully laden, ensure that the machine is

turned round and reverse down the slope.

CAUTION

Emptying the Skip

1. Stop the machine by releasing the Drive Lever (4) followed by releasing the red Park Brake Lever (11).

2. Once the machine has become stationary compress the Skip Release Lever (9) and slightly lift-up the rear of the machine. The

Skip (1) will tip forwards disposing of its contents.

3. When the Skip (1) is empty, push back to its original postion. The Skip (1) will lock into place automatically.

Note: The numbers shown in brackets above refer to the pictures shown in the Machine Description section of the booklet.

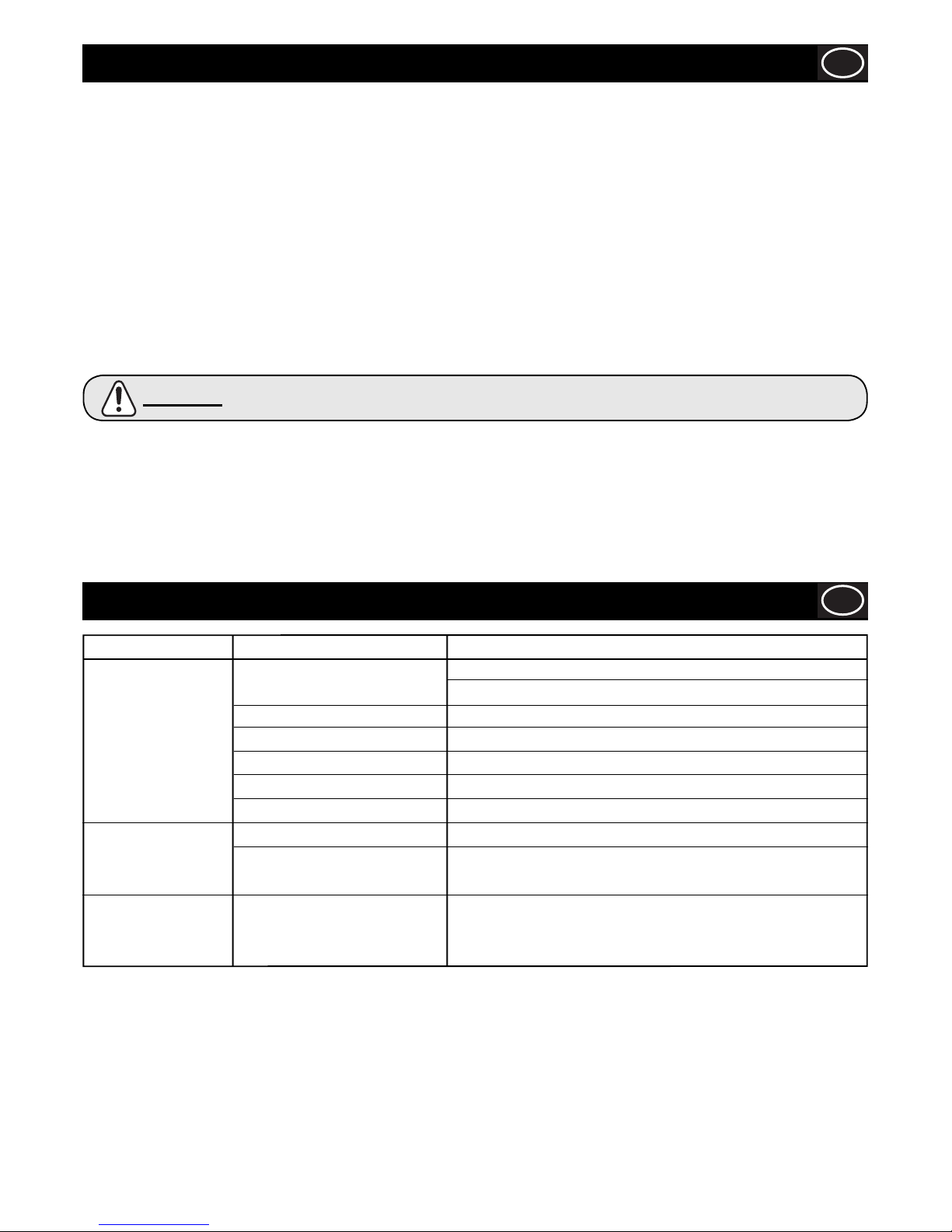

Troubleshooting Guide

GB

Problem Cause Remedy

Engine will not start. No fuel getting to engine. Open fuel tap.

Fill fuel tank.

Engine switched off. Switch engine on.

Spark plug fouled. Clean, check and reset plug gap.

Engine cold. Close choke.

Engine flooded. Open choke, fully open throttle, pull recoil starter until engine fires.

Cutout switch wire Reconnect disconnected wire.

BMD Minidumper does Gear is not properly selected. Ensure Gear Lever is not in-between two different gears.

not move whilst Drive Belt is not tight enough. Tighten Drive Belt

engine is running.

Front wheels are Under inflated tyres. Inflate tyres to 30 psi.

spinning whilst 4-wheel

drive is engaged.

12

Service and Maintenance

GB

Gearbox Oil

There should be no maintenance required as this is a sealed Gearbox. If there are any signs of leakage, stop using the machine

and contact your local dealer or the Belle Group.

Machine Cleaning

Clean the machine after it has been used to prevent the collection of hardened debris. Hardened debris is very difficult to remove.

To clean it use an old brush or hand brush with water.

Note: Never pressure wash or hose down the engine. Clean only with a cloth or compressed air.

Park Brake

The Parking Brake operates automatically when the red Parking Brake Lever is in the upright position. A spring holds the brake

on until the lever is compressed to release it. Correct adjustment is crititcal. If the brake cable is too tight the brake spring will not

be applying full pressure to the brake arm. If the brake cable it too slack, the brake may not release correctly when the lever is

depressed and the brake will drag causing overheating and wear to the brake pads and damage to the gearbox.

Air Filter

If it is dirty, proceed as follows:-

Foam Element - Wash the element in a solution of washing-up liquid and water. Allow the element to dry, then soak in clean engine

oil and squeeze out the excess oil. If the engine smokes during start-up then too much oil has been left on the foam.

Paper Element - Tap the element on a hard surface or blow from inside using compressed air to remove any excess dust within

the filter. Replace every 200 hours or if it is extremely dirty.

Oil / Fuel Type & Quantity - Spark Plug Type

Oil type Quantity Fuel Type Capacity Spark Plug Electrode

(Litre) (Litre) Type Gap (mm)

Petrol Honda GXV160 S.A.E. 10W 30 0.65 Unleaded 2.0 BPR5ES 0.7 - 0.8

Routine Maintenance Every Every Every Every

20 hours 50 Hours 75 Hours 200 Hours

Engine Oil Change 9

Air Filter Check Condition 9

Clean / Replace 9

Spark Plug Change 9

Note: Remove all Oil and Fuel before tipping the machine over.

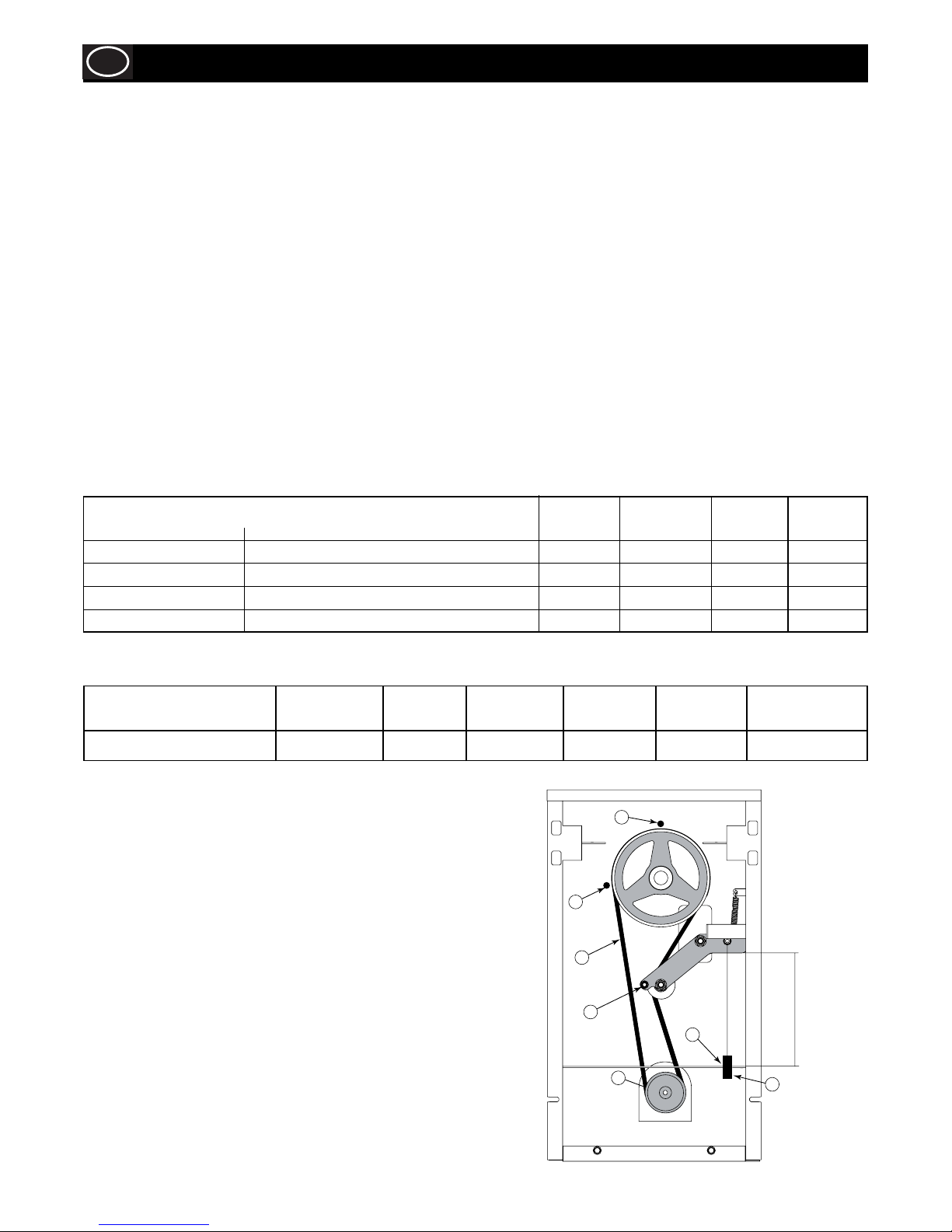

Belt Removal (On Machines Up To Serial No. 141778)

1. Remove the 6 x M8 Bolts from the Sump Guard and then remove

the Sump Guard from the machine.

2. Remove 3 X Bolts (A). This will allow you to remove the Belt (B).

NOTE:- Ensure the Belt is removed from the Engine pulley (D) first.

Belt Fitting (On Machines Up To Serial No. 141778)

1. Place the Belt (B) onto the transmission pulley (C), and then onto the

engine pulley (D).

2. Ensure the Belt (B) runs on the outside of the Clutch Tensioning Arm.

(See the diagram on the right to see the route of the Belt (B))

3. Add Bolt (A) to the Clutch Tensioning Arm and tighten so that the arm

is 245mm from the Cross Plate (See the diagram on the right).

If adjustment is required, tweak the 2 Nuts (E) until correct distance is

achieved.

4. Attach the Sump Guard using the 6 x M8 Bolts to a torque setting of

28Nm.

A

B

245mm

C

D

A

A

E

E

13

Service and Maintenance

GB

Your new Belle Group ‘BMD’ Minidumper is warranted to the original purchaser for a period of one-year (12 months) from the original

date of purchase. The Belle Group warranty is against defects in design, materials and workmanship.

The following are not covered under the Belle Group warranty:

1. Damage caused by abuse, misuse, dropping or other similar damage caused by or as a result of failure to follow assembly,

operation or user maintenance instructions.

2. Alterations, additions or repairs carried out by persons other than Belle Group or their recognised agents.

3. Transportation or shipment costs to and from Belle Group or their recognised agents, for repair or assessment against a

warranty claim, on any machine.

4. Materials and/or labour costs to renew, repair or replace components due to fair wear and tear.

The following components are not covered by warranty.

· Drivebelt/s

· Engine air filter

· Engine spark plug

Belle Group and/or their recognised agents, directors, employees or insurers will not be held liable for consequential or other

damages, losses or expenses in connection with or by reason of or the inability to use the machine for any purpose.

Warranty Claims

All warranty claims should firstly be directed to Belle Group, either by telephone, by Fax, by Email, or in writing.

For warranty claims:

Write to:

Belle Group Warranty Department,

Unit 5, Bode Business Park,

Ball Haye Green,

Leek,

Staffordshire, ST13 6BW

England.

Warranty

GB

Note: Remove all Oil and Fuel before tipping the machine over.

Belt Removal (On Machines From Serial No. 141779)

1. Remove the 6 x M8 Bolts from the Sump Guard and then remove

the Sump Guard from the machine.

2. Remove 4 X Bolts (A). This will allow you to remove the Belt (B).

NOTE:- Ensure the Belt is removed from the Engine pulley (D) first.

Belt Fitting (On Machines From Serial No. 141779)

1. Place the Belt (B) onto the transmission pulley (C), and then onto the

engine pulley (D).

2. Ensure the Belt (B) runs on the outside of the Clutch Tensioning Arm.

(See the diagram on the right to see the route of the Belt (B))

3. Add Bolt (A) to the Clutch Tensioning Arm and tighten so that the arm

is 235mm from the Cross Plate (See the diagram on the right).

If adjustment is required, tweak the 2 Nuts (E) until correct distance is

achieved.

4. Attach the Sump Guard using the 6 x M8 Bolts to a torque setting of

28Nm.

A

B

235mm

C

D

A

A

E

E

A

14

How To Use This Manual

The product can be at risk. The machine or yourself can be damaged or injured if procedures are not

carried out in the correct way.

CAUTION

The life of the operator can be at risk.

WARNING

WARNING

Before you operate or carry out any maintenance on this machine YOU MUST READ and STUDY

this manual.

WARNING

Contents

KNOW how to safely use the unit’s controls and what you must do for safe maintenance. (NB Be sure that you know how to switch the

machine off before you switch on, in case you get into difficulty.)

ALWAYS wear or use the proper safety items required for your personal protection. If you have ANY QUESTIONS about the safe use

or maintenance of this unit, ASK YOUR SUPERVISOR OR CONTACT: BELLE GROUP (UK): +44 (0) 1298 84606

How to use this manual...........................................................................................................................................................................14

Warning ...................................................................................................................................................................................................14

Machine Description................................................................................................................................................................................15

Environment ............................................................................................................................................................................................15

Technical Data.........................................................................................................................................................................................16

General Safety ........................................................................................................................................................................................17

Health and Safety....................................................................................................................................................................................17

Pre-Start Checks.....................................................................................................................................................................................18

Start and Stop Procedure........................................................................................................................................................................18

Operating Instructions .............................................................................................................................................................................19

Trouble Shooting Guide ..........................................................................................................................................................................19

Service and Maintenance................................................................................................................................................................ 20 - 21

Warranty ..................................................................................................................................................................................................21

Belle Group reserves the right to change machine specification without prior notice or obligation.

This manual has been written to help you operate and service the BMD Minidumper safely.

This manual is intended for dealers and operators of the BMD Minidumper.

Foreword

The ‘Environment’ section gives instructions on how to handle the recycling of discarded apparatus in an environmentally friendly way.

The ‘Machine Description’ section helps you to familiarize yourself with the machine’s layout and controls.

The ‘General Safety’ and ‘Health and Safety’ sections explain how to use the machine to ensure your safety and the safety of the general

public.

The ‘Trouble Shooting’ guide helps you if you have a problem with your machine.

The ‘Servicing’ section is to help you with the general maintenance and servicing of your machine.

The ‘Warranty’ Section details the nature of the warranty cover and the claims procedure.

The ‘Declaration of Conformity’ section shows the standards that the machine has been built to.

Directives with regard to the notations.

Text in this manual to which special attention must be paid are shown in the following way:

15

Machine Description

1. Skip / Bucket.

2. Gear Lever.

3. Operating Handles.

4. Drive Lever.

5. Strapping Points.

6. Throttle Lever.

7. 4-Wheel Drive Engagement Levers.

8. Oil Fill and Dipstick.

9. Skip Release Lever.

10. Lifting Eye.

11. Park Brake Lever

12. Friction Wheel (This engages the

4-wheel Drive option)

Safe Disposal.

Instructions for the protection of the environment.

The machine contains valuable materials. Take the discarded

apparatus and accessories to the relevant recycling facilities.

Environment

Component Material.

Handle Steel

Hand Grips Rubber

Chassis Steel

Engine Aluminium and Steel

Gearbox Aluminium, Steel and

Phosphor Bronze

Skip Steel

Various Parts Steel and Rubber

1

3

4

5

6

2

9

78

10

11

12

16

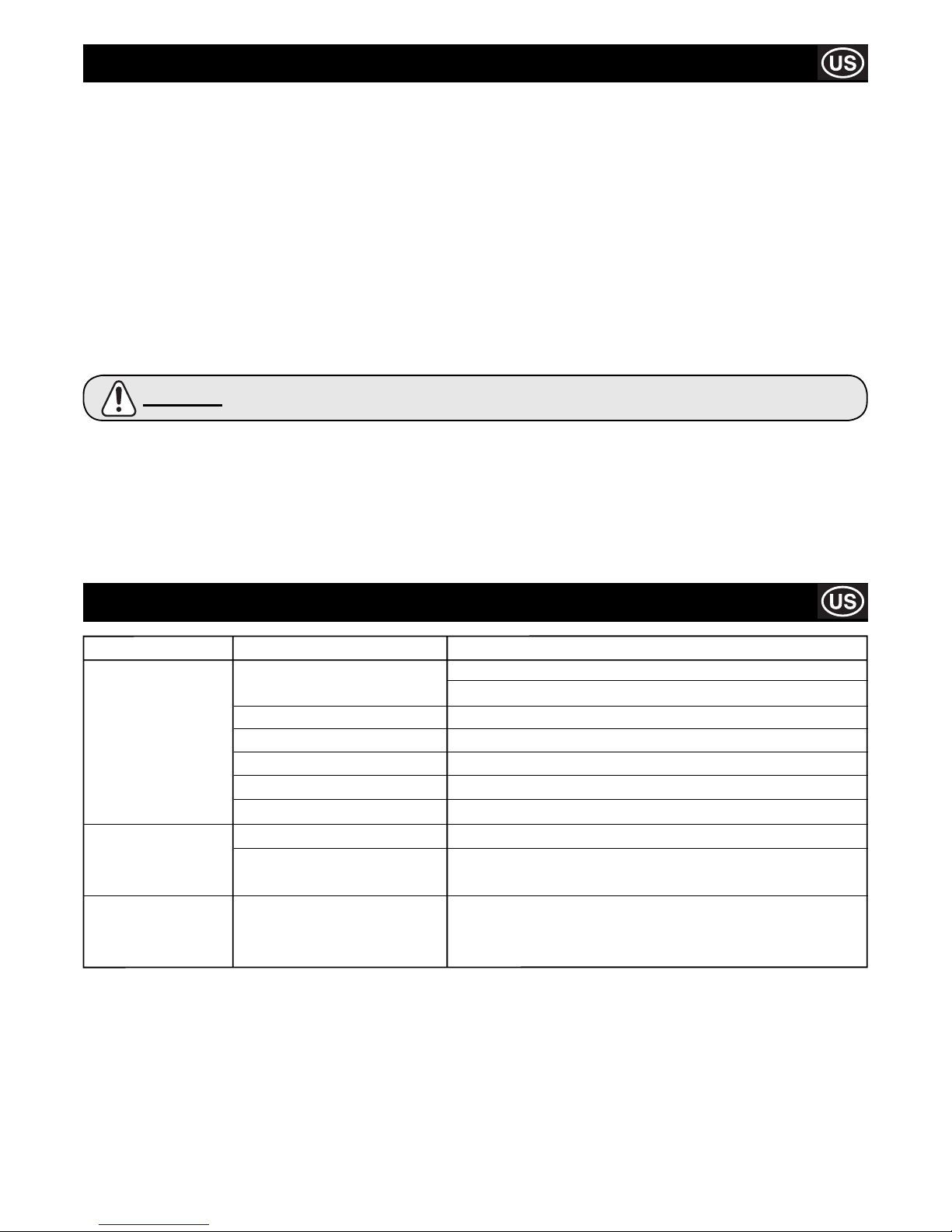

Technical Data

BMD 300

A - Machine Width (in) 28.2

B - Machine Length (in) 62.5

C - Machine Length During Tipping (in) 77.0

D - Machine Height (in) 36.4

E - Machine Height During Tipping (in) 33.8

F - Wheel Base 20.8

Engine Model Honda GXV160 (5.5Hp)

Engine Type Unleaded Gasoline

Maximum Engine RPM 3000

Maximum Travel Speed - Forward (Km/h) 6

Maximum Travel Speed - Reverse (Km/h) 2.6

Skip Capacity - Fill Volume (Gals) 29.9

Skip Capacity - Heaped Volume (Gals) 35.4

Tire Pressure (PSI / Bar) 30 / 2.1

Tire Size (in) 4.00 x 10

Tire Pressure - Friction Wheel (PSI / Bar) 35 / 2.4

Tire Size - Friction Wheel (in) 9 x 3.5 -4

Machine Weight (lbs) 341.7

Maximum Axle Weight (lbs) 661.4

Maximum Uphill Gradient 20º

Maximum Downhill Gradient 20º

Noise Level (dB(A)) 101

A

B

F

D

E

C

17

General Safety

• Before refuelling, switch off the engine and allow it to cool.

• When refuelling, DO NOT smoke or allow naked flames in the area.

• Spilt fuel must be made safe immediately, by using sand. If fuel is spilt on your clothes, change them.

• Store gasoline in an approved, purpose made container away from heat and ignition sources.

• If fuel is spilt when re-fuelling the tank, wipe off the excess and wait 2 minutes before re-starting.

• This equipment is heavy and must not be lifted single-handedly, GET HELP and use suitable lifting equipment.

• Cordon off the work area and keep members of the public and unauthorized personnel at a safe distance.

• Personal Protective Equipment (PPE) must be worn by the operator when ever this equipment is being used (see Health & Safety).

• Make sure you know how to safely switch this machine OFF before you switch it ON in case you get into difficulty.

• Always switch OFF the engine before transporting, moving it around the site or servicing it.

• During use the engine becomes very hot, allow the engine to cool before touching it. Never leave the engine running and

unattended.

• Never remove or tamper with any guards fitted, they are there for your protection. Always check guards for condition and

security, if any are damaged or missing, DO NOT USE THE BMD MINIDUMPER until the guard has been replaced or repaired.

• Do not operate the machine when you are ill, feeling tired, or when under the influence of alcohol or drugs.

• Do not stand the machine on end with the engine running.

• Do not use the BMD Minidumper to transport people.

• Do not release the brake suddenly when travelling forward at speed with a heavy load as the machine may topple forward.

• When travelling downhill, engage the reverse gear with the clutch lever fully engaged and parking brake lever pressed down

(brake off). Close the throttle if necessary so that engine braking controls the speed.

• Always ensure that when moving downwards on a hill, the machine is travelling in reverse.

Fuel Safety

Gasoline is flammable. It may cause injury and property damage. Shut down the engine, extinguish all

open flames and do not smoke while filling the fuel tank. Always wipe up any spilled fuel.

WARNING

Improper maintenance can be hazardous. Read and Understand this section before you perform any

maintenance, service or repairs.

WARNING

For your own personal protection and for the safety of those around you, please read and ensure you fully understand the following

safety information. It is the responsibility of the operator to ensure that he/she fully understands how to operate this equipment safely.

If you are unsure about the safe and correct use of the BMD Minidumper, consult your supervisor or Belle Group.

Health And Safety

Vibration.

Some vibration from the operation is transmitted through the handle to the operator’s hands. DO NOT exceed the maximum usage times.

(See Technical Data section)

PPE (Personal Protective Equipment).

Suitable PPE must be worn when using this equipment i.e. Safety Goggles, Gloves, Ear Defenders, Dust Mask and Steel Toe capped

footwear. Wear clothing suitable for the work you are doing. Tie back long hair and remove any jewellery which may catch in the

equipment’s moving parts.

Petrol Machines.

Fuel.

Do not ingest fuel or inhale fuel vapours and avoid contact with your skin. Wash fuel splashes immediately. If you get fuel in your eyes,

irrigate with copious amounts of water and seek medical attention as soon as possible.

Exhaust Fumes

Do not operate the BMD Minidumper indoors or in a confined space, make sure the work area is adequately ventilated.

The exhaust fumes produced by this equipment are highly toxic and can kill!

WARNING

18

Honda GXV 160 Gasoline Engine

Starting

1. Turn the fuel shut off valve to the ON position.

2. Move the throttle control to the choke position. Do not use the choke when the engine is warm. Move the throttle control slightly

Maximum RPM (Hare) position.

3. Pull the starter grip lightly until resistance is felt, then pull briskly.

NOTE:- Do not allow the starter grip to snap back against the engine. Return it gently to prevent damage to the starter.

4. If the choke was used to start the engine, move the throttle to the fast (or high) position as soon as the engine warms up enough

to run smoothly without use of the choke.

Throttle Lever

5. Position the throttle control for the desired engine speed. For best engine performance, it is recommended that the engine be

operated with the throttle in the fast (or high) position.

Pre-start Checks

Pre start-up inspection.

The following Pre-start-up inspection must be performed before the start of each work session or after every four hours of use, which-

ever is first. Please refer to the service section for detailed guidance. If any fault is discovered, the BMD Minidumper must not be used

until the fault is rectified.

1. Thoroughly inspect the BMD Minidumper for signs of damage. Check components are present and secure.

2. Check fluid lines, hoses filler openings, drain plugs and any other areas for signs of leakage. Fix any leaks before operating.

3. Check the engine oil level and top up as necessary.

4. Check the engine fuel level and top up as necessary.

5. Check for fuel and oil leaks.

Start and Stop Procedure

For safety reasons, the maximum operating speed must be adjusted with a special tool. Please consult

your authorised Honda dealer for this operation.

CAUTION

6. Using a tachometer, check the engine speed. If you can’t obtain the top no load engine speed specified, consult your

Honda dealer.

Stopping

7. Move the throttle control to the stop position. The fuel cock will automatically turn off.

8. When the engine has stopped, turn the fuel valve to the OFF position if you do not intend to restart the engine soon.

19

Operating Instructions

Troubleshooting Guide

Problem Cause Remedy

Engine will not start. No fuel getting to engine. Open fuel tap.

Fill fuel tank.

Engine switched off. Switch engine on.

Spark plug fouled. Clean, check and reset plug gap.

Engine cold. Close choke.

Engine flooded. Open choke, fully open throttle, pull recoil starter until engine fires.

Cutout switch wire Reconnect disconnected wire.

BMD Minidumper does Gear is not properly selected. Ensure Gear Lever is not in-between two different gears.

not move whilst Drive Belt is not tight enough. Tighten Drive Belt

engine is running.

Front wheels are Under inflated tyres. Inflate tyres to 30 psi.

spinning whilst 4-wheel

drive is engaged.

Gear Selection Options

1st Gear = Climbing steep slopes, steps or ramps.

2nd Gear = Climbing slopes.

3rd Gear = Travelling on level ground when laden.

4th Gear = Travelling on level ground when unladen.

Operating the BMD Minidumper

1. Start the engine.

2. With the engine running, select the gear by turning the Gear Lever (2) to the desired position.

3. Release the brake by pressing the red Park Brake Lever (11) down towards the operating handle and pull the Drive Lever (4)

upwards to engage drive. The machine will now begin to move.

4. Once the machine is moving the throttle can be opened or closed to increase or decrease the speed of the machine.

(If more speed is required, follow steps 2, 3 and 4 but select a higher gear than is currently in use)

NOTE: The gears cannot be altered whilst the machine is in motion.

If it is necessary to travel down a slope of more than 15° when fully laden, ensure that the machine is

turned round and reverse down the slope.

CAUTION

Emptying the Skip

1. Stop the machine by releasing the Drive Lever (4) followed by releasing the red Park Brake Lever (11).

2. Once the machine has become stationary compress the Skip Release Lever (9) and slightly lift-up the rear of the machine. The

Skip (1) will tip forwards disposing of its contents.

3. When the Skip (1) is empty, push back to its original postion. The Skip (1) will lock into place automatically.

Note: The numbers shown in brackets above refer to the pictures shown in the Machine Description section of the booklet.

20

Service and Maintenance

Gearbox Oil

There should be no maintenance required as this is a sealed Gearbox. If there are any signs of leakage, stop using the machine

and contact your local dealer or the Belle Group.

Machine Cleaning

Clean the machine after it has been used to prevent the collection of hardened debris. Hardened debris is very difficult to remove.

To clean it use an old brush or hand brush with water.

Note: Never pressure wash or hose down the engine. Clean only with a cloth or compressed air.

Park Brake

The Parking Brake operates automatically when the red Parking Brake Lever is in the upright position. A spring holds the brake

on until the lever is compressed to release it. Correct adjustment is crititcal. If the brake cable is too tight the brake spring will not

be applying full pressure to the brake arm. If the brake cable it too slack, the brake may not release correctly when the lever is

depressed and the brake will drag causing overheating and wear to the brake pads and damage to the gearbox.

Air Filter

If it is dirty, proceed as follows:-

Foam Element - Wash the element in a solution of washing-up liquid and water. Allow the element to dry, then soak in clean engine

oil and squeeze out the excess oil. If the engine smokes during start-up then too much oil has been left on the foam.

Paper Element - Tap the element on a hard surface or blow from inside using compressed air to remove any excess dust within

the filter. Replace every 200 hours or if it is extremely dirty.

Oil / Fuel Type & Quantity - Spark Plug Type

Oil type Quantity Fuel Type Capacity Spark Plug Electrode

(Gals) (Gals) Type Gap (mm)

Gasoline Honda GXV160 S.A.E. 10W 30 0.17 Unleaded 0.53 BPR5ES 0.07 - 0.8

Routine Maintenance Every Every Every Every

20 hours 50 Hours 75 Hours 200 Hours

Engine Oil Change 9

Air Filter Check Condition 9

Clean / Replace 9

Spark Plug Change 9

Note: Remove all Oil and Fuel before tipping the machine over.

Belt Removal (On Machines Up To Serial No. 141778)

1. Remove the 6 x M8 Bolts from the Sump Guard and then remove

the Sump Guard from the machine.

2. Remove 3 X Bolts (A). This will allow you to remove the Belt (B).

NOTE:- Ensure the Belt is removed from the Engine pulley (D) first.

Belt Fitting (On Machines Up To Serial No. 141778)

1. Place the Belt (B) onto the transmission pulley (C), and then onto the

engine pulley (D).

2. Ensure the Belt (B) runs on the outside of the Clutch Tensioning Arm.

(See the diagram on the right to see the route of the Belt (B))

3. Add Bolt (A) to the Clutch Tensioning Arm and tighten so that the arm

is 245mm from the Cross Plate (See the diagram on the right).

If adjustment is required, tweak the 2 Nuts (E) until correct distance is

achieved.

4. Attach the Sump Guard using the 6 x M8 Bolts to a torque setting of

28Nm.

A

B

245mm

C

D

A

A

E

E

Table of contents

Popular Tractor manuals by other brands

David Brown

David Brown Cropmaster VAK1 Series Operating and maintenance instructions

Verts Loisirs

Verts Loisirs VLB12597 instruction manual

Iseki

Iseki TXG23 user manual

Egimotors

Egimotors RANGER XP 1000 CREW 2023 owner's manual

Mahindra

Mahindra Jivo 365 DI Service manual

McCormick-Deering

McCormick-Deering Farmall F-14 owner's manual