2

TXG23

TO OUR CUSTOMER

TABLE OF CONTENTS

SAFETY

MAKING YOUR TRACTOR A SAFE VHICLE ……00

UHOW TO MAINTAIN SAFETY …………………00

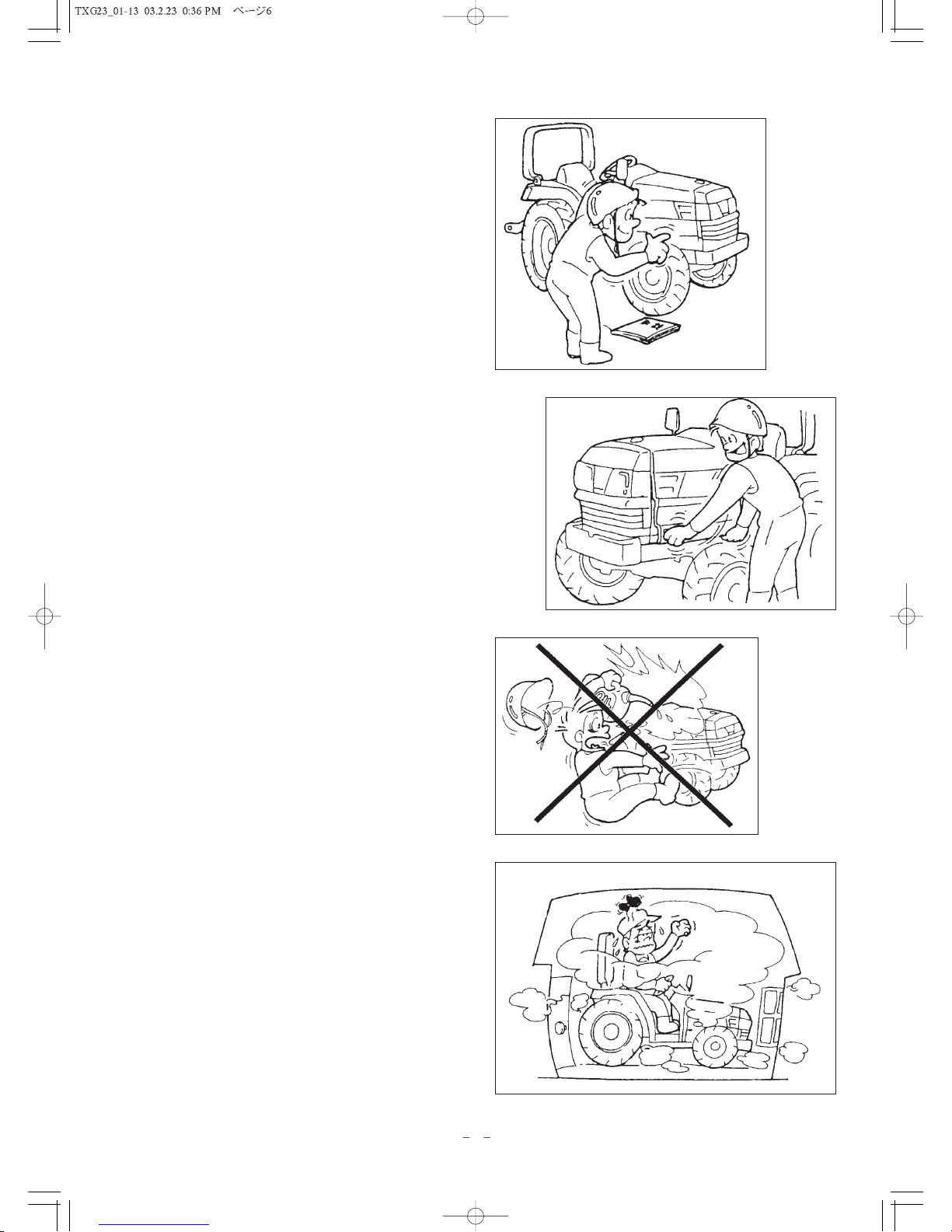

FOR SAFE OPERATION ……………………………00

UHOW TO BE A SAFE OPERATOR ……………00

UWHEN ANOTHER PERSON OPERATES YOUR

MACHINE …………………………………………00

UBEFORE OPERATION……………………………00

USTARTING ENGINE AND MOVING TRACTOR 00

UWHEN TRAVELING ………………………………00

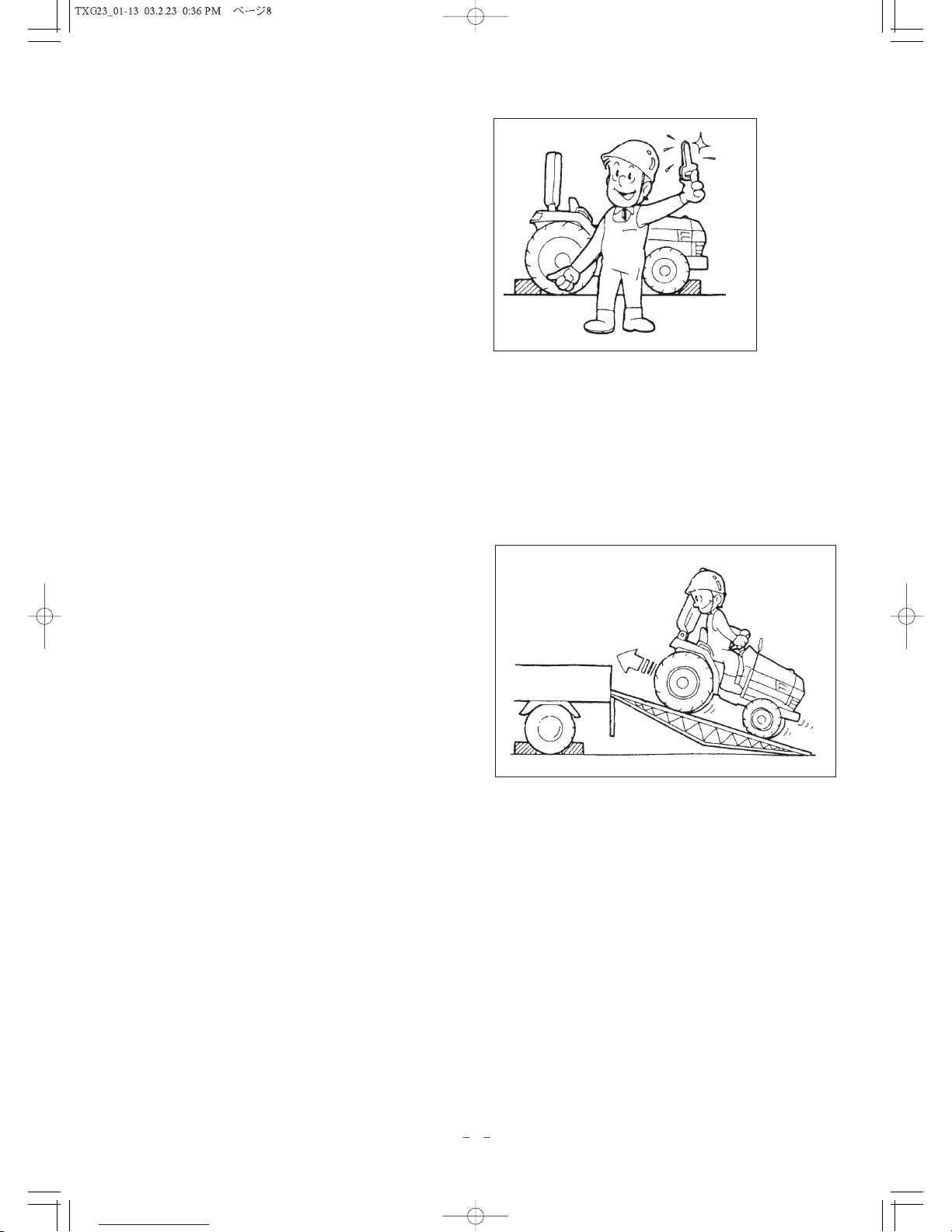

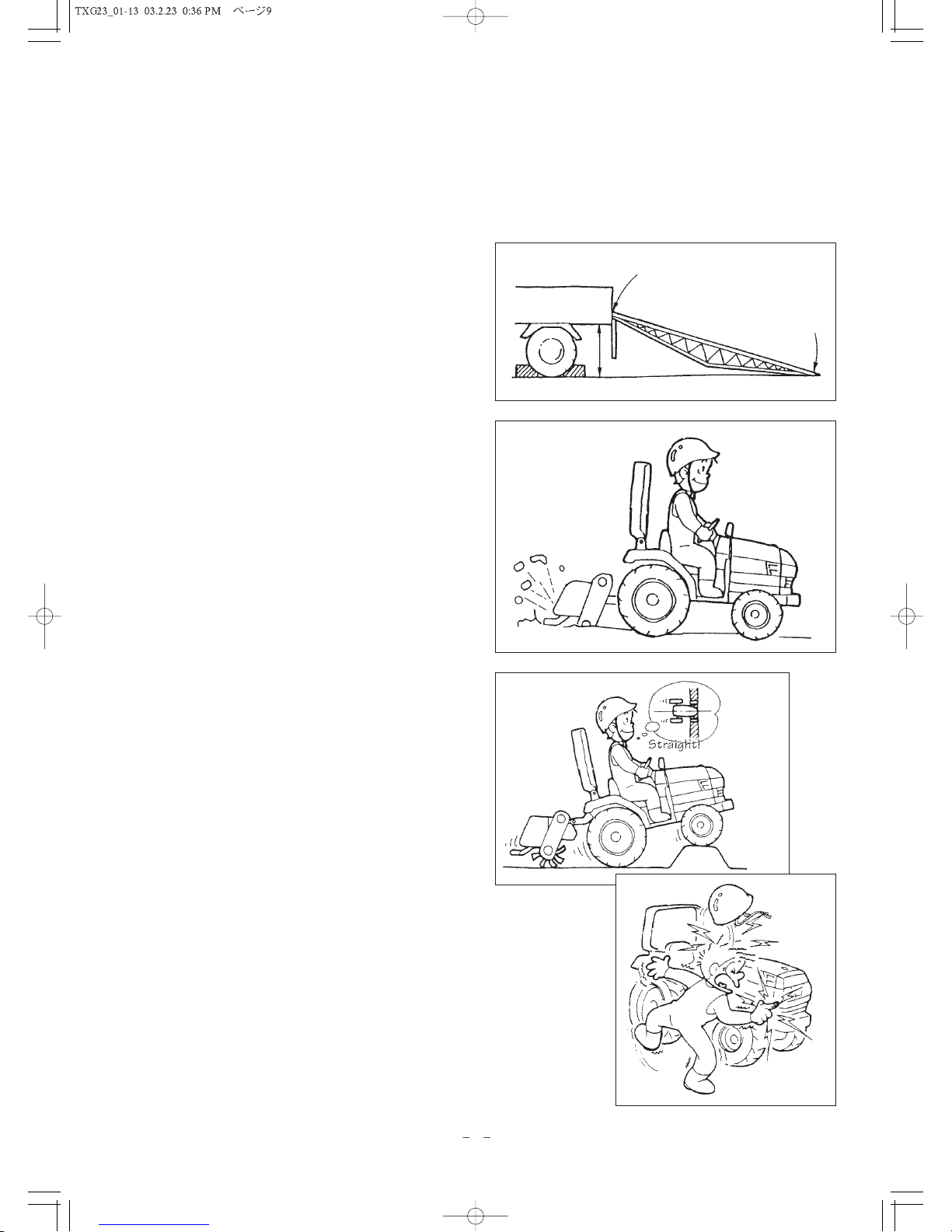

ULOADING ONTO OR UNLOADING FROM A

TRUCK ……………………………………………00

UDURING OPERATION……………………………00

UINSPECTION AND MAINTENANCE ……………00

USTORAGE …………………………………………00

MAINTENANCE OF THE ELECTRIC SYSTEM, …00

UTO MAINTAIN ELECTRIC WIRING ……………00

UTO HANDLE THE BATTERY ……………………00

UTO HANDLE BOOSTER CABLES………………00

USAFETY DECALS…………………………………00

USAFETY DECALS AND THEIR LOCATIONS …00

TRACTOR IDENTIFICATION ……………………………00

MAJOR COMPONENTS ……………………………00

SERIAL NUMBER ……………………………………00

INSTRUMENTS & CONTROLS …………………………00

INSTRUMENT PANEL ………………………………00

MAIN SWITCH ………………………………………00

Indicator Light Strip ………………………………00

Hour Meter …………………………………………00

Combination Switch ………………………………00

Fuel Gauge…………………………………………00

BRAKES ………………………………………………00

Brake Pedal ………………………………………00

Parking Brake………………………………………00

ENGINE SPEED CONTROLS ………………………00

Throttle Lever………………………………………00

TRANSMISSION SHIFT LEVER AND

CONTROLS ………………………………………00

Range Gearshift Lever ……………………………00

Hydrostatic Control Pedal ………………………00

DIFFERENTIAL LOOK PEDAL ……………………00

FOUR-WHEEL DRIVE SHIFT LEVER ……………00

PTO CLUTCH LEVER ………………………………00

REAR & MID PTO SELECTOR LEVERS …………00

THREE-POINT HITCH ………………………………00

Control Lever ………………………………………00

Lowering Rate Control Knob ……………………00

COMFORT ADJUSTMENT …………………………00

Seat Adjustment …………………………………00

OPERATION ………………………………………………00

BREAK-IN PERIOD …………………………………00

STARTING ……………………………………………00

Pre-Start Inspection ………………………………00

Normal Starting ……………………………………00

Restarting Warm Engine …………………………00

Cold Weather Staring ……………………………00

Warm-Up Period …………………………………00

Operator Observations……………………………00

Starting Circuit Operation…………………………00

GROUND SPEED SELECTION ……………………00

Hydrostatic Transmission…………………………00

STOPPING TRACTOR ………………………………00

DIFFERENTIAL LOCK ………………………………00

FOUR-WHEEL DRIVE (4WD Model) ………………00

POWER TAKE OFF (PTO) …………………………00

Rear PTO Shaft……………………………………00

Mid PTO Shaft ……………………………………00

PTO Operating Controls …………………………00

THREE-POINT HITCH ………………………………00

Hitch Controls………………………………………00

Rear Linkage ………………………………………00

Attaching Implements ……………………………00

Using Position Control ……………………………00

Detaching Implements ……………………………00

Cutting Height Control Knob ……………………00

ROLL OVER PROTECTIVE STRUCTURE (ROPS)00

MAINTENANCE & ADJUSTMENT ……………………00

LUBRICATIONS & CAPACITIES……………………00

PERIODIC MAINTENANCE SCHEDULE …………00

LUBRICATION / FILL POINTS………………………00

SERVICE ACCESS …………………………………00

LUBRICATION DETAILS ……………………………00

Grease Fittings ……………………………………00

Engine Oil & Filter …………………………………00

Transmission Oil & Filter …………………………00

Front Axle Oil (4WD)………………………………00

COOLING SYSTEM …………………………………00

ENGINE AIR CLEANER ……………………………00

FUEL SYSTEM ………………………………………00

Fuel Filter …………………………………………00

Air-Bleeding Fuel System…………………………00

Fuel Tank Filter Cap ………………………………00

Throttle Lever………………………………………00

ELECTRICAL SYSTEM………………………………00

Battery………………………………………………00

Starting Switches …………………………………00

Wiring / Fuse Arrangement ………………………00

BRAKE ADJUSTMENT ………………………………00

HYDROSTATIC ADJUSTMENTS …………………00

WHEELS & TIRES ……………………………………00

Tire Inflation Pressures……………………………00

Wheel Bolt Torque…………………………………00

Steering Free-Play ………………………………00

TORQUE CHART ……………………………………00

STORAGE ……………………………………………00

TROUBLESHOOTING ……………………………………00

ENGINE ………………………………………………00

BRAKES ………………………………………………00

TABLE OF CONTENTS