Belmed PC7-C User manual

PC7-C Flowmeter O2/N2O Sedation Unit

Instruction Manual

!

IMPORTANT:

READ MANUAL COMPLETELY BEFORE OPERATING THIS DEVICE

This manual contains instructions on periodically required checks to be performed

by the user. These checks are necessary to ensure the proper performance of this

device and its safety features.

RETAIN THIS MANUAL FOR FUTURE REFERENCE

CAUTION: Federal law requires this device for use by or on the order of a physician

or dentist.

CAUTION: Do not attempt to repair, alter, or calibrate this device. Unauthorized

repair, alteration or misuse of this device is likely to adversely affect the

performance and will void the warranty.

WARNING: The PC7-C and its accessories, in need of repair, should ONLY be

repaired by Belmed, Inc. or an authorized Belmed, Inc. dealer.

WARNING: The PC7-C and its accessories are designed to perform in accordance

with the product specications when installed, operated and maintained as

instructed in this manual.

The National Institute for Occupational Safety and Health has issued a warning

for dental workers exposed to N2O during administration of N2O/O2 conscious

sedation analgesia. NIOSH has recommended that exposures should be minimized.

Contact NIOSH to receive NIOSH Publications on Control of Nitrous Oxide in Dental

Operatories at 1-800-232-4036. Exposure can be minimized by effective controls,

including System Maintenance, Ventilation, and Work Practices can effectively

reduce N2O concentrations in dental operations. A scavenger system is a

signicant part of exposure control.

Your sedation machine includes a fail-safe and other safety features. It also

includes the required and accepted specications by the ADA Council on Dental

Materials and Devices. Which includes Emergency Air Valve, Rebreathing Check

Valve, and Resuscitator Quick Connect. The ADA also requires the system be

installed by a competent supplier of gases and equipment. The gas storage and

delivery system should meet the recommendations for the National Fire Protection

Association (See NFPA Code).

WARNING

1

Cut-Out Dimensions for PC7-C............................................................12

Installation...............................................................................................6

PC7-C Flowmeter Dimensions..............................................................11

PC7-C Flushmount Flowmeter................................................................3

PercentageChart..................................................................................14

Purchase Record...................................................................................13

Remote Tee Block Hose Barb Option....................................................8

Remote Tee Block Template................................................................12

Remote Tee Bracket Installation......................................................9-10

Scavenger Rubber Goods Assembly....................................................7

TeeInstallation.........................................................................................8

Test Procedures/Operation....................................................................4

Warnings...................................................................................................1

Warranty.................................................................................................13

Index

2

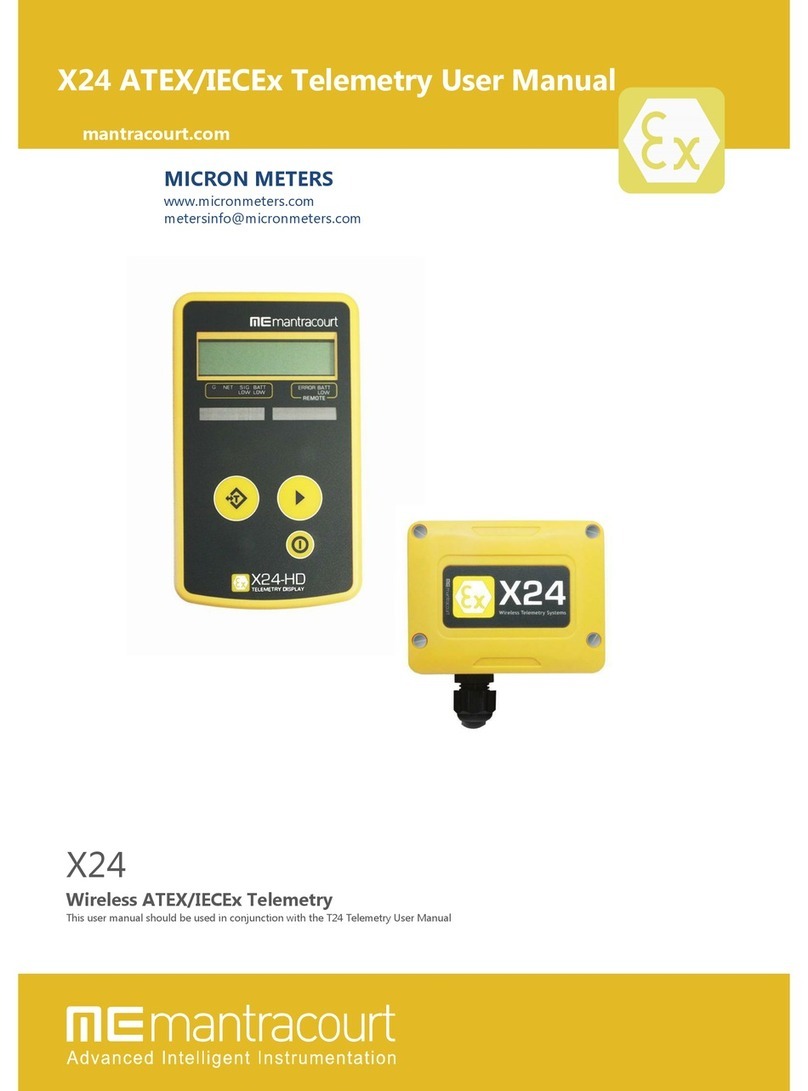

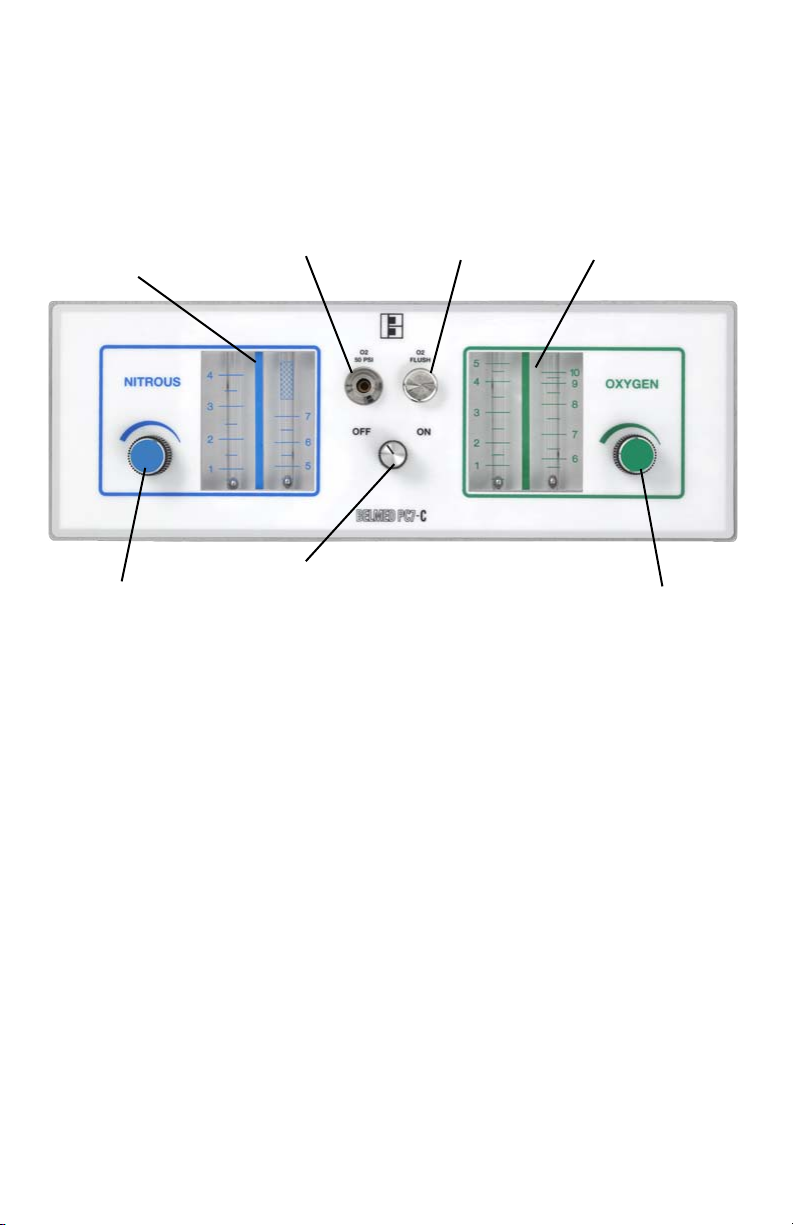

PC7-C Flushmount Flowmeter

The PC7-C has been recongured to t ush into today’s

cabinetry and provides the same time proven precision

and dependability as our stand PC-7 unit.

Nitrous Oxide

Flowmeter Tubes

Oxygen Resuscitator

Quick Connect O2 Flush

Oxygen

Flowmeter Tubes

Oxygen Flow

Control

On/Off Control

Nitrous Oxide

Flow Control

gure 1

Dimensions

4.25” H x 12.187” W x 4.687” D

On/Off Control simple 1/4 turn,

establishes a 3 liter minimum O2

ow.

O2 Flush provides a rapid ow

of oxygen directly into patient

breathing circuit.

Flow Control Valves Micrometer

needle valves allow quick

responsive ow adjustments.

Needle valve design prevents seat

damage.

Dual Cascading Flowmeter Tubes

are calibrated in liters per minute at

½ liter increments.

Oxygen Fail-Safe Automatically

and proportionally reduces N2O in

the event O2 is reduced or shut off.

Non-Rebreathing Check Valve

Prevents the rebreathing of expired

gases and guards against CO2

build-up.

Air Intake Valve entrains ambient air

into the breathing circuit in the event

ow from the machine is lost for any

reason.

Solid Gas Control Block Designed to

eliminate internal gas leaks

Oxygen Resuscitator Quick Connect

provides connection of auxiliary

resuscitation equipment.

3

Test Procedures

Note: Failure of the following test will require unit to be returned for service.

These tests must be conducted periodically to ensure proper operation.

(Refer to gure 1)

Test: Connect unit to a 50psi gas source. Check to make sure control

valves are turned off. Gently turn both valves clockwise until unit

resistance is felt.

1. Minimum oxygen: Turn on unit by pushing and turning on/off knob. A 3

liter ow of oxygen should be produced through O2 tube.

2. Oxygen ush: Depress O2 ush button to determine a rapid ow of

oxygen into breathing circuit. Flow should stop when button is released.

3. Maximum nitrous: Turn N2O needle valve wide open. N2O ow should

not exceed 7 LPM.

4. Fail safe test: Establish a 7 LPM N2O ow and 3 LPM O2 ow. Disconnect

O2 supply source or turn off O2 shut-off valve. Both O2 and N2O ows

should stop owing.

5. Air intake valve: Attach breathing bag and corrugated breathing tube

to proper ports of tee. Unit should be turned off and bag attened. Inhale

through breathing tube. Room air must enter through air intake located on

bottom of breathing circuit tee.

6. Non-Rebreathing valve: Connect corrugated tube to front of tee and

attempt to exhale through tube. Valve should be closed preventing

exhaled air from going into tube.

Maintenance

1. Ascertain a proper gas supply

pressure of 50psi.

2. Inspect machine hoses and

connections for damage, wear and

leaks daily.

3. Perform functional test periodically.

4. Keep unit clean. Unit and

accessories may be cleaned with

activated dialdehyde (Cidex).

Follow manufacturers directions

for use.

Service: All Service and repair must

be completed at Belmed, Inc. Have

your dealer return the unit to our

facility for service.

Operation

1. Turn unit on (100% O2) and set

the oxygen ow rate to equal total

gas ow (minute volume) to be

administered to patient. Maintain

breathing bag about ⅔full.

2. Apply nasal hood to patient.

3. Gradually introduce nitrous

oxide ow rate while proportionally

decreasing oxygen ow rate

(maintaining total gas ow) until

determined patient ratio is reached.

4. If oxygen is required, press oxygen

ush button.

5. To remove patient from conscious

sedation, return to 100% oxygen ow

rate established at beginning of

procedure. 4

IMPORTANT: PRIOR TO INSTALLATION, TURN OFF CENTRAL GAS SUPPLY SYSTEM AND

CLOSE ALL GAS TANK VALVES IN TANK ROOM. DISS SHUT-OFF VALVES SHOULD BE IN

CLOSED POSITION THROUGHOUT INSTALLATION OF THE FLOWMETER.

Install the gas lines: A qualied plumber can install the delivery piping up to and including the

DISS shut-off valves.

The dental dealer is responsible for the nal connections to the owmeter, the details of

owmeter installation checking for crossed-lines, leak testing of connections to the owmeter,

and basic owmeter operation.

1. Determine desired location of the owmeter. Use the provided cut-out dimensions to cut

an opening in the cabinet or mounting apparatus.

Note: Flowmeter location needs to accommodate 5 feet DISS hose-to-shut-off valve

distance, and 10 feet mixed gas hose-to-remote bag tee distance.

2. Determine the location of the remote bag tee that accommodates visual monitoring of

the breathing bag during patient treatment. Use the provided diagram to pre-drill and mount

the remote bag tee block. Insert tee and tighten set screw with provided Allen wrench.

(MAKE SURE SET SCREW IS ACCESSIBLE).

Note: Bag Tee ideally is to be installed within 10 feet of the owmeter.

3. Connect the O2 DISS hose (green) to the O2 shut-off valve and the N2O DISS hose (blue) to

the N2O shut-off valve.

4. Connect 10 feet mixed gas hose to the hose barb on the Remote Tee. Shorten the hose if

desired and attach the ferrules to the ends. Moisten the hose barb to ease installation.

5. Pull O2 and N2O DISS hoses and mixed gas hose through the cut-out for the owmeter and

attach O2, N2O and mixed gas hose to the back-side of the owmeter.

Note: Make certain hoses are not crimped. Check O2 and N2O hose

connections for leaks.

6. Position owmeter over opening and line up screws on the owmeter with the pre-drilled

holes of the cut-out. Secure the owmeter by tightening the provided nuts.

7. Perform the Check for Crossed Lines, The Leak Test of the Flowmeter Installation, and the

Flowmeter Function Test.

CHECK FOR CROSSED LINES: (Refer to NFPA Gas and Vacuum Systems for Type II Systems

Crossguard Warning.) Open both the O2 and N2O shut-off valves to allow gas to the

owmeter. Before using owmeter, check for crossed lines by opening the O2 valve and

making certain that only oxygen ows through the owmeter.

LEAK TEST OF THE FLOWMETER INSTALLATION: After all hose connections are tightened, turn the

ow control knobs to the off position and the on/off knob to the off position. Conrm that the

DISS shut-off valves are in the open position. Pressurize the sedation gas supply lines with 50psi.

Observe any pressure decay after an overnight time period. (5psi drop allowed.)

Installation

!Caution: Be sure to use two wrenches when

tightening or removing hoses from the gas ttings.

5

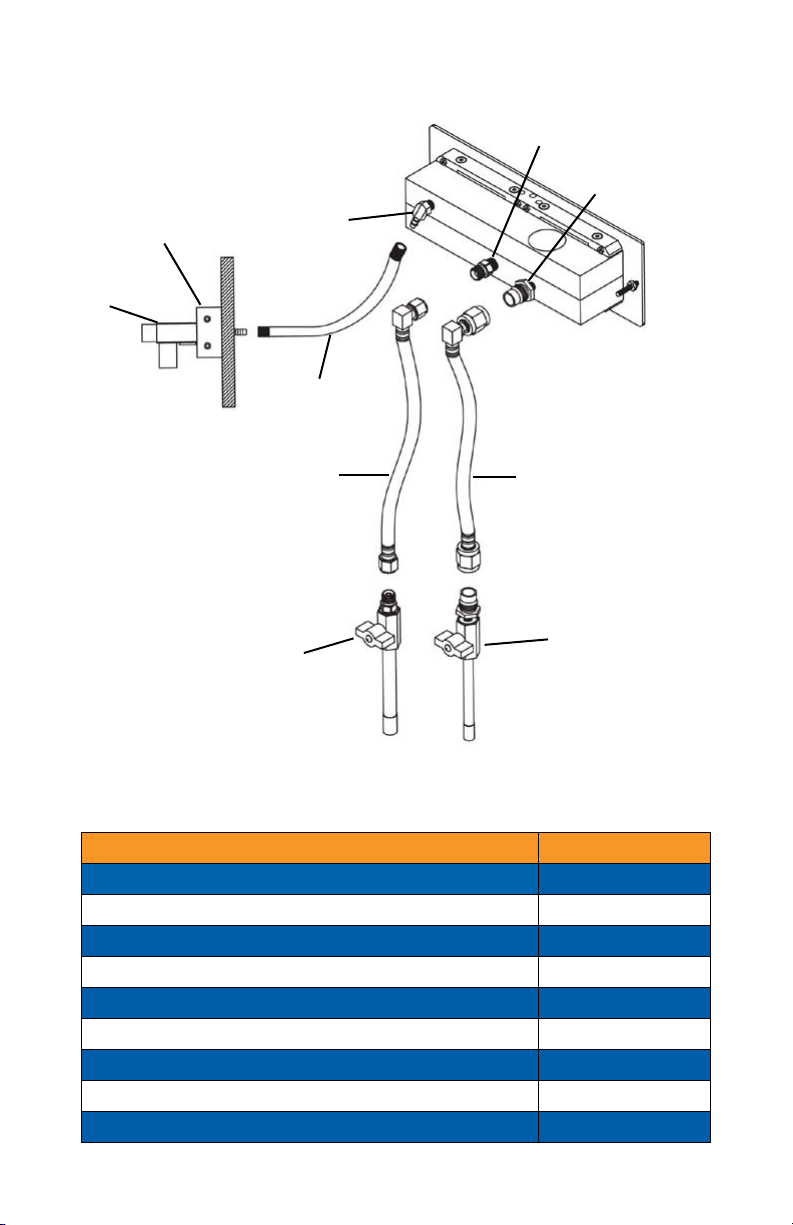

PC7-C Flushmount Flowmeter

Parts List

Description Part Number

Accessory Angle 5500-600

Flushmount Flowmeter (includes Remote Tee) 5500

Mixed Gas Hose (10ft) 5500-76

N2O DISS Hose (5ft) 8031

N2O DISS Shut-Off Valve 7302

O2 DISS Hose (5ft) 8030

O2 Diss Shut-Off Valve 7304

Remote Tee Block 5500-500

Sliding Bracket 5500-700

O2 DISS Male

N2O DISS Male

N2O DISS Hose

(green)

N2O DISS

Shut-off Valve

O2 DISS

Shut-off Valve

O2 DISS Hose

(blue)

Mixed Gas Hose

Bag Tee

Bag Tee Block

¼“ Hose Barb

gure 2

6

Scavenger Rubber Goods Assembly

Small Tube

7¼” – #25594

Scavenger

Hub – #22099

Large Tube

5” – #25593

Double Connector –

#21178

Small Y Connector –

#21246

Large Y Connector –

#21245

Spiral Vacuum

1½” – #25592

Spiral Vacuum

3½” – #25591

Vacuum Gauge –

#22122

Single Vacuum

Connector – #22122

↕

Tube Slide Double – #26253

Single Connector –

#21179

Double Tubing –

#25590

gure 3

gure 4

7

Remote Tee Block Hose Barb Option

Tee Installation

gure 5

gure 6

The hose barb can be moved from the back location to the down

location in a few simple steps.

1. Remove the hose barb with a 7/16” open end wrench.

2. Remove the plug with a 3/16” Allen wrench.

3. Wrap both the hose barb and plug with Teon Tape.

4. Tighten the hose barb to the bottom of the block.

5. Tighten the plug to the back of the block.

8

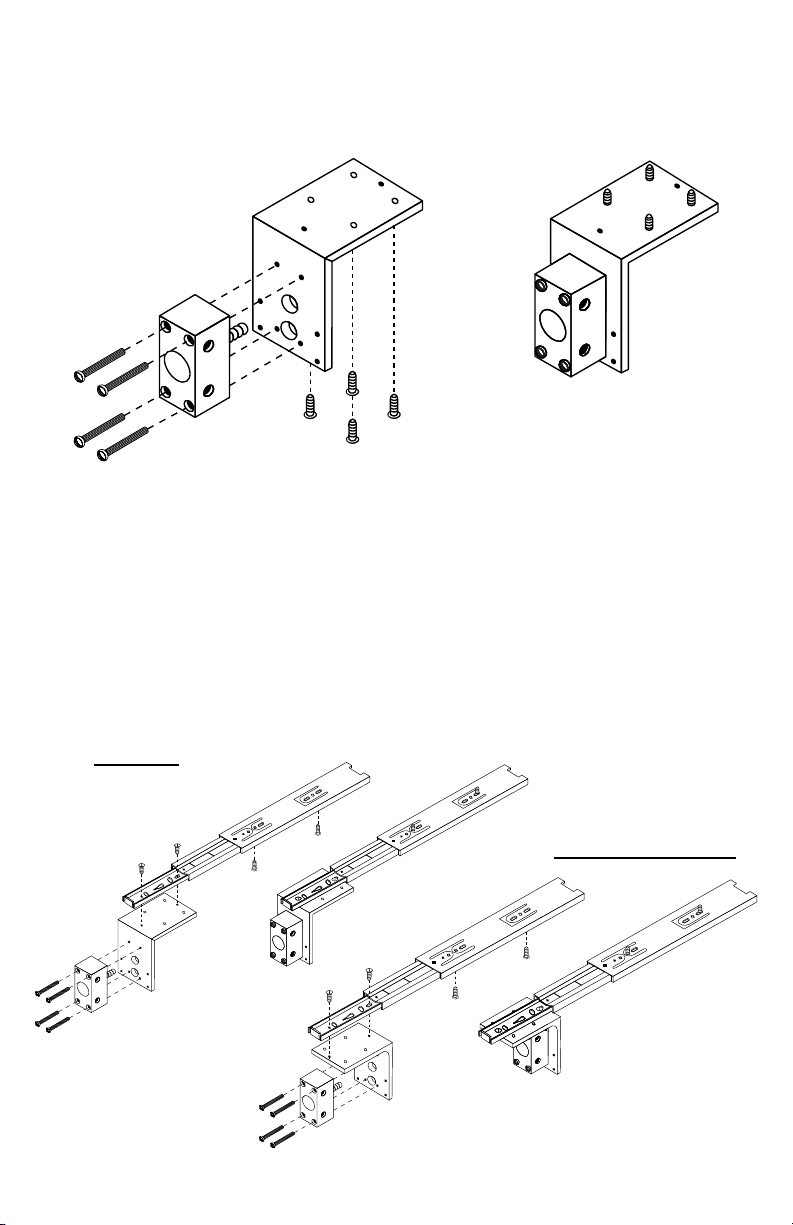

Remote Tee Bracket Installation

Left or Right Side Installation

gure 8

gure 7

gure 9

Compact (save 3”)

1. Use Remote Tee Bracket as drilling guide.

2. Pre-drill all 4 holes 7/64”

3. Mount Bracket with #8 x 5/8 wood screws (4 included).

4. Attach Remote Tee Block to the Remote Tee Bracket with #8 x 1 1/2”

machine screws (4 included).

5. Attach Mixed Gas hose to hose barb on block.

6. Insert Tee and tighten set screw with 3/32” Allen wrench.

7. Attach Rubber Goods.

Standard

9

Remote Tee Bracket Installation

Top Installation

1. Use Remote Tee Bracket as drilling guide.

2. Pre-drill all 4 holes 7/64”

3. Mount Bracket with #8 x 5/8 wood screws (4 included)

4. Attach Remote Tee Block to the Remote Tee Bracket with #8 x 1 1/2”

machine screws (4 included).

5. Attach Mixed Gas hose to hose barb on block.

6. Insert Tee and tighten set screw with 3/32” Allen wrench.

7. Attach Rubber Goods.

gure 10

gure 11

gure 12

Compact (save 3”)

Standard

10

PC7-C Flowmeter Dimensions

gure 13

gure 14

3.7250

12.1875

11.5900

9.6562

6.0937

3.8437

4.2500

2.1250

11

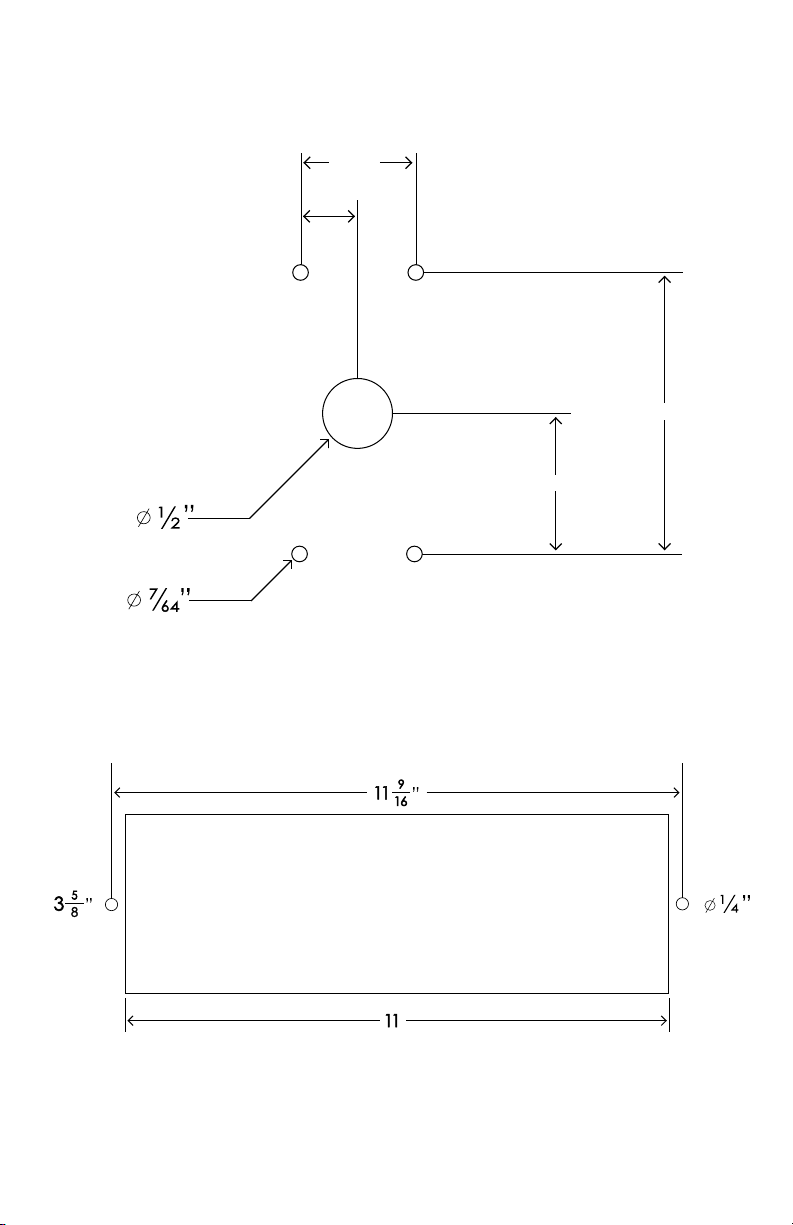

Remote Tee Block Template

Cut-Out Dimensions

”

0.834”

0.417”

2.0”

1.0”

(2X)

CUT–OUT DIMENSIONS

gure 15

gure 16

12

Purchase Record

MODEL NO. SERIAL NO. PURCHASE DATE

Denition of Warranty Return: A product or part covered by the Belmed, Inc. warranty, that

fails while the terms of the warranty are in effect.

THIS WARRANTY IS GIVEN IN PLACE OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR OTHERWISE.

No statement or claim about the product by any employee, agent, representative or dealer

of Belmed, Inc. shall constitute a warranty by Belmed, Inc. or give rise to any liability or

obligation of Belmed, Inc.

Subject to the next sentence, Belmed, Inc warrants that each product or part shall be

free from defects in workmanship and materials, under normal use and with appropriate

maintenance, for one (1) year from the date of delivery to customer. For plastic, rubber and

disposable parts or items Belmed, Inc. warrants only that each such part and item shall be

free from defects in workmanship and materials at the time of delivery to the customer.

Belmed, Inc.’s obligation for breach of this warranty, or for negligence or otherwise, shall

be strictly and exclusively limited to Belmed Inc.’s choice of repair or replacement of the

product or part. This warranty shall be void for any product on which the serial number has

been altered, defaced or removed.

Belmed, Inc. shall not be liable for any damage, injury or loss arising out of the use of

the product, whether as a result of a defect in the product or otherwise, if, prior to such

damagve, injury or loss, the product was (1) damaged, misused, or misapplied; (2) repaired,

altered or modied by persons other than Belmed, Inc. (3) not installed in strict compliance

with applicable codes and ordinances; or (4) not installed by Belmed, Inc. or an authorized

Belmed, Inc. dealer.

UNDER NO CIRCUMSTANCES SHALL BELMED, INC. BE LIABLE FOR INCIDENTAL OR

CONSEQUENTIAL DAMAGES AS THOSE TERMS ARE DEFINED IN THE UNIFORM COMMERCIAL

CODE.

Important: Traceability/Warranty Registration

Medical device legislation of 1976 mandates traceability of this

equipment. Please ll out and return warranty card.

Warranty

13

www.belmedinc.com

MEDICAL GAS SYSTEMS & EQUIPMENT

* Greater than 70% N2O administered exceeds the amount able to be delivered by sedation machine.

LPM OXYGEN

N

I

T

R

O

U

S

O

X

I

D

E

0.5 1 1.5 2 3 3.5 4 4.5 5 5.5 6 6.5 7 7.5 8 8.5 92.5 9.5 10

0.5 50% 33% 25% 20% 17% 14% 13% 11% 10% 9% 8% 8% 7% 7% 6% 6% 6% 5% 5% 5%

167% 50% 40% 33% 29% 25% 22% 20% 18% 17% 15% 14% 13% 13% 12% 11% 11% 10% 10% 9%

1.5 75% 60% 50% 43% 38% 33% 30% 27% 25% 23% 21% 20% 19% 18% 17% 16% 15% 14% 14% 13%

280% 67% 57% 50% 44% 40% 36% 33% 31% 29% 27% 25% 24% 22% 21% 20% 19% 18% 17% 17%

2.5 83% 71% 63% 56% 50% 45% 42% 38% 36% 33% 31% 29% 28% 26% 25% 24% 23% 22% 21% 20%

793% 88% 82% 78% 74% 70% 67% 64% 61% 58% 56% 54% 52% 50% 48% 47% 45% 44% 42% 41%

6.5 93% 87% 81% 76% 72% 68% 65% 62% 59% 57% 54% 52% 50% 48% 46% 45% 43% 42% 41% 39%

692% 86% 80% 75% 71% 67% 63% 60% 57% 55% 52% 50% 48% 46% 44% 43% 41% 40% 39% 38%

5.5 92% 85% 79% 73% 69% 65% 61% 58% 55% 52% 50% 48% 46% 44% 42% 41% 39% 38% 37% 35%

591% 83% 77% 71% 67% 63% 59% 56% 53% 50% 48% 45% 43% 42% 40% 38% 37% 36% 34% 33%

4.5 90% 82% 75% 69% 64% 60% 56% 53% 50% 47% 45% 43% 41% 39% 38% 36% 35% 33% 32% 31%

489% 80% 73% 67% 62% 57% 53% 50% 47% 44% 42% 40% 38% 36% 35% 33% 32% 31% 30% 29%

3.5 88% 78% 70% 64% 58% 54% 50% 47% 44% 41% 39% 37% 35% 33% 32% 30% 29% 28% 27% 26%

386% 75% 67% 60% 55% 50% 46% 43% 40% 38% 35% 33% 32% 30% 23%24%25%26%27%29%

14

Other Belmed Measuring Instrument manuals