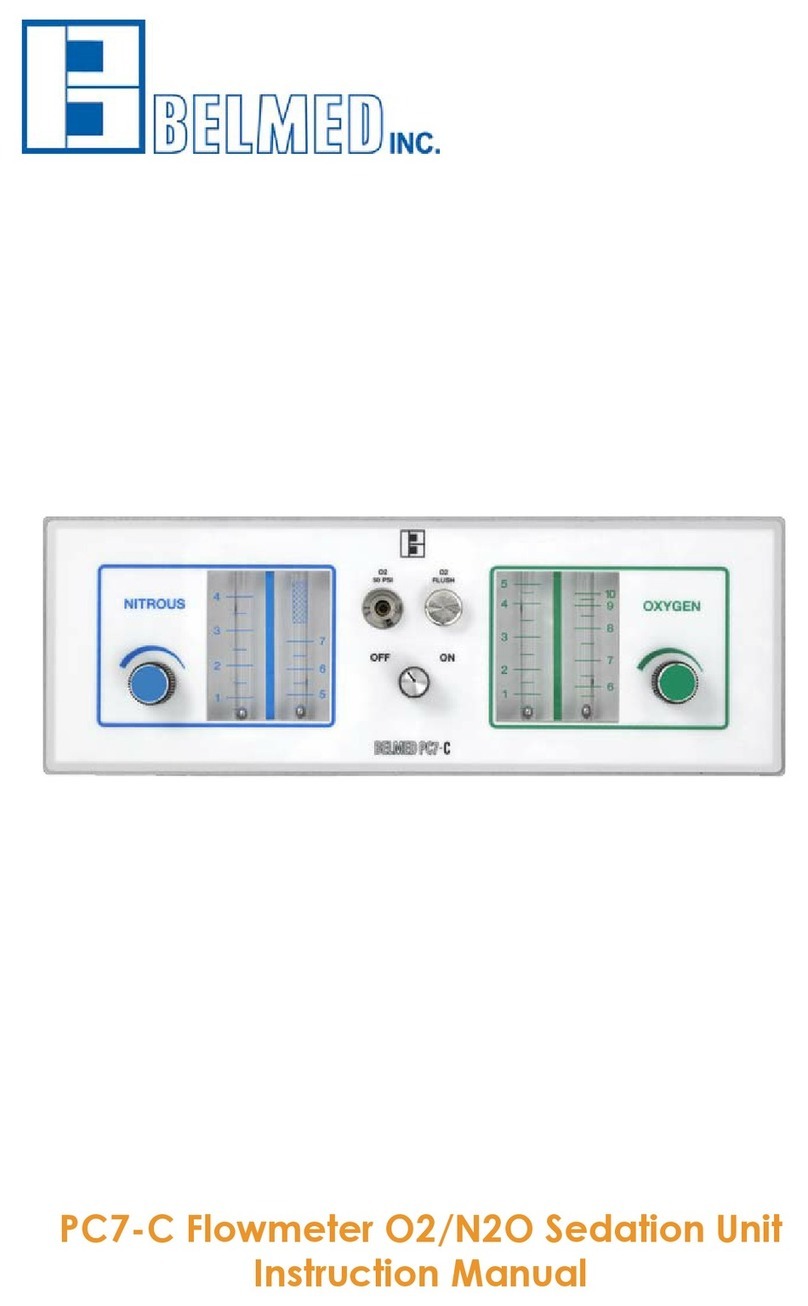

Belmed PC-7 User manual

PC-7 Flowmeter O2/N2O Sedation

Unit Instruction Manual

1

!

WARNING

IMPORTANT:

READ MANUAL COMPLETELY BEFORE OPERATING THIS DEVICE

This manual contains instructions on periodically required checks

to be performed by the user. These checks are necessary to

ensure the proper performance of this device and its safety

features.

RETAIN THIS MANUAL FOR FUTURE REFERENCE

CAUTION: Federal law requires this device for use by or on the

order of a physician or dentist.

CAUTION: Do not attempt to repair or alter this device.

Unauthorized repair, alteration or misuse of this device is likely to

adversely affect the performance and will void

the warranty.

CAUTION: Never oil or grease any part of this system.

The National Institute for Occupational Safety and Health has

issued a warning for dental workers exposed to N2O during

administration of N2O/O2 conscious sedation analgesia. NIOSH

has recommended that exposures should be minimized. Contact

NIOSH to receive NIOSH Publications on Control of Nitrous Oxide in

Dental Operatories at 1-800-232-4036. Exposure can be minimized

by effective controls, including System Maintenance, Ventilation,

and Work Practices can effectively reduce N2O concentrations

in dental operations. A scavenger system is a signicant part of

exposure control.

Your sedation machine includes a fail-safe and other safety

features. It also includes the required and accepted specications

by the ADA Council on dental materials and devices. Which

includes; emergency air valve, rebreathing check valve, and

resuscitator quick connect. The ADA also requires; the system to

be installed by a competent supplier of gases and equipment; the

gas storage and delivery system meets the recommendations for

the National Fire Protection Association. (See NFPA Code)

Arm Mounting........................................................................................11

Cabinet Bracket....................................................................................14

Cabinet Hinge Bracket Installation.....................................................13

Maintenance..........................................................................................5

Mobile Stand Detail...............................................................................16

Mobile Stand Installation........................................................................6

O2 Demand Valve................................................................................18

Operation................................................................................................5

PC-7 Flowmeter Description..................................................................3

PC-7 Flowmeter Dimension..................................................................15

PercentageChart..................................................................................22

Purchase Record...................................................................................21

Scavenger Rubber Goods Assembly..................................................10

Supply Hose Connections......................................................................9

Telescoping Arm System......................................................................12

Test Procedure.........................................................................................4

Wall Arm/Cabinet Bracket Installation.................................................8

Warnings...................................................................................................1

Warranty.................................................................................................20

Yoke.........................................................................................................7

Index

2

FLOWMETER HEAD DIMENSIONS

8.75”H X 3.75”W X 10.25”D

WEIGHT OF FLOWMETER HEAD

5lbs

BAG AND OUTLET DIAMETER

22mm (approx. ⅞”)

OXYGEN FLOW RANGE

3-10 LPM

NITROUS OXIDE FLOW RANGE

0-7 LPM

FAIL-SAFE TYPE

Proportional

PC-7 Flowmeter

Nitrous Oxide/Oxygen Flowmeter

Tubes are calibrated in liters per

minute at ½liter increments. A

minimum of 30% O2 is achieved by

limiting ows to a minimum of 3 liters

for O2 and a maximum of 7 liters

for N2O.

Flow Control Valves allows for quick

responsive ow adjustments.

Oxygen Fail-Safe automatically and

proportionally reduces N2O in the

event O2 is reduced or shut off.

Air Intake Valve entrains ambient air

into the breathing circuit in the event

ow from the machine is lost for any

reason.

Non-Rebreathing Check Valve

prevents the rebreathing of expired

gases and guards against CO2

build-up.

Oxygen Flush provides a rapid ow of

oxygen directly into patient breathing

circuit.

On/Off Control provides a 3 liter

minimum O2 ow when the unit is

turned on.

Oxygen Resuscitator Quick Connect

provides connection of auxiliary

resuscitation equipment.

Solid Block Design is designed to

eliminate internal gas leaks.

Nitrous Oxide

Flowmeter Tube

Flow Control

Oxygen Fail-Safe

Non-Rebreathing

Check Valve

Air Intake Valve

Oxygen

Flowmeter Tube

Solid Block

Design

gure 1

Oxygen Resuscitator

Quick Connect

Oxygen Flush

On/Off

3

Test Procedures

Note: Failure of the following test will require unit to be returned for service.

These tests must be conducted periodically to ensure proper operation.

(Refer to gure 1)

Test: Connect unit to a 50psi gas source. Check to make sure control

valves are turned off. Gently turn both valves clockwise until unit

resistance is felt.

1. Minimum oxygen: Turn on unit by pushing and turning on/off knob. A 3

liter ow of oxygen should be produced through O2 tube.

2. Oxygen ush: Depress O2 ush button to determine a rapid ow of

oxygen into breathing circuit. Flow should stop when button is released.

3. Maximum nitrous: Turn N2O needle valve wide open. N2O ow should

not exceed 7 LPM.

4. Fail safe test: Establish a 7 LPM N2O ow and 3 LPM O2 ow. Disconnect

O2 supply source or shut off O2 supply. Both O2 and N2O ows should

stop owing.

5. Air intake valve: Attach breathing bag and corrugated breathing tube

to proper ports of tee. Unit should be turned off and bag attened. Inhale

through breathing tube. Room air must enter through air intake located on

bottom of breathing circuit tee.

6. Non-Rebreathing valve: Connect corrugated tube to front of tee and

attempt to exhale through tube. Valve should be closed preventing

exhaled air from going into tube.

4

Operation

Maintenance

1. Ascertain a proper gas supply pressure of 50psi.

2. Inspect machine hoses and connections for damage, wear and

leaks daily.

3. Perform functional test periodically.

4. Keep unit clean. Unit and accessories may be cleaned with activated

dialdehyde (Cidex). Follow manufacturers directions for use.

Service: All Service and repair must be accomplished at Belmed, Inc.

Have your dealer return unit to our facility for service.

1. Turn unit on (100% O2) and set the oxygen ow rate to equal total gas

ow (minute volume) to be administered to patient. Maintain breathing

bag about ⅔full.

2. Apply nasal hood to patient.

3. Gradually introduce nitrous oxide ow rate while proportionally

decreasing oxygen ow rate (maintaining total gas ow) until determined

patient ratio is reached.

4. If oxygen is required, press oxygen ush button.

5. To remove patient from conscious sedation, return to 100% oxygen ow

rate established at beginning of procedure.

5

Installation Instructions

Flowmeter on Yoke Block Stand

Mobile stand assembly: Remove packaging from the base and column.

Push tapered end of column into base (gure 13).

Flowmeter attachment: Remove ½ in. diameter height adjustment rod

from column. Hand tighen the end of threaded rod into mounting adapter

located on bottom of owmeter. Lock rod into owmeter adapter by

tightening nut with ¾in. open end wrench while holding rod. Replace rod

into column and tighten toggle screw at desired height (gure 2).

Rubber goods: Connect breathing bag to bottom of bag tee. Connect

90 adapter to front of tee. Connect corrugated breathing tube to 90°

adapter. Connect nasal inhaler to other end of breathing tube (gure 6).

Connect gas supply hoses to DISS ttings located on bottom of owmeter

(gure 5).

Test machine.

Note: If optional O2 resuscitator is purchased with machine, plug hose end

into female quick connect located on bottom of machine. Depress button

to determine O2 ows through resuscitator. For demand ow test, breathe

through face mask (gure 15).

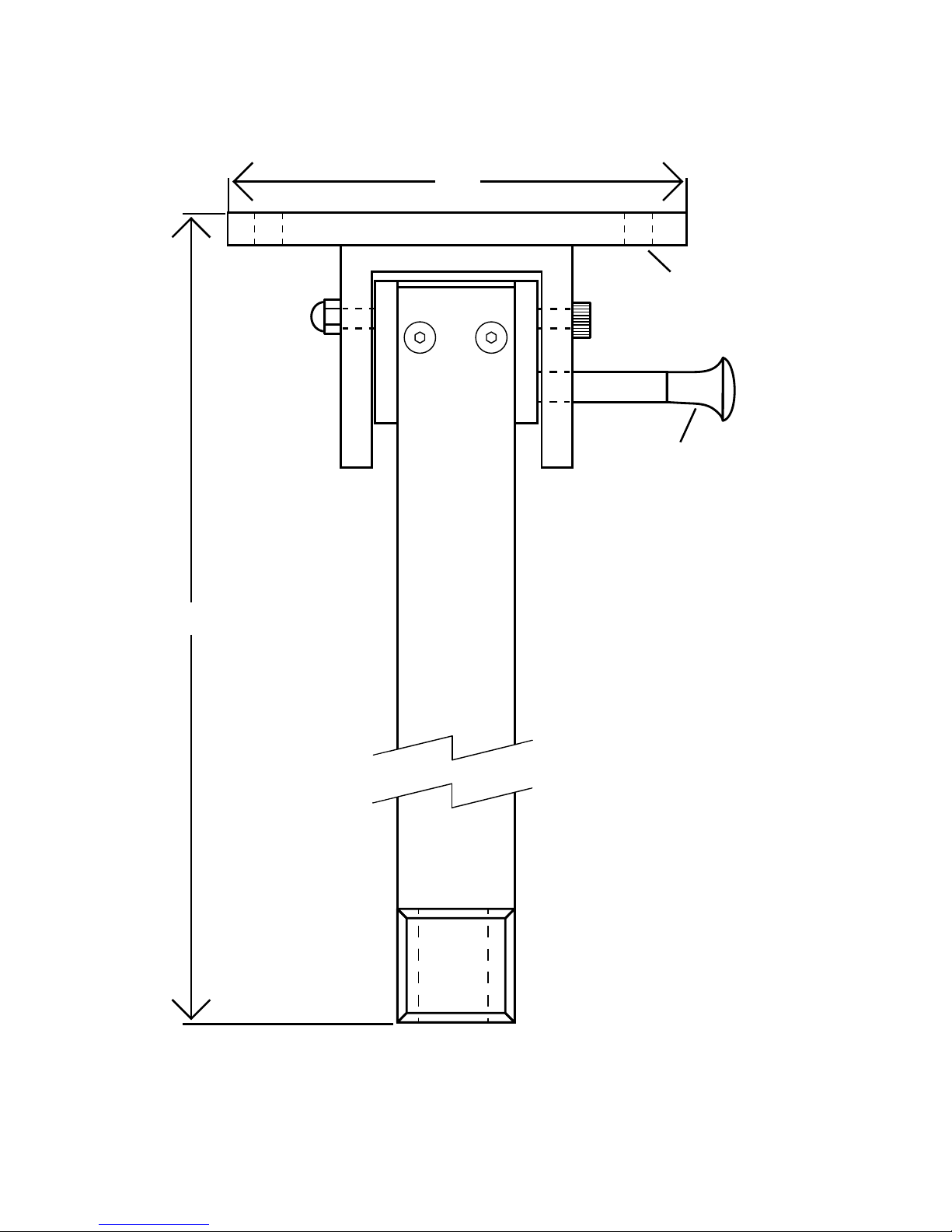

gure 2

Flowmeter Connection

to Mobile Stand

6

Yoke

Yoke block stand assembly: Remove packaging from the base, column,

and yoke block. Follow the assembly instructions in the yoke block

instruction manual to complete the assembly of these parts.

Flowmeter attachment: Remove ½ in. diameter height adjustment rod

from column. (Z bracket should already be attached to the height

adjustment rod). Use the two provided screws to fasten the Z bracket to

the Flowmeter. Replace rod into column and tighten height adjustment

knob at desired height (gure 3).

Rubber goods: Connect breathing bag to bottom of bag tee. Connect

90 adapter to front of tee. Connect corrugated breathing tube to 90°

adapter. Connect nasal inhaler to other end of breathing tube (gure 6).

Connect gas supply hoses to DISS ttings located on bottom of owmeter

(gure 5).

Test machine.

Note: If optional O2 resuscitator is purchased with machine, plug hose end

into female quick connect located on bottom of machine. Depress button

to determine O2 ows through resuscitator. For demand ow test, breathe

through face mask (gure 15).

gure 3

7

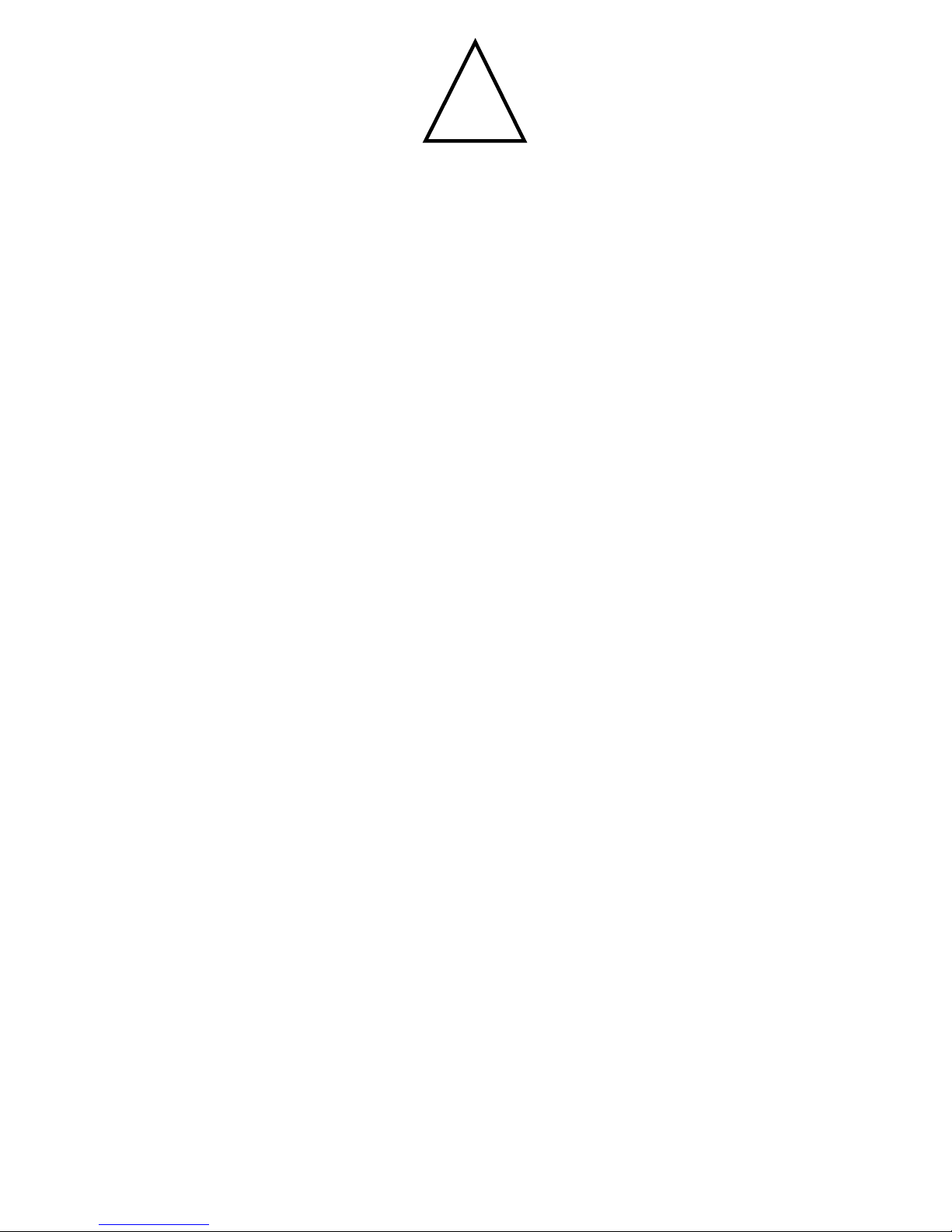

Installation Instructions

Flowmeter on Wall Arm or Cabinet Bracket

Arm Mounting Detail

Wall Arm/Cabinet Bracket: Attach arm to wall stud or other similar rm

support with lag screws (gure 7). Mount cabinet bracket to roof of

cabinet with lag screws (gure 9).

Flowmeter attachment: Remove screw and washer assembly from stud on

owmeter mount and attach owmeter to arm bracket by inserting stud

into hole located on arm. Replace screw and washer assembly into stud.

Telescoping arm will extend owmeter approximately a max of 24 in. from

mounting surface (gure 4).

Rubber goods: Connect breathing bag to bottom of bag tee. Connect

corrugated breathing tube to front end of tee. Connect nasal inhaler to

other end of breathing tube (gure 6).

Connect gas supply hoses to DISS ttings located on bottom of owmeter

(gure 5).

Test machine.

Note: If optional O2 resuscitator is purchased with machine, plug hose end

into female quick connect located on bottom of machine. Depress button

to determine O2 ows through resuscitator. For demand ow test, breathe

through face mask (gure 15).

gure 4

Telescoping Arm

⅝Mounting

Stud

#8-32

Retaining Screw

#10-24

Screws (2)

Arm Adapter

8

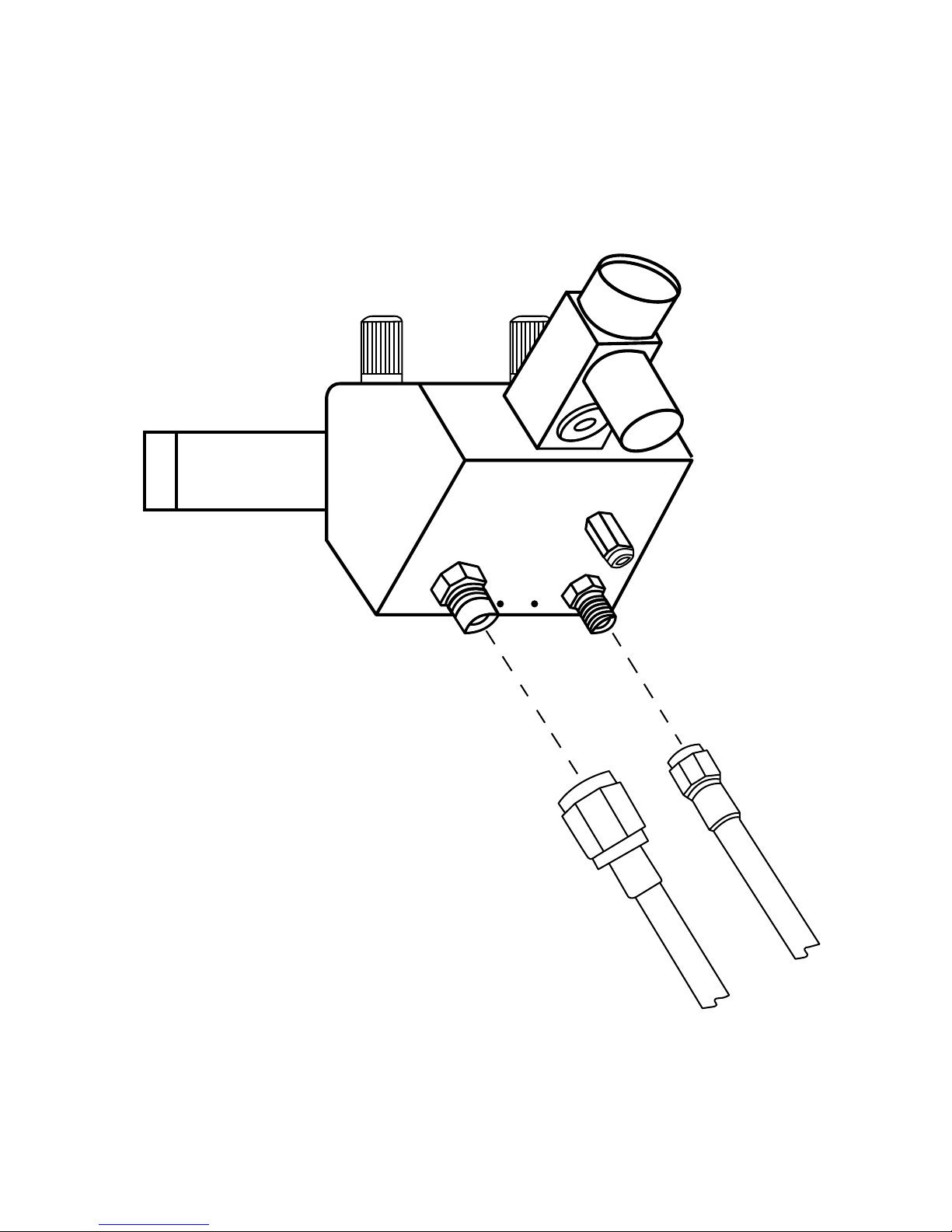

Supply Hose Connections

gure 5

N2O

(blue)

O2

(green)

9

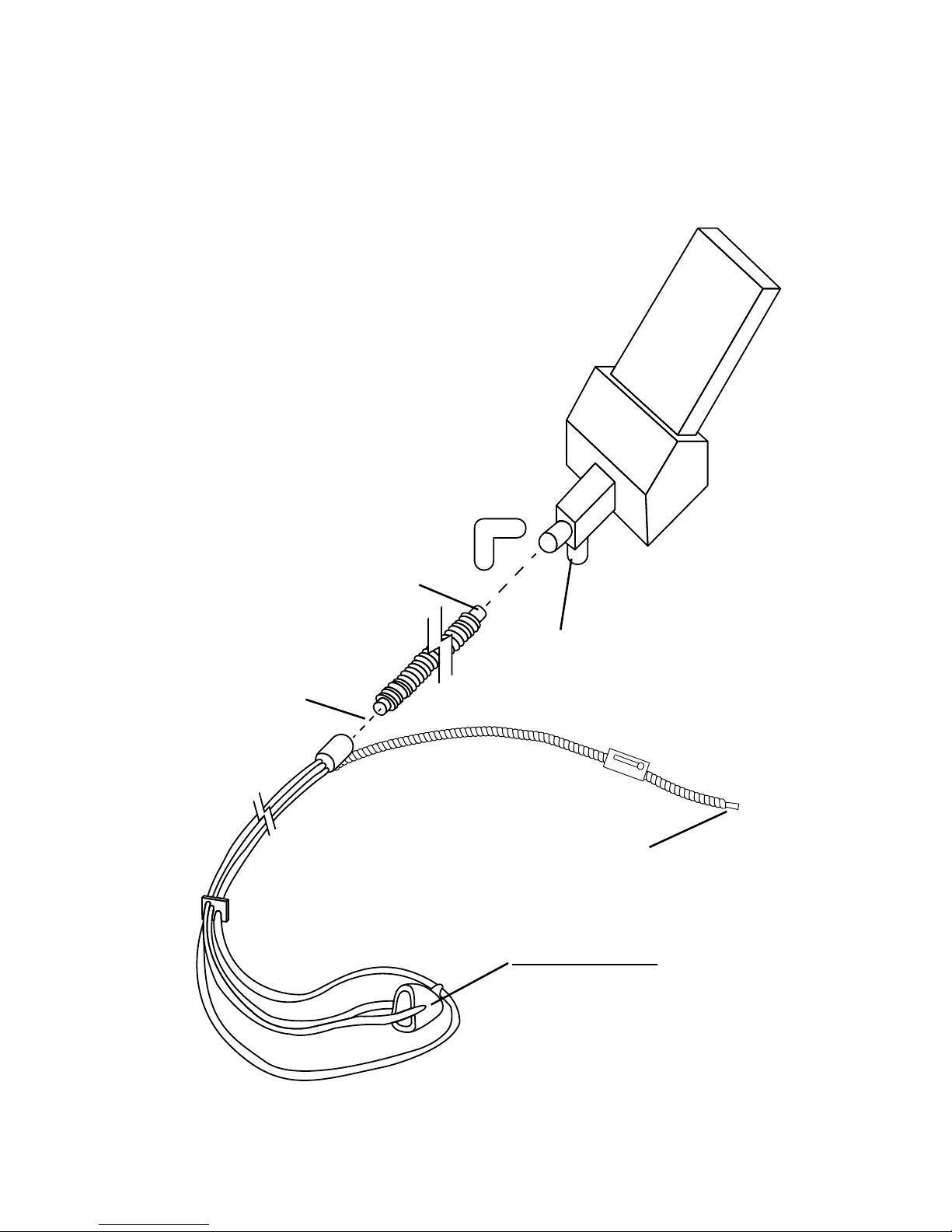

Scavenger Rubber Goods Assembly

(Part #’s 5600-0001, 5600-0002, 5600-0003)

gure 6

3L Breathing Bag (not shown)

connects to bottom port

5600-0021

Connects to

vacuum supply

Scavenger inhaler

Pedo - 5600-0001

Medium - 5600-0002

Large 5600-0003

Scavenger inhaler

connects to open end

of breathing tube

Breathing Tube

connects to end port

5600-0022

90° Elbow (Optional)

5600-0015

10

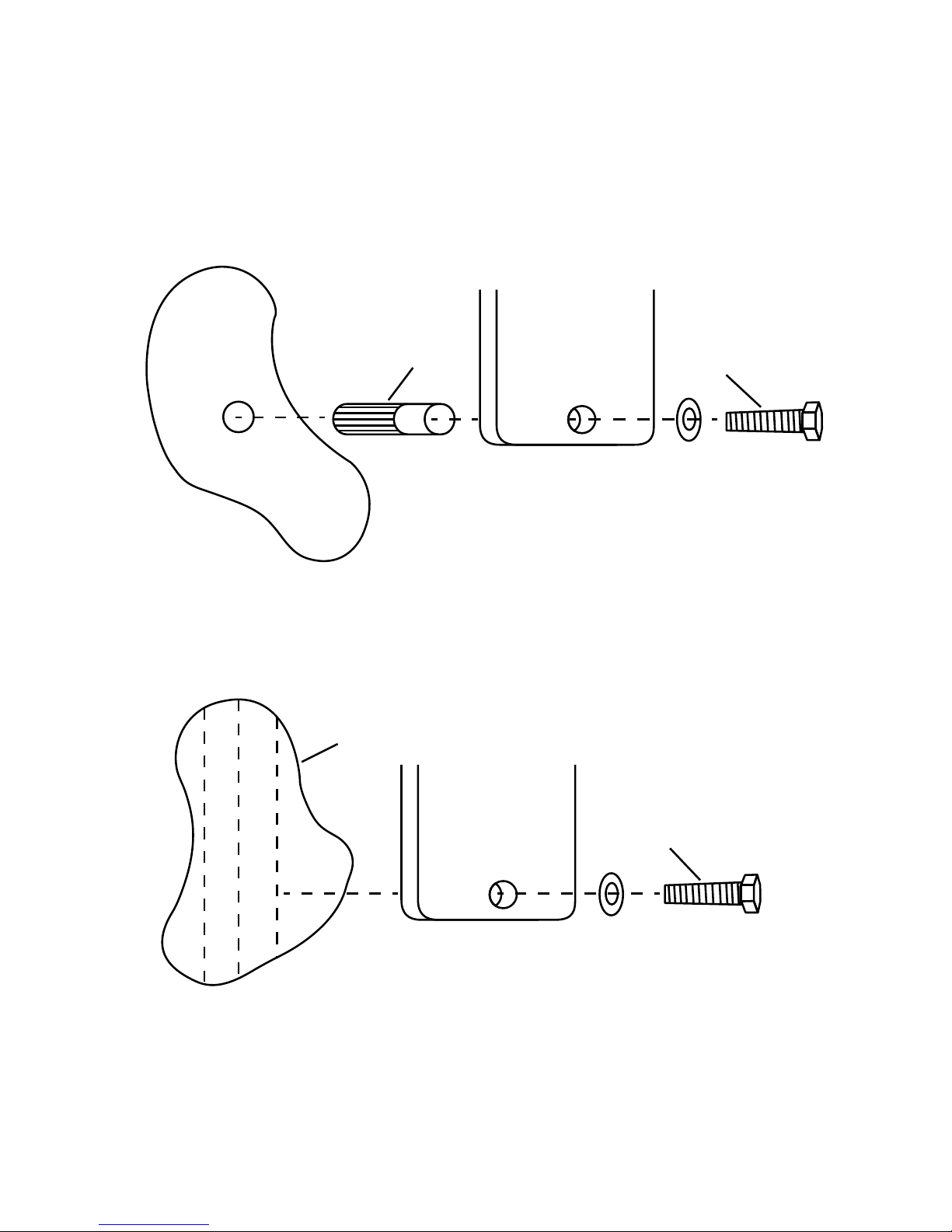

Arm Mounting

heavy duty

expander ¼in. lag

screw

¼in. lag

screw

dry wall application

stud mounting method

(preferred)

stud

gure 7

11

Top View of Telescoping Arm System

gure 8

27 in.

24 in.

Extends controls up to approximately 24 in. from wall surface

12

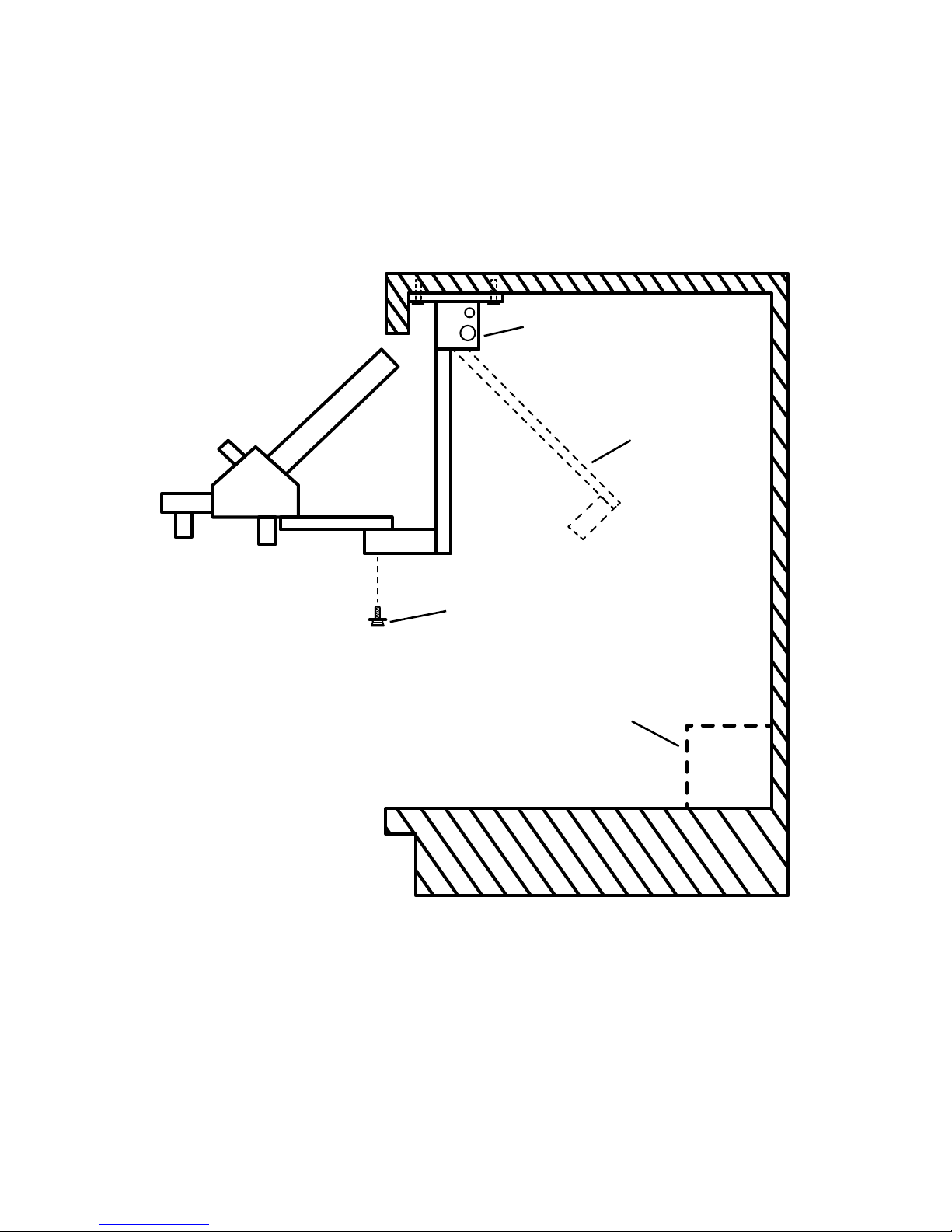

Cabinet Hinge Bracket InstallationCabinet Hinge Bracket Installation

Cabinet Bracket Detail

Mount bracket as shown to roof of cabinet with 4 lag screws up to ¼in.

diameter that is suitable for type of cabinet construction and ensures that

bracket will not loosen. Note: If the top material inside of cabinet is too thin

to secure bracket, it may be necessary to rst attach a piece of 1 in. x 6 in.

board to the cabinet and then attach cabinet bracket to board.

Operation: To release bracket for use from its retracted position, hold

owmeter with one hand and release catch (located on upper right of

bracket) by pulling knob to right. Allow owmeter to gently come forward

and release pull knob. Catch will release itself when the use position is

reached. To stow unit; pull knob to release catch, push unit back, and

release knob. Unit will latch itself when stowed position is reached.

catch rod – pull to release

retracted position

for storage

Free cabinet space required:

(inside dimensions)

H – 22 in.

D – 12 in.

W – 6 in.

8-32 retaining

screw

supply connections

(typical)

gure 9

13

Cabinet Bracket

10 ½in.

4 in.

mounting holes (4)

catch/release

gure 10

14

Flowmeter Head

Overall Dimensions

gure 11

3 ¾ in.

10 ¼ in.

8 ¾ in.

15

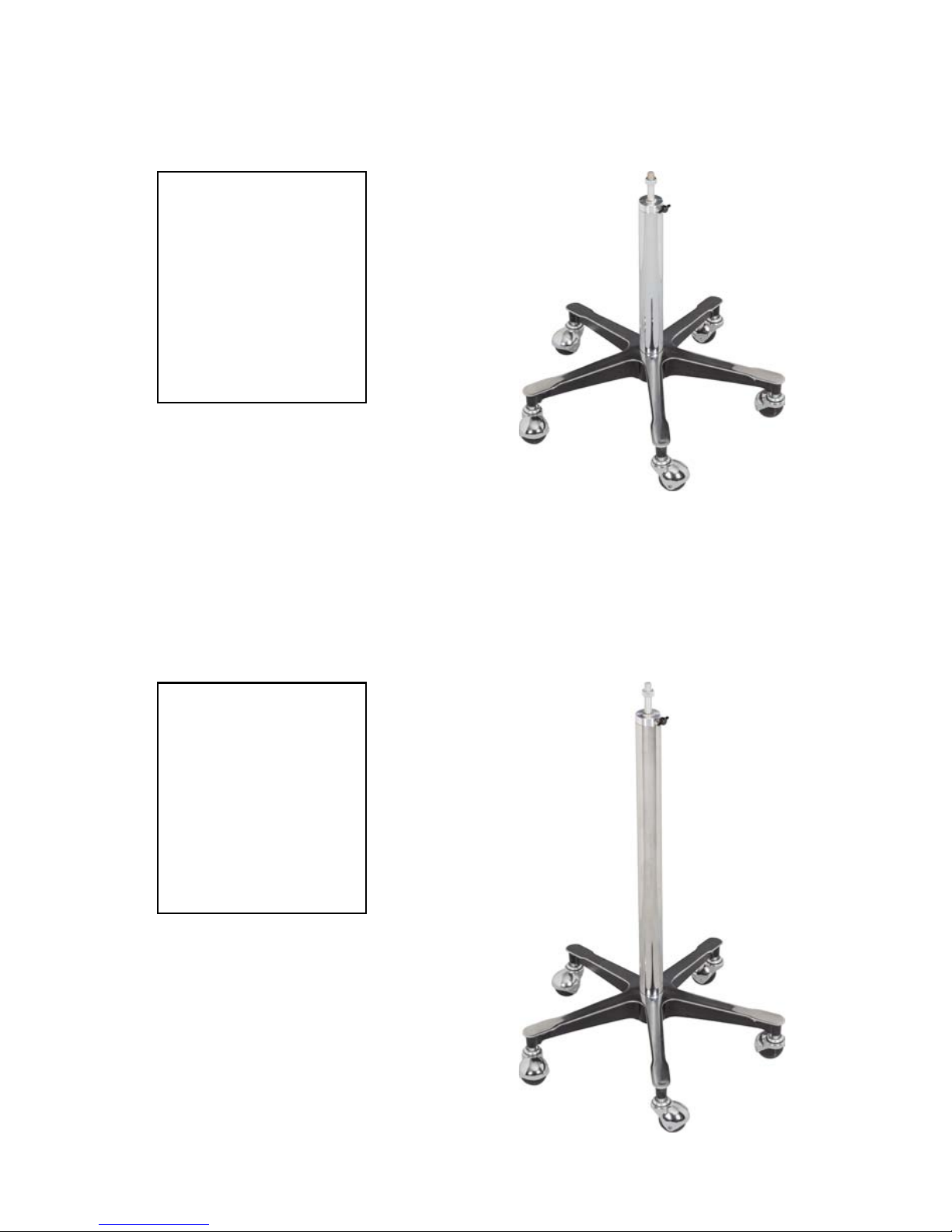

Mobile Stand Detail

SHORT STAND

5300-1001

HEIGHT

20.5 in.

WIDTH

19 in.

HEIGHT ADJUSTMENT

10 in.

TALL STAND

5300-1011

HEIGHT

30.5 in.

WIDTH

19 in.

HEIGHT ADJUSTMENT

10 in.

gure 12

gure 13

16

Yoke System

gure 14

HEIGHT

31 in.

WIDTH

19 in.

DEPTH

19 in.

17

O2 Demand Valve

Resuscitator Quick Connect

(Part# E201)

gure 15

18

Ratio Flow Control

5000-0000-0100 Ratio Flow Control for PC-7...........$140.00

O2 ow rate can be reduced to as low as 1 liter per

minute to match patient breathing volumes while still

maintaining minimum 30% O2 and 70% maximum N2O

gure 16

19

Table of contents

Other Belmed Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Flomec

Flomec QSE Series owner's manual

Setra Systems

Setra Systems SRIMV User's installation and operation manual

BIRD

BIRD Termaline 8930 Series Operation manual

Hanna Instruments

Hanna Instruments HI 718 manual

Hydrotechnik

Hydrotechnik MultiSystem 5070 operating instructions

Eastron

Eastron SDM230-LoRaWAN user manual

Grundfos

Grundfos DIT-M Installation and operating instructions

Elenco Electronics

Elenco Electronics TWT-1 instruction manual

Solinst

Solinst 101 Replacement manual

Henlee Electronics

Henlee Electronics 3G-SMKDT1 user manual

Teledyne Lecroy

Teledyne Lecroy frontline SODERA quick start guide

Crystal

Crystal 235 Series operating manual