Benchmark 1282-111 User manual

Oxygen

nydrogen

Combustible

explosive

CAUTION!AlwaysensurethatthetoolhasstoppedbeforedisconnectingtheairsupplyDonotwearwatches,rings,bracelets,orlooseclothingwhenusinganyair-poweredtool

Donotoverloadthetool.Allowthetooltooperateatitsoptimumspeedformaximumefficiency.

Donotuseatoolthatisleakingair,thathasmissingordamagedparts,orthatrequiresrepairs.VerifythatallscrewsaresecurelytightenedForoptimalsafetyandtoolperformance,inspectthetoolbeforeeveryusage,inordertoensurefreemovementofthetrigger,safetymechanisms,andsprings.Alwayskeepyourairtoolcleanandlubricated.Dailylubricationisessentialtoavoidinternalcorrosionandpossiblefailures.Ensurethefloorisnotslipperyandwearnon-slipshoes.Floorsshouldbekeptcleanandclear.Alwaysfollowallworkshopsafetyrules,regulations,andconditionswhenusingthetoolandkeeptheworkareaclean.Carrythetoolbythehandleonly,keepingfingersawayfromthetrigger.Donotcarrythetoolbythehose,magazine,oranyotherparts.Donotusethetoolnearorbelowfreezingpoint,asdoingsomaycausetoolfailure.Donotstorethetoolinafreezingenvironmenttopreventiceformationonthetoolsoperatingvalves,asdoingsomaycausetoolfailure.Handlingandstorageofoil:Usewithadequateventilation.Avoidcontactofoilwitheyes,skin,andclothing.Avoidbreathingsprayormist.Storeinatightlyclosedcontainerinacool,dry,well-ventilatedareafreefromIncompatiblesubstances.Trippinghazard.Theairhosemaybecomeatrippinghazardwhenitisplacedintheworkarea.Usecarewhenwalkingintheworkarea.

Recycle unwanted materials rather than disposing of them as waste. Sort the tools,

hoses, and packaging in specific categories and take to the local recycling center or

dispose of in an environmentally safe way.

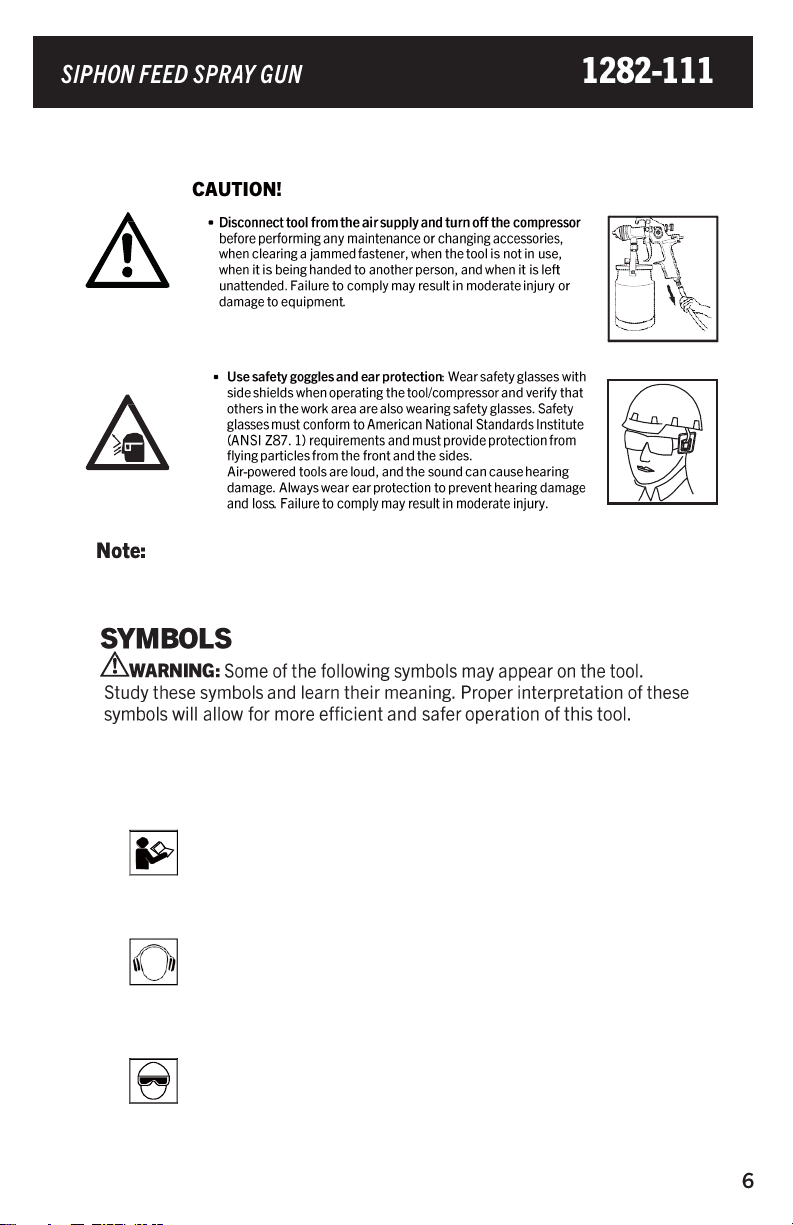

SYMBOLS

Read operator s manual:To reduce the risk of injury,

user must read and understand operator s manual

before using this product.

Risk to hearing

using this tool.

In hearing loss.

Always wear ear protection when

Failure to do so m a y r e s u l t

Eye protection: Always wear safety goggles, safety

glasses with side shields, or a full- f a c e shield

when operating this product.

Use compressed air at regulated pressure: Always use clean, dry, and

compressed

air at the regulated pressure.

Do not exceed the maximum operating pressure of 50 PSI.

Failure to comply

could lead to serious injury or loss of life.

Do not use this tool in the presence of flammable liquids or gases: Sparks that are

created during use may ignite gases. Please use the tool in a well-ventilated area only

and avoid any ignition sources

Use components recommended by manufacturers: Never modify the tool for other

applications.

Use only parts, nozzles, and accessories with specifications as mentioned in this

manual (see section technical specifications). Inspect the tool components and

attachments before operation and

ensure that they are assembled properly and are

not damaged.

Failure to comply could lead to serious injury or loss of life.

Disconnect the spray gun from the air supply hose and turn of the compressor before

performing any maintenance when the tool is not in use, when it is being handed to

another person, and when it is left unattended. It is recommended to use a ball valve

in the gun to air supply for emergency stoppage and to prevent unintended operation

Use safety respirator: Toxic vapors produced by spraying certain materials can cause

serious damage to health.

Always wear safety gloves and a respirator to prevent hazards caused by inhaling

toxic vapor or contact of solvent and paint with eyes or skin. Failure to comply may

result in moderate injury.

Do not use Latex paint for air powered suction spray gun. It is recommended to

use non-latex water-based paint. Latex is water-based paint bit with a large

granule that is easy to jam the nozzle. This type of sprayer is normally used for

painting metal surfaces, not drywall.

Do not use paint stripper because it will damage the aluminum housing.

Never allow the sprayer gun to lean a side when spraying.

The kind of paint depends on the viscosity. Pour the paint into the Ford 4 viscosity cup, flow

empty within 24s, it is appropriate.

Attached a viscosity cup for reference.

7

5

6

4

1

2

3

8

Air adjusting knob

8

This spray gun has all-metal components and reinforced base for long lasting durability.

Features include an adjustable pattern and material control for total control and an even coat.

10

2 5 7

3 3 8

1 9

6

4

Keep hands and other parts of the body away from the work areas when connecting the tool

to the air supply. Failure to comply could lead to serious injury or loss of life.

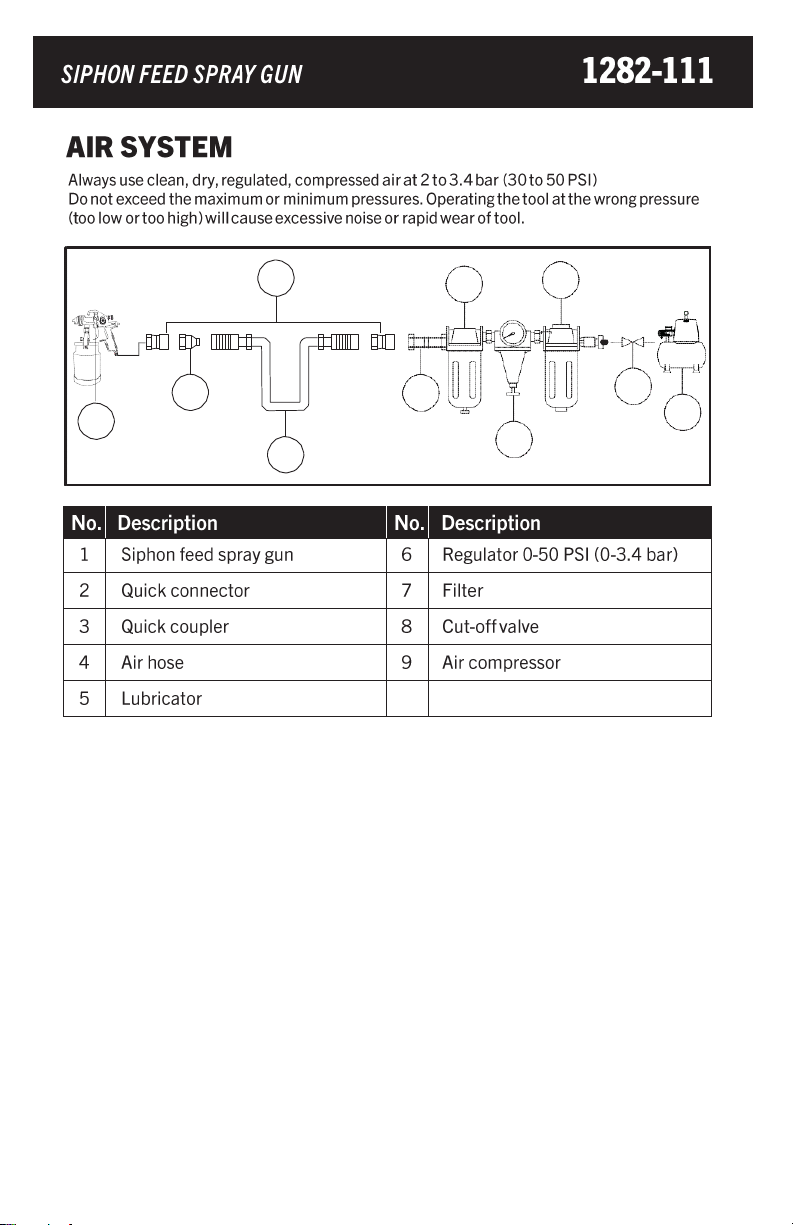

It is recommended that a filter-regulator-lubricator be used and be located as close to the tool

as possible.

If a filter-regulator-lubricator is not installed, place up to 6 drops of pneumatic tool oil into the

air inlet plug before each use.

If a filter-regulator-lubricator is installed, keep the air filter clean. A dirty filter will reduce the

air pressure to the tool, which will cause a reduction in power, efficiency, and general

performance.

For optimal performance, install a quick connector to the tool and a quick coupler on the

hose, if applicable.

Verify that all connections in the air supply system are sealed in order to

prevent air from leaking. Failure to comply may result in moderate injury or

damage to equipment.

Read all safety guidelines (see section "Safety guidelines”) at the beginning of this manual.

Always inspect the air tool prior to each use to

-

ensure proper use of power source.

-

determine whether the tool is in proper working order.

Clean the air inlet filter weekly.

Line pressure should be increased to compensate for unusually long air hoses. The hose

diameter should be 3/8".

Do not use the tool if it is not in proper working order.

Do not use oxygen or any other combustible or bottled gas to power this tool.

Do not use this tool in the presence of any flammable liquids or gases.

Keep hose away from heat, oil, and sharp edges. Check hose for wear and

tear, ensure that all connections are secure. Failure to comply could lead to

serious injury or loss of life.

AirtoolsReadthisInstructionManualcarefullybeforeusingthetool

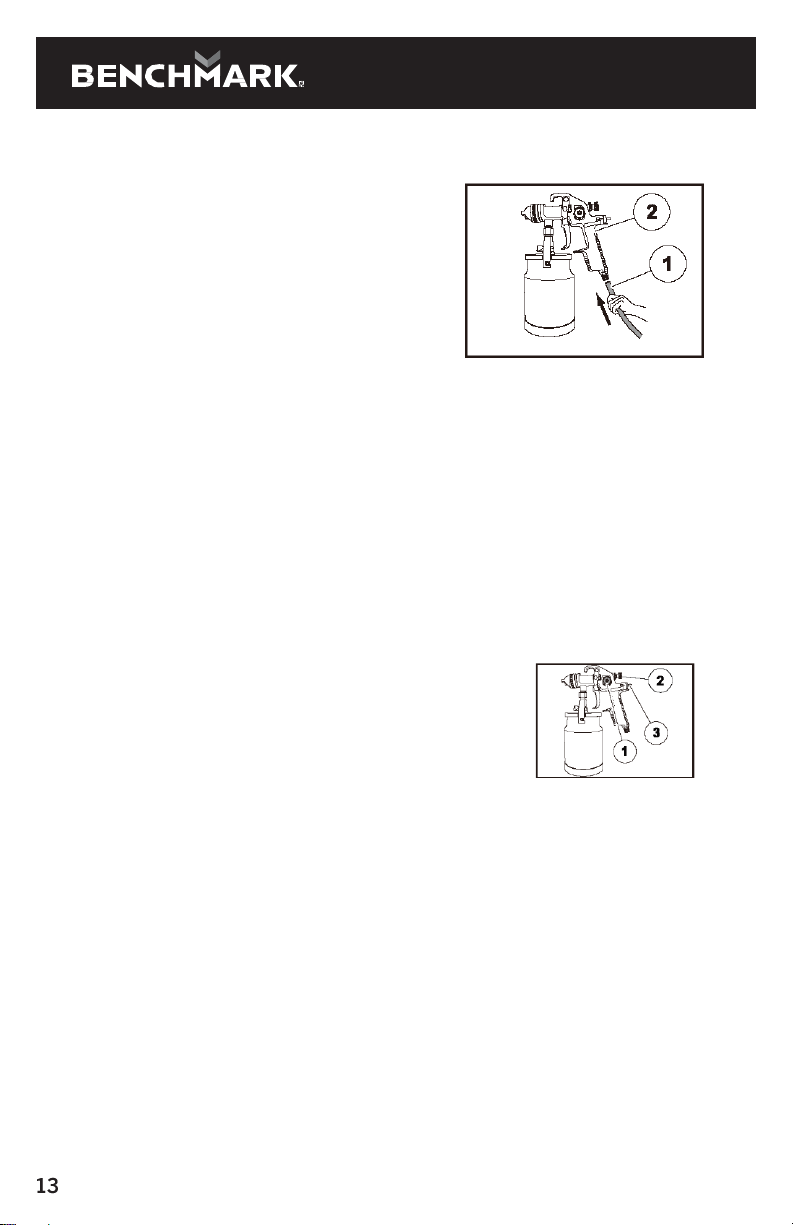

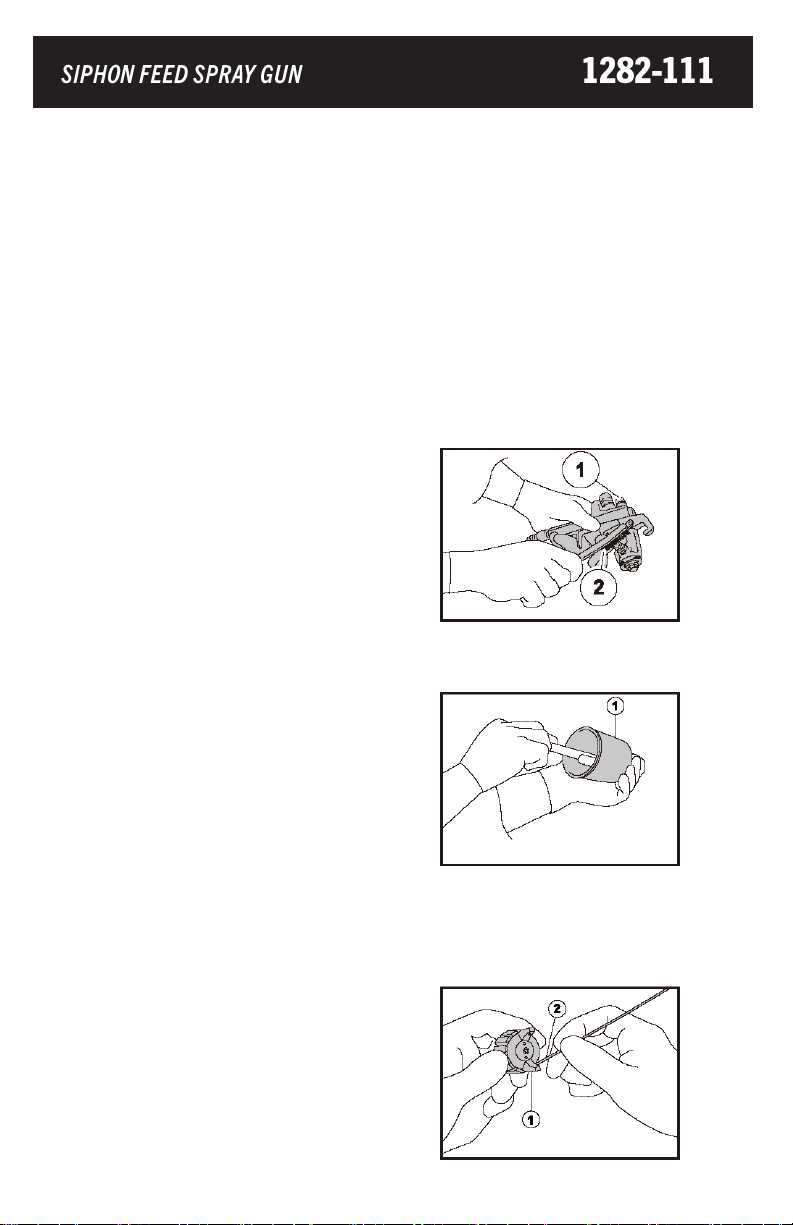

1 . Pour paint through a strainer

,

cheese

cloth or a paint strainer to remove any

foreign substance from the paint.

2 . Fill canister ( 1 ) three quarters full with

paint (2) .

3 . Close the canister ( 1 ) by turning the lid

(2) clockwise. Tum the lid tightly until

“arms” on the top of the lid click into

the pins on either side of the canister.

Secure into place by turning the

locking lever on the lid clockwise.

4

. Attach the gun ( 1 ) to the canister ( 2 )

filled with paint , by firmly holding

the canister.

5 . Tighten the nut ( 1 ) connecting the gun

and canister , by rotating it clockwise

using the wrench provided.

Fillingthepaintcanister

6. Plug in the compressor, turn on and

set the pressure regulator to 40PSI.

Attach one end of the air hose to the

compressor and the other end of

the air hose (1) to the tool (2).

7. Mixing and thinning of the paint

should be performed in accordance

with the paint manufacturer’s

instructions.

8.Most materials readily spray if

thinning is performed properly.

Test the consistency of the paint by making a

few strokes on a cardboard target. If the stroke appears

to be very thick, add a small amount of thinner.

⚠CAUTION! Do not exceed the thinning limits recommended

by the paint manufacturer. Failure to comply may result in moderate injury or

damage to the equipment.

ADJUSTMENTS

The siphon-feed spray gun has a pattern adjusting

knob (1), a paint adjusting knob (2) and an air

adjusting knob (3)

these are used to obtain the desired pattern, to control the output volume of

paint, and to obtain fine atomization, respectively

PATTERN ADJUSTMENT

Rotate the pattern adjustment knob in a clockwise direction to form a circular spray

pattern and rotate the knob in a counter-clockwise direction to form an elliptical

spray pattern.

PAINT ADJUSTMENT

Rotate the paint adjusting knob clockwise to reduce the output volume of paint and

rotate the knob in a counterclockwise direction to increase the output volume of

paint.

AIR VOLUME ADJUSTMENT

Rotate the air adjusting knob clockwise to reduce the output volume of air and rotate

the knob in a counterclockwise direction to increase the output volume of air.

14

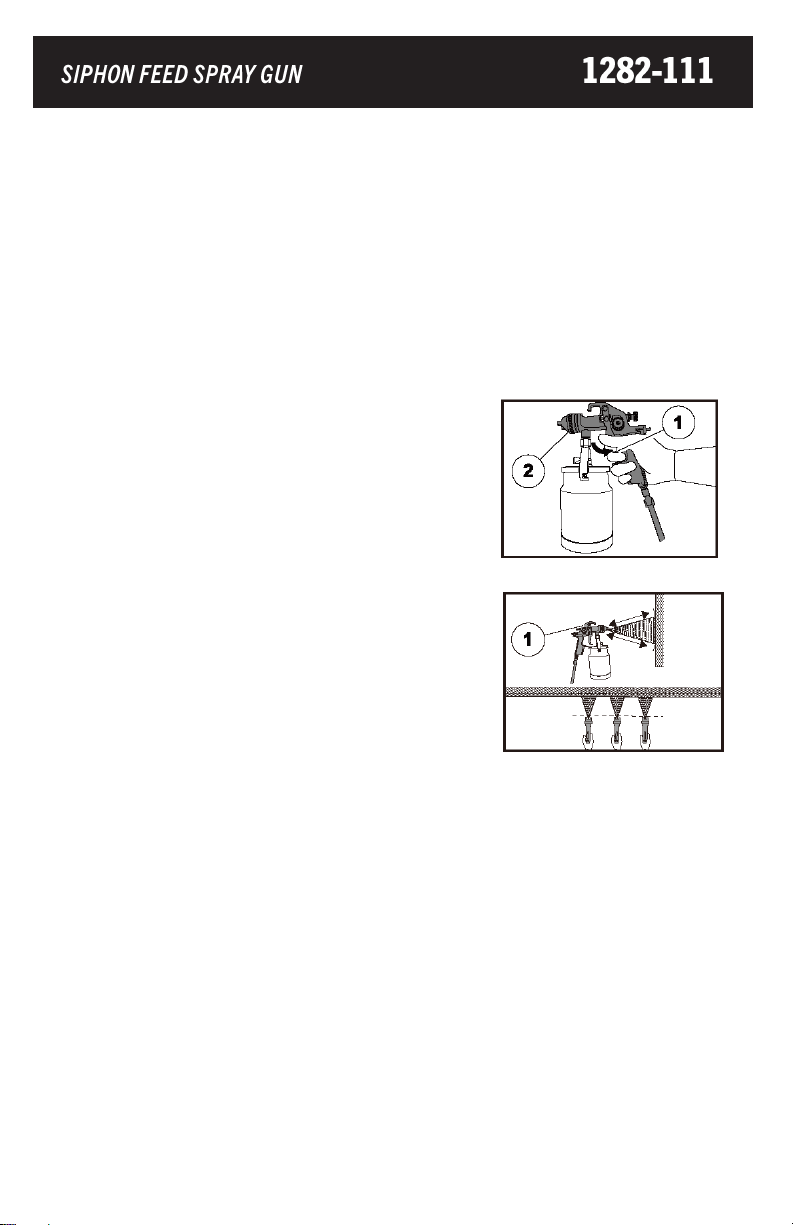

Operation

1. Plug in the compressor, turn it on, set the pressure regulator

to 40 PSI, attach one end of the air hose to the compressor

and the other end of the air hose to the air tool.

2. Hold the gun (1) in such a way

that the nozzle is approximately

6-12” away from the work

surface, perpendicular to

spraying area.

3. Squeeze the trigger (1) of the spray gun (2).

Start moving the gun before pressing the trigger

and release the trigger before stopping the gun

movement at the end of each stroke.

This procedure will blend each stroke with

the next without any overlap or unevenness

4. Move the gun (1) at a constant pace in a

parallel direction for spraying,

maintaining uniform distance from the

surface to be painted.

5.

Repeat the strokes until a uniform

coating is formed.

Note:

Use a piece of cardboard as a shield to capture the loss of spray paint at the ends of the workpiece to protect

the other surfaces from being painted.

The speed of stroke, the distance from the work surface, and the adjustment of the paint adjusting knob will vary the

amount of paint being applied

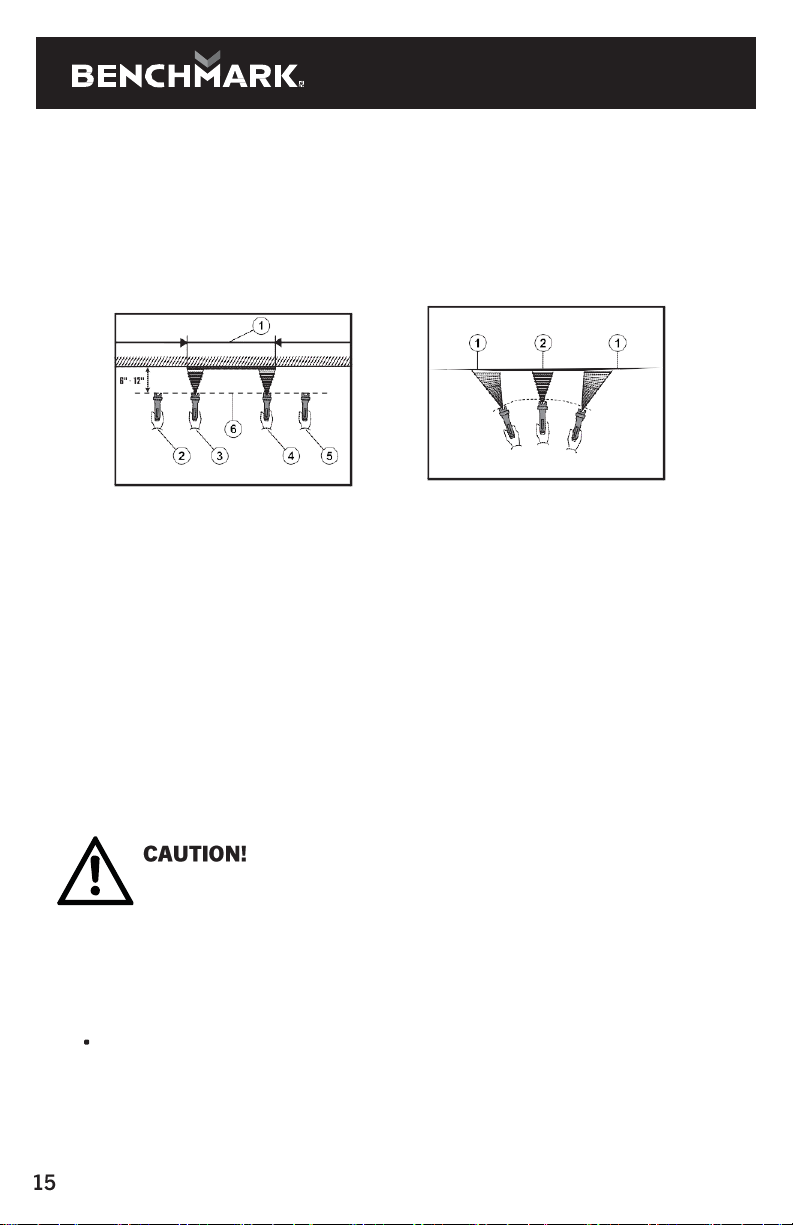

Do’s

Always move the gun in parallel direction

.

1 . Uniform coating region

2 . Stroke starting position

3 . Trigger pressing position

4 . Trigger releasing position

5 . Stroke stopping position

6 . Gun movement path

DONT’S

Do not press the trigger with the gun at an

inclined or angled position.

1 . Improper / thin coating region

2 . Uniform / thick coating region

Do not stop the sprayer movement in between, which will cause a build-up of

paint and result in runs.

Do not fan the gun while painting. This will cause a build-up of paint in the

center of the stroke and an insufficient coating at the ends. Failure to comply

may result in moderate injury or damage to equipment.

Storage

Rotate the paint adjusting knob in a counterclockwise direction and open the knob

when the gun is not in use. This will reduce spring tension on the needle fluid tip.

Clean the Spray Gun thoroughly and slightly lubricate it,

before and after storage.

Note:

Two thin coats of paint, rather than one thick layer, will yield better results and have lesser

chance of runs.

16

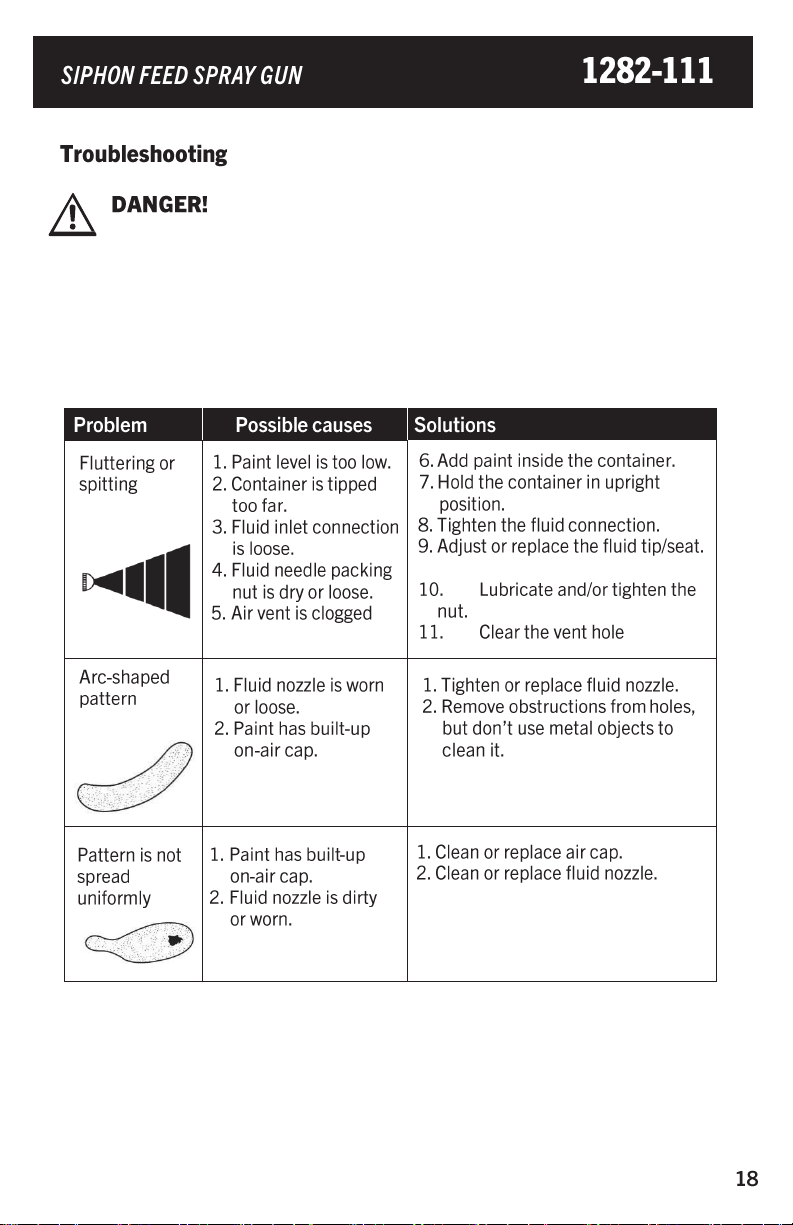

CARING FOR YOUR SPRAY GUN

The spray gun should be cleaned after

every use. Any paint remaining inside the

gun will thicken and may damage the inner

components and the mechanism of the gun.

.

Washing Procedure

1. Cover the air cap with a cloth and pull the

trigger. The air that is blown out of the paint

nozzle tip enters the paint passage and

cleans the inside of the gun.

2.Discard the paint remaining in the canister

and add some thinner to help in washing it

out of the sprayer.

3.Clean the inside and outside of the spray

gun

(1) with a brush (2).

4. Clean the inside of the paint canister

(1).

5.Remove and clean the inside and

outside of the air cap with a brush soaked

in cleaning solvent

.

Note: Wash the air cap (1) carefully without causing

any damage to the air hole as this would

affect the spraying pattern. Never use a

steel wire or wire brush for cleaning.

If the air hole is clogged, clean it using a

wooden Toothpick (2).

DANGER

Disconnect the tool from the air compressor before maintenance,

adjusting, cleaning, filling and when it is not in use. Ensure the needle is removed

before disassembling the nozzle, to avoid damage to the nozzle closure housing.

Repairs must be performed by a qualified service technician only. Failure to comply

will lead to serious injury or loss of life.

Lubrication: If the tool and the

compressor are not equipped with an in-

line lubrication system, place 2 to3 drops

of pneumatic tool oil into the air inlet

before each use or after every

two hours

of continuous use, depending

on the

characteristics of the workpiece

Maintenance

NOTE:Donotstorethetoolanywheretemperatureswillfallbelowfreezing.MAINTENANCEREQUIREDDESCRIPTIONTOOLSORMATERIALSREQUIREDMAXIMUMSERVICEINTERVALEachuseorevery2hrs.MonthlyAsneeded

Generalinspection-freemovementTrigger,spring,NoneXIn-depthinspectionWornorbrokenpartsXXReplacewornorbrokenpartsXLubricationSeebelow

Pneumatic

tooloilX

If any of the following symptoms appear while the tool is in use, turn it off

and disconnect it from the air supply immediately. Failure to comply will

lead to serious injury or loss of life.

Disconnect the tool from the air supply

before making any adjustments.

Repairs must be performed by a qualified service technician only.

The following chart lists common issues and solutions. Please read it carefully and

follow all instructions carefully.

Table of contents

Other Benchmark Paint Sprayer manuals

Popular Paint Sprayer manuals by other brands

Jacto

Jacto PJB-16U Operator's manual

3M

3M Scotchkote HSS-450 User instructions

Carlisle

Carlisle Binks AA1600M Service manual

Air Gunsa

Air Gunsa AZ3 HTE2 instruction manual

Graymills

Graymills Tempest T-10 Operation and maintenance instructions

Graco

Graco SaniSpray HP ProPack 25T781 Operation - repair - parts

Surtek

Surtek 108006 User manual and warranty

BUFFALO TURBINE

BUFFALO TURBINE BT-CS4 Original instructions and parts manual

Fast Mover

Fast Mover FMT9800 instruction manual

Guarany

Guarany Knapsack SP Operator's manual

Graco

Graco MAGNUM 232751 Operation

Clarke

Clarke CHHSB1 Operating & maintenance instructions