Hardi New NAVIGATOR 1100 User manual

New NAVIGATOR

67020803 (10/04)

Operator’s Manual

New NAVIGATOR

Operator’s Manual

HARDI

HARDI

HARDI® reserves the right to make changes in design,

material, or specification without notice thereof.

HARDI®and other product names are registered trademarks

of HARDI®Inc. in the U.S. and in other countries.

67020803 (10/04)

2 HARDI®New NAVIGATOR OPERATOR’S MANUAL

Table of Contents

Introduction................................................................. 4

Description.................................................................. 5

Frame..................................................................... 5

Adjustable wheel spacing.......................................5

Suspension (optional) ............................................ 5

Tank ....................................................................... 5

Pump...................................................................... 5

HARDI®SMART VALVE MANIFOLD system......... 5

ECP operating unit................................................. 5

ECPC operating unit .............................................. 5

Filters (standard and optional) ............................... 5

Booms.................................................................... 5

Safety Instructions ..................................................... 6

Operating the sprayer safely .................................. 6

Handling chemical products safely......................... 7

Local poison information center .............................7

Connection.................................................................. 8

Support jack ........................................................... 8

Bottom step (optional)............................................ 8

P.T.O. Shaft .................................................................. 9

P.T.O. shaft operator safety ....................................9

Installation of P.T.O. shaft ....................................... 9

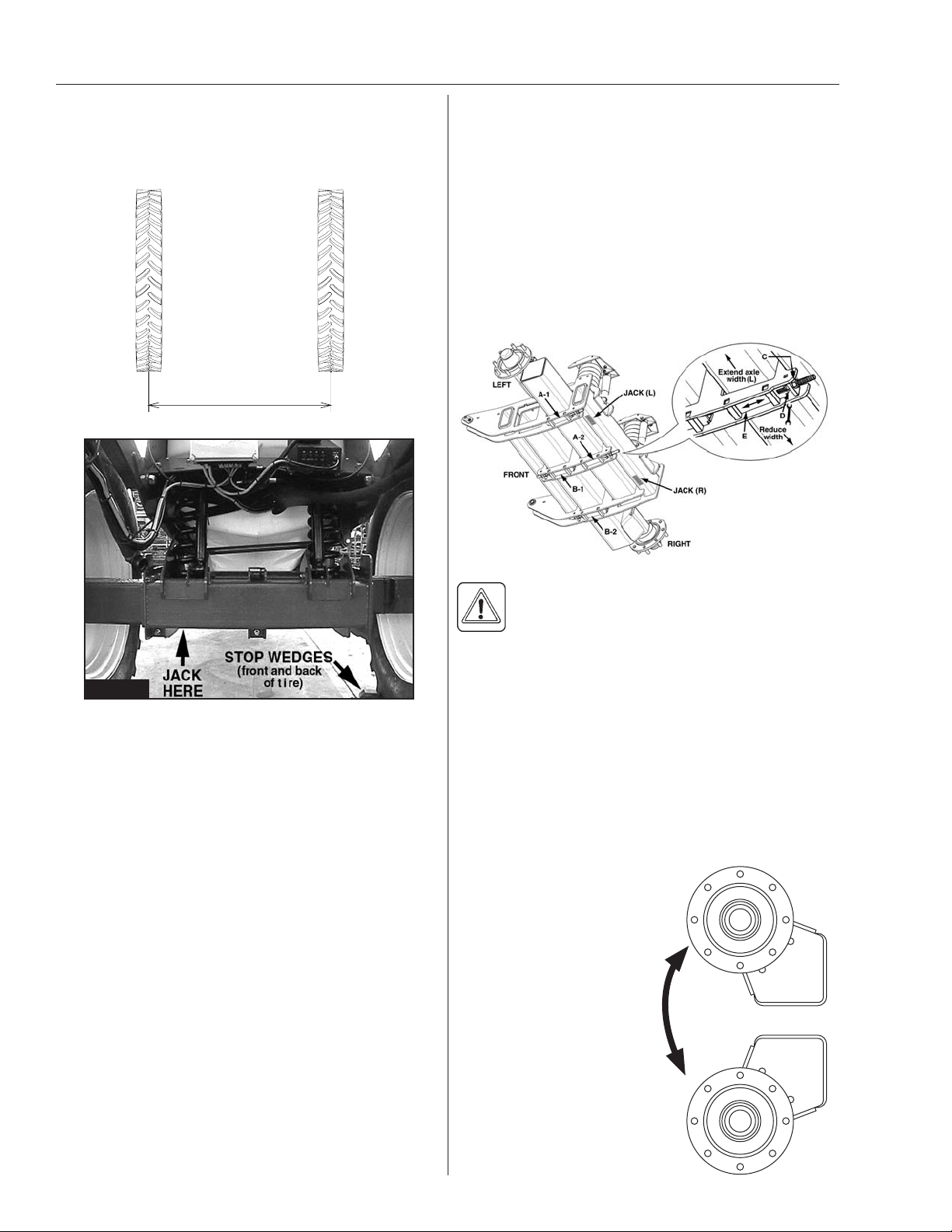

Wheel Spacing Adjustment

(Suspended and Non-suspended axle) .................. 10

Axle Clearance Adjustment

(Suspended and Non-suspended axle) .................. 10

Tires ........................................................................... 11

Hydraulic System ..................................................... 11

Connection requirements..................................... 11

Hydraulics - standard joystick handle................... 12

Direct Acting Hydraulic system (D.H.) .................. 12

Connecting electric controls................................. 13

Disconnecting sprayer.......................................... 13

Before operating sprayer...................................... 13

Transport ................................................................... 13

Roadworthiness ................................................... 13

Rear lights............................................................ 13

Transport bracket settings .................................... 14

Adjusting boom transport position........................ 14

ECP Plumbing Diagram ........................................... 15

ECPC Plumbing Diagram......................................... 16

Operation................................................................... 17

Operation of spraying functions ........................... 17

Filling tanks with water......................................... 17

Tank capacities .................................................... 17

Filling through tank lids ........................................ 17

Quick Fill (optional).................................................. 18

General Quick Filling guidelines........................... 18

ECP & ECPC Operating Unit.................................... 19

Controls adjustment ............................................. 19

Adjustment of constant pressure .........................19

Operating the control unit while spraying ............. 19

Emergency operation........................................... 20

Remote 4” pressure gauge (optional) .................. 20

Filters ................................................................... 20

Self cleaning filter (ECP only) .............................. 20

Adding Chemicals .................................................... 21

Filling through the tank lid .................................... 21

Filling with the HARDI®chemical filler (optional) .21

Operating with Liquid-based chemicals ............... 21

Operating with Powder-based chemicals............. 22

Use of flush tank and rinse nozzles (optional) ...... 23

Technical residue ................................................. 23

Draining tanks ...................................................... 23

Nozzle Selection ....................................................... 24

Calibration................................................................. 26

Maintenance - rules of thumb.................................. 27

Cleaning the sprayer ............................................ 27

Guidelines ............................................................ 27

Cleaning the tank ................................................. 28

Cleaning and maintenance of filters..................... 28

Lubrication ................................................................ 29

About lubricants ................................................... 29

Recommended lubricants .................................... 29

Lubrication schedule ............................................ 30

Service and Maintenance Intervals......................... 33

10 hours service................................................... 33

50 hours service................................................... 34

250 hours service................................................. 34

1000 hours service............................................... 35

Occasional maintenance...................................... 35

Pump valves and diaphragms replacement

(363/463 pumps) .............................................. 35

Pump valves and diaphragms replacement

(1302 pumps) ................................................... 36

Cone check/replacement ECP/ECPC

operating unit ................................................... 37

Cone check/replacement ECP/ECPC

distribution valve............................................... 37

Wear bushing replacement, boom lift............... 37

Shock absorbers .............................................. 37

Level indicator adjustment................................ 38

Cord replacement, level indicator..................... 38

Nozzle tubes and fittings .................................. 38

Off-Season Storage .................................................. 39

Preparation after off season storage.................... 39

Equipment and Accessories ................................... 40

Troubleshooting........................................................ 43

Emergency Operation of the Sprayer ..................... 48

Technical Specifications.......................................... 49

Overall measurements ......................................... 49

Weight .................................................................. 49

Filters and nozzles ............................................... 50

Temperature and pressure ranges ....................... 50

Electrical connections - Rear lights......................50

Electrical connections for ECP/ECPC

operating unit ....................................................... 50

EAGLE™ boom hydraulics SPB-HZ and SPC-HZ

.51

EAGLE™ boom hydraulics SPB-HY and SPC-HY

.51

DH Hydraulics ...................................................... 52

Warranty Policy and Conditions ............................. 53

Notes.......................................................................... 55

Dear Owner,

Thank you for purchasing a HARDI®product and welcome to the ever- increasing family of

HARDI®sprayer owners.

Our sprayers and accessories are rapidly becoming a familiar sight on North American farms.

We believe that this results from growers becoming increasingly conscious of crop protection

input costs and the vital need for cost effective spray application equipment.

Please take the time to thoroughly read the Operator’s Manual before using your equipment.

You will find many helpful hints as well as important safety and operation information.

Some of the features on your HARDI®New NAVIGATOR sprayer were suggested by growers.

There is no substitute for “on farm” experience and we invite your comments and suggestions.

If any portion of this instruction book remains unclear after reading it, contact your HARDI®

dealer or service personnel for further explanation before using the equipment.

For Product, Service or Warranty Information:

- Please contact your local HARDI®dealer.

To contact HARDI®directly:

- Please use the HARDI®Customer Service number: 1-866-770-7063

HARDI®INC. Visit us online at: www.hardi-us.com

HARDI®MIDWEST

1500 West 76th St.

Davenport, Iowa 52806

Phone: (563) 386-1730

Fax: (563) 386-1710

HARDI®WEST COAST

8550 W. Roosevelt Avenue

Visalia, California 93291

Phone: (559) 651-4016

Fax: (559) 651-4160

HARDI®GREAT LAKES

290 Sovereign Rd.

London, Ontario N6M 1B3

Phone: (519) 659-2771

Fax: (519) 659-2821

Sincerely,

Tom L. Kinzenbaw

President

4 HARDI®New NAVIGATOR OPERATOR’S MANUAL

We congratulate you for choosing a HARDI®plant protection product. The reliability and efficiency of this product

depends upon your care. The first step is to carefully read and pay attention to this instruction book. It contains

essential information for the efficient use and long life of this quality product.

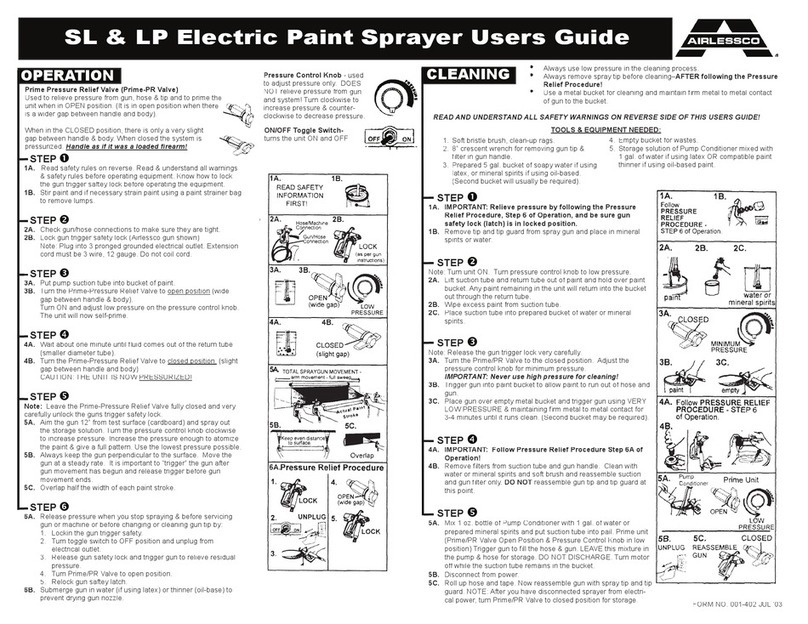

The New Navigator 1100 trailer sprayer consists of a powder coated frame with a tank, diaphragm or centrifugal

pump, ECP control (Electric Control Plus) for diaphragm pump system or ECPC control (Electric Control Plus

Centrifugal) for centrifugal pump system, HARDI®Smart Valve Manifold system, Self-Cleaning Filter (diaphragm

only), Paralift™ Boom Lift System, and a 45’, 50’, 60’, or 66’ EAGLE™ SPB series spray boom. The 1100 trailer

sprayers also offer an 80’, 88’, 90’, or 100’ EAGLE™ SPC series spray boom.

Introduction

New NAVIGATOR 1100 gallon with 100’ Eagle™ SPC (HZ) boom

5HARDI®New NAVIGATOR OPERATOR’S MANUAL

Description

Description

Frame

The frame is all steel construction. It has a strong

chemical and weather resistant powder coat. Screws,

nuts, etc. have been electrochemically treated to be

resistant to corrosion.

Adjustable wheel spacing

Allows infinite wheel spacing adjustment of 60” to 120”.

WARNING! Use extreme caution with narrower

wheel spacing (close to 60”). Always slow

down before entering a curve, especially when

turning on uneven ground or on a hillside.

Note: The wider the wheel spacing, the better the

stability of the sprayer and boom.

Suspension (optional)

Suspended axle systems are available featuring swing

arms, dual coil springs and gas shock absorbers.

Tank

The tanks, made of impact proof and chemical

resistant polyethylene, have a purposeful design with

rounded contours which allows for efficient cleaning

and draining. The tanks are designed with a large

deep sump, so that they can be completely emptied

even when the sprayer is used on slopes up to 15%

inclination. A remote operated drain valve is fitted for

efficient draining. Available tank size - 1100 gallon.

Pump

The HARDI®diaphragm pumps have low maintenance

requirements and guaranteed pump life. The bearings

and crankshaft are grease lubricated and are therefore

protected from spray solution if any diaphragm fails in

service. A drain hole is in the base of the crank case

to facilitate the draining of any foreign matter. The

diaphragm pumps are self priming and can be run

dry without damage. Centrifugal pumps and plumbing

systems are also available.

HARDI®SMART VALVE MANIFOLD system

All functions of the spray circuit are selected via

the centrally located simple, logical and functional

MANIFOLD valves, featuring color coding and clear

symbols for easy operation.

ECP operating unit

The ECP operating unit consists of: control box,

adjustable pressure agitation, pressure filter,

HARDIMATIC mechanical rate controller (within same

gear), 2-1/2” pressure gauge and individual boom feed

valve featuring constant pressure device for unchanged

application rate even if one or more boom sections are

shut off. The master on/off switch on the control box

operates by shutting off all boom sections regardless of

whether individual boom switches are on or off.

ECPC operating unit

The ECPC operating unit consists of: control box,

adjustable pressure agitation, 2-1/2” pressure gauge

and individual boom feed valves featuring constant

pressure device for unchanged application rate even

if one or more boom sections are shut off. The master

on/off switch on the control box operates by shutting

off all boom sections regardless of whether individual

boom switches are on or off.

Filters (standard and optional)

With the self-cleaning filter (ECP only), the impurities

that exist in the spray liquid will pass the filter and be

re-circulated back to the tank via the return flow. When

the tank is emptied, the impurities are then flushed out

through the drain. In-line filters and nozzle filters are

standard to ensure the sprayer will have minimal nozzle

blockages. Suction filter and filling filter are optional.

Booms

The HARDI®New NAVIGATOR boom options are as

follows:

New NAVIGATOR 1100

• 45’, 50’, 60’, 66’ Eagle™ SPB booms

• 80’, 88’, 90’, 100’ Eagle™ SPC booms

All of the booms are suspended in a strong, stable

parallelogram boom lift - Paralift™.

Booms feature trapeze/pendulum suspension and

an integrated spring suspension system with shock

absorber dampening.

Please refer to the

EAGLE™ BOOM

Operator’s Manual

for more information.

6 HARDI®New NAVIGATOR OPERATOR’S MANUAL

Safety Instructions

SAFETY INFORMATION

WARNING

ALWAYS READ OPERATOR’S MANUAL BEFORE

USING EQUIPMENT

DO NOT REMOVE ANY SAFETY DEVICES OR

SHIELDS. NEVER SERVICE, CLEAN OR REPAIR A

MACHINE WHILE IT IS OPERATING

WARNING

ALWAYS WATCH FOR THIS SYMBOL TO POINT OUT

IMPORTANT SAFETY PRECAUTIONS

IT MEANS ATTENTION! BECOME ALERT!

YOUR SAFETY IS INVOLVED!

RECOGNIZE SAFETY INFORMATION

This is the Safety-alert symbol.

When you see this symbol on your

machine or in this manual, be alert

to the potential for personal injury.

Follow recommended precautions

and safe operating practices.

Follow safety instructions

• Carefully read all the safety messages in this man-

ual and the safety labels fitted to the machine. Keep

safety labels in good condition. Replace missing

or damaged safety labels. Be sure that new equip-

ment components include any current safety labels.

Replacement safety labels are available from your

authorized HARDI®dealer.

• Learn how to operate the sprayer and how to use

the controls properly. Do not let anyone operate the

machine without proper instructions.

• Keep your sprayer in proper working condition. Unau-

thorized modifications or use may impair the function

and/or safety and affect the machine’s life.

• If you do not understand any part of this manual and

need assistance, please contact your authorized

HARDI®dealer.

Operating the sprayer safely

1. Read the complete manual carefully and become

familiar with the operation of the equipment before

initial operation in each spraying season. Failure to

do so may result in possible over or under appli-

cation of spray solution which may drastically affect

crop production and lead to personal injury.

2. Before starting the engine on the tractor unit, be

sure all operating controls are in the off or neutral

position, including (but not limited to) the P.T.O.

shaft and/or spray controls. Be sure the tractor

power train is disengaged.

3. Operate spray and boom functions only when

seated in the operator’s seat.

4. One of the most frequent causes of personal injury

or death results from persons falling off or being

run over. Do not permit others to ride on or in. Only

one person should be working the machine when in

operation.

5. Before leaving the tractor seat, stop the engine,

put all controls in neutral, and put the transmission

control lever in the park position or neutral with the

brakes locked. Read the tractor operation manual

for added safety precautions.

6. P.T.O. driven equipment can cause serious injury.

Before working on or near the P.T.O. shaft, servicing

or cleaning the equipment, put P.T.O. lever in the

DISENGAGE position and stop the engine.

7. Do not fold or unfold boom near overhead wires.

Serious injury or death could result if contact is

made with electric wires.

8. Keep hands, feet & clothing away from moving

parts.

9. Wear relatively tight and belted clothing to prevent

from being caught on some part of the machine.

10. Slow down when turning, especially with boom

unfolded.

11. Always keep children away from your sprayer and/

or tractor unit.

7HARDI®New NAVIGATOR OPERATOR’S MANUAL

Safety Instructions

12. Before transporting the sprayer, ensure that the

boom is fully folded and fully locked into transport

position. Ensure all locking devices are fully en-

gaged, whether hydraulic or mechanical.

13. Slow moving tractors and spray equipment can cre-

ate a hazard when on public roads. Avoid personal

injury or death resulting from any accidents by

using flashing lights. Local regulations may require

installation of flashing warning lights.

14. Avoid injuries from high pressure fluids penetrating

the skin by relieving system pressure before discon-

necting hydraulics or other lines. Ensure all fittings

are tight before applying pressure to the system.

15. Understand service procedures before undertaking

any maintenance. Never lubricate, service, or adjust

the machine while it’s moving. Securely support any

components before working on them.

16. Keep all parts in good condition and properly

installed. Fix damaged parts immediately. Replace

worn or broken parts. Remove excessive buildup of

grease, oil or debris.

Handling chemical products safely

1. Direct exposure to hazardous chemicals can cause

serious injury. These chemicals can include lubri-

cants, coolants, paints, adhesives and agricultural

chemicals. Material Safety Data Sheets (M.S.D.S.)

are available for all hazardous chemicals which

inform the user of specific details including: physical

and health hazards, safety procedures, and emer-

gency response techniques.

2. Protective clothing such as rubber gloves, goggles,

coveralls and respirator must be worn while han-

dling chemicals. All protective clothing should be

kept in excellent condition and cleaned regularly or

discarded.

3. If chemicals come in contact with any exposed

skin areas, wash immediately with clean water and

detergent. Never place nozzle tips or any other

components that have been exposed to chemicals

to lips to blow out obstructions. Use a soft brush to

clean spray nozzles.

4. Dedicate an area to fill, flush, calibrate and decon-

taminate sprayer where chemicals will not drift or

run off to contaminate people, animals, vegetation,

water supply, etc. Locate this area where there is

no chance of children coming in contact with this

residue.

5. Decontaminate equipment used in mixing, trans-

ferring and applying chemicals after use. Follow

the instructions on the chemical label for the cor-

rect procedure required. Wash spray residue from

outside of the sprayer to prevent corrosion.

6. Extreme care should be taken in measuring spray

products. Powders should be used in suitable sized

packages or weighed accurately. Liquids should be

poured into a suitable graduated container. Keep

chemical containers low when pouring. Wear a

filtered respirator and let the wind blow away from

you to avoid dust and/or splashes contacting the

skin or hair.

7. Store chemicals in a separate, plainly marked

locked building. Keep the chemical in its original

container with the label intact.

8. Dispose all empty containers after rinsing in ac-

cordance with local regulations & by-laws. Dispose

of all unused chemicals and left over fertilizer in an

approved manner.

9. Keep a first aid kit and fire extinguisher available at

all times when handling chemicals.

Local poison information center

If you live anywhere in the United States, the following

toll free number will connect you to your Local Poison

Information Center.

PHONE NO. 1 - 8 0 0 - 2 2 2 - 1 2 2 2

If you live outside the United States, find the number for

the poison control center in your phone book and write

it in the space below:

PHONE NO. _______-_______-__________

Keep a list, in the space provided below, of all the

chemicals that you have in use.

1._________________________________________

2._________________________________________

3._________________________________________

4._________________________________________

5._________________________________________

6._________________________________________

7._________________________________________

8._________________________________________

9._________________________________________

10._________________________________________

8 HARDI®New NAVIGATOR OPERATOR’S MANUAL

Sprayer Setup

Connection

Connect the sprayer to the tractor, adjusting the hitch

mounting height (A

Fig. 1

) on the drawbar so that the

sprayer is level.

WARNING! The drawbar bolts must be re-tight-

ened to the specified torque every 8 hours of

work until the torque is stabilized, and then at

intervals stated in the service scheme (p. 34).

WARNING! Ensure the drawbar is secured to

the tractor and cannot be accidentally discon-

nected. Safety chains are recommended when

towing the sprayer.

WARNING! Your tractor will have decreased

braking efficiency with the sprayer connected,

particularly when the tank is full.

Support jack

To remove support jack (B

Fig. 1

): lift leg, remove

securing pin and pull out support jack. When sprayer

is attached to the tractor, support jack is stored in a

bracket on the left side of the frame (

Fig. 2

).

WARNING! The support jack is not designed

for lifting a full sprayer or supporting the trailer

for extended periods if the sprayer is full of

water.

Bottom step (optional)

To access the front platform, pull the step lock pin out

and lower the step (

Fig. 3

). Always lift up and push the

step in to the locked position before driving. The step

will lock automatically when it is lifted up.

WARNING! Ensure the molded steps on the

Flush Tank are kept clear of mud and debris to

optimize their slip-resistant properties.

WARNING! Always ensure the Flush Tank tie-

down strap is secured before moving sprayer or

climbing onto steps (

Fig. 4

).

Tie-down strap in secured position.

Fig. 2

Fig. 4

Fig. 3

LOCK PIN

LOCK PIN

Fig. 1

B

A

9HARDI®New NAVIGATOR OPERATOR’S MANUAL

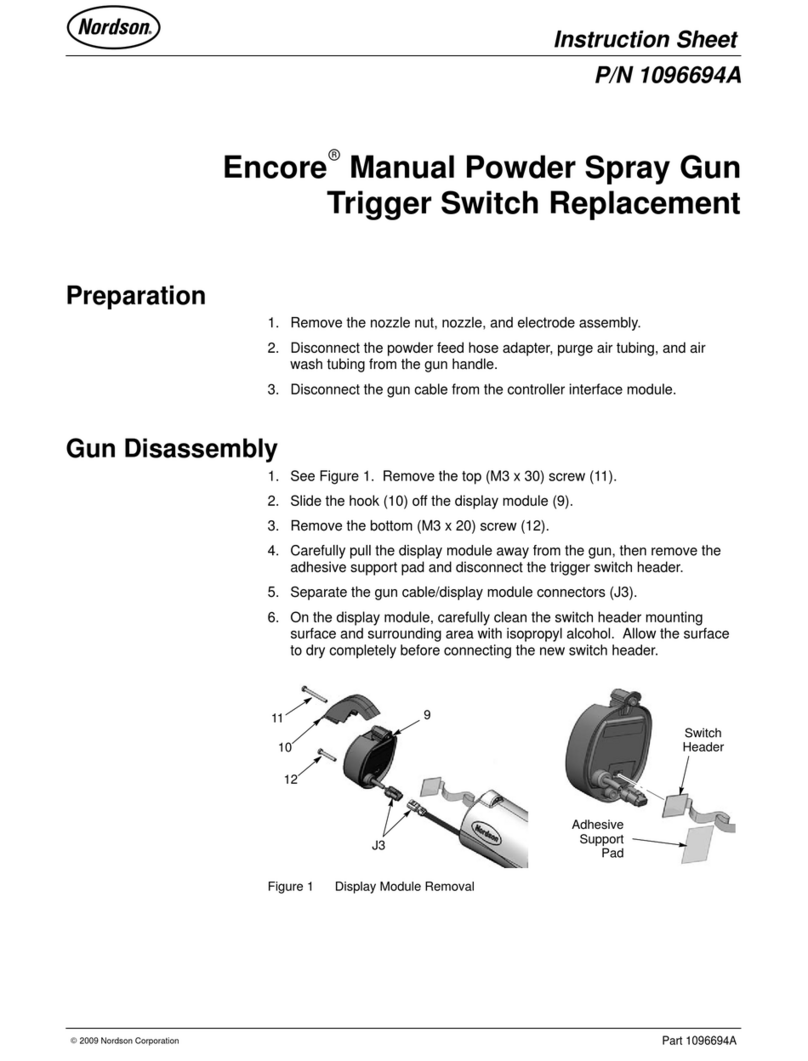

P.T.O. shaft operator safety

WARNING:

ALWAYS STOP ENGINE BEFORE

ATTACHING THE TRANSMISSION SHAFT

TO TRACTOR P.T.O. MOST TRACTOR P.T.O.

SHAFTS CAN BE ROTATED BY HAND TO FACILI

TATE

SPLINE ALIGNMENT WHEN ENGINE IS STOPPED.

When attaching the shaft, make sure that the snap lock

is FULLY ENGAGED - push and pull shaft until it locks.

WARNING:

ROTATING TRANSMISSION

SHAFTS WITHOUT PROTECTION GUARDS

ARE FATAL.

Always keep protection guards and chains intact and

make sure that the guards cover all rotating parts,

including CV-joints at each end of the shaft.

Do not use without protection guard.

Do not touch or stand on the transmission shaft when it

is rotating - safety distance: min 5’ (1.5 meters).

Prevent protection guards from rotating by attaching the

chains, allowing sufficient slack for turns.

Make sure that protection guards around the tractor

P.T.O. and implement shaft are intact. Always STOP

ENGINE and remove the ignition key before carrying

out maintenance or repairs to the transmission shaft or

implement.

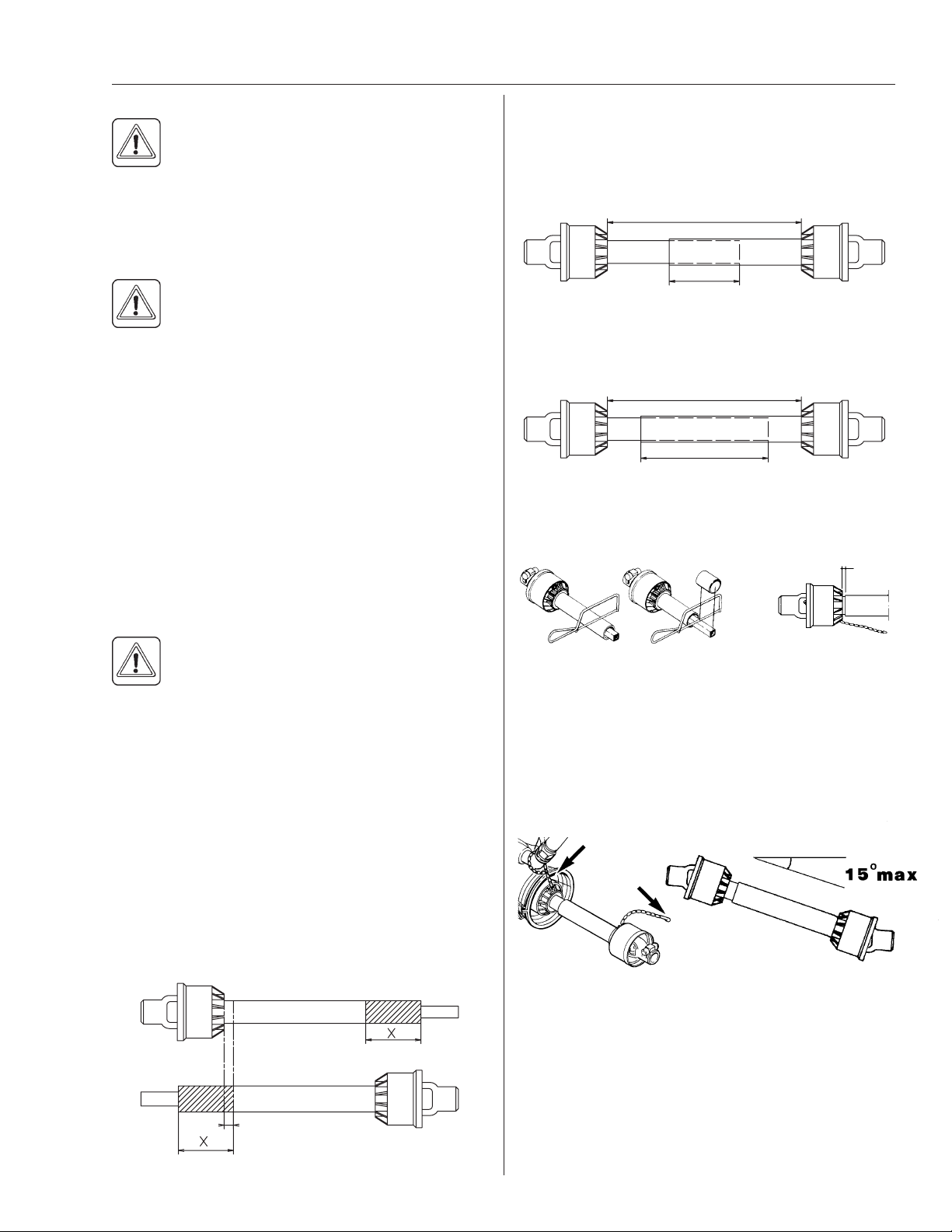

Installation of P.T.O. shaft

WARNING:

THE P.T.O. SHAFT ANGLE WILL

CHANGE WHEN RAISING AND LOWERING

THE CLEVIS. TO PREVENT EXCESSIVE

LOADING AND BINDING ON THE P.T.O. SHAFT, IT

MAY BE ADVISABLE TO LEAVE THE P.T.O. SHAFT

DISCONNECTED UNTIL THE CLEVIS ADJUSTMENT

IS COMPLETED. THEN THE P.T.O. SHAFT ADJUST-

MENTS CAN BE MADE.

Initial installation of the shaft is done as follows:

1. Attach sprayer to tractor and set sprayer in the posi-

tion with shortest distance between the tractor and

sprayer pump P.T.O. shafts.

2. Stop engine and remove ignition key.

3. If P.T.O. shaft must be shortened, the shaft is pulled

apart. Fit the two shaft parts at tractor and sprayer

pump and measure how much it is necessary to

shorten the shaft. Mark the protection guards.

Sprayer setup

Note: The minimum allowable overlap for the shaft

depends on the pump model.

Pump with 6 splines (540 r.p.m.)

The shaft must always have a minimum overlap of 1/3

the length.

Pump with 21 splines (1000 r.p.m.)

The shaft must always have a minimum overlap of 2/3

the length.

4. The two parts are shortened equally. Use a saw, and

file the profiles afterwards to remove burrs.

5. Grease the profiles, and assemble male and female

parts again.

6. Fit the shaft to tractor and sprayer pump.

Note: Female part towards tractor. Fit chains to prevent

the protection guards from rotating with the shaft.

7. To ensure long life of the P.T.O. shaft, try to avoid

working angles greater than 15°.

Min 13/16" (20mm)

Min. 13/16” (20mm)

Min. 1/3 of Length

Length

Length

Min. 2/3 of Length

10 HARDI®New NAVIGATOR OPERATOR’S MANUAL

Sprayer Setup

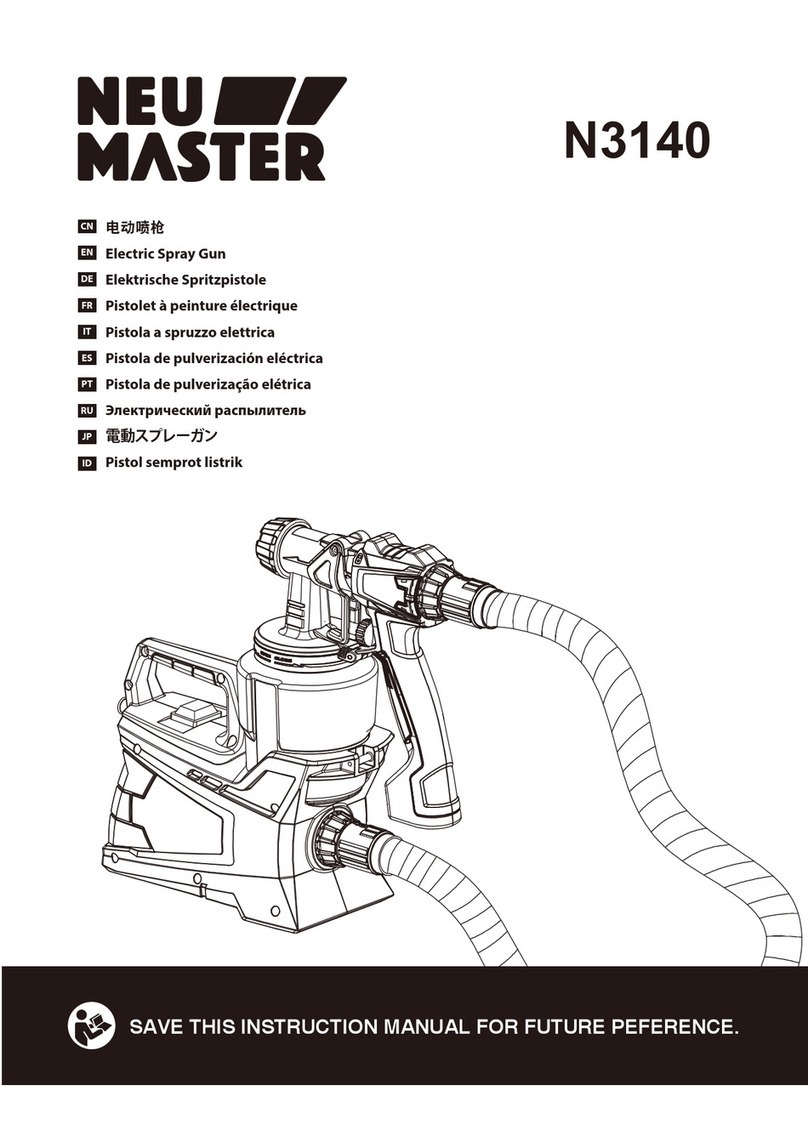

Wheel Spacing Adjustment

(Suspended and Non-suspended Axle)

Wheel spacing can be infinitely adjusted from 60” to

120” with suspended or non-suspended axle systems.

1Measure the correct wheel spacing (Center of right

hand tire to center of left hand tire). Each side must

be extended or retracted half the desired alteration.

2Attach sprayer to the tractor and engage tractor

parking brake.

3Place stop wedges in front of and behind the right

hand wheel (

Fig 5

). Using suitable heavy duty

equipment, jack up the left hand wheel. Ensure

secure support for the sprayer body.

4To release axle wedge for the left hand wheel axle

and extend or retract the axle:

Turn Nut (C

Fig 6

) counterclockwise to allow

approx. 1” clearance. With an open-ended wrench,

turn Nut (D

Fig 6

) against anchor plate until hold on

axle is released. Shift axle to measured position.

5To tighten axle wedge and secure axle at required

width:

Turn Nut (D

Fig 6

) counterclockwise to allow

movement of stop wedge. Turn Nut (C

Fig 6

)

clockwise against anchor plate to draw stop wedge

up against the axle and hold it in position. Tighten

to torque of 100 Ft/lb (135 Nm), then lock by re-

tightening Nut (D

Fig 6

).

6 If the wheels were reversed and exchanged,

remember to tighten the wheel nuts to the specified

torque - rim plate to hub 120 Ft./lb (180 Nm).

7Repeat the procedure on the right hand wheel.

8Check the distance from the center of the tire to

the center of the tank, to make sure the distance is

equal from left to right.

9Re-tighten the clamp bolts and wheel nuts to the

specified torque after 8 hours of work.

IMPORTANT! Always place a jack under axle and

lift the wheel to remove the load from the clamps

before tightening the clamp bolts.

WARNING! Use extreme caution with narrower

wheel spacing (close to 60”). Always slow

down before entering a curve, especially when

turning on uneven ground or on a hillside.

Note: The wider the wheel spacing, the better the

stability of the sprayer and boom.

Axle Clearance Adjustment

(Suspended and Non-suspended Axle)

The two axle inserts are equipped with offset spindles

allowing for a "low" or "high" clearance setting. To

change axle clearance:

1Follow steps 1-4 in "Wheel spacing adjustment"

section to release left

axle insert.

2Slide axle insert

completely out and

rotate 90°.

60” to 120”

Fig. 6

Fig. 5

11HARDI®New NAVIGATOR OPERATOR’S MANUAL

Note: Make sure the left axle offset faces the front of

the sprayer and the right axle offset faces the

rear of the sprayer so the axles are aligned.

3Re-insert axle insert and follow steps 5-9 in "Wheel

spacing adjustment" section to tighten.

4Repeat procedure for right axle insert.

Tires

Equal pressure in both tires is essential. Pressure

should be kept as low as practical. For recommended

pressures see

Tire pressures

(p. 34).

WARNING! Never inflate tires above the

specified pressures. Over-inflated tires can

explode and cause severe personal injuries.

Note: Sprayers fitted with rate controllers/monitors

must always maintain the same tire pressure as

when calibrated.

Sprayer Setup

Hydraulic System

Connection requirements

Connection requirements for

EAGLE™ booms

are:

• One single acting outlet for the lift function of the

spray boom.

• One double acting outlet for the folding and/or tilt

function of the spray boom.

Note: The hydraulic system requires an oil capacity

of approximately 0.8 GPM (3 liters) and a minimum

pressure of 1,950 PSI (130 bar).

BE SURE TO HOOK UP HYDRAULIC LINES

PROPERLY !

ENSURE HYDRAULIC LINES HAVE NOT BEEN

DAMAGED DURING SHIPPING.

ESCAPING HYDRAULIC FLUID UNDER PRESSURE

CAN PENETRATE THE SKIN CAUSING SERIOUS

INJURY. AVOID THIS HAZARD BY RELIEVING

PRESSURE BEFORE DISCONNECTING

HYDRAULIC LINES.

ENSURE ALL CONNECTIONS ARE TIGHT BEFORE

APPLYING PRESSURE, SEARCH FOR LEAKS WITH

A PIECE OF CARDBOARD NOT YOUR HANDS!

IMPROPER HOOK-UP CAN CAUSE DANGEROUS

BOOM MOVEMENTS AND/OR DAMAGE TO THE

SPRAYER HYDRAULICS.

DO NOT ALLOW ANYONE NEAR A HYDRAULIC

BOOM IN OPERATION.

ALWAYS SHUT TRACTOR OFF WHEN

CONNECTING, SERVICING OR ADJUSTING BOOM.

Make sure that the hydraulic couplers are clean before

connecting to the tractor’s remote outlets.

IMPORTANT! Due to the variation in tractor hydraulic

systems and capacities, care should be exercised when

initially operating the sprayer hydraulic cylinders. It is

advisable to adjust the hydraulic flow control down to

the minimum rate before operating the system. Adjust/

increase the flow control after the system is bled of any

air, if necessary.

BOTTOM VIEW

12 HARDI®New NAVIGATOR OPERATOR’S MANUAL

Sprayer Setup

Hydraulics - standard joystick handle

Installation of handle

1. Attach the control handle/joystick (A

Fig 9

) to the

hydraulic lever that operates the double acting outlet

to be used. The universal mounting bracket (B

Fig 9

)

is very flexible and a number of different mounting

positions can be used.

2. Connect the plug (C

Fig 9

) to the tractor’s 12V

power system. Try to hook-up the handle as close

as possible to the battery power supply. HARDI®

recommends using an electric distribution box (ref.

no. 817925) to ensure a good power supply to

various 12V attachments.

Note: Check with your dealer or tractor operator’s

manual for the best location to hook up the 12V system.

Note polarity:

BROWN wire = Positive (+)

BLUE wire = Negative (-)

3. Connect electric plug (D

Fig 9

) from sprayer’s

hydraulics to plug (E

Fig 9

) on handle.

Hydraulic lever

A

B

C

D

E

Fig. 9

Direct Acting Hydraulic system (D.H.)

Installation of control box

1. Connect the plug (A

Fig 10

) to the tractor’s 12V

power system. Try to hook up the handle as close

as possible to the battery power supply. HARDI®

recommends using an electric distribution box (ref.

no. 817925) to ensure a good power supply to

various 12V attachments.

Note: Check with your dealer or tractor operator’s

manual for the best location to hook up the 12V system.

Note polarity: BROWN wire = Positive (+)

BLUE wire = Negative (-)

2. Route the cable, with the 7 pins, from the hydraulic

mount plate to the tractor.

3. Mount the hydraulic control box (B

Fig 10

) in a

suitable location in the tractor cabin.

4. Connect the female 7 pin plug (C

Fig 10

) from the

switch box to the 7 pin male plug (D

Fig 10

) from the

sprayer.

C

D

B

A

Fig. 10

13HARDI®New NAVIGATOR OPERATOR’S MANUAL

Connecting electric controls

The control box for ECP or ECPC controls should be

mounted at a convenient place in the tractor cab. The

control box has 4 screw holes in the back cover which

need to be drilled out for mounting on a flat surface

(using the mount plate, bracket and hardware furnished

with the sprayer).

There should be a minimum of 8 amp fuse protecting

this circuit. Power requirement is 12 volt DC.

Note polarity:

Brown pos. (+)

Blue neg. (-)

The wires must have a cross-sectional area of at least

12wg (4mm2) to ensure sufficient power supply. The

boxes must be fused according to the following table.

Use the optional HARDI®Electric 12 volt outlet box

(#817925 -

Fig 11

) if more than one power outlet is

needed.

Disconnecting sprayer

Always clean the sprayer inside and outside before

disconnecting and parking it. See

Cleaning

(pp. 28-29).

Before disconnecting the sprayer from the tractor, make

sure the support jack is properly fitted.

WARNING! To prevent the sprayer from tipping

over, do not disconnect the sprayer from the

tractor with the boom unfolded, unless the

boom is securely supported.

Place stop wedges in front of and behind wheels.

Remember to disconnect all hoses and cables from the

tractor.

WARNING! If the sprayer is parked unattended,

avoid unauthorized persons, children and

animals having access to the sprayer.

Sprayer Setup

Before operating sprayer

Although the sprayer has had a strong and protective

surface treatment applied to steel parts, bolts, etc. in

the factories, it is recommended to apply a thin layer of

anti-corrosion oil to all metal parts, hoses and tires.

There are many factors that affect the selection of

protective oils, such as temperature and humidity,

and exposure to UV, salt and chemicals. Your local

distributor of oil products will be able to advise on the

best specific formula for you local conditions. If this is

done before the sprayer is put into operation for the first

time, it will always be easy to clean the sprayer, avoid

chemicals discoloring the protective coating, and keep

the coatings shiny for many years.

This treatment should be carried out every time the

protective film is washed off.

Transport

Roadworthiness

Slow moving tractors and spray equipment can create

a hazard when on public roads. Make sure the S.M.V.

sign is in place and clearly visible from the rear of the

sprayer (

Fig 12

).

NOTE! Max. driving speed is 15 mph (25 km/h).

Rear lights

Local regulations may require the use of flashing

warning lights. Connect plug for rear lights to the

tractor’s 7-pin socket, and check function of rear lights,

stop lights and direction indicators on both sides before

driving.

Fig. 11

Fig. 12

14 HARDI®New NAVIGATOR OPERATOR’S MANUAL

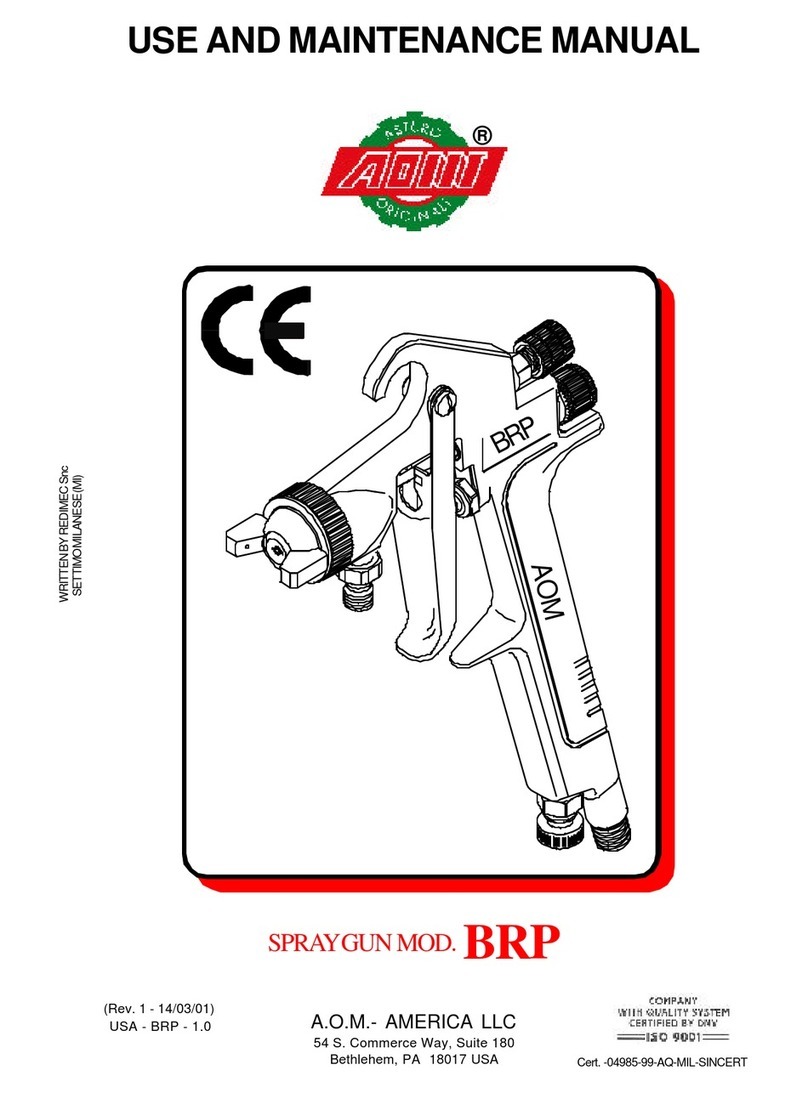

Adjusting boom transport position

If the boom wings do not rest accurately in the

transport brackets, the hydraulic fold cylinders can be

adjusted so the wings stop at the right position above

the transport brackets (

Fig 13

).

Fig. 14

The cylinders can be adjusted as described below:

1. Lift the boom all the way to the top.

2. Fold the boom into transport position. With the fold

cylinder pressurized, determine if the boom wings

need to be adjusted inwards or outwards.

3. Relieve the pressure from the fold cylinder by

unfolding the boom a few inches.

If the boom rests too far in on the transport brackets,

loosen the nut (B

Fig 14

) and adjust collar (A

Fig 14

)

in towards the cylinder housing.

If the boom rests too far out on the transport brackets,

the collar (A

Fig 14

) has to go out from the cylinder

housing.

4. Secure jam nut (B

Fig 14

).

5. Pressurize the cylinder to see if the boom is properly

adjusted. If not, repeat the above procedure until it is

correctly adjusted.

Sprayer Setup

Transport bracket settings

The transport brackets on the New Navigator for the

Eagle™ SPB and SPC booms are installed at the fac-

tory and have no adjustment.

The rear transport lock is adjustable, but is set at the

factory according to the boom installed on the sprayer.

This should not need adjustment unless a different

boom is installed on the sprayer.

WARNING! Always measure the actual total

height of your sprayer to be sure that there is

plenty of clearance at all times while trans-

porting the sprayer.

Eagle™ Transport bracket

Fig. 13

15HARDI®New NAVIGATOR OPERATOR’S MANUAL

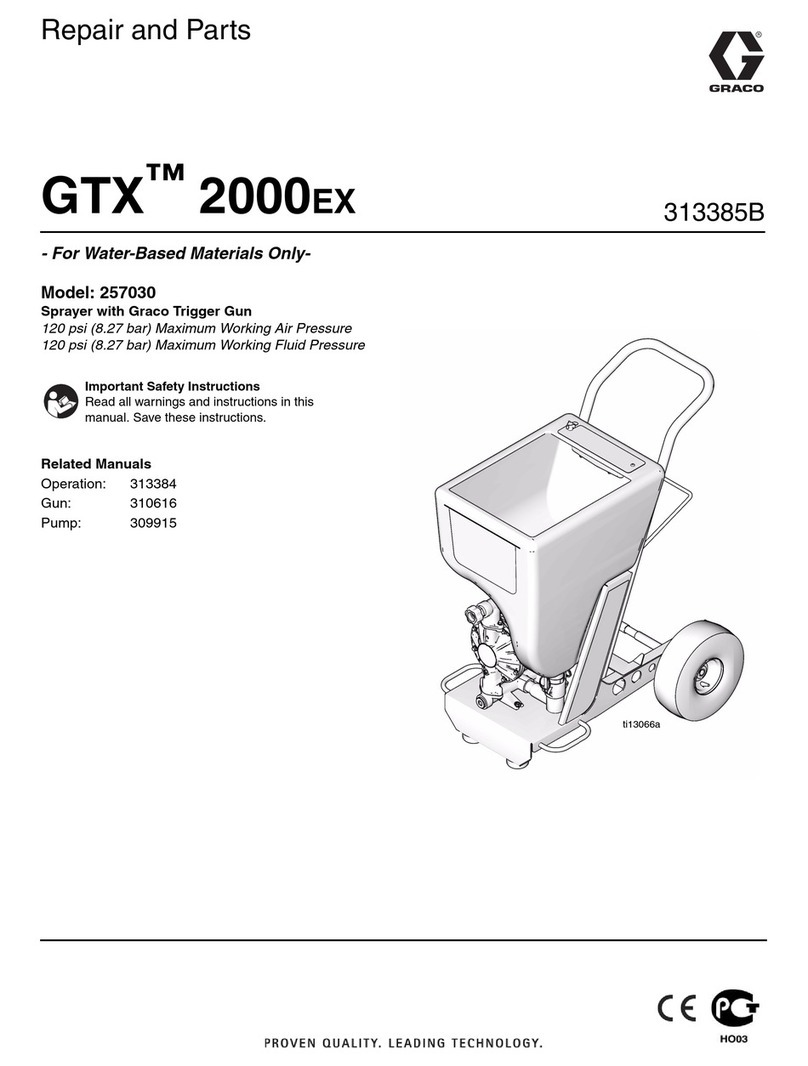

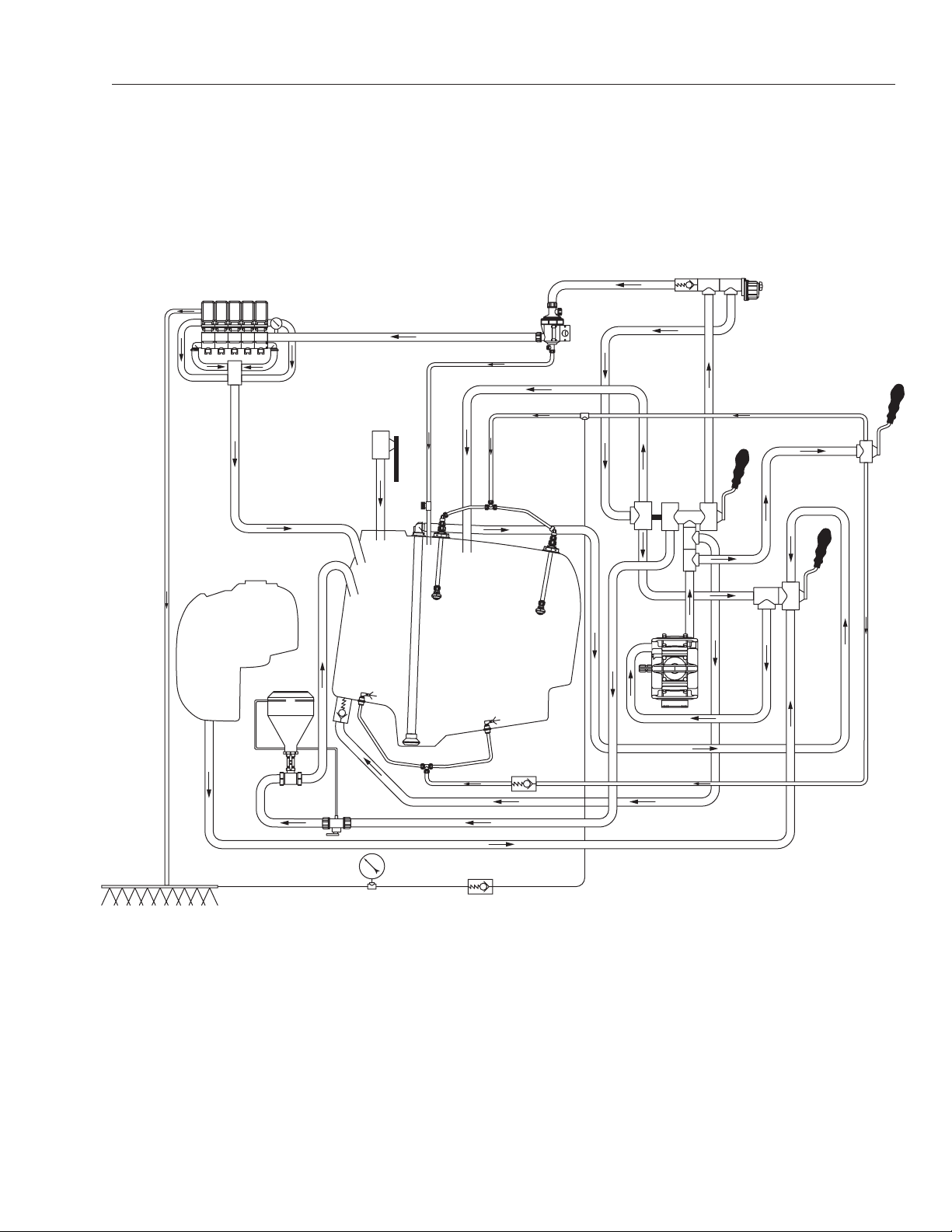

The HARDI®New NAVIGATOR trailer sprayer is available with either diaphragm or centrifugal

plumbing systems. Take time to review and study the plumbing diagram for your sprayer. By

following the flow through the diagram, you will better understand the various functions of your

sprayer system.

1. Suction filter

2. Suction manifold

3. Pump

4. Pressure manifold

5. Agitation

6. Safety valve

7. HARDI-MATIC

8. Return line (Self-cleaning filter)

9. Self-cleaning filter

10. Check valves

11. Boom section valves

Operation

ECP PLUMBING DIAGRAM (for diaphragm pump systems)

12. Pressure equalization return

13. Boom

14. Boom pressure gauge

15. Flush tank

16. Quick fill

17. Variable Agitation manifold

18. HARDI®chemical inductor

19. Tank rinse nozzles

20. Self-cleaning filter shut-off

21. Return by-pass

1

2

3

4

5

5

9

11

12

13 14

15

16

18

19

19

10

10

8

20

10

6

21

17

7

16 HARDI®New NAVIGATOR OPERATOR’S MANUAL

Operation

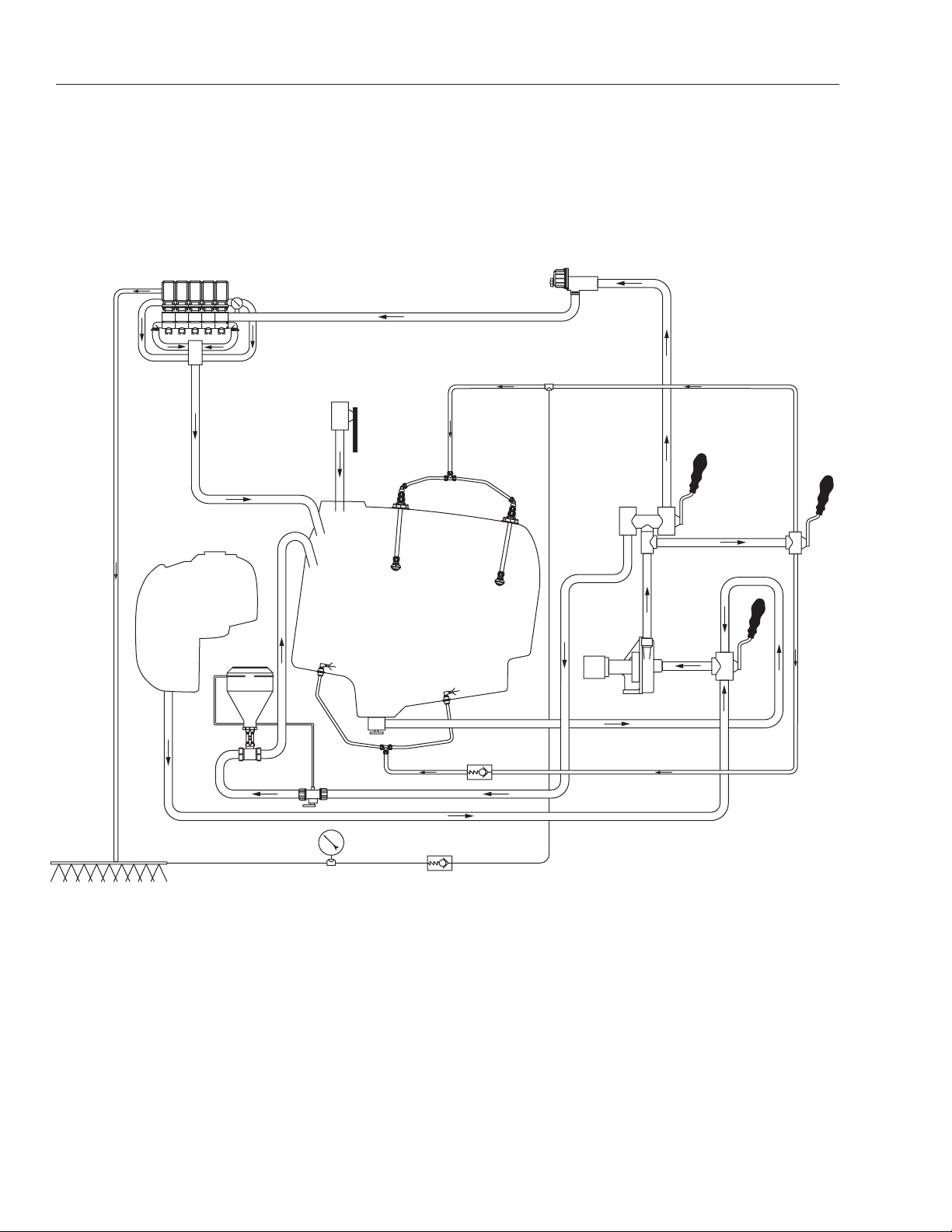

ECPC PLUMBING DIAGRAM (for centrifugal pump systems)

The HARDI®New NAVIGATOR trailer sprayer is available with either diaphragm or centrifugal

plumbing systems. Take time to review and study the plumbing diagram for your sprayer. By

following the flow through the diagram, you will better understand the various functions of your

sprayer system.

1. Bottom Suction Valve

2. Suction manifold

3. Pump

4. Pressure manifold

5. Agitation

6. HARDI-MATIC

7. Boom section valves

8. Boom

9. Boom pressure gauge

10. Flush tank

11. Quick fill

12. Variable Agitation manifold

13. Pressure equalization return

14. HARDI®chemical inductor

15. Tank rinse nozzles

16. Check valves

2

5

5

13

89

10

14

15

15

1

3

6

7

16

16

11

4

12

17HARDI®New NAVIGATOR OPERATOR’S MANUAL

Operation

Operation

The HARDI®SMART VALVE system is located on

the left hand side of the sprayer. This 3-part plumbing

control system permits easy operation of the HARDI®

NAVIGATOR sprayer.

Operation of spraying functions:

• Use the SELECT FUNCTION handle (upper right)

to select the desired function. Note that function

icons shown within the Green outer ring (e.g.

SPRAY MAX AGITATION), indicates the source of

fluid is the Main Tank. Function icons within the Blue

inner ring indicate fluid supplied from the Flush Tank

(optional system).

• Use the SELECT SOURCE handle (lower right)

to select the correct source of the water and/or

chemical solution. Note the color coding: Green for

main tank and Blue for flush tank (optional system).

• Use the Variable Agitation handle (left) to conrol the

amount of flow through the agitation nozzles. It also

operates the Rinse nozzles (optional).

IMPORTANT! Always ensure the indicator arrows

on the handles are carefully aligned with the the

corresponding arrows on the decal. Misalignment

may result in incorrect fluid movement.

NOTE! All fluid system options are shown in this

manual. If your sprayer is not equipped with all

options, some of the selections shown may not be

possible on your sprayer without adding additional

equipment (e.g. HARDI®Chemical filler).

Filling tanks with water

WARNING! Do not overfill any tank as this may

cause chemical spillage out of the tank.

Tank capacities

(U.S. Gallons) (Liters)

Main Tank 1100 4000

Foam Marker Tank 20 or 40 75 or 150

Flush Tank 130 (Nav 1100) 500 (Nav 5000)

Clean Water Tank 4 15

Water can be filled into the tanks in the following ways:

1Filled through tank lids (All tanks).

2Filled by external water supply through the quick fill

system (main tank only).

The main tank should normally be filled with 25% of the

required spraying water before adding the chemicals.

IMPORTANT! Always read the instructions on the

chemical container.

IMPORTANT! The clean water handwash tank is filled

separately to ensure that there is no risk of chemical

solution moving from the valve system into handwash

water.

IMPORTANT! It is recommended to use water as clean

as possible for spraying purposes.

Filling through tank lids

Handwash (clean water) tank

Screw open the clean water tank lid and fill with clean

water only.

IMPORTANT! The water from this tank is only for hand

washing, cleaning blocked nozzles, etc.

WARNING! Although the Handwash tank is

only filled with clean water, the water must

never be used for drinking, due to the small risk

of contamination while filling, etc.

SPRAY

SPRAY

BYPASS

TO

SUCTION

BYPASS

TO TANK,

PRIME,

MAX AGITATION

SELECT FUNCTION

OFF

SELECT SOURCE

MAIN

TANK

97608703

SAFETY

VALV E

PURGE

CHEM

FILL

FLUSH CHEM

FILL

FLUSH

BOOM

OFFOFF

FLUSH

TANK

FLUSH

TANK

FLUSH

TANK

18 HARDI®New NAVIGATOR OPERATOR’S MANUAL

Operation

Flush tank (optional system)

Screw open the flush tank lid and fill with water.

Foam marker tank (optional)

The fill inlet for the foam marker tank is found to the

right of the Hardi®Navigator Smart Valve Control Panel

as shown in (

Fig 15

).

Main tank

Screw open the main tank lid and fill with water through

the strainer to prevent rust or other particles entering

the tank.

An overhead tank will allow high filling capacity.

WARNING!

Do not let the filling hose etc., enter

any tank. Keep it outside the tank, pointing

towards the filling hole. If the end of the hose

is beneath the surface of the tank contents,

and the water pump at the water supply plant

stops, chemicals could be siphoned back and

contaminate water supply lines.

Quick Fill (Optional)

The optional QUICK FILL allows the operator to

connect a hose from a water supply (i.e. overhead fill

tank), and fill the main tank.

WARNING! Do not fill tank so rapidly that air

cannot escape - tank may rupture.

General Quick Filling guidelines

1Remove the camlock plug from the front of the quick

fill valve (

Fig 16

).

2Connect the filling hose from the water supply.

3Open the quick fill valve and fill tank to desired level.

4Close the quick fill valve and remove filling hose.

5Remember to re-fit the camlock plug to the quick fill

coupler when filling is complete.

Fig. 16

Fig. 15

Table of contents

Other Hardi Paint Sprayer manuals

Hardi

Hardi Delta Force Boom User manual

Hardi

Hardi BL Series User manual

Hardi

Hardi Boss Series User manual

Hardi

Hardi ES 50 User manual

Hardi

Hardi Front Tank User manual

Hardi

Hardi NAVIGATOR DELTA User manual

Hardi

Hardi LX-MB Series User manual

Hardi

Hardi EAGLE SPB BOOM User manual

Hardi

Hardi Commander Plus Operating instructions

Hardi

Hardi BPE18 User manual

Hardi

Hardi Eagle Boom User manual

Hardi

Hardi PRESIDIO 2700 User manual

Hardi

Hardi Navigator 3100 User manual

Hardi

Hardi Ranger Series User manual

Hardi

Hardi N Series User manual

Hardi

Hardi MARRO TWIN FORCE 1000 User manual

Hardi

Hardi ES 30 User manual

Hardi

Hardi ZEBRA AXIAL User manual

Hardi

Hardi ATV Series User manual

Hardi

Hardi RANGER PRO User manual