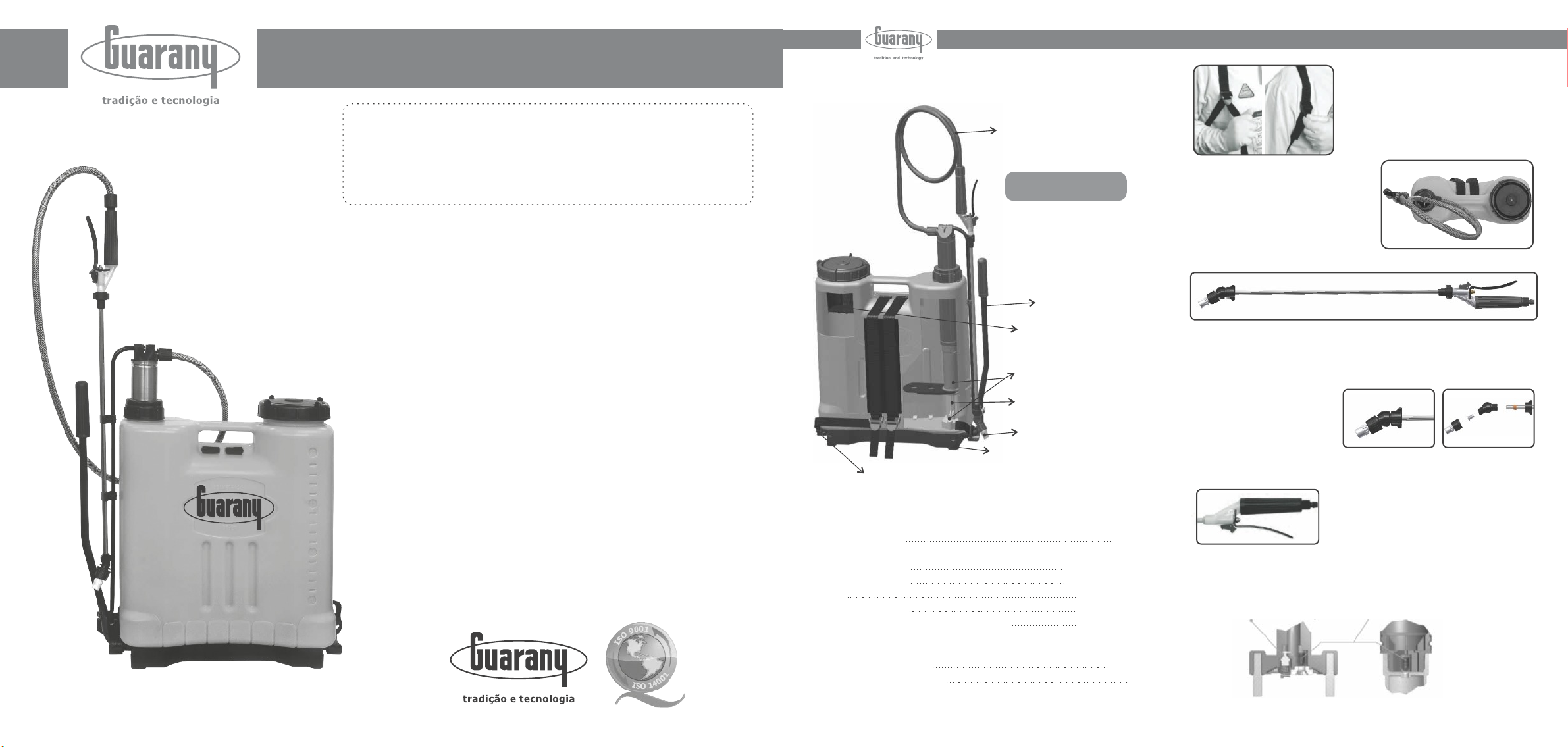

Horizontal Rear Boom

U9888.00.00

8. LIST OF ACCESSORIES

Vertical Rear Boom

4 Nozzles: U9898.00.00

6 Nozzles: U4288.00.00

Universal Boom

200 mm: K9798.00.00

400 mm: K9895.00.00

500 mm: K9960.00.00

Liquid Metering Device

U4575.00.00

U7860.00.00

Weed Control Shield

Dosimeter Valve

With applicator pipe: U8018.00.00 0,9m: K4281.00.00

Without applicator pipe: U8096.00.00 1,2m: K4280.00.00

Universal S3 Discharge Set

(with Hose Connection)

U9537.00.00

Telescopic Discharge Lance

with Valve (1 Nozzle)

U9767.00.00

Rotary Nozzle Discharge Set

U4750.00.00

2 Nozzle Discharge Set

U4222.00.00

Discharge Tube

U9634.00.00

Flowrate Regulator with Pressure Gauge

OPERATOR’S MANUAL | Symetrical Knapsack Sprayers SP

09. WARRANTY CERTIFICATE

Guarany together with its accredited resale network and subject to the limits set by this Certificate

provides for the initial purchaser and user of this product, a warranty against any defects caused in the

manufacturing process. The Guarany technical assistance warranty covers the entire line of its

products.

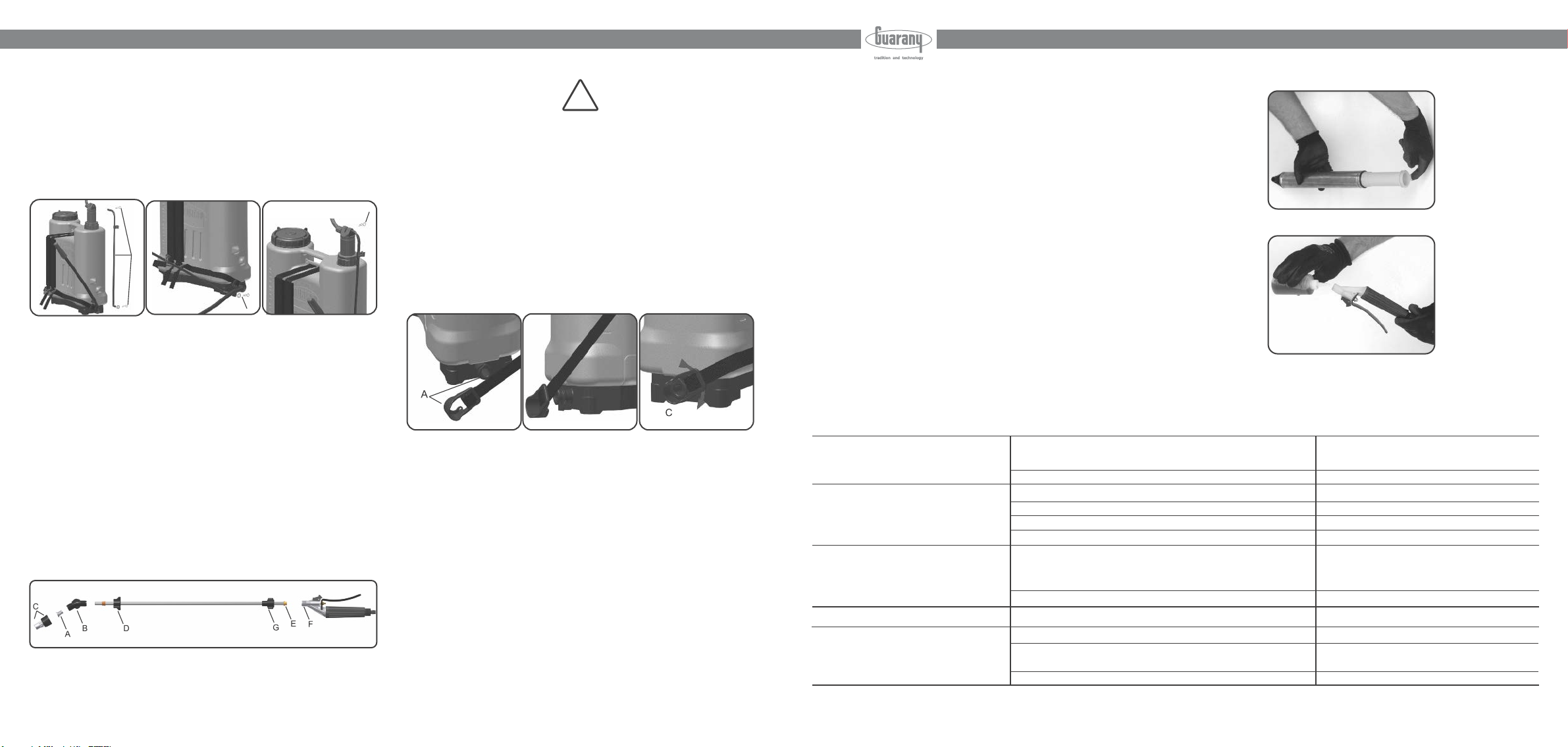

GENERALCONDITIONSOFWARRANTY:

1-Guaranyprovidesthepurchaserthefollowingguarantees:

EquipmentLine: 1year.

ConsumerLine:90 days.

Furthertothe conditions establishedinitem 5, anyclaiminvoking this warrantymust be accompanied

bythe originalinvoiceto provethepurchase dateoftheproduct.

2 - For the full application of this warranty the buyer must return the product to an authorized Guarany

retail outlet (dealer). All costs and risks for shipping the product back to our dealer and its subsequent

return are the responsibility of the buyer. No claim for compensation or reimbursement of

transportation expenses will be accepted by Guarany or their agents. Any such repair is considered to

bean "overthecounter" repair, i.e.,theequipmentisrepairedbythedealer.

3- Ourdealers areauthorized toreplace thedefective partswith originalparts orGuaranyalternatives,

while maintaining and respecting the equivalent integrity of the equipment's quality and performance.

Any equipment parts removed during the repairs performed under warranty become the property of

Guarany.

4-The followingitemsarenotcoveredbythiswarranty:

4.A-Incorrectassembly,installationoruse.

4.B-Components thatcanwearout naturallythroughregularuse ofthe equipmentsuchas:

O-rings, membranes, gaskets, valves, pistons, rings, bushings, drive-belts, hoses, pressure gauges,

bearings, spark plug, parts supplied in the kit that came with the product as well as components in

permanentcontactwithagrochemicals.

5-The warrantywillbe automaticallycancelled ifor when:

5.A-The equipmentis improperlyinstalled, assembledorused;

5.B-The equipmentcontainsanynon-originalpartsorcomponents;

5.C - The equipment was not used in accordance with the procedures described in our technical

bulletinandinstructionmanualprovidedwithallourproducts;

5.D - There has occurred any mistreatment such as: damage; impact; dropping; bumping or if there

areholes foundinthetank;

5.E - The equipment has been connected to a power supply with a voltage other than that specified on

theequipmentand/orintheinstructionmanual(110or220V);

5.F-Whenever theoil/fuelmixindicatedinourmanual isnot respected.

5.G-Repairs havebeenmadebyanyperson orentity notauthorizedbyGuarany;

5.H-There hasbeen anyviolationoftheinternalorexternal originalfeatures;

5.I-Used bynon-qualified persons;

5.J-There hasbeen negligencein thecorrectiveorpreventivemaintenance;

5.K-The equipmenthas undergonechangesthataffectits function,stabilityor safety;

5.L-Erasures ortampering oftheserialnumberor invoicehaveoccurred.

6 - This warranty is limited to the repair or replacement of defective parts; no other expressed or

impliedwarrantyisgiventothe buyer;

7 - Guarany is not responsible for any damage, loss, inconvenience, direct or indirect losses that may

arise from misuse of its products, or from the use of harsh or inappropriate chemicals or products not

compatible with the components in our equipment (any questions, doubts or concerns regarding

these items must be referred to an authorized dealer or retailer or directly through our telephone

customerservice number+55112118-8400)

8 - Claims for missing parts and accessories will be accepted only at the time of purchase and in the

presenceofarepresentativefromaGuaranyauthorizedretailer/dealer.

9 - Guarany will continue to provide spare parts for our products for a period of up to five (5) years

fromthe dateonwhichthefactory discontinuestheproduct.

10 - Guarany reserves the right to make technical changes to improve the product without prior

notice.

IMPORTANT:

*Tokeep yourproductoriginalandwiththesameoperationalquality,use onlyour authorizednetwork

(see our site www.guaranyind.com.br) ensuring the use of original replacement parts and skilled

labour.

* For any questions about the use of our equipment and products please consult our local distributor

* For possible claims covered by this Warranty Certificate, the invoice should be retained during the

warrantyvalidityperiod.

* By purchasing this product, the purchaser agrees that Guarany may review, modify, enhance,

discontinue or change the equipment, parts or components at any time, as well as maintaining the

expressedconditionsinthiscertificatewithoutincurringanyliability orobligationrelative tothe client;

* Our responsibility is limited to the terms of this warranty. The warranty is not transferrable and

ceasesautomatically incaseofequipmentresale.

HOWTOUSETHEWARRANTY:

To qualify for these guarantee terms, the customer must make a claim at one of our technical

assistancepoints whichare dulyregistered inthe "nationalnetwork" index;if the regiondoes nothave

a service point, the claim must be made at the store or distributor where the equipment was

purchased.

The defects should be thoroughly described in the defect claim form which can be obtained from our

technical assistance points or sales offices. The completed claim form should be delivered to the

technical assistance point together with the product requiring servicing and a copy of the original

invoice.

*Consult ourproductlineinthe websitewww.guaranyind.com.br