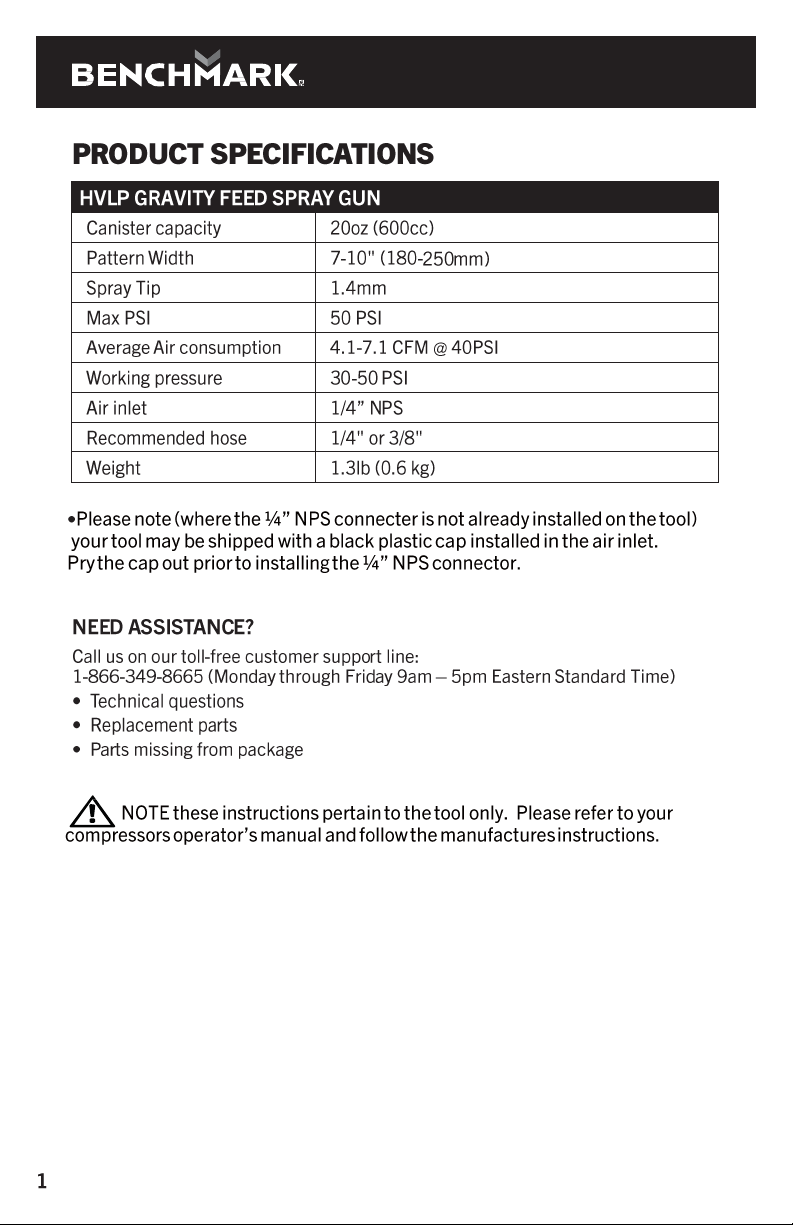

Benchmark 1282-113 User manual

Oxygen

nydrogen

Combustible

explosive

SYMBOL MEANING

6

Recycle unwanted materials rather than disposing of them as waste. Sort the tools,

hoses, and packaging in specific categories and take to the local recycling center or

dispose of in an environmentally safe way.

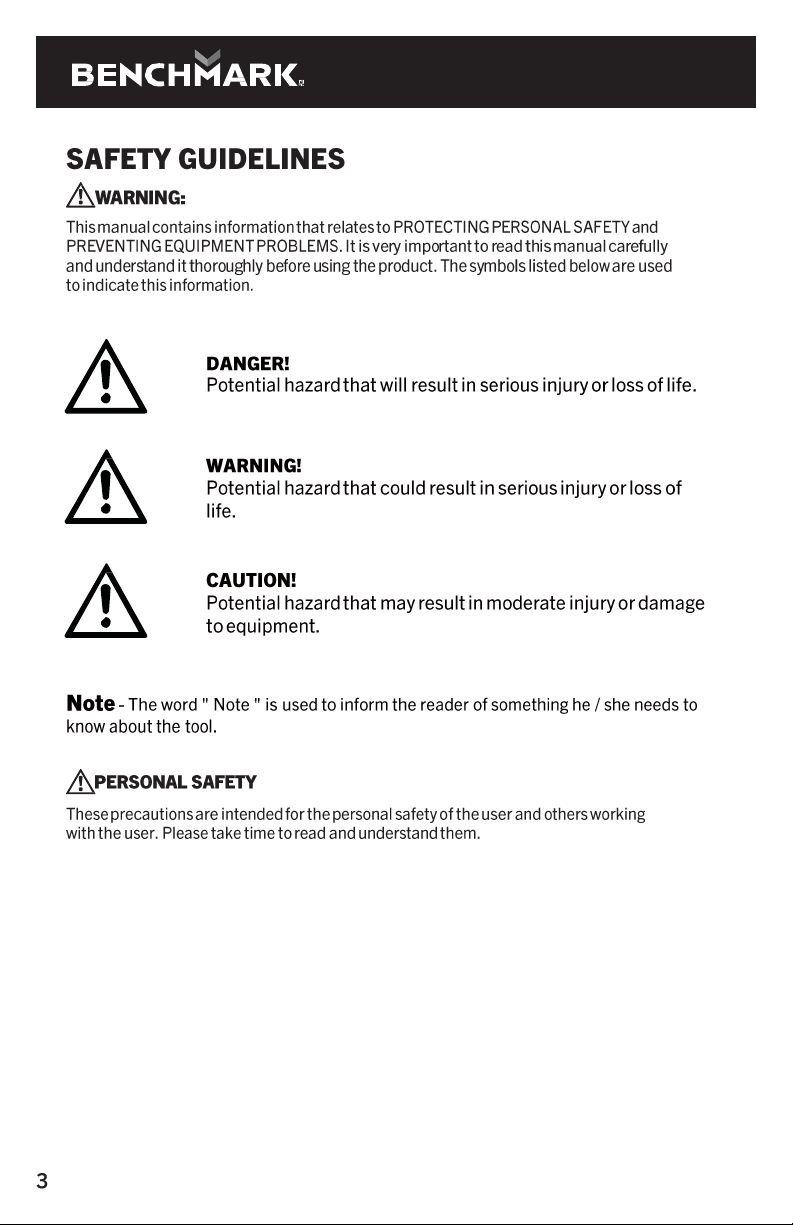

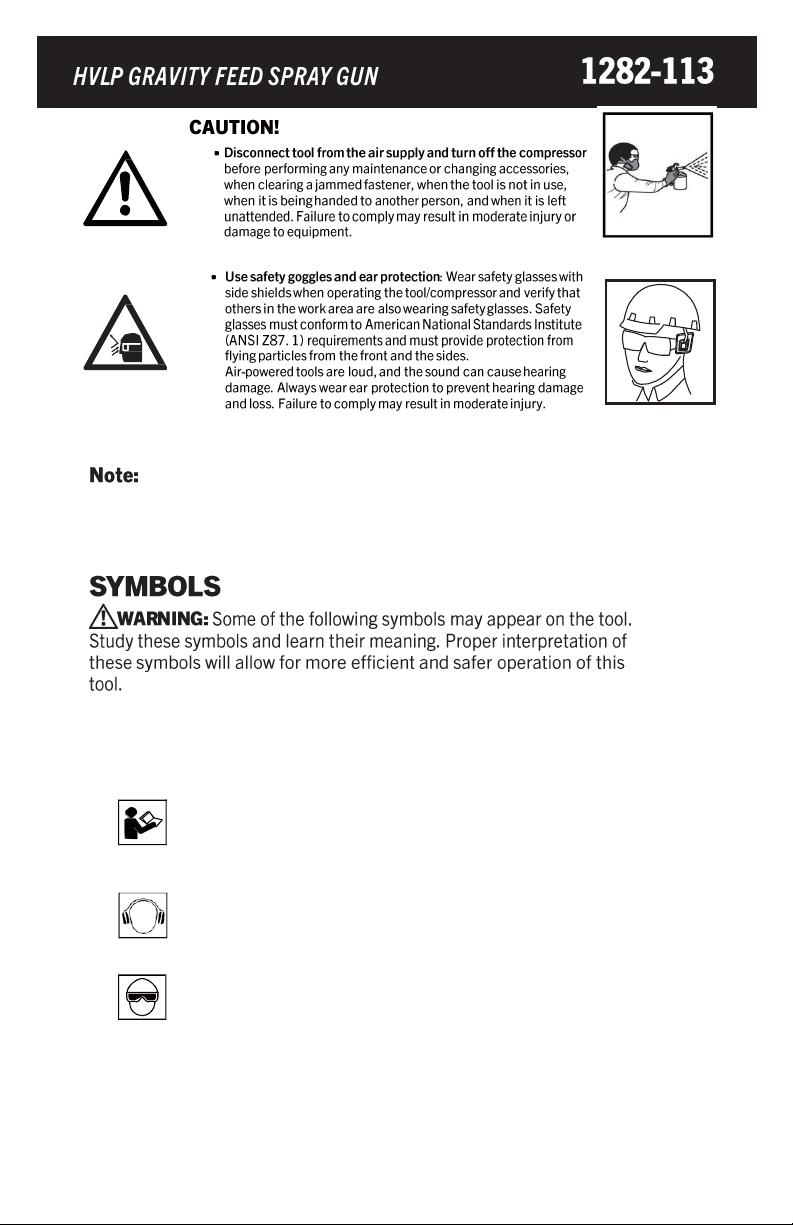

SYMBOLS

Read operator s manual: To reduce the risk of injury,

user must read and understand operator’s manual

before using this product.

Eye protection: Always wear safety goggles, safety

glasses with side shields, or a full-face shield when

operating this product.

Risk to hearing Always wear ear prptection

when using this tool ,failure to do so may result

in hearing loss.

7

Use safety respirator: Toxic vapors produced by spraying certain

materials can cause serious damage to health.

Always wear safety gloves and a respirator to prevent hazards caused by

inhaling toxic vapor or contact of solvent and paint with eyes or skin.

Failure to comply may result in moderate injury.

Ensure proper tool operation before painting. Before painting, inspect to

ensure free movement of the trigger and nozzle.

Check the tightness of screws before operating the tool. Before operating

the tool, make sure all the screws and caps are securely tightened to

prevent leakage.

Keep the work area clean. A cluttered or dirty workbench may lead to an

accident. Floors should be kept clear.

Handling and storage of paint: Use with adequate ventilation. Avoid

contact of paint with eyes, skin, and clothing. Avoid breathing spray

or mist. Store in a tightly closed container in a cool, dry, well-

ventilated area free from incompatible substances.

Disconnect the spray gun from the air supply hose and turn off the

compressor before performing any maintenance when the tool is not in

use, when it is being handed to another person, and when it is left

unattended. It is recommended to use a ball valve in the gun to air

supply for emergency stoppage and to prevent unintended

operation

8

9

10

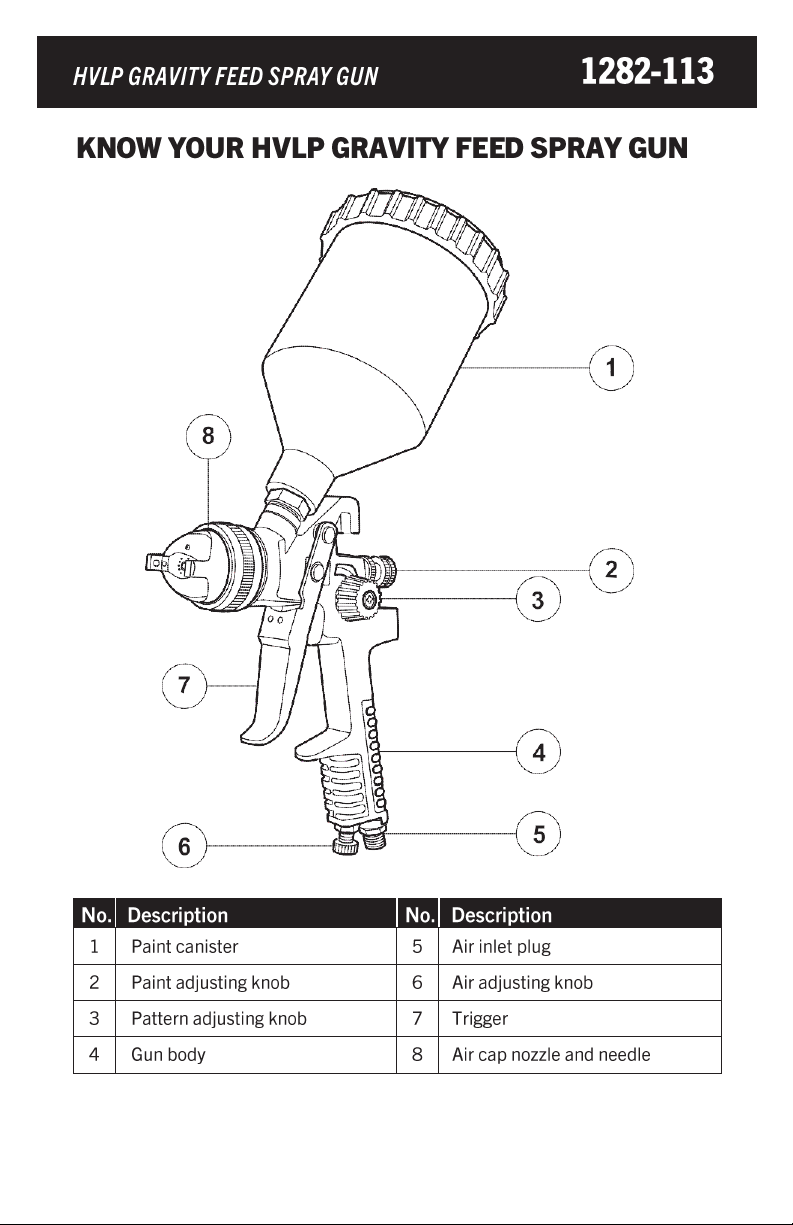

2 5 7

3 3 8

1 9

6

4

Keep hands and other parts of the body away from the work areas when connecting the tool

to the air supply. Failure to comply could lead to serious injury or loss of life.

It is recommended that a filter-regulator-lubricator be used and be located as close to the tool

as possible.

If a filter-regulator-lubricator is not installed, place 2 to 3 drops of oil into the air inlet

plug before each use.

If a filter-regulator-lubricator is installed, keep the air filter clean. A dirty filter will reduce the

air pressure to the tool, which will cause a reduction in power, efficiency, and general

performance.

For optimal performance, install a quick connector to the tool and a quick coupler on the

hose, if applicable.

Verify that all connections in the air supply system are sealed in order to

prevent air from leaking. Failure to comply may result in moderate injury or

damage to equipment.

Read all safety guidelines (see section "Safety guidelines”) at the beginning of this manual.

Always inspect the air tool prior to each use to

-

ensure proper use of power source.

-

determine whether the tool is in proper working order.

Clean the air inlet in the filter weekly.

Line pressure should be increased to compensate for unusually long air hoses. The hose

diameter should be 1/4" or 3/8”.

Do not use the tool if it is not in proper working order.

Do not use oxygen or any other combustible or bottled gas to power this tool.

Do not use this tool in the presence of any flammable liquids or gases.

Keep hose away from heat, oil, and sharp edges. Check hose for wear and

tear, ensure that all connections are secure. Failure to comply could lead to

serious injury or loss of life.

Mixing and thinning of paint should be performed in accordance with the paint

manufacturer’s instructions. Most materials readily spray if thinning is properly

performed.

Do not exceed the thinning recommendations of the paint manufacturer.

Failure to comply may result in moderate injury or damage to equipment.

1 . Attach the empty canister ( 1 ) to the

spray gun by lining up the threads then

holding the gun stationary and twisting

the canister clockwise until snug

.

Note : Do not tighten the canister too much by

hand , as doing so may break the plastic

canister.

2 . Use the wrench provided and tighten the

nut ( 1 ) securely to ensure paint does not

leak.

3 . Pour paint through a strainer , cheese

cloth or paint strainer to remove any

foreign substances from the paint.

4

. Fill the canister three quarters full with

paint.

5 . Plug in compressor , turn it on set the

pressure regulator to 40PSI , attach one

end of the air hose to the compressor

and

the other end of the air hose to the

spray

gun . The spray gun is now ready

for use.

6 . After connecting the spray gun to the air

supply , ensure the fluid cap , canister ,

and air hose are tightly connected to the

Air-powered Gravity-feed Spray Gun.

7. Use a piece of cardboard

or other scrap material as a

target for trial spraying and

adjust for desired spray

pattern.

8. Test the consistency of the

paint by making a few strokes

on a cardboard target. If the

stroke appears to be very

thick, add a small amount of

thinner.

1 . Plug in compressor , turn it on , set the

pressure regulator to 40 PSI , attach one

end of the air hose to the compressor

and

the other end of the air hose ( 1 ) to

the air tool

.

2

. Hold the gun ( 1 ) so that the nozzle is

approximately 6 " to 12’’ from the work

surface , perpendicular to the spraying

area.

Note : Do some practice sprays to check and

adjust the spray pattern and gun set up , using

a spare surface ( scrap piece of metal ).

3 . Squeeze the trigger ( 1 ) of the spray gun

( 2 ) . Start moving the gun before pressing

the trigger and release the trigger before

stopping the gun movement at the end

of each stroke . This procedure will blend

each stroke with the next without

overlap or unevenness

.

4 . Move the gun ( 1 ) at a constant pace in a

back and forth parallel direction .

maintaining a uniform distance from

the surface to be painted

.

5 . Repeat the strokes until a uniform

coating is formed.

note: Use a piece of cardboard as a shield to

capture the loss of spray paint at the ends of

the wprkpiece to protect the other surfaces

from being painted.

The speed of stroke,the distance from

work surface, and the adjustment of

paint adjusting knob vary the amount of

paint being applied.

Do’s

DONT’S

Always move the gun in parallel direction

.

1 . Uniform coating region

2 . Stroke starting position

3 . Trigger pressing position

4 . Trigger releasing position

5 . Stroke stopping position

6 . Gun movement path

Do not press the trigger with the gun at an

inclined or angled position.

Do not stop the sprayer movement in between

strokes, as this will cause a build-up of paint

and result in runs.

1 . Improper / thin coating region

2 . Uniform / thick coating region

:

Two thin coats of paint, rather than one thick layer,will yield better results and have lesser

chance of runs.

Do not stop the sprayer movement in between,which will cause a build-up of

paint and result in runs .

Do not fan the gun while painting . This will cause a build-up of paint in the

centre of the stroke and an insufficient coating at the ends . Failure to comply

may result in moderate moderate injury or damage to equipment.

Rotate the paint adjusting knob in a counter-clockwise direction and open the knob

when the gun is not in use. This will reduce spring tension on the needie fluid tip.

Clean the Air-powered Gravity-feed Spray Gun thoroughly and silghtly lubricate it,

after the and before storage.

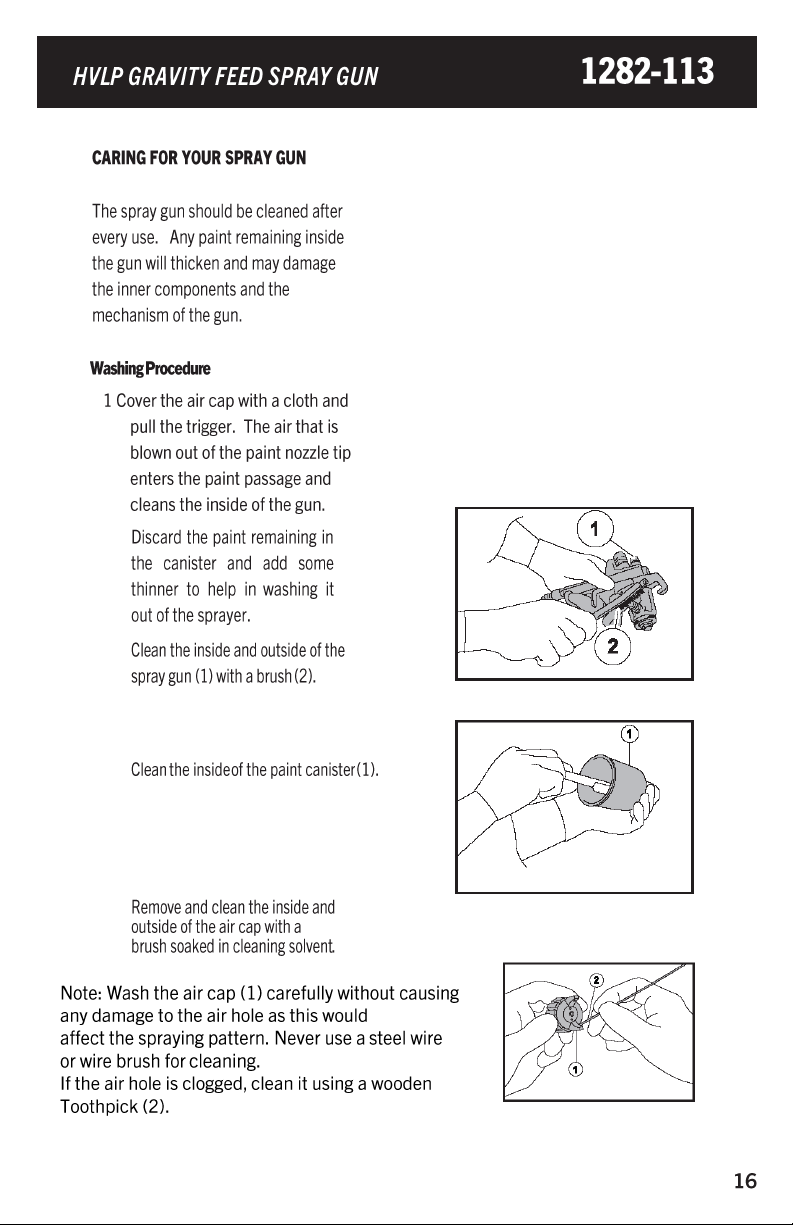

2.

3.

4.

5.

Lubrication: If the tool and the

compressor are not equipped with an in-

line lubrication system, place fill 2to3

drops of pneumatic tool oil into the air

inlet before each use or after every

two

hours of continuous use, depending on

the characteristics of the workpiec

18

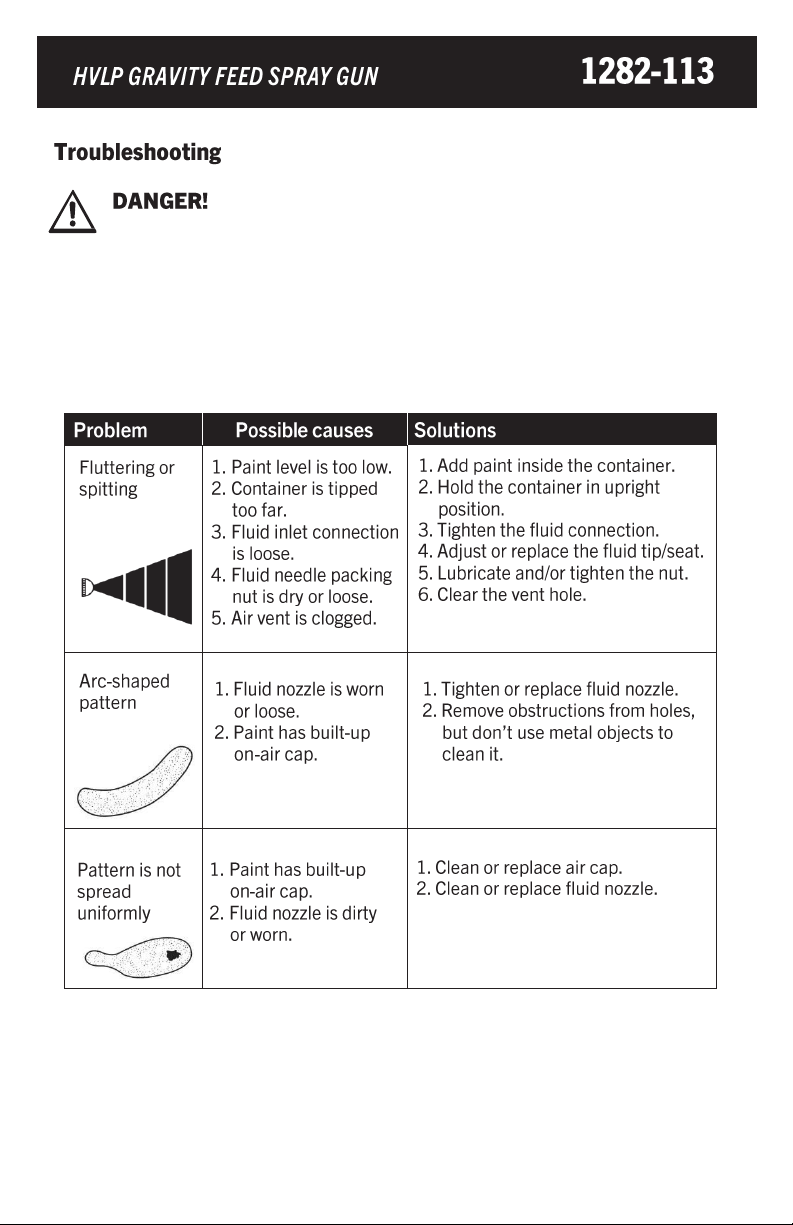

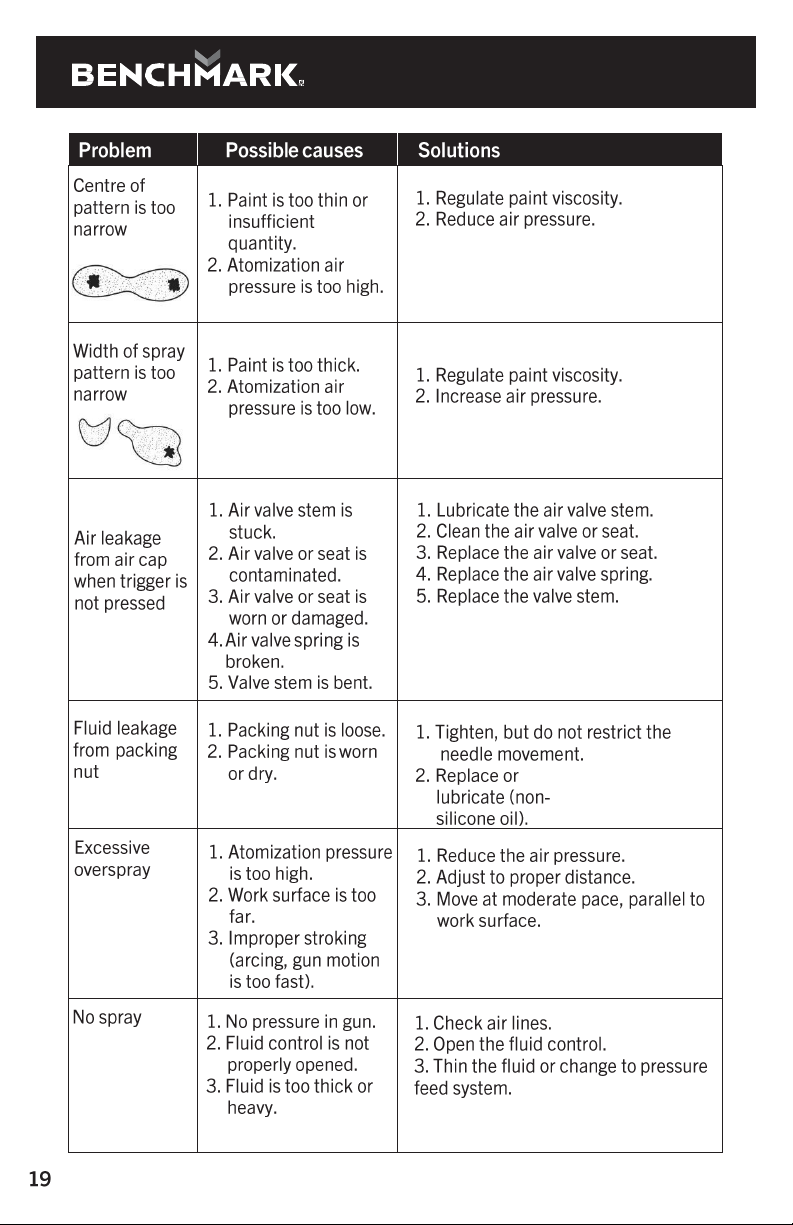

If any of the following symptoms appear while the tool is in use, turn it off

and disconnect it from the air supply immediately. Failure to comply will

lead to serious injury or loss of life.

Disconnect the tool from the air supply before making any adjustments.

Repairs must be performed by a qualified service technician only.

The following chart lists common issues and solutions. Please read it carefully and

follow all instructions carefully.

Other Benchmark Paint Sprayer manuals

Popular Paint Sprayer manuals by other brands

WAGNER

WAGNER WOOD&METAL EXTRA GRAVITY FEED manual

Parkside

Parkside PFS 400 A1 Translation of the original instructions

C.A. Technologies

C.A. Technologies CPR quick guide

MedPro

MedPro assura 007-710 instruction manual

Enduraplas

Enduraplas IceMaster Systems Liquid Master W Series owner's manual

Smithco

Smithco 300G255 Parts & Service