BENDEL 810 010 User guide

2

Ver. 2004-01

General information/how to use

This tool was developed for the centralized pushing back of brake pistons without jamming. To avoid

damage of the brake piston cuff, the piston or the piston bore in the brake caliper, we stress that the tool

can’t bechanged or used in a differentway than the intended use. Changes that lead totechnical progress

canbelaunchedbythemanufacturerwithoutpreviousnoticeandpossiblyarenotincludedintheinstruction

manual.

Safety instructions

To prevent false functions, damages or injuries, please always respect the following hints:

•In addition to the occupational safety instructions in this application note, the general

safety, accident prevention and environmental protection regulations applicable to the

area of application of the device must be observed and followed.

•People with any kind of handicapsare not allowed to use the brake piston tool if not being

supervised and instructed by a supervisor.

•Keep uninvolved people / children away from the work area.

•Never work under the influence of alcohol or drugs/medicine.

•Special knowledge or an explicit education is acquired forthe usage and repair of the tool.

•Only keep packaging parts (foils, plastic bags, styrofoam, etc.) in places that are not

accessible to children, especially infants,since packaging parts often harbor undetectable

dangers (eg risk of suffocation).

Intended Use

•The device must be checked for full functionality before each use. If the functionality is not

guaranteed after the result of this test or if damage is found, the tool must not be used.

Storage/maintenance

The device must be stored and kept under the following conditions:

•Never leave it outside, only dry and without access to dust. Ideal is lightly oiled

•Never expose to liquids and / or aggressive substances

•Never let children have access to the tool.

General safety information

Please read this manual in detail before the first use and don’t throw away this manual. Share the manual

with other users or give it along to a new user. The manufacturer is not liable for personal injury and

property damage due to wrong usage or other usage than mentioned in this manual.

Furthermore in these cases any warranty claims expire.

3

Ver. 2004-01

Application for floating calipers

1. Insert the ¼ “extension (F) from behind into the plastic

cap at the rear end of the brake piston tool (A) and

push the extension through the entire tool.

2. Take a feed spring (H) from the tool case and slide it

over the ¼ “square drive of the extension (F)

3. Take a suitable pin adapter for your brake piston from

an existing adapter set and ensure that the guide lugs

fit into the recesses in the brake piston

4. Place the selected pin adapter on the magnetic

adapter (E) and put both together on the ¼ “drive of

the ¼“ extension (F)

4

Ver. 2004-01

5. Push the release lever of the tool forward in the

direction of the arrow and push the magnetic adapter

(E) flush to the retaining plate.

6. Position the retaining plate between the brake piston

and the saddle frame.

7. Thread the pins of the pin adapter into the recesses

of the brake piston and clamp the reset between the

brake piston and the saddle frame by lifting

movements on the lifting calliper (A) until the feed

spring (H) is also tensioned.

8. Attach a ¼ “ratchet, a ¼“ lever or a ¼ “multi handle of

your choice to the rear of the ¼“ extension (F).

9. Turn the ¼ “extension (F) clockwise or

counterclockwise, depending on the direction of

rotation of the brake piston.

10. While turning, the feed spring (H) pushes the brake

piston back and thus resets it.

11. By pressing the trigger, you relax the reset and can

carefully remove it from the brake caliper.

5

Ver. 2004-01

Application for firm and fixed calipers:

1. Position the front pressure plate (C) and the rear

pressure plate (B) between the brake piston and the

caliper frame.

2. Make sure that the pressure plates ((B) + (C)) do not

tilt and do not damage the sleeves.

3. Carry out slight lifting movements and push the brake

piston back into its starting position.

4. Push the release lever forwards in the direction of the

arrow and use it to relax the brake piston reset device

before pulling it out of the brake caliper.

5. If there are 2 or more brake pistons, please take the

appropriate medium (F) or large adapter plates (E)

from the case.

6. Fit the side with the recess and the round 8.00mm

magnet in the 8.2mm hole of the pressure plates.

6

Ver. 2004-01

7. Position the front and rear pressure plate between the

brake pistons and the caliper frame and push the

brake pistons back with slight lifting movements.

8. Push the release lever forwards in the direction of the

arrow, relax the brake piston tool and pull it out of the

brake caliper.

Modification

How to convert the brake piston tool:

1. Remove the two safety pins and disassemble the

front and rear pressure plates.

2. Insert the ¼ “extension (F) from behind into the plastic

cap of the brake piston tool and push the extension

through the entire tool.

3. Take a feed spring (F) from the tool case and slide it

over the ¼ “square drive of the extension (F)

4. Proceed as mentioned in no. 3“Application for

floating calipers“.

7

Ver. 2004-01

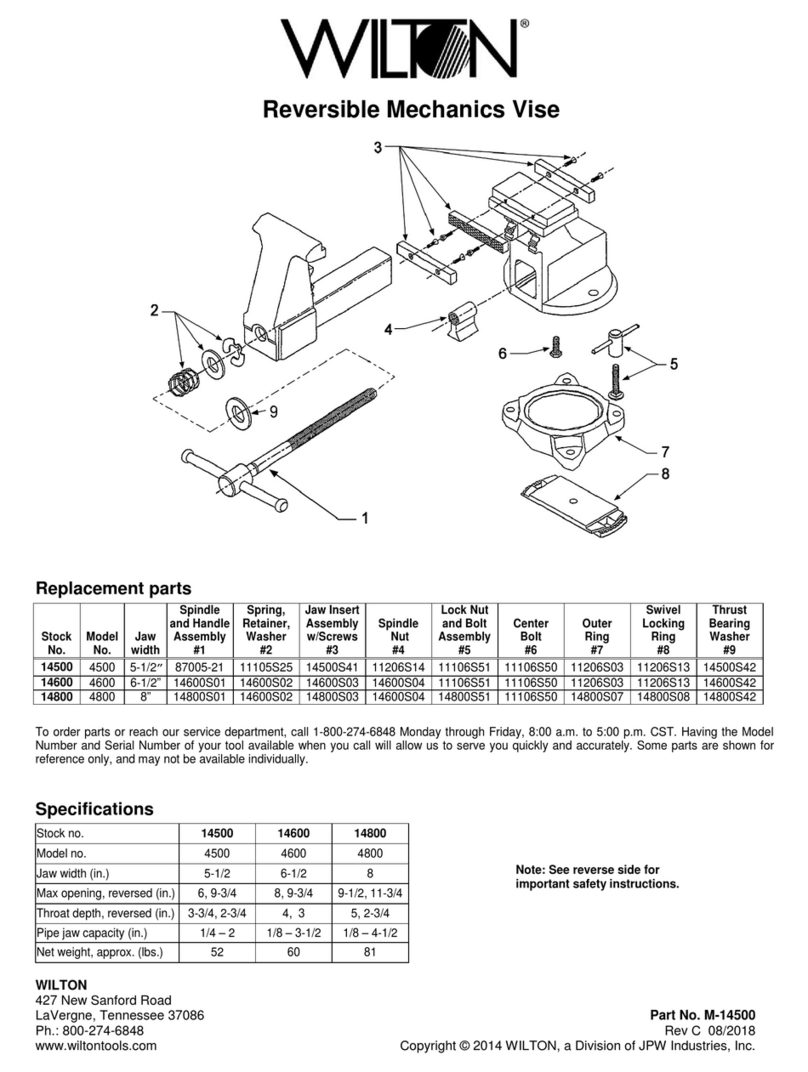

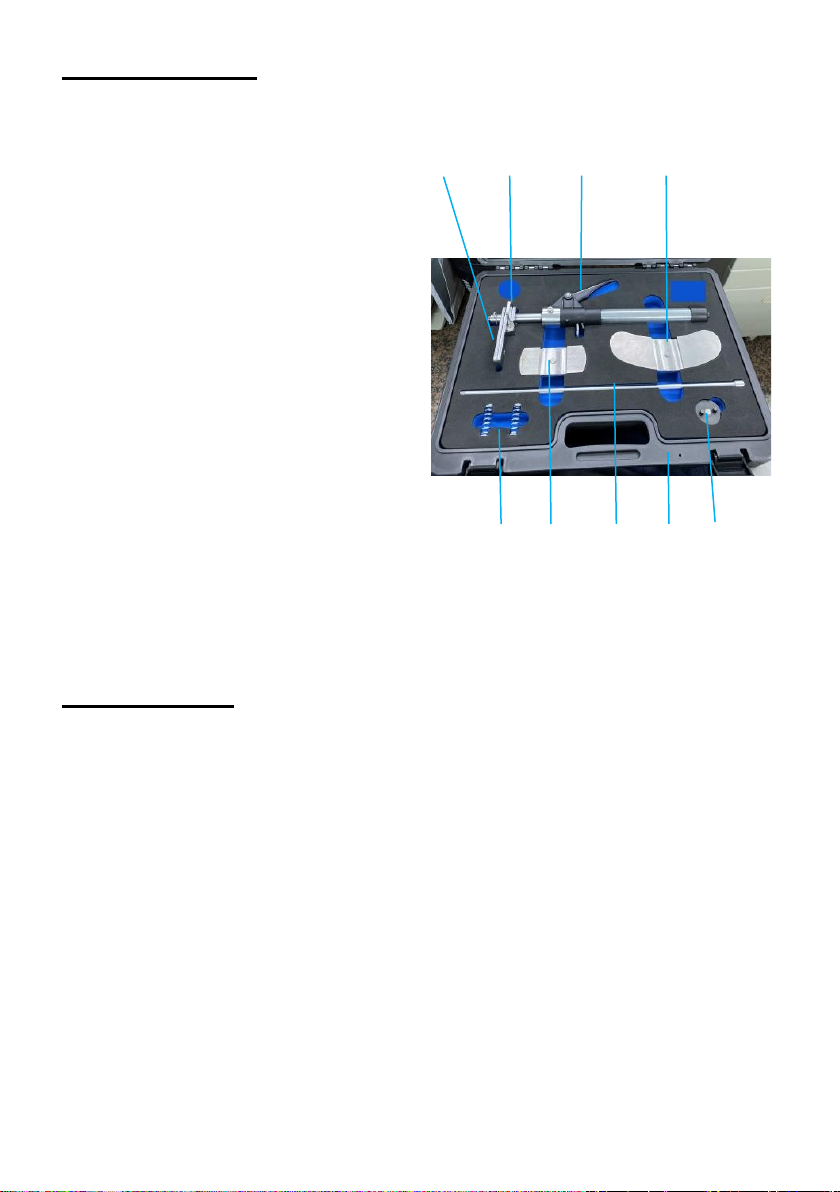

Scope of delivery

(A) Lifting pliers with pre-assembled

retaining plates

C B A G

(B) Rear pressure plate

(C) Front pressure plate

(D) ¼“ extention

(with ¼” square drive)

(E) Magnet adapter

for pin-Adapter

(F) Adapter pressure plates (2 pcs.)

100mm, with magnet

(G) Adapter- pressure plates (2 pcs.)

175mm, with magnet

(H) Feed springs (2 pcs.) H F D I E

(I) Tool case

Waste disposal

At the end of the product's lifespan, please dispose of it in accordance with the applicable

statutory provisions. Do the same with the packaging material. In this way you make your

contribution to environmental protection.

Table of contents

Other BENDEL Power Tools manuals