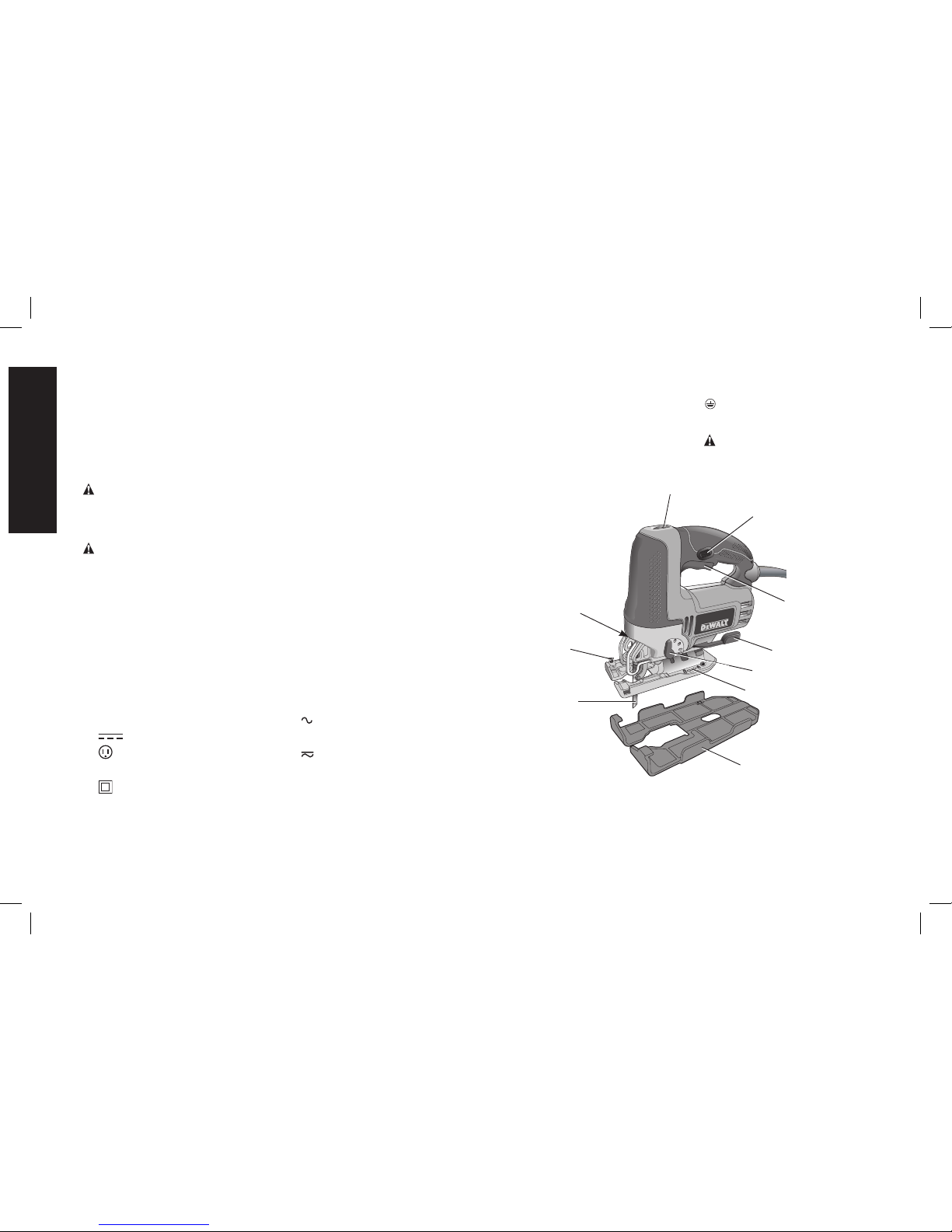

• Keep hands away from cutting area. Never reach underneath

the material for any reason. Hold front of saw by grasping the

contoured gripping area. Do not insert fingers or thumb into the

vicinity of the reciprocating blade and blade clamp. Do not stabilize

the saw by gripping the shoe.

• Keep blades sharp. Dull blades may cause the saw to swerve or

stall under pressure.

• When cutting pipe or conduit ensure that they are free from

water, electrical wiring, etc.

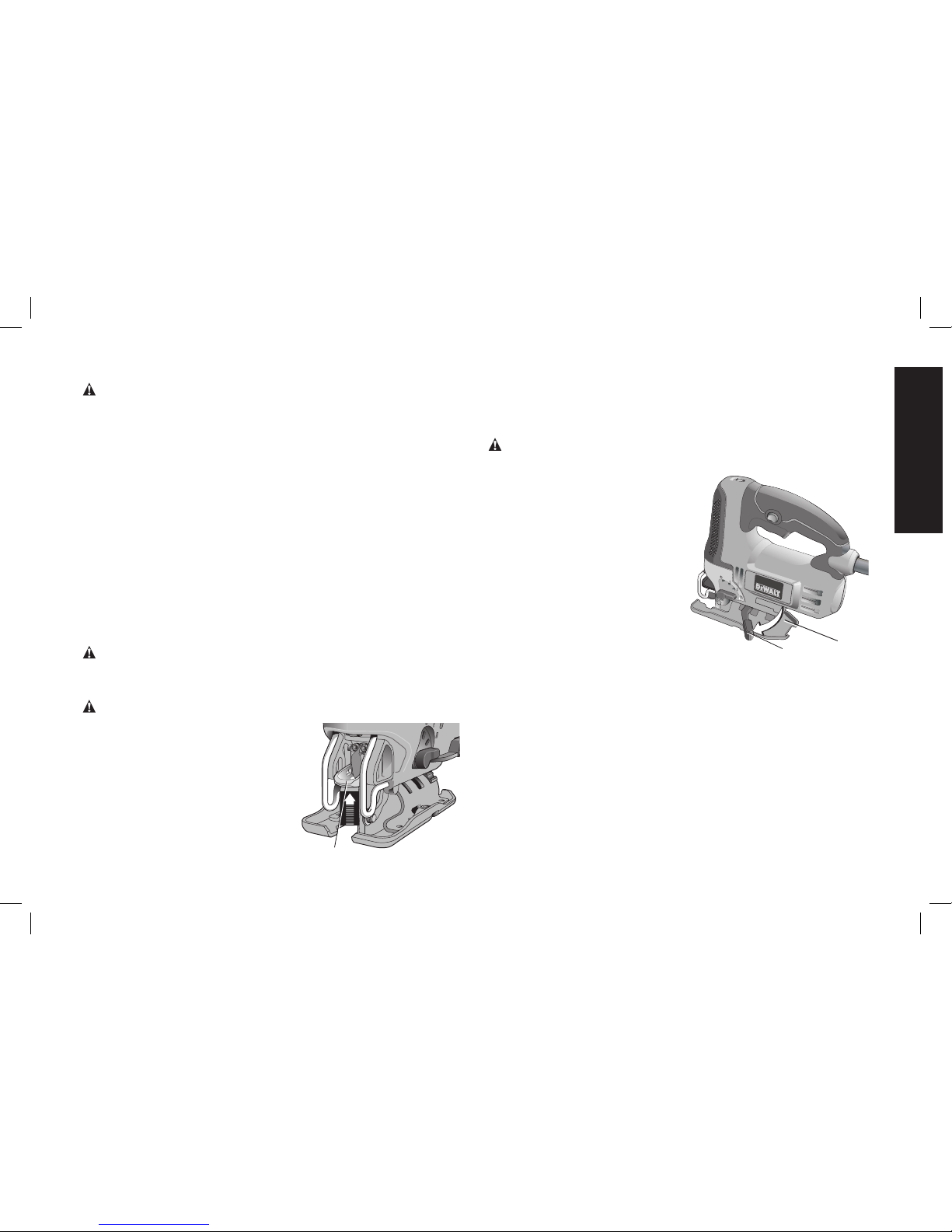

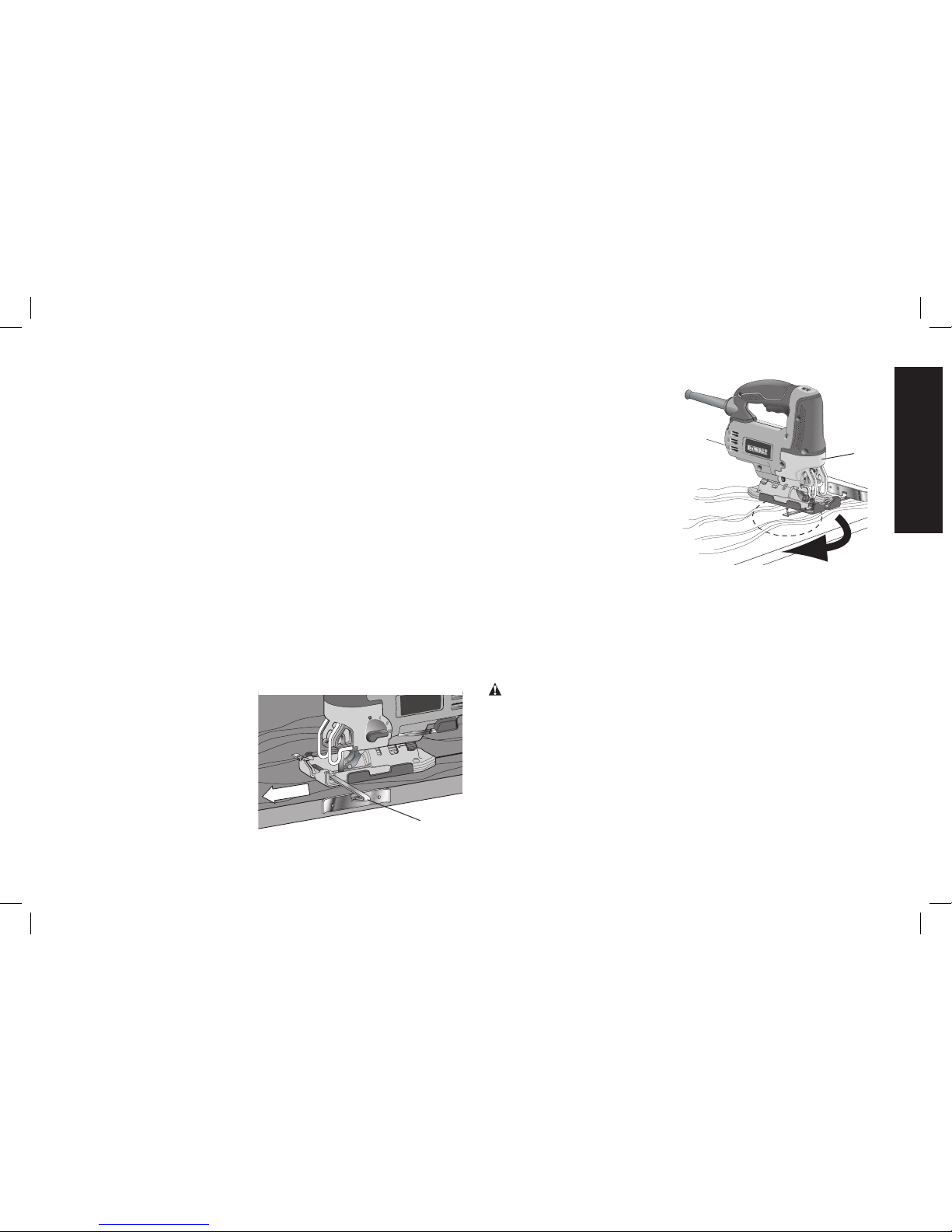

• Allow the motor to come to a complete stop before

withdrawing the blade from the kerf (the slot created by

cutting). A moving blade may impact the workpiece causing a

broken blade, workpiece damage or loss of control and possible

personal injury.

• Never hold work in your hand, lap or against parts of your

body when sawing. The saw may slip and the blade could

contact the body causing injury.

• Keep handles dry, clean, free from oil and grease. This will

enable better control of the tool.

• Clean out your tool often, especially after heavy use. Dust

and grit containing metal particles often accumulate on interior

surfaces and could create an electric shock hazard.

• Do not operate this tool for long periods of time. Vibration

caused by the operating action of this tool may cause permanent

injury to fingers, hands, and arms. Use gloves to provide extra

cushion, take frequent rest periods, and limit daily time of use.

• Avoid prolonged contact with dust from power sanding,

sawing, grinding, drilling, and other construction activities.

Wear protective clothing and wash exposed areas with

soap and water. Allowing dust to get into your mouth, eyes, or

lay on the skin may promote absorption of harmful chemicals.

WARNING: Wear appropriate hearing protection during use.

Under some conditions and duration of use, noise from this product

may contribute to hearing loss.

• Air vents often cover moving parts and should be avoided.

Loose clothes, jewelry or long hair can be caught in moving parts.

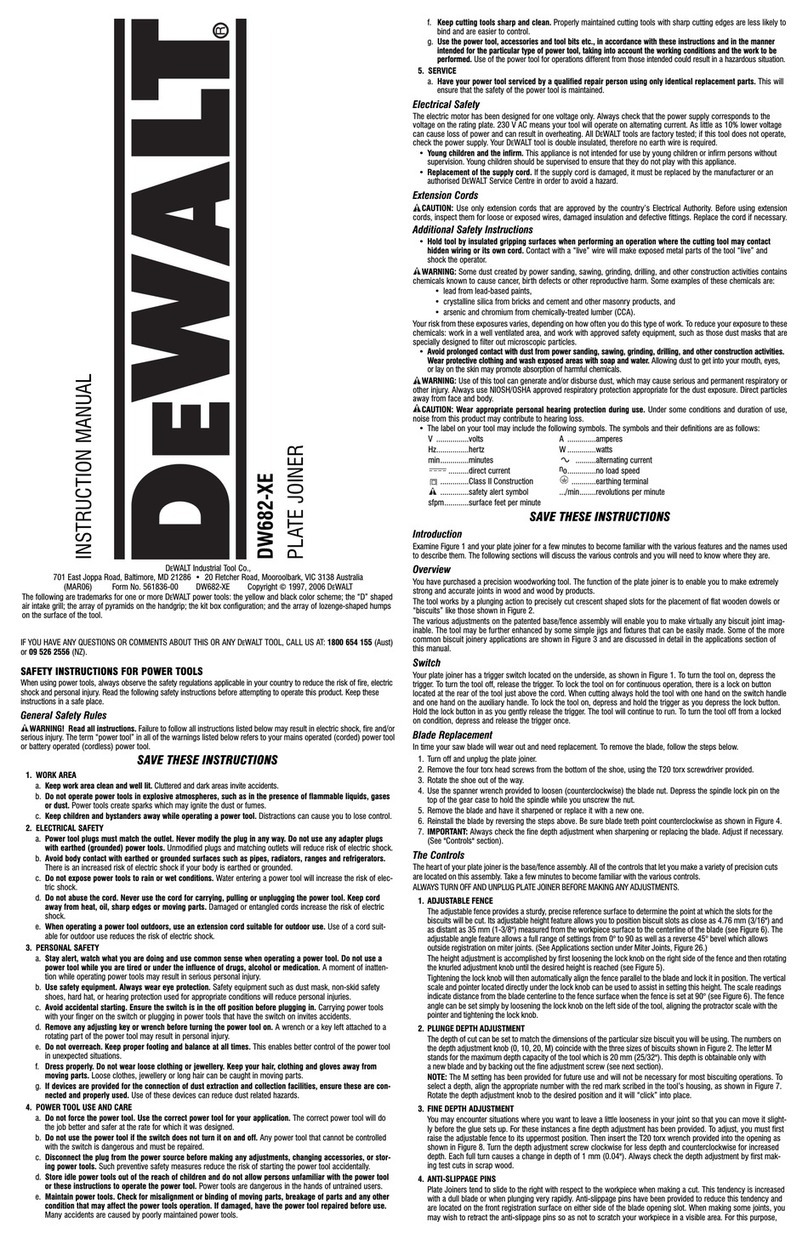

• An extension cord must have adequate wire size for safety.

An undersized cord will cause a drop in line voltage resulting in loss

of power and overheating. When using more than one extension

to make up the total length, be sure each individual extension

contains at least the minimum wire size. The following table shows

the correct size to use depending on cord length and nameplate

ampere rating. If in doubt, use the next heavier gauge. The smaller

the gauge number, the heavier the cord.

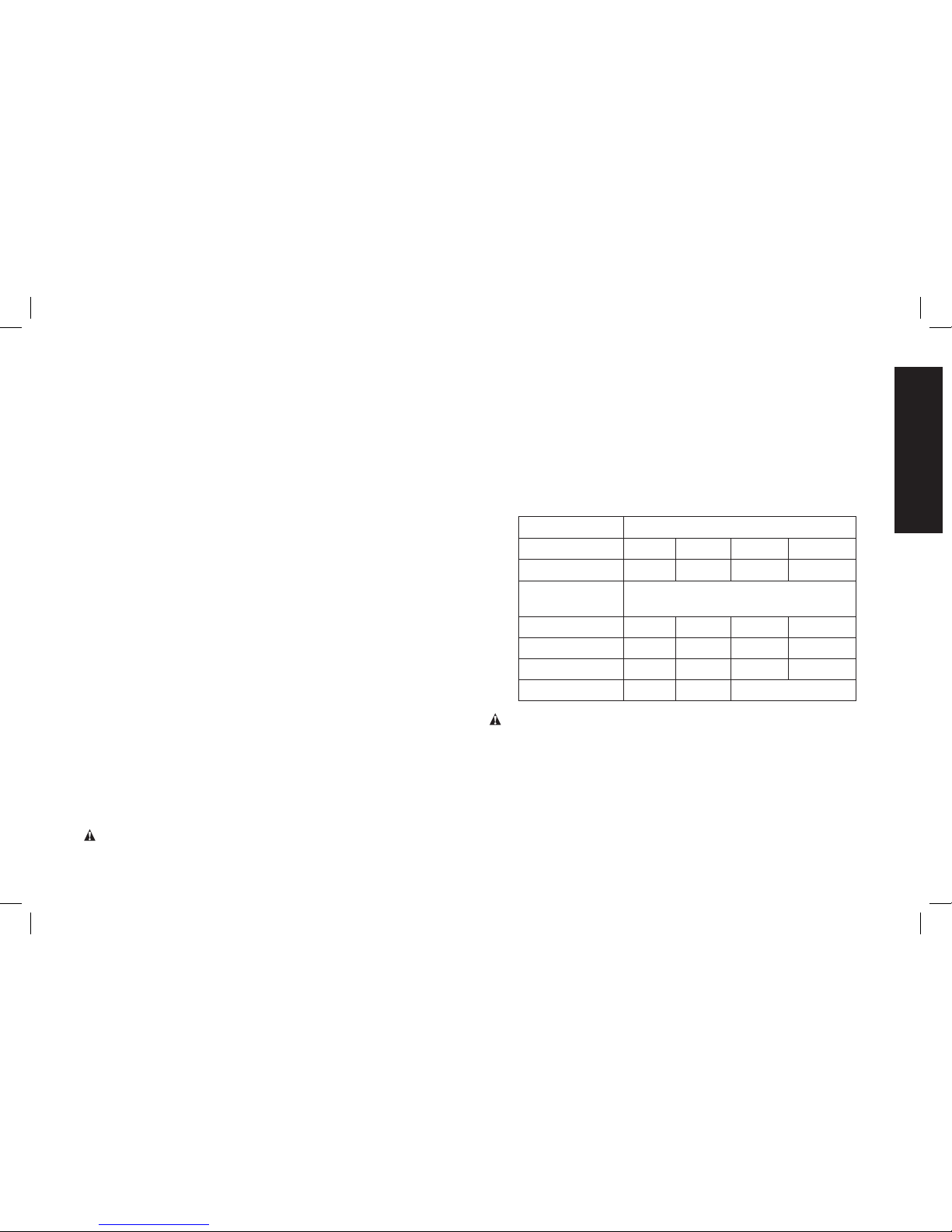

Voltage (Volts) Total length of cord in meters (m)

120–127V 0–7 7–15 15–30 30–50

220–240V 0–15 15–30 30–60 60–100

Rated Ampere

range

Minimal cross-sectional area of the

cord in meters (mm2)

0–6A 1.0 1.5 1.5 2.5

6–10A 1.0 1.5 2.5 4.0

10–12A 1.5 1.5 2.5 4.0

12–16A 2.5 4.0 Not Recommended

WARNING: Some dust created by power sanding, sawing,

grinding, drilling, and other construction activities contains chemicals

known to cause cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry

products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals: