4

ofthe contaminants to condenseand drop to thebottom of

the air dryer and reservoir system purge valve assembly,

ready to be expelled at the next purge cycle. The air then

flowsintothedesiccantcartridge,where it flows through an

oilseparatorwhichremovesliquidoilandsolidcontaminants.

Air then flows into the desiccant drying bed and becomes

progressivelydrieraswatervaporadherestothedesiccant

material in a process known as “ADSORPTION.”

Dry air exits the desiccant cartridge through the center of

thebaseassembly. The air then flows to thedeliverycheck

valve and also through an orifice into the purge reservoir.

Thedeliverycheckvalveopens,supplyingairtothepressure

protectionvalves(A)through(D)simultaneously,thesafety

valve,andalsoto thereservoirportofthe attachedgovernor.

The purge reservoir fills, storing air that will be used to

reactivate the desiccant during the purge cycle. This air is

available to supply downstream components during the

chargemode.

When the air pressure reaches approximately 106 psi, the

four pressure protection valves will open and air will be

supplied to the primary reservoir, secondary reservoir and

accessories. Ifthepressureprotectionvalvesare preset to

differentvaluesthevalveswill openinorderoflowestsetting

to highest setting when charging a flat system.

Theairdryerandreservoirsystemwill remain in the charge

cycle until the air brake system pressure builds to the

governor cut-out setting of approximately 130 p.s.i.

PURGE CYCLE (Refer to Figure 3.)

Whenairbrakesystempressurereachesthe cut-out setting

ofthe governor, the governorunloadsthe compressor and

thepurgecycleoftheairdryerandreservoir system begins.

The governor unloads the compressor by allowing air

pressure to fill the line leading to the compressor unloader

mechanism - causing the delivery of compressed air to

theAD-IS®airdryerandreservoirsystem to be suspended.

Similarly, the governor also supplies air pressure to the

AD-IS®airdryerand reservoirsystempurgecontrolchannel.

The AD-IS®air dryer and reservoir system purge piston

moves down in response to this air pressure, causing the

purgevalvetoopentotheatmosphereandtheturbocut-off

valvetocloseoffthesupplyofairfromthe compressor (this

will be further discussed in the Turbo Cut-off Feature

section). Waterand contaminants whichhave collected in

the purge valve base are expelled immediately when the

purgevalveopens. Also,air which was flowing through the

desiccant cartridge changes direction and begins to flow

toward the open purge valve. Oil and solid contaminants

collected by the oil separator are removed by air flowing

from the purge reservoir through the desiccant drying bed

totheopenpurgevalve.

The initial purge and desiccant cartridge decompression

lasts only a few seconds and is evidenced by an audible

burst of air at the AD-IS®air dryer and reservoir system

exhaust.

The actual reactivation of the desiccant drying bed begins

as dry air from the purge reservoir flows through the purge

orifice into the desiccant bed. Pressurized air from the

purge reservoir expands after passing through the purge

orifice; its pressure is lowered and its volume increased.

The flow of dry air through the drying bed reactivates the

desiccantmaterialbyremovingthewatervaporadheringto

it. Approximately 30 seconds are required for the entire

contentsofthe purgereservoirofastandardAD-IS®airdryer

and reservoir system to flow through the desiccant drying

bed.

Thedeliverycheckvalveassemblypreventsairpressurein

thebrakesystemfromreturningtotheairdryerandreservoir

system during the purge cycle. After the purge cycle is

complete, the air dryer and reservoir system is ready for

the next charge cycle to begin.

TURBO CUT-OFF FEATURE (Refer to Figure 3.)

Theprimary function ofthe turbo cut-offvalve is to prevent

loss of engine turbocharger air pressure through the

AD-IS®air dryer and reservoir system when the dryer is in

theunloadedmode.

At the onset of the purge cycle, the downward travel of the

purgepistonisstoppedwhentheturbocut-off valve(tapered

portion of purge piston) contacts its mating metal seat in

thepurgevalvehousing. Withtheturbocut-off valve seated

(closed position), air in the compressor discharge line and

AD-IS®air dryerandreservoirsysteminletportcannotenter

theairdryerand reservoir system. In this manner the turbo

cut-off effectively maintains turbo charger boost pressure

to the engine.

PREVENTIVE MAINTENANCE

Important: Review the warranty policy before performing

any intrusive maintenance procedures. An extended

warrantymaybevoidedifintrusivemaintenanceisperformed

duringthisperiod. Purgevalvemaintenanceis permissible

duringthewarrantyperiodonlywhen usingagenuineBendix

purgevalvekit.

Becausenotwovehiclesoperate underidenticalconditions,

maintenance and maintenance intervals will vary.

Experience is a valuable guide in determining the best

maintenanceintervalfor any one particularoperation.

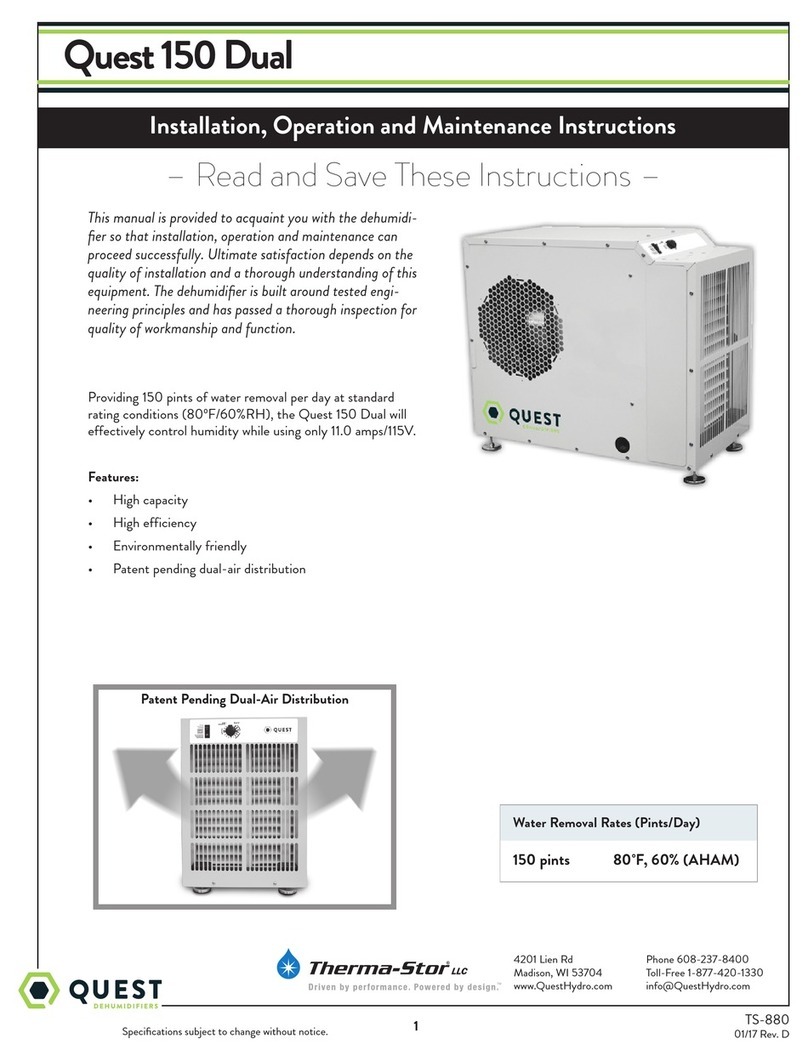

Every 900 operating hours, or 25,000 miles or three (3)

months:

1. Check for moisture in the air brake system by opening

reservoir drain valves and checking for presence of

water. If moisture is present, the desiccant cartridge