9

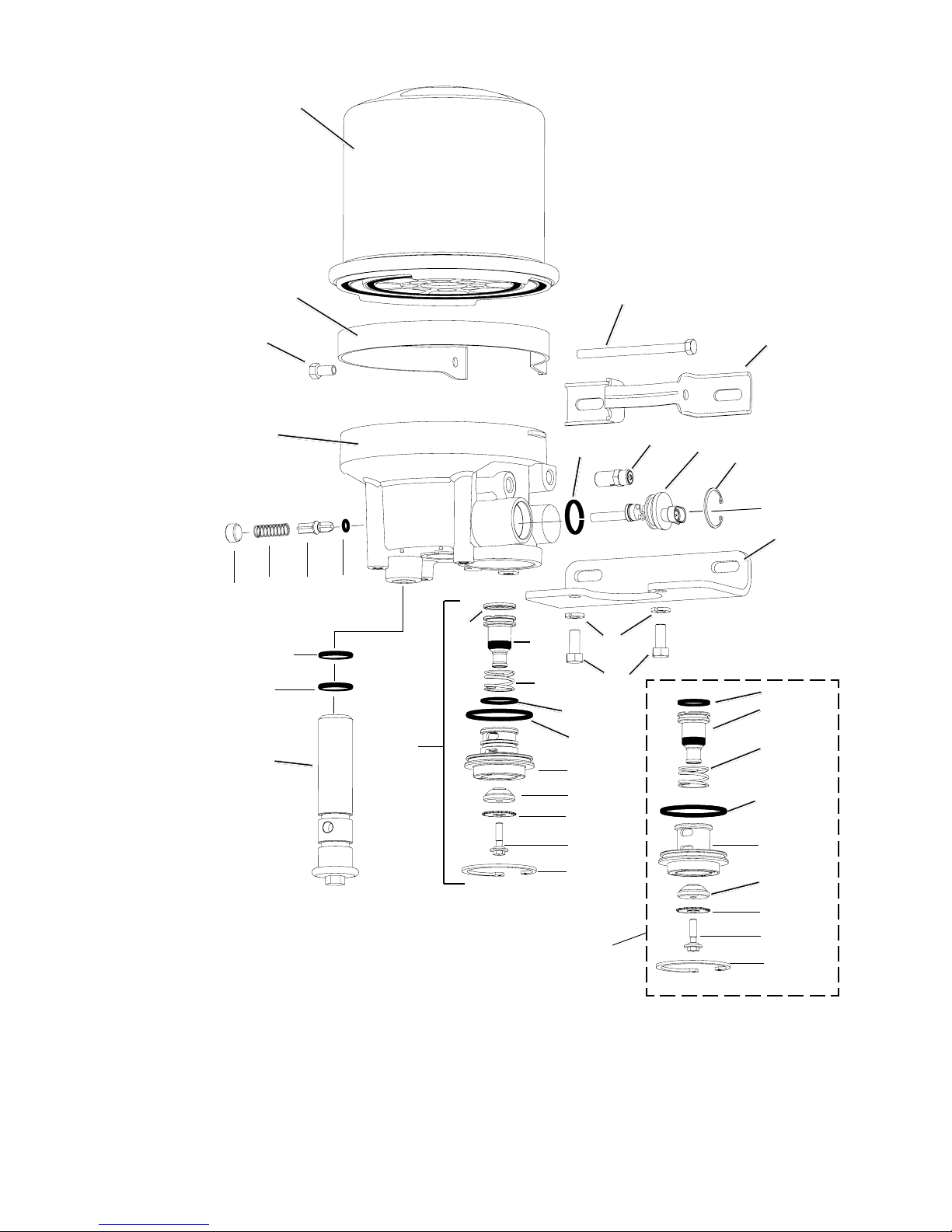

2. Install and center the exhaust diaphragm (17) over the

shoulderbolt (16) making certainthatthe diaphragm ID

is over the bolt shoulder. Then install the purge valve

(18)ontheshoulderboltmakingcertainitsmetalsupport

sideis against the diaphragm (17).

3. Push the purge piston (20) into the housing (19) until it

bottoms and insert a large blade screw driver in the

piston’sslottedhead.Whiledepressingthe purgepiston

with the screw driver, install the shoulder bolt (16) with

exhaustdiaphragm(17)andpurgevalve(18)inthepiston.

Torque the shoulder bolt (16) to between 60-80 in. lbs.

4. Installthetwoo-rings(23&24)onthepurgevalvehousing

(19)placingeachinitsappropriate location.DLUmodels

donotcontaino-ring (23). Install the assembled purge

valvehousing in the end cover (6) while making certain

the purge valve housing is fully seated against the end

cover.Securethepurge valve housing in the end cover

usingtheretaining ring (14). Make certain the retaining

ring is fully seated in its groove in the end cover (6).

5. Usinga 9/16” wrench, install the safety valve assembly

(33)into the end cover (6).

6. Vertical check valve models: Installtheo-ring(29) on

the check valve body (28) and push the o-ring down,

over the 3 guide lands until it is in the o-ring groove of

thecheck valvebody(28). Installthecheck valvespring

(27) on the check valve body so that the small coils of

the spring slip over the check valve body. Install the

assembledcheck valve body,o-ring, and spring(27,28

& 29) in the end cover (6) so that the o-ring rests on its

seatin theendcover (6) andthespring is visible. Install

theperforatedplate (26),in theend cover(6) andsecure

the check valve assembly using the retaining ring (25).

Makecertaintheretainingringisfullyseated initsgroove

inthe end cover (6).

7. Horizontal check valve models: Install o-ring (2)onto

check valve (36). Place the check valve in the delivery

check valve port of the end cover (6). Install the spring

(35)overthe delivery check valve (36) and secure with

thedelivery checkvalveplug (34).

8. Install the o-ring (32) on the heater and thermostat

assembly (31).After making certain the sponge rubber

cushion is positioned between the connector body and

thermostat, gently push the heater and thermostat

assembly (31) into the end cover (6), making certain

the heating element enters the small diameter bore in

the larger heater and thermostat bore in the end cover

(6). Secure the heater and thermostat assembly in the

body using the retaining ring (30). Make certain the

retainingringisfullyseatedinitsgrooveintheendcover

(6).

9. Installboth o-rings (12 & 13) on the desiccant cartridge

bolt (10) and using a twisting motion, insert the

assembleddesiccant cartridge boltin the end cover(6).

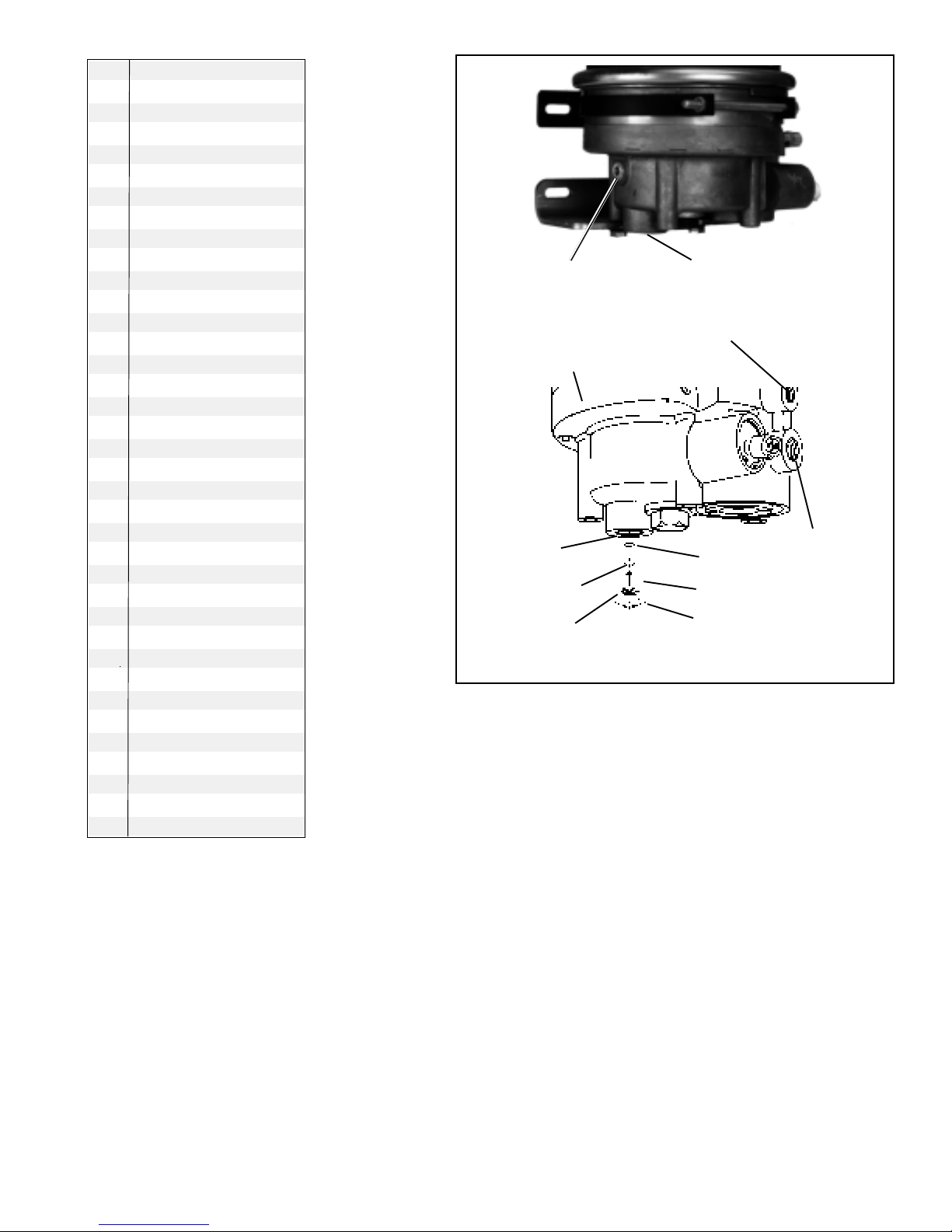

8. Vertical check valve models: Remove the retaining

ring(25)thatsecures thedelivery checkvalve assembly

intheendcover(6).Removeandseparatetheperforated

plate(26), spring (27),checkvalve body (28)ando-ring

(29).

9. Horizontal check valve models: Remove delivery

check valve plug (34) that secures the check valve

assemblyin the endcover(6). Remove the spring(35),

checkvalve (36)and o-ring (2).

10. Remove the retaining ring (30) that secures the heater

andthermostatassembly(31)intheendcover(6).Gently

pullthe heater and thermostat (31) out of the endcover

(6)and removethe o-ring (32).

11. Usinga9/16”wrench,remove thesafetyvalveassembly

(33)from the endcover (6).

CLEANING & INSPECTION

1. Usingmineral spiritsor an equivalentsolvent, cleanand

thoroughly dry all metal parts except the desiccant

cartridge.

2. Inspect the interior and exterior of all metal parts that

will be reused for severe corrosion, pitting and cracks.

Superficialcorrosionand orpittingontheexteriorportion

oftheendcoverisacceptable.

3. Inspect the bores of both the end cover and the purge

valvehousing fordeep scuffingorgouges.

4. Makecertain thatall purge valvehousing andendcover

passagesare open and free of obstructions.

5. Inspectthe pipe threads in the end cover. Make certain

theyareclean and free of thread sealant.

6. Inspect the purge valve housing bore and seats for

excessivewear and scuffing.

7. Inspectthe purge valve pistonseatfor excessive wear.

8. Make certain that the purge orifice in the cartridge bolt

isopenandfreeofobstructions.

9. Inspect all air line fittings for corrosion. Clean all old

threadsealant from the pipe threads.

10. All o-rings removed should be discarded and replaced

withnew o-rings providedinappropriate kit(s).

ASSEMBLY

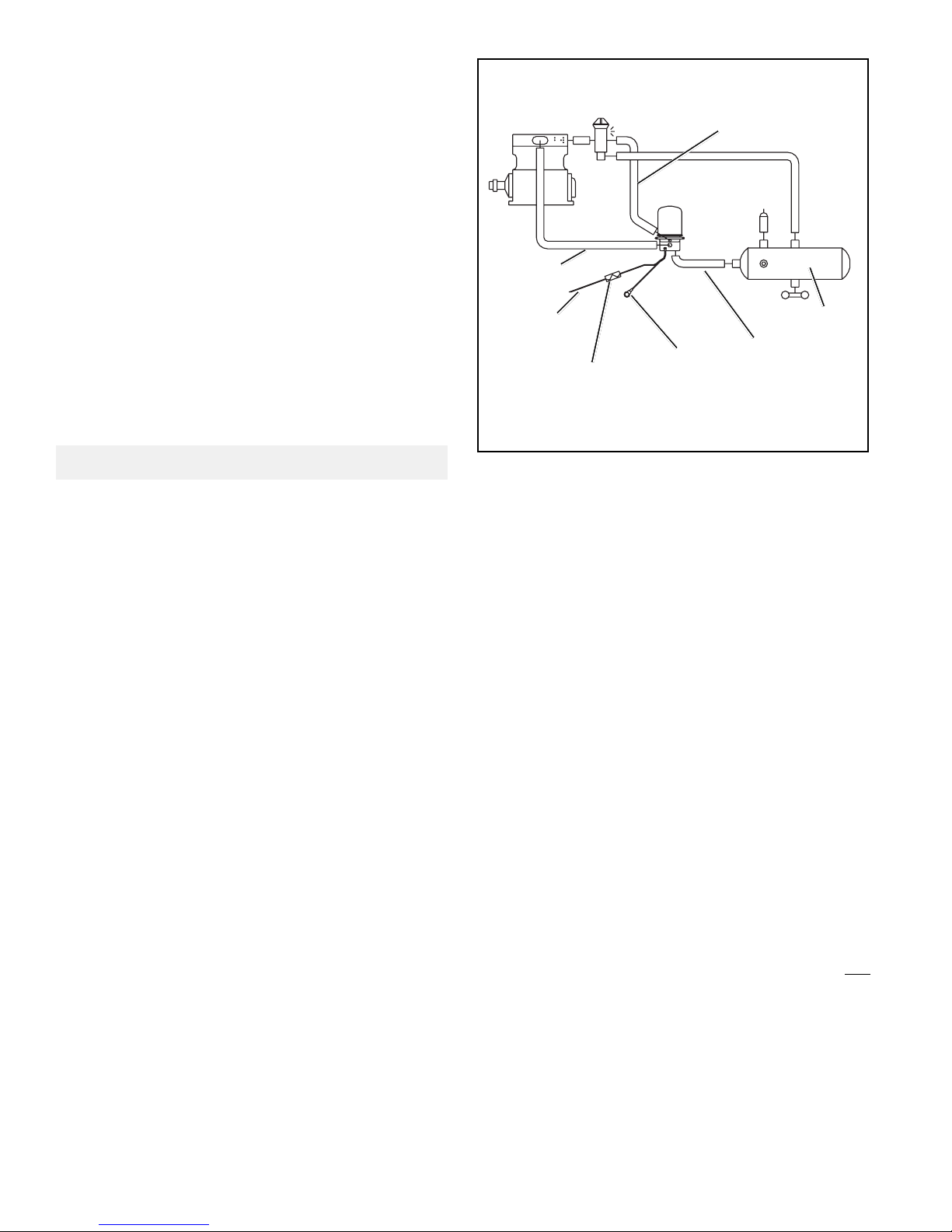

Priortoassembly,coat allo-rings, o-ringgrooves, andbores

withagenerousamountofsilicone grease.(RefertoFigures

9and 10 during assembly unless otherwise advised.)

1. Installthe quad ring (21) in its groove on theO.D.ofthe

purge piston (20). Place the return spring (22) in the

boreofthepurgevalvehousing(19),theninsertthepurge

piston (20) into the I.D. of the spring (22).