BENDIX AD-1 Mounting instructions

1

Bendix AD-1™ and AD-2 Air Dryers

SD-08-2403

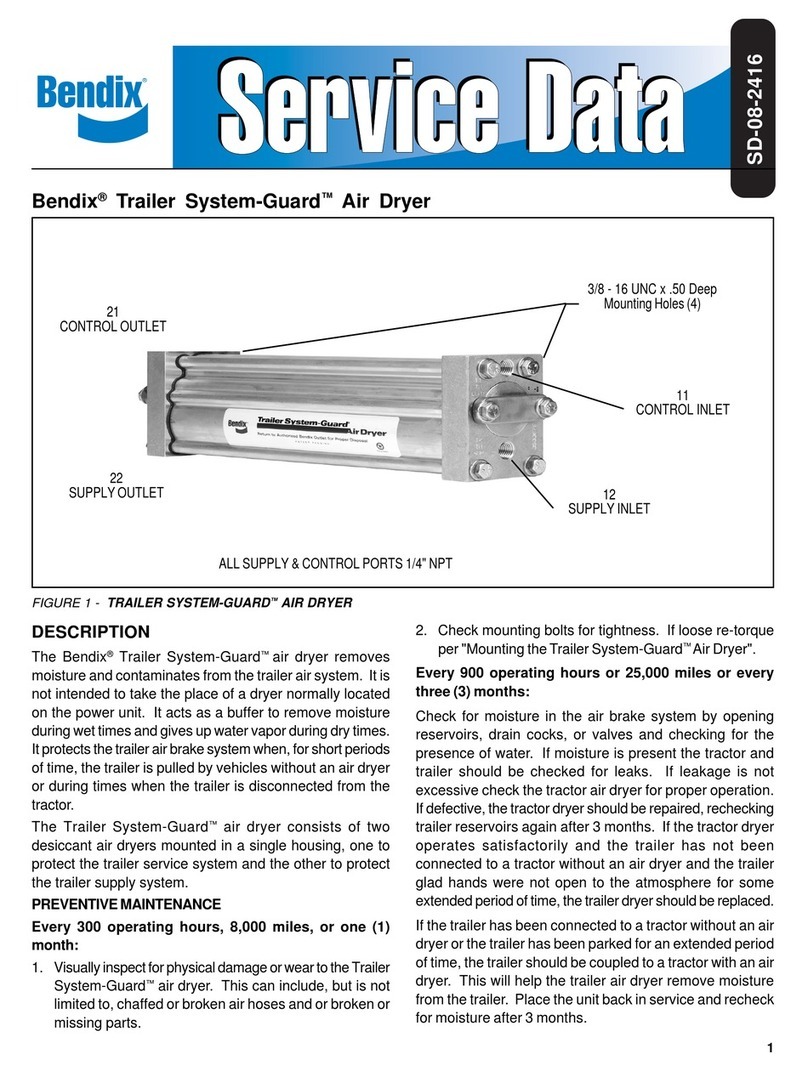

Figure 1 – Bendix®AD-1™and AD-2®Air Dryers

BENDIX®AD-2®AIR DRYER

BENDIX®AD-1™AIR DRYER

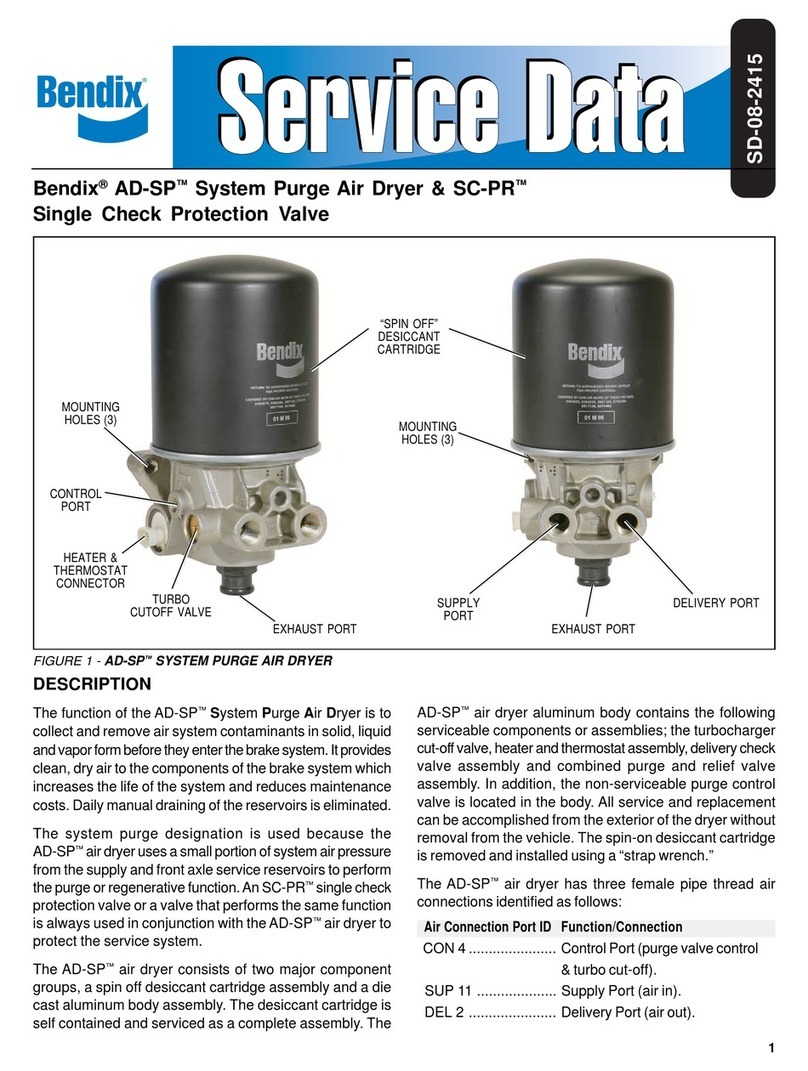

DESCRIPTION

The air dryer collects and removes moisture and

contaminants before the air reaches the •rst reservoir. It is

distinctly different than a reservoir drain valve or aftercooler

in that it provides “dry air” for the air brake system. The daily

draining of the system’s reservoirs is no longer necessary,

thus reducing maintenance considerably when compared

to an air brake system without an air dryer.

In a system without an air dryer, the life of air brake

components is substantially reduced because of contact

with water and oil in the system, and – since the air dryer

removes water and oil in vapor form– life of the component

devices is substantially increased when the air dryer is

used.

The air dryer can be used on most highway vehicles where

normal compressor loaded time is 90 seconds or less and

unloaded time is 30 seconds or more. If the compressor

remains loaded for long periods of time, such as on a transit

bus, certain changes in the purge volume of the dryer

must be made. For more information regarding increase

of the purge volume, contact the Bendix TechTeam at

1-800-AIR-BRAKE (1-800-247-2725).

The air dryer is installed in the discharge line between

the compressor and the •rst reservoir. The unit must be

mounted vertically and mounting brackets – which can be

adjusted to meet installation requirements – are provided.

2

Figure 2 – Sectional Views

BENDIX®AD-1™AIR DRYER

The housing assembly consists of two cylindrical steel

stampings welded together. For piping convenience, two

inlet ports – one reservoir port and one purge volume

port – are provided in the Bendix®AD-2®air dryer. The side

outlet port of the AD-2 air dryer incorporates an integral

single check valve with the top port used for the addition

of purge volume. (Refer to Figure 2.)

A safety valve mounted in the housing assembly protects

against excessive pressure build-up within the housing.

The desiccant sealing plate assembly is located mid-way in

the housing assembly and houses a replaceable ball-type

single check. Also located in the plate assembly is the

purge ori!ce.

The desiccant cartridge and aluminum oil separator !lter

are removable and comprise a complete serviceable unit.

The desiccant beads, which are referred to as the “drying

bed”, are a drying substance that has the unique property

of exposing a tremendous surface area in proportion to

its bulk. One pound of the desiccant beads has about two

million square feet of adsorptive area made up of a large

number of submicroscopic cavities in each bead. Each

desiccant bead adsorbs or collects moisture.

The desiccant beads are held in place by steel perforated

plates and !lter cloths. The top plate is held in place

by a spring, and the bottom plate rests on a shoulder

approximately 1/8” from the bottom of the cartridge housing.

BENDIX®AD-2®AIR DRYER

5-1/2”

19-1/2”

PURGE

VOLUME

PURGE

ORIFICE

INLET

DESICCANT

“O” RING

HEATER

PURGE

VALVE EXHAUST

DEFLECTOR

RETAINING

RING

OIL

FILTER

MOUNTING

BRACKET

SAFETY

VALVE

“O” RING

“O” RING

CHECK

VALVE

LOCK

NUT

MOUNTING

BRACKET

OUTLET

CHECK

VALVE

OUTLET

LOCK

NUT

SPRING

RETAINER

PERFORATED

PLATE

OIL

FILTER

HEATER

THERMOSTAT

ENCLOSURE

ELECTRICAL

TERMINAL

PURGE

VALVE

CONTROL

PORT

PURGE

VALVE

PISTON

DESICCANT

CARTRIDGE

CARTRIDGE

BOLT

INLET

DESICCANT

SEALING

PLATE

3

The end cover assembly is retained by a lock ring, as well

as cap screws and retainers, and houses the purge valve

and heater assembly if so equipped.

The heater and thermostat assembly prevent freeze-up

in the purge drain valve when the dryer is used in severe

winter conditions. The heater and thermostat assembly is

standard in the Bendix®AD-2®air dryer and was optional

equipment for the Bendix®AD-1™air dryer. The 12 volt / 60

watt and 24 volt / 60 or 120 watt DC heater and thermostat

assembly has an operating range between 45°F and 85°F.

NOTE: The heater and thermostat assembly provided with

the AD-2 air dryer has a 3/16” diameter threaded electrical

terminal protected by a boot. The AD-1 air dryer assembly

incorporates a #16 gauge lead wire. Both types are

serviceable. The heater and thermostat assembly should

be connected to the “on” position of the engine control or

ignition switch and protected with the proper size fuse.

For details on installation, please refer to the “Installation”

section.

OPERATION

The operation of the air dryer can best be described by

separating the operation into two cycles; the charge cycle

and the purge cycle.

Charge Cycle: (See Figure 3.) A compressor in the

compressing cycle - With the compressor in its “loaded”

or compressing cycle, air from the compressor enters the

air dryer through the discharge line. When the air – along

with the water and contaminants – enters the air dryer, the

velocity or speed of the air reduces substantially and much

of the entrained liquid drops to the bottom (or sump) of

the air dryer. The initial air !ow is toward the bottom of the

dryer, but air !ow direction changes 180° at the bottom of

the air dryer, dropping some water and oil.

The air now passes through the oil separator "lter which

removes oil and foreign material but does not remove water

vapor. At this point, the air remains saturated with water.

The "ltered air and vapors penetrate the desiccant drying

bed and the adsorption process begins. Water vapor is

removed from the air by the desiccant.

The unsaturated “dry” air passes through the ball check

valve and purge ori"ce into the purge volume. From the

purge volume air !ows through an outlet check valve, and

into the "rst reservoir.

NOTE: The AD-1 air dryer does not incorporate an integral

outlet check valve. The single check valve in an AD-1 air

dryer installation would be located in the line between the

AD-1 air dryer outlet port and the !rst reservoir.

GENERAL SAFETY GUIDELINES

WARNING! PLEASE READ AND

FOLLOW THESE INSTRUCTIONS

TO AVOID PERSONAL INJURY OR DEATH:

When working on or around a vehicle, the following

guidelines should be observed AT ALL TIMES:

▲Park the vehicle on a level surface, apply the parking

brakes and always block the wheels. Always wear personal

protection equipment.

▲Stop the engine and remove the ignition key when working

under or around the vehicle. When working in the engine

compartment, the engine should be shut off and the ignition

key should be removed. Where circumstances require that

the engine be in operation, EXTREME CAUTION should be

used to prevent personal injury resulting from contact with

moving, rotating, leaking, heated or electrically-charged

components.

▲Do not attempt to install, remove, disassemble or

assemble a component until you have read, and thoroughly

understand, the recommended procedures. Use only the

proper tools and observe all precautions pertaining to use

of those tools.

▲If the work is being performed on the vehicle’s air brake

system, or any auxiliary pressurized air systems, make

certain to drain the air pressure from all reservoirs before

beginning ANY work on the vehicle. If the vehicle is

equipped with a Bendix®AD-IS®air dryer system, a Bendix®

DRM™dryer reservoir module, or a Bendix® AD-9si®air

dryer, be sure to drain the purge reservoir.

▲

Following the vehicle manufacturer’s recommended

procedures, deactivate the electrical system in a manner

that safely removes all electrical power from the vehicle

.

▲Never exceed manufacturer’s recommended pressures.

▲Never connect or disconnect a hose or line containing

pressure; it may whip and/or cause hazardous airborne

dust and dirt particles. Wear eye protection. Slowly open

connections with care, and verify that no pressure is

present. Never remove a component or plug unless you are

certain all system pressure has been depleted.

▲Use only genuine Bendix®brand replacement parts,

components and kits. Replacement hardware, tubing, hose,

fittings, wiring, etc. must be of equivalent size, type and

strength as original equipment and be designed specifically

for such applications and systems.

▲Components with stripped threads or damaged parts should

be replaced rather than repaired. Do not attempt repairs

requiring machining or welding unless specifically stated

and approved by the vehicle and component manufacturer.

▲Prior to returning the vehicle to service, make certain all

components and systems are restored to their proper

operating condition.

▲For vehicles with Automatic Traction Control (ATC), the ATC

function must be disabled (ATC indicator lamp should be

ON) prior to performing any vehicle maintenance where

one or more wheels on a drive axle are lifted off the ground

and moving.

▲The power MUST be temporarily disconnected from the

radar sensor whenever any tests USING A DYNAMOMETER

are conducted on a vehicle equipped with a Bendix®

Wingman®system.

▲You should consult the vehicle manufacturer's operating

and ser vice manuals, and any related literature, in

conjunction with the Guidelines above.

4

Figure 3 – Bendix®AD-2®Air Dryer Operational Purge Cycle

Figure 4 – Bendix AD-2 Air Dryer Operational Purge Cycle

- AIR PRESSURE

- AIR PRESSURE

5

Figure 5 – Ball Check Valve

Purge Cycle: (See Figure 4.) When the desired system

pressure is reached, the governor cuts-out, pressurizing

the unloader cavity of the compressor which unloads the

compressor (non- compressing cycle). The line connecting

the governor unloader port to the end cover purge valve

port (bottom of the air dryer) is also pressurized, opening

the exhaust of the purge valve to atmosphere. With the

exhaust of the purge valve open, contaminants in the

discharge line and dryer sump are purged, or forced past

the open exhaust out to atmosphere.

The reverse air !ows across the desiccant and starts the

removal process of moisture from the desiccant surface.

Dry air !owing from the purge volume through the purge

ori"ce and across the drying bed further dries the desiccant.

The combination of these reverse !ows strips the water

vapor from the desiccant (drying bed). This normally takes

between 15–30 seconds.

The desiccant becomes activated from this cycle and is

now ready for another charge cycle, which occurs when

the compressor returns to the compressing cycle. It is for

this reason the air dryer must be purged for 30 seconds

after receiving moisture-saturated air for a maximum of 90

seconds from a 12 CFM compressor.

This air dryer is intended to remove moisture and other

contaminants normally found in the air brake system. Do

not inject alcohol, anti-freeze, or other de-icing substances

into, or upstream of, the air dryer. Alcohol is removed by

the dryer, but reduces the effectiveness of the device to

dry air. Use of other substances can damage the air dryer

and may void the warranty.

PREVENTIVE MAINTENANCE AND CHECKING

SERVICEABILITY

IMPORTANT

Review the warranty policy before performing any intrusive

maintenance procedures. An extended warranty may be

voided if intrusive maintenance is performed during this

period.

Every 900 operating hours, or 25,000 miles, or every three

(3) months:

1. Check for moisture in the air brake system by opening

reservoirs, drain cocks, or valves, and look for the

presence of water. If moisture is present, the desiccant

may require replacement; however, the following

conditions can also cause water accumulation and

should be considered before replacing the desiccant:

A. An outside air source has been used to charge the

system. This air did not pass through the drying

bed.

B. Air usage is exceptionally high and not normal for

a highway vehicle. This may be due to accessory

air demands or some unusual air requirement that

does not allow the compressor to load and unload

(compressing and non-compressing cycle) in a

normal fashion. Check for high air system leakage.

C. The air dryer has been installed in a system that

has been previously used without an air dryer. This

type of system will be saturated with moisture and

several weeks of operation may be required to dry

it out.

D. Location of the air dryer is too close to the air

compressor. Refer to “Installation” section.

E. In areas where more than a 30° range of

temperature occurs in one day, small amounts

of water can accumulate in the air brake system

due to condensation. Under these conditions, the

presence of small amounts of moisture is normal

and should not be considered as an indication that

the dryer is not performing properly.

Note also that a small amount of oil in the system

may be normal and should not, in itself, be

considered a reason to replace the desiccant; oil

stained desiccant can often function adequately.

2. Check mounting bolts for tightness.

3. Check the operation of the integral single check valve

in the Bendix®AD-2®air dryer or the “in line” check

valve used with the Bendix®AD-1™air dryer. Build the

air system to governor cut-out and observe the test

air gauge installed in the #1 reservoir. A rapid loss of

pressure could indicate a failed check valve. This can

be con"rmed by checking at the purge valve exhaust.

6

Note: Purge valve will be open when governor cut-out

pressure is reached. Allow two minutes for purge cycle

before testing the check valve.

4. Check for excessive leakage at the purge valve by

coating the exhaust with a soap solution while the

compressor is loaded (compressing air).

5. Check the operation of the safety valve by pulling

the exposed stem while the compressor is loaded

(compressing air). There must be an exhaust of air while

the stem is held and the valve should re-seat when the

stem is released.

6. Check all lines and •ttings leading to and from the air

dryer for leakage and integrity.

7. Check the operation of the end cover heater and

thermostat assembly during cold weather operation as

follows:

A. Electric Power to the Dryer

With the ignition or engine control “on”, check

for power at the dryer’s electrical terminal with a

voltmeter or test light. (See Figure 16.) If there is

no voltage, look for a blown fuse, broken wires, or

corrosion in the vehicle wiring harness.

B. Thermostat and Heater

1. Turn off the ignition switch and cool the

end cover assembly to below 40°F. With an

ohmmeter, check the resistance between the

electrical terminal and the aluminum of the end

cover. (See Figure 16.)

This resistance should be 2.0–4.0 ohms for a

12 volt end cover; 8.1–13 ohms for a 24 volt/ 60

watt end cover; and 4.0–7.0 ohms for a 24

volt /120 watt end cover.

2. Warm the end cover assembly to over 90°F and

check the resistance as above. This resistance

should exceed 1,000 ohms.

If these resistances are within the limits, the

thermostat and heater are operating properly.

If these resistances are outside the limits,

proceed to Step C to determine the cause.

C. Heater Element

With the ignition or engine control switch “off”,

remove the thermostat cover. (See Figure 17.)

With an ohmmeter, check the resistance between

the aluminum of the end cover and the heater post.

For a 12 volt end cover, the resistance should be

2.0–2.8 ohms. For a 24 volt / 60 watt end cover,

8.1–11.1 ohms; and for a 24 volt / 120 watt end

cover, 4.0–4.6 ohms. If the heater resistance is

outside these ranges, a new or remanufactured end

cover should be installed, since the heater element

cannot be serviced.

If the heater resistance is within the limits the

thermostat should be replaced (Kit Number

102657N) or a new or remanufactured end cover

installed.

D. Reassembly

Reinstall the thermostat cover as shown in

Figure 17. Use care to ensure the rubber spacer

and the gasket are correctly installed.

8. Every 7,200 hours, 200,000 miles, or every 24 months,

change the desiccant cartridge.

NOTE: The desiccant change interval may vary from

vehicle to vehicle. Although typical desiccant cartridge

life is two years, many will perform adequately for three

to four years. In order to take maximum advantage of

desiccant life and ensure that replacement occurs only

when necessary, it is important that Serviceability Checks

1–7 be performed.

REPLACING OR REBUILDING THE BENDIX®

AD-1™AND AD-2®AIR DRYER

GENERAL

If, after completing the routine serviceability tests, it has

been determined that one or more components of the air

dryer requires replacement or maintenance, refer to page

13 to identify the appropriate kit(s) needed. When rebuilding

or replacing components of the air dryer, use only genuine

Bendix®replacement parts or kits.

REMOVAL OF THE DESICCANT CARTRIDGE

1. Loosen the air line to the control port of the air dryer

and allow the trapped air to escape to atmosphere.

After the air escapes, remove the control line from the

air dryer.

2. Loosen the delivery line from the delivery port or outlet

of the air dryer. After the pressure drops, remove the

delivery line. Loosen the delivery check valve from

this port to relieve any trapped air above the desiccant

plate assembly. If the AD-1 air dryer has an external

check valve at the delivery port, loosen it to relieve air

pressure.

3. Disconnect the heater wire.

4. Remove any exhaust silencers or the exhaust check

valve cover from the base of the air dryer. Using a hex

socket and wrench, loosen the purge valve assembly

and allow any trapped air to escape. Slowly unscrew

the purge valve and remove it.

5. Check all ports to ensure that air is not trapped in the

air dryer by powdered desiccant material.

7

Figure 7 – Replacement Desiccant CartridgeFigure 6 – Desiccant Sealing Plate

Air Dryer End Cover Removal Procedure

The Bendix®AD-2®air dryer cartridge contains a high

spring load. When replacing the AD-2 air dryer cartridge, or

performing any maintenance requiring end cover removal,

follow the procedure outlined below.

End Cover Removal

1. Loosen the three cap screws on the end cover and

turn the retaining clamps aside (cap screws may be

left !nger tight).

2. Locate the notch in the air dryer shell. While pushing

the end cover up into the dryer, insert the blade of a

screwdriver in the notch and slowly pry out the retaining

ring. If the cartridge bolt has loosened, the cartridge

spring may exert a force on the end cover retaining

ring making removal of the retaining ring and end

cover dif!cult. This spring force will prohibit the end

cover moving up into the dryer shell when pushed up.

Warning: This same force can also cause the end

cover to come out of the air dryer shell unexpectedly

during the removal process. Exercise extreme caution

to prevent bodily injury.

3. Do not stand or lay directly under the end cover while

servicing. Ensure adequate clearance between the

end cover and other surfaces to prevent hand injury if

the end cover dislodges rapidly during removal. NOTE:

Be certain the desiccant sealing plate assembly comes

out with the cartridge.

Before attempting to remove the desiccant sealing plate,

measure the cartridge bolt from the top of the desiccant

plate lock nut to the end of the bolt threads. If that

measurement is approximately 3-3/16 inches, proceed

with the disassembly.

If the bolt measures approximately 1-9/16 inches,

disassemble using CAUTION. Approximately 75 pounds

of spring force will remain against the desiccant plate

when the lock nut reaches the end of the bolt thread and

is removed.

REMOVING AND REBUILDING THE AIR DRYER

DESICCANT SEALING PLATE

Before the desiccant cartridge can be replaced or

rebuilt, the desiccant sealing plate must be removed. It

is recommended that all non-metallic parts be replaced

when the plate is removed. In the past, three methods have

been employed to secure the desiccant sealing plate to the

desiccant cartridge: a TruArc®retaining ring; two special

thin nuts; and the latest method – a single hex lock nut.

Removing the securing device will permit the desiccant

plate to be separated from the desiccant cartridge. After

removing the desiccant cartridge:

1. Remove the two o-rings from the desiccant plate and

discard them.

2. Remove the ball check valve retaining clip and remove

and discard the rubber ball valve.

3. Clean the desiccant plate thoroughly using a quality

commercial solvent, making sure the purge ori!ce and

check valve seat are clean.

4. Install a new ball check valve and replace the retaining

clip and screw. (See Figure 5.)

8

REBUILDING THE DESICCANT CARTRIDGE

IMPORTANT

Only the current revision desiccant cartridges can be

rebuilt. (See Figure 7.) Current revision desiccant cartridges

are identi!ed positively by the Bendix trademark BW

stamped in the hex head of the cartridge bolt, and by

“AD-2” displayed on the bottom face of the oil !lter. If an

old revision desiccant cartridge is removed from the

air dryer, it should be replaced with a complete current

revision desiccant cartridge.

Figure 9 – Oil Separator

Figure 10 – Cartridge Bolt Installation

Figure 8 – Desiccant Cartridge Assembly

5. Thoroughly lubricate the two new o-rings and install

them in their respective grooves in the purge plate.

(See Figure 6.)

6. Set the desiccant sealing plate aside for reinstallation

on the desiccant cartridge.

REINSTALLING THE DESICCANT CARTRIDGE IN

THE AIR DRYER

If the desiccant cartridge is to be replaced as an assembly

rather than rebuilt (see the desiccant cartridge rebuilding

instructions), remove the cartridge from the air dryer.

The current revision replacement desiccant cartridge is

shown in Figure 7. All prior revisions of the cartridge will

interchange with no modi!cations to either air dryer.

Prior to installing the new replacement cartridge in the air

dryer, the following steps must be followed:

1. Carefully remove the lock nut from the cartridge bolt

using an 11/16 inch open end or box wrench.

IMPORTANT

Care must be taken not to allow the cartridge bolt to slip

out of the cartridge when the lock nut is removed. Loss

of desiccant material will occur should this happen.

2. Install the previously rebuilt desiccant sealing plate on

the cartridge bolt so that the ball check retaining clip

remains visible. (See Figure 15-1 & 15-2.)

3. While holding the cartridge bolt, reinstall the lock nut on

the cartridge bolt.

IMPORTANT

Before tightening the lock nut down, make certain that

the shoulder (the unthreaded portion) of the cartridge

bolt extends slightly above the perforated desiccant

plate. (See Figure 12.)

4. By tightening the lock nut, draw the desiccant sealing

plate down into the desiccant cartridge until the shoulder

of the desiccant sealing plate is against the cartridge

shell. (See Figure 15.)

9

DESICCANT CARTRIDGE DISASSEMBLY

1. Carefully remove and discard the lock nut on top of the

desiccant sealing plate. (The plate is spring loaded; see

the “Caution” note in “Removal of Desiccant Cartridge”

section.)

2. Remove the desiccant sealing plate and rebuild it

as outlined under the Removing and Rebuilding the

Desiccant Sealing Plate section of this manual.

3. Remove and retain the spring, spring seat, bolt, and

cartridge shell. Discard the oil separator !lter and two

perforated plates. Discard the desiccant material as a

solid waste according to local laws and regulations.

4. Insert one of the perforated plates into the cartridge,

cloth side up, and tap it !rmly to the bottom. (The cloth

always faces desiccant material.) (See Figure 8.)

5. Slide the oil separator !lter over the cartridge bolt with

the gasket surface next to the shell. (See Figure 9.)

6. Install the bolt with the oil separator into the bottom of

the shell and through the center hole of the perforated

plate in the bottom of the shell. (See Figure 10.)

7. Pour the entire package of desiccant material into the

shell, making sure none is lost. Handle carefully so

that the bolt does not fall out. (See Figure 11.)

8. Level the desiccant material and install the second

perforated plate cloth side down. Make sure the

shoulder of the bolt is centered, and extends slightly

above the top of the perforated plate. (See Figure 12.)

NOTE: If the shoulder of the bolt does not extend

above the perforated plate, tap the side of the desiccant

container.

9. Set the conical spring on top of the perforated plate

(large diameter down - small diameter up.)

Figure 12 – Perforated Plate

Figure 11 – Desiccant Material

Figure 13 – Conical Spring

10. Place the spring retainer on top of the spring. (See

Figure 13.)

11. Install the previously rebuilt desiccant sealing plate on

the cartridge bolt so that the ball check retaining clip is

in view.

10

Figure 15-2 – Secured Cartridge

Figure 15-1 – Securing the Cartridge

12. Using the lock nut, draw the assembly together to

approximately half of the spring’s free height. While

slowly turning the cartridge, tap the side of the shell

with a plastic mallet. (See Figure 14.) This allows

the desiccant material to settle properly into place.

Continue to tighten the nut, making sure all items are

properly aligned. Tighten nut !rmly using an 11/16”

socket or box wrench. (See Figures 15-1 and 15-2)

REBUILDING THE BENDIX®AD-1™AIR DRYER

END COVER ASSEMBLY

To remove the end cover assembly from the air dryer,

follow steps 1-6 under the section of this manual entitled

Removal of Desiccant Cartridge. Before rebuilding the

end cover, clean the exterior thoroughly using a quality

commercial solvent.

DISASSEMBLY

1. Remove and discard the large o-ring around the end

cover.

2. Remove the exhaust elbow and clamp.

3. Remove the cap nut and discard the cap nut o-ring.

4. Place the handle of a large screwdriver in a vise and

secure it.

5. Place the slot in the plunger (cap nut end) over the

blade of the screwdriver, hold it securely and remove

the nut from the plunger using a 1/2” socket wrench.

6. Remove the plunger, spring, and valve. Discard the

valve.

7. Clean and inspect the plunger bore and the valve seat.

8. Remove and discard the three o-rings from the plunger.

Clean the plunger.

NOTE: If during the serviceability checks it was

determined that the heater and thermostat were

defective, use the following procedure. It is not

necessary to replace this assembly each time the purge

valve is rebuilt.

9. Remove the two screws that secure the shield or

thermostat retaining clip to the end cover.

10. Remove the shield or clip and the thermostat and

inspect the bore for corrosion.

11. Remove the square-cut seal ring at the bottom of the

thermostat bore.

12. Remove the screw, retaining clip, o-ring, and the heater

element. Inspect the bore for corrosion and if necessary,

clean it.

Figure 14 – Settling Desiccant

11

ASSEMBLY

1. Install the heater element, securing it in the end cover

with the retainer clip and screw.

2. Install the square-cut seal ring in the thermostat bore.

3. Install the thermostat metal side down in the end cover

bore and secure it in place using the retaining clip or

shield and the two screws.

4. Lubricate and install the o-rings on the plunger and cap

nut.

5. Lubricate the plunger bore and install the spring and

plunger (through the cap nut end).

6. Install the valve on the plunger, making certain the

chamfered end of the valve is in contact with the metal

seat of the body.

7. Using the screwdriver held in the vise, as described in

Steps 4 & 5, compress the plunger into the bore while

installing and tightening the nut.

8. Install the cap nut and tighten it.

9. Lubricate and install the large diameter o-ring around

the end cover assembly.

REBUILDING THE BENDIX®AD-2®AIR DRYER

END COVER

ASSEMBLY

To remove the end cover assembly from the air dryer,

follow steps 1-6 under the section of this manual entitled

Removal of Desiccant Cartridge. Before rebuilding the

end cover, clean the exterior thoroughly using a quality

commercial solvent.

DISASSEMBLY

1. Remove and discard the large o-ring around the end

cover assembly.

2. Remove the single #6-32 screw securing the exhaust

diaphragm and separate the diaphragm, washer, and

screw. Discard the diaphragm.

3. Remove the three #6-32 screws securing the exhaust

cover and remove the exhaust cover.

4. Remove the purge valve assembly and the large hex

cap nut from the end cover and discard both o-rings

around the cap nut.

5. Using a 7/16” socket wrench and a large screwdriver,

remove the 1/4”-20 hex head cap screw which holds

the assembly together.

6. Separate cap screw, purge valve, purge valve piston

and the piston return spring.

7. Discard the piston o-ring, the purge valve, and the

piston return spring.

8. Wash all remaining parts in a commercial solvent,

making sure all surfaces, bores, ports, and passages

are clean and dry before assembly.

NOTE: If during the serviceability checks it was determined

that the thermostat was defective, use the following

procedure. It is not necessary to replace this unit each time

the end cover is rebuilt. To service, install the thermostat

kit as shown in Figure 17.

9. Remove nut (2), then lock washer (3), plain washer (4)

and o-ring (5). Discard o-ring and retain other parts.

10. Remove and retain the four Phillips head screws (7)

and cover (6).

11. Remove and discard gasket (10).

12. Remove and retain spacer (11).

13. Cut uninsulated thermostat wire at Point B. (Figure

17), remove and discard the thermostat and terminal

assembly (1).

14. Clean the remaining wire attached to the heater

terminal.

15. Clean the thermostat “pocket” in the end cover (9).

ASSEMBLY

1. Cut the uninsulated lead of new thermostat (1) at Point

A (Figure 17).

2. Install thermostat in end cover “pocket” and position

uninsulated leads next to each other.

3. Using a soldering heat sink, clamp uninsulated leads at

Point B and solder leads with straight rosin core solder.

DO NOT USE ACID CORE SOLDER. Clean excess

solder off of the end cover.

4. Install thermostat terminal (1) in cover (6).

5. Install o-ring (5), washer (4), lock washer (3) and nut

(2). Torque nut to 20-30 in-lbs.

6. Install spacer (11) over thermostat (1).

7. Install gasket (7) and cover (6) and secure cover to end

cover (9) using screws (7) and lock washers (8).

8. Torque to 30-40 in-lbs.

9. Test thermostat as follows:

A. At a temperature above 85°F, check resistance

between thermostat terminal (1) and end cover (9).

Resistance should be 200,000 ohms or greater; if

not, check for solder “path” short.

B. Chill the entire end cover assembly to 35°F or below

and check resistance again. Resistance should be

2-15 ohms.

10. Lubricate the piston o-ring and install it on the piston.

11. Lubricate the piston bore.

12. Install the purge piston return spring and piston.

13. Install the purge valve in the large cap nut so that the

rubber portion rests on the metal seat of the cap nut.

14. Secure the valve to the piston using the 1/4”-20 cap

screw and lock washer and torque to 50 in-lbs.

12

Figure 17 – Heather and Thermostat

Figure 16 – Bendix®AD-2®Air Dryer End Cover

15. Lubricate and install the two cap nut o-rings.

16. Lubricate the cap nut threads and the cap nut bore

of the end cover and install the cap nut, torquing it to

180–250 in-lbs.

17. Secure the exhaust diaphragm to the exhaust cover

using the #6-32 Phillips head screw and diaphragm

washer.

18. Secure the exhaust cover to the purge valve hex head

cap nut using the #6-32 Phillips head screws.

19. Lubricate and install the large diameter o-ring around

the end cover assembly.

REBUILDING THE BENDIX®AD-2®AIR DRYER

OUTLET PORT CHECK VALVE

1. Make certain the vehicle is safely parked. Block the

wheels if necessary.

2. Locate and remove the line connected to the outlet port

of the AD-2 air dryer.

3. Remove the check valve from the outlet port. (See

Figure 2.)

4. Remove the rubber sealing ring from the external

threaded portion of the body and discard it.

5. Disassemble the check valve by unscrewing the body

halves and note the order of the removal of the parts.

6. Discard and replace the check valve, valve spring and

metal seal washer.

7. Wash all parts in a quality commercial solvent, making

sure all surfaces are clean and dry prior to reassembly.

8. Coat all parts with a !lm of barium base lubricant such

as Bendix piece number 246671 which is supplied with

the maintenance kit.

9. Reassemble the check valve and torque the body

halves to between 200 and 225 in-lbs.

10. Reinstall the check valve in the AD-2 air dryer outlet

port and reconnect the line leading to the !rst reservoir.

REINSTALLING THE DESICCANT CARTRIDGE

IN THE AIR DRYER

1. Wipe the inside of the dryer clean. If a solvent is used,

be certain that no residue is left in the shell.

2. Check to be certain a !lm of barium base grease is

present on the o-rings and install the cartridge and

purge plate assembly into the body. Engage the bolt

and tighten to 375 in-lbs or 32 ft-lbs torque.

3. Check the end cover o-ring to be certain it is clean and

lubricate the o-ring with a barium base lubricant such as

Bendix piece number 246671. Install the o-ring on the

end cover and install the end cover in the dryer body.

4. Position the end cover as marked during removal and

install the retainer ring so that the gap in the ring is

within an inch of the notch in the body.

5. Grease the threads on the three cap screws and

reinstall them with their retainers in the end cover.

HEATER POST

9

A

B

1

8

5

3

214611

7

10

9

1

THERMOSTAT

COVER

13

6. Reconnect the air control line to the purge valve port

in the end cover.

7. Reconnect the thermostat and heater wire.

8. Test the air dryer as outlined under the Preventive

Maintenance and Checking Serviceability Section of

this manual.

AIR DRYER INSTALLATION

1. Install the air dryer in the compressor discharge line

as close to the supply (!rst) reservoir as possible. The

discharge line between the compressor and air dryer:

a) must not exceed 20 feet in length; b) nor less than

six feet in length for a two cylinder compressor; c) or

ten feet in length for a single cylinder compressor. Six

feet of discharge line and a 90 cubic inch reservoir can

be used in lieu of ten feet of discharge line for single

cylinder compressors.

The discharge line should slope downward from the

compressor to the air dryer inlet to avoid water traps

and to allow drainage to the air dryer. (If the 90 cubic

inch reservoir is used, it should also be mounted and

plumbed to avoid water traps and to allow drainage into

the air dryer.) Discharge lines may be either copper

tubing or high temperature hose. Note that Bendix

compressors require a minimum of four feet of copper

tubing extending from the discharge port. The balance

of the discharge line may be either copper tubing or

high temperature hose.

2. Locate outside the engine compartment in an area of air

"ow when the vehicle is in motion. Do not mount near

exhaust system or other heat-producing components

and avoid road-splash areas. Provide 20 cm (8 in.) of

clearance below the dryer for servicing.

3. Mount vertically, with the purge valve exhaust toward

the ground, away from the frame and other components.

Connect a hose to the exhaust cover, if necessary, since

this valve may expel rust and scale particles as well as

condensate and oil collected in the dryer.

4. Connect the purge valve control port to one of the

governor unloader ports. This line should be routed

such that no water traps are formed.

5. For the dryers with a 3/4-14 or 1 - 11-1/2 dry seal outlet

port, a check valve must be placed between the purge

volume and the !rst downstream reservoir. (Dryers with

1/2-14 dryseal outlet ports have a built-in check valve.)

6. Connect a fused #16 gauge wire from the “on” position

of the engine control or ignition switch to the heater

terminal. This connection must be waterproof. Use an

8 to 10 amp fuse with 12 volt end covers and with 24

volt end covers identi!ed with the marking “24V 120W.”

Use a 4 to 5 amp fuse with 24 volt end covers identi!ed

with the marking “24V.”

MAINTENANCE KITS

286718 – DESICCANT CARTRIDGE REFILL KIT: This

kit can only be used on new revision cartridges. See

the cartridge rebuild section of this manual for proper

identi•cation of current revision cartridge. This kit contains

the necessary parts to rebuild the cartridge and the

desiccant sealing plate.

286875N –END COVER ASSEMBLY KIT: This kit contains

the complete end cover.

287313–DESICCANT CARTRIDGE REPLACEMENT KIT:

This kit contains a factory replacement desiccant cartridge

and the parts necessary to rebuild the desiccant sealing

plate.

1 0 1 9 0 0 X – R E M A N U FA C T U R E D D E S I C C A N T

CARTRIDGE AND DESICCANT SEALING PLATE:

This unit allows for complete exchange, as a unit, of the

cartridge and desiccant plate.

287053N – Bendix®AD-2®AIR DRYER PURGE VALVE

MAINTENANCE KIT: This kit contains the parts necessary

to rebuild the AD-2 air dryer end cover purge valve.

287 2 9 8 N – A D -2 A I R D RY ER CH EC K VA LV E

MAINTENANCE KIT: This kit contains the components

necessary to rebuild the old-style, two-piece check valve.

It does not service the new-style, one-piece check valve

assembly.

107454N – AD-2 AIR DRYER CHECK VALVE: Replaces

the one-piece and two-piece check valves.

288918 – THERMOSTAT COVER REPLACEMENT

KIT: This kit contains the parts required to replace the

non-metallic thermostat cover only. This kit is used to

replace a damaged cover and does not contain thermostat

parts.

102657N – THERMOSTAT MAINTENANCE KIT: This

kit contains the necessary components to rebuild the

thermostat assembly in the AD-2 air dryer.

14

Figure 19 – Typical Installation for the Bendix®AD-1™Air Dryer

COMPRESSOR

UNLOADER

GOVERNOR

RESERVOIR #1

BENDIX®

AD-1™

AIR

DRYER

SAFETY VALVE

PURGE DRAIN

VALVE

#16 GAUGE WIRE

TO IGNITION

TO NO. 2

RESERVOIR

HEATER

CHECK VALVE*

* (NOTE) A CHECK VALVE MUST BE PLACED BETWEEN THE AIR DRYER AND THE NO.1 RESERVOIR

Figure 18 – Typical Installation for the Bendix®AD-2®Air Dryer

COMPRESSOR

UNLOADER

GOVERNOR

RESERVOIR #1

BENDIX®

AD-2®

AIR

DRYER

SAFETY VALVE

PURGE DRAIN

VALVE

#16 GAUGE WIRE

TO IGNITION

TO NO. 2

RESERVOIR

15

Contact the Bendix Tech Team at 1-800-247-2725 (option 2)

assist you Monday – Thursday, 8:00 a.m. – 6:00 p.m. ET

and Friday, 8:00 a.m. – 5:00 p.m. ET.

BENDIX AD-2 AIR DRYER TROUBLESHOOTING

SYMPTOM CAUSE REMEDY

1. Dryer is constantly

“cycling” or purging.

A. Excessive system leakage. A. Test for excessive leakage and repair. Allowable

leakage:

• Pre-121 vehicles, single vehicle - 2 psi/minute.

• Tractor trailer - 3 psi/minute.

• 121 vehicles, single vehicle - 1 psi/minute per

service reservoir.

B. Excessive leakage in !ttings, hoses and

tubing connected to compressor, air

dryer and !rst reservoir.

B. Using a soap solution, test for leakage at the !ttings,

drain valve (if any) and safety valve in the !rst

reservoir. Repair or replace as necessary.

C. Defective check valve between the air

dryer and !rst reservoir. (In standard

AD-2 air dryer, check valve to outlet port.)

C. Test the check valve. Leakage should not exceed a

1” soap bubble in 5 seconds. It may be necessary to

remove the air dryer check valve to test. Repair or

replace as necessary.

D. Defective governor. D. Test the governor for proper cut-in or cut-out

pressures and excessive leakage in both positions.

E. Leaking purge valve in the air dryer end

cover (control side).

E. Remove the end cover. Apply 120 psi at the control

port. Soap both sides around purge valve to test for

control piston leakage. (Permissible leakage - 1”

bubble in 5 seconds.)

F. Compressor unloader mechanism is

leaking excessively.

F. Remove the air strainer or !tting from the compressor

inlet cavity. With the compressor unloaded, check for

unloader piston leakage. Slight leakage is permissible.

2. Water in vehicle

reservoirs.

A. Desiccant requires replacement. A. Replace the desiccant cartridge.

B. Improper discharge line length or

improper line material.

B. Discharge Line Length:

• Minimum of 6’ metal tubing for a two-cylinder

compressor.

• 10’ for a one-cylinder compressor.

• "ex hose can be substituted at ratio of 1-1/2’ "ex

hose for each 1’ of metal.

C. Air system charged from outside air

source (outside air not passing through

the air dryer).

C. If the system must have an outside air !ll provision,

the outside air should pass through the air dryer.

(Unused inlet on air dryer can be used.) Use of this

should be minimized.

D. Air dryer not purging (see Symptom #5). D. See cause and remedy for Symptom #5.

E. Purge (air exhaust) time insuf!cient due

to excessive system leakage (see causes

for Symptom #1).

E. Check causes and remedies for Symptom #1.

F. Air dryer/vehicle application requires

additional purge volume.

F. When compressor is loaded (compressing) longer

than 90 seconds during normal operation, additional

purge volume may be needed. (Before proceeding,

contact the Bendix Tech Team. See contact

information below.)

G. Air dryer is not compatible with the

vehicle air system requirement -

(Improper air dryer/vehicle application).

G. Air dryer requires minimum purge time of 30 seconds.

If the compressor stays loaded longer than 90

seconds and additional purge volume is added,

longer purge time is required. Air dryer ef!ciency

will decrease as compressor loaded time increases

beyond 120 seconds, during normal operation of

the vehicle. (This limitation assumes a compressor

of approximately 12 CFM and engine operation at

1600-1900 RPM.) The air dryer will accommodate

occasional longer loaded times, such as the initial

system build-up.

3. Safety valve on the

air dryer “popping off”

or exhausting air.

A. Desiccant cartridge plugged or saturated. A. Check compressor for excessive oil passing and/or

correct compressor installation. Repair or replace as

necessary. Rebuild or replace the cartridge.

B. Defective check valve between air dryer

outlet port and !rst reservoir. (in standard

AD-2 air dryer, check valve in outlet port.)

B. Test to determine if air is passing through check valve.

Repair or replace.

C. Defective !ttings, hose or tubing between

air dryer and !rst reservoir.

C. Check to determine if the air is reaching the !rst

reservoir. Inspect for kinked tubing or hose. Check for

undrilled or restricted hose or tubing !ttings.

16

SD-08-2403 Rev. 006 © 2017 Bendix Commercial Vehicle Systems LLC, a member of the Knorr-Bremse Group • 06/17 • All Rights Reserved

BENDIX AD-2 AIR DRYER TROUBLESHOOTING

SYMPTOM CAUSE REMEDY

4. Constant exhaust of

air at the air dryer

purge valve exhaust

or unable to build the

system pressure.

A. Air dryer purge valve leaking excessively. A. With the compressor loaded, apply a soap solution on

the purge valve exhaust, to test for excessive

B. Defective governor. B. Check the governor for proper “cut-in”, “cut-out”

pressure and excessive leakage in both positions.

Repair or replace as necessary.

C. Purge control line connected to reservoir

or exhaust port of governor.

C. The purge control line must be connected to the

unloader port of governor.

D. Purge valve frozen open - faulty heater

and thermostat, wiring or blown fuse.

D. Test heater and thermostat as described in Step 7 of

the Preventive Maintenance Section.

E. Inlet and outlet air connections are

reversed.

E. Compressor discharge to inlet port. Reconnect the

lines properly.

F. Check valve between the air dryer and

the !rst reservoir is defective.

F. Test the check valve for proper operation (see

Symptom #3, Remedy B).

G. Kinked or blocked (plugged) discharge

line.

G. Check to determine if air passes through the

discharge line. Check for kinks, bends or excessive

carbon deposits.

H. Excessive bends in the discharge line

(water collects and freezes).

H. Discharge line should be constantly sloping from

compressor to air dryer with as few bends as possible.

I. Excessive system leakage. I. See Symptom #1’s Causes and Remedies.

5. The air dryer does

not purge or exhaust

air.

A. Broken, kinked, frozen, plugged or

disconnected purge control line.

A. Test to determine if air "ows through purge control line

when the compressor is unloaded. Check for undrilled

!ttings. (See Symptom #4, Remedy C.)

B. Faulty air dryer purge valve. B. After determining that the air reaches purge valve

(Remedy A above), repair the purge valve.

C. See Causes B,E,F,G,H, for Symptom #4. C. Refer to Remedies B, E, F, G, H, for Symptom #4.

6. Desiccant material

being expelled from

the air dryer purge

valve exhaust (may

look like whitish liquid

or paste or small

beads).

OR

Unsatisfactory

desiccant life.

A. This symptom is almost always

accompanied by one or more of

Symptoms #1,2,3,4 and 5. See related

causes for these Symptoms above.

A. See Causes and Remedies for Symptoms #1,2,3,4

and 5.

B. Air dryer not securely mounted.

(Excessive vibration).

B. Vibration should be held to a minimum. Add bracket

supports or change the air dryer mounting location if

necessary.

C. Defective cloth covered perforated plate

in the air dryer desiccant cartridge or

improperly rebuilt desiccant cartridge.

C. Replace or rebuild the desiccant cartridge. NOTE:

If rebuilding the cartridge, carefully follow the

instructions packed with cartridge rebuild kit.

D. Compressor is passing excessive oil. D. Check for proper compressor installation; if symptoms

persist, replace the compressor.

E. Faulty heater and thermostat, wiring or

fuse not allowing purge. (Cold weather

operation only.)

E. Refer to Remedy D under Symptom #4.

7. Unable to remove

the end cover, or

unable to install new

desiccant cartridge.

A. Result of reversing the inlet and outlet

connections. (See Symptom #4, Cause

E.)

A. Refer to Symptom #4, Cause E.

8. Air dryer end cover

separates from the

air dryer housing

during operation.

A. Excessive system pressure build-up

within air dryer; caused by either plugged

desiccant, check valve failure, frozen

or obstructed discharge line (between

air dryer and !rst reservoir) or governor

failure in conjunction with safety valve

failure.

A. Because it is dif!cult to determine the extent of the

internal damage to the air dryer, it is recommended

that the air dryer be replaced. NOTE: This type of

failure can be prevented by checking the dryer for

proper operation every three (3) months.

Log-on and Learn from the Best

On-line training that's available when you are 24/7/365.

Visit www.brake-school.com.

This manual suits for next models

1

Table of contents

Other BENDIX Dehumidifier manuals

BENDIX

BENDIX AD-9 Mounting instructions

BENDIX

BENDIX TRAILER SYSTEM GUARD AIR DRYER User manual

BENDIX

BENDIX AD-SP SYSTEM PURGE AIR DRYER User manual

BENDIX

BENDIX AD-9si Mounting instructions

BENDIX

BENDIX AD-IS - User manual

BENDIX

BENDIX AD-1 AIR DRYER User manual

BENDIX

BENDIX AD-IS - Mounting instructions

BENDIX

BENDIX SD-08-2418 User manual

BENDIX

BENDIX AD-9 AIR DRYER User manual

BENDIX

BENDIX AD-IP INTEGRAL PURGE AIR DRYER User manual