BENDIX AD-9 Mounting instructions

1

®

SD-08-2412

AD-9 AIR DRYER

EXTENDED PURGE AD-9 AIR DRYER STANDARD AD-9 AIR DRYER

OUTER

SHELL

UPPER

BRACKET

LOWER

BRACKET

SUPPLY

PORT

WIRING HARNESS

CONNECTION

DELIVERY PORT

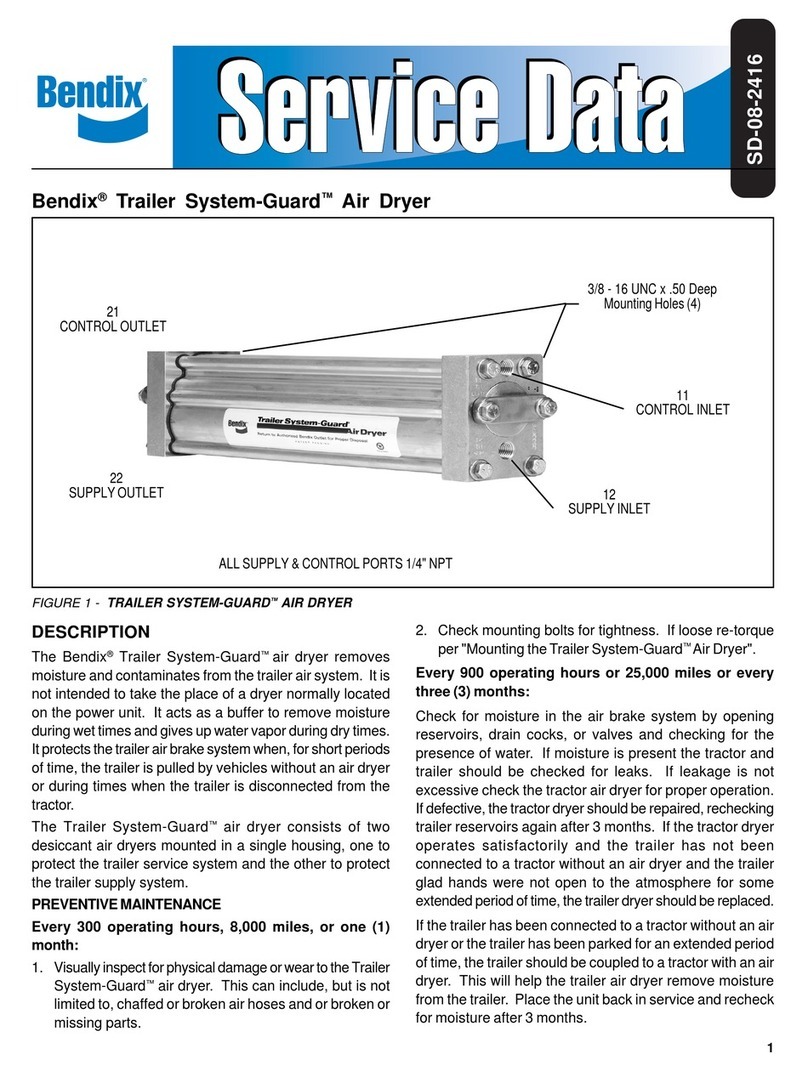

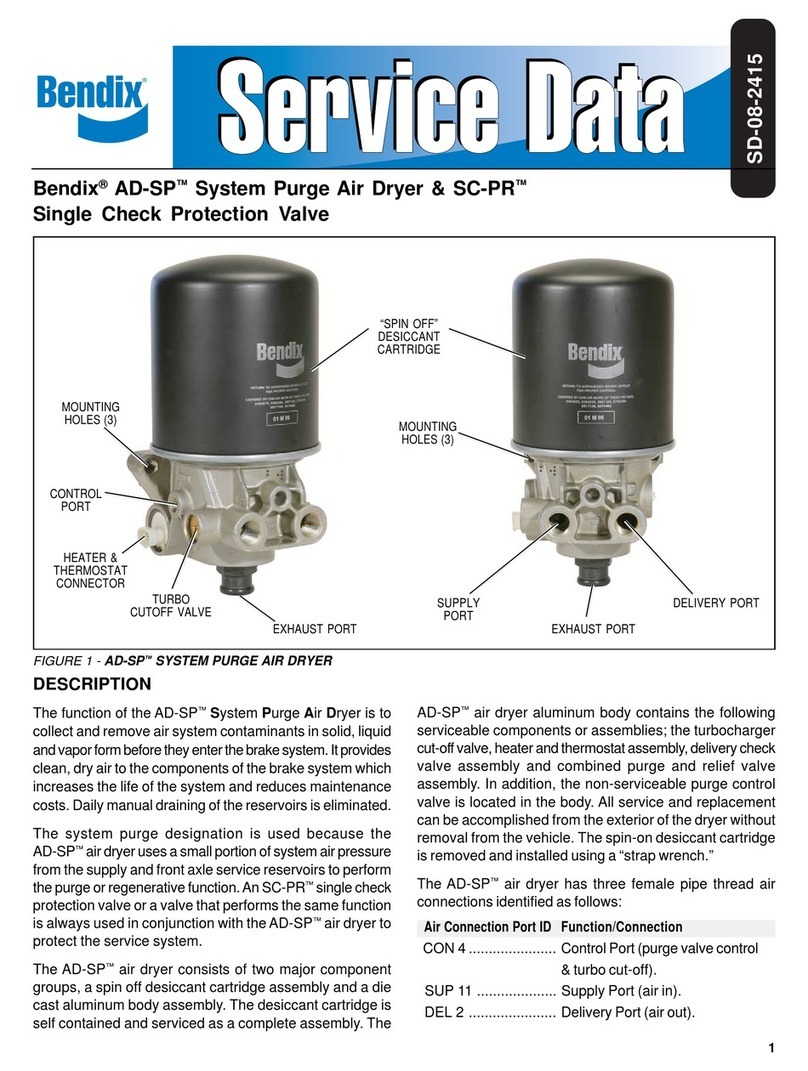

DESCRIPTION

The function of the AD-9 Air Dryer is to collect and remove

air system contaminants in solid, liquid and vapor form be-

fore they enter the brake system. It provides clean, dry air

to the components of the brake system which increases

the life of the system and reduces maintenance costs. Daily

manual drainin of the reservoirs is eliminated.

The AD-9 Air Dryer consists of a desiccant cartrid e and a

die cast aluminum end cover secured to a cylindrical steel

outer shell with ei ht cap screws and nuts. The end cover

contains a check valve assembly, a safety valve, three

threaded air connections and the pur e valve housin

assembly. The removable pur e valve housin assembly

incorporates a pur e valve mechanism and a turbo char er

cut-off feature that is desi ned to prevent loss of en ine

turbo boost pressure durin the pur e cycle of the AD-9 air

dryer. For ease of serviceability, the desiccant cartrid e and

dischar e check valve assembly are screw in type. The pur e

valve housin assembly, which includes the heater and

thermostat assembly, and the dischar e check valve

assembly, is serviceable from the exterior of the air dryer,

while servicin the screw-in desiccant cartrid e requires

removal of the air dryer assembly from the vehicle.

The AD-9 has three female pipe thread air connections and

each is identified as follows:

Port l.D. Function/Connection

CON 4............... Control Port

(pur e valve control and turbo cut-off).

SUP 11 ............. Supply Port (air in).

DEL 2 ............... Delivery Port (air out).

OUTER

SHELL

UPPER

BRACKET

LOWER

BRACKET

SUPPLY

PORT

WIRING HARNESS

CONNECTION

DELIVERY PORT

CHECK

VALVE

ASSEMBLY

END COVER

CHECK

VALVE

ASSEMBLY

END COVER

PORT

CONTROL

FIGURE 1 - AD-9 AIR DRYER MODELS

CONTROL

PORT

2

ORIFICE

PURGE

VOLUME

DELIVERY

PORT

HEATER

ELEMENT

SUMP

EXHAUST

PURGE

VALVE

RESERVOIR

SUPPLY

PORT

COMPRESSORGOVERNOR

ENGINE

TURBO

CONTROL

PORT

OIL

SEPARATOR

DESICCANT

BED

DESICCANT

CARTRIDGE

¬

¬

¬

¬

¬

¬

¬

¬

¬

¬

¬¬

¬

¬¬

¬

¬

¬

¬¬¬¬

¬¬¬¬

¬¬

¬¬

¬¬

¬

¬

CHECK

VALVE

OPERATION OF THE AD-9 AIR DRYER

The AD-9 air dryer alternates between two operational modes

or cycles durin operation: the charge cycle and the purge

cycle. The followin description of operation is separated

into these cycles of operation.

CHARGE CYCLE (refer to Figure 2)

When the compressor is loaded (compressin air)

compressed air, alon with oil, oil vapor, water and water

vapor flows throu h the compressor dischar e line to the

supply port of the air dryer end cover. As air travels throu h

the end cover assembly, its direction of flow chan es several

times, reducin the temperature, causin contaminants to

condense and drop to the bottom or sump of the air dryer

end cover.

After exitin the end cover, the air flows into the desiccant

cartrid e. Once in the desiccant cartrid e air first flows

throu h an oil separator which removes water in liquid form

as well as oil, oil vapor and solid contaminants.

Air exits the oil separator and enters the desiccant dryin

bed. Air flowin throu h the column of desiccant becomes

FIGURE 2 - AD-9 CHARGE CYCLE

pro ressively dryer as water vapor adheres to the desiccant

material in a process known as adsorption. The desiccant

cartrid e usin the adsorption process typically removes

95% of the water vapor from the pressurized air.

The majority of dry air exits the desiccant cartrid e throu h

its inte ral sin le check valve to fill the pur e volume between

the desiccant cartrid e and outer shell. Some air will also

exit the desiccant cartrid e throu h the pur e orifice adjacent

to the check valve.

Dry air flows out of the pur e volume throu h the sin le

check valve assembly and out the delivery port to the first

(supply) reservoir of the air system.

The air dryer will remain in the char e cycle until air brake

system pressure builds to the overnor cutout settin .

PURGE CYCLE (refer to Figure 3)

When air brake system pressure reaches the cutout settin

of the overnor, the compressor unloads (air compression

stopped) and the pur e cycle of the air dryer be ins. When

the overnor unloads the compressor, it pressurizes the

compressor unloader mechanism and line connectin the

¬

¬

¬

¬

¬

¬¬

¬¬

¬

¬

¬

CHECK

VALVE

ASSEMBLY

3

vapor adherin to it. Generally 15-30 seconds are required

for the entire pur e volume of a standard AD-9 to flow throu h

the desiccant dryin bed.

The end cover sin le check valve assembly prevents air

pressure in the brake system from returnin to the air dryer

durin the pur e cycle. After the 30 second pur e cycle is

complete, the air dryer is ready for the next char e cycle to

be in.

The pur e valve will remain open after the pur e cycle is

complete and will not close until air brake system pressure

is reduced and the overnor si nals the compressor to

char e.

TURBO CUT-OFF FEATURE (Refer to Figure 4)

The primary function of the turbo cut-off valve is to prevent

loss of en ine turbochar er air pressure throu h the AD-9 in

systems where the compressor intake is connected to the

en ine turbochar er. The turbo cut-off valve also reduces

the puffin of air out the open exhaust when a naturally

aspirated, sin le cylinder compressor equipped with an inlet

check valve is in use.

CHECK

VALVE ORIFICE

PURGE

VOLUME

DELIVERY

PORT

HEATER

ELEMENT

SUMP

EXHAUST

PURGE

VALVE

RESERVOIR

SUPPLY

PORT

COMPRESSORGOVERNOR

ENGINE

TURBO

CONTROL

PORT

OIL

SEPARATOR

DESICCANT

BED

DESICCANT

CARTRIDGE

¬

¬¬

¬¬

¬¬

¬

¬

¬

¬

¬¬

¬

¬¬

¬

¬

¬

¬

¬

¬

¬

¬

¬

¬

¬

¬

¬

TURBO

CUTOFF

PISTON

¬

CHECK

VALVE

ASSEMBLY

FIGURE 3 - AD-9 PURGE CYCLE

overnor unloader port to the AD-9 end cover control port.

The pur e piston moves in response to air pressure causin

the pur e valve to open to atmosphere and (partially) closin

off the supply of air from the compressor, this will be further

discussed in the section coverin the turbo cut-off feature.

Contaminants in the end cover sump are expelled

immediately when the pur e valve opens. Also, air which

was flowin throu h the desiccant cartrid e chan es direction

and be ins to flow toward the open pur e valve. Oil and solid

contaminants collected by the oil separator are removed by

air flowin from the desiccant dryin bed to the open pur e

valve.

The initial pur e and desiccant cartrid e decompression lasts

only a few seconds and is evidenced by an audible burst of

air at the AD-9 exhaust.

The actual reactivation of the desiccant dryin bed be ins

as dry air flows from the pur e volume throu h the desiccant

cartrid e pur e orifice and into the desiccant dryin bed.

Pressurized air from the pur e volume expands after passin

throu h the pur e orifice; its pressure is lowered and its

volume increased. The flow of dry air throu h the dryin bed

reactivates the desiccant material by removin the water

¬

¬

¬

¬

¬

¬

4

FIGURE 4 - AD-9 TURBO CUTOFF

At the onset of the pur e cycle, the downward travel of the

pur e piston is stopped when the turbo cut-off valve (tapered

portion of pur e piston) contacts its matin metal seat in

the pur e valve housin . With the turbo cut-off valve seated

(closed position), air in the dischar e line and AD-9 inlet

port is restricted from enterin the air dryer. While the turbo

cut-off effectively prevents loss of turbo char er boost

pressure to the en ine, some seepa e of air may be

detected under certain conditions of compressor en ine and

turbo char er operation, even so there will always be low

pressure trapped in the dischar e line.

PREVENT VE MA NTENANCE

Important: Review the warranty policy before performin

any intrusive maintenance procedures. An extended warranty

may be voided if intrusive maintenance is performed durin

this period.

Because no two vehicles operate under identical conditions,

maintenance and maintenance intervals will vary. Experience

is a valuable uide in determinin the best maintenance

interval for any one particular operation.

Every 900 operating hours or 2 ,000 miles or every three

(3) months:

1. Check for moisture in the air brake system by openin

reservoirs, drain cocks, or valves and checkin for

presence of water. If moisture is present, the desiccant

may require replacement; however, the followin

conditions can also cause water accumulation and

should be considered before replacin the desiccant:

A. An outside air source has been used to char e the

system. This air did not pass throu h the dryin bed.

UPPER

BRACKET

CHECK

VALVE

ASSEMBLY

SUPPLY

PORT

¬

¬

¬

¬

¬

¬

¬

¬

¬

¬

¬

¬

UPPER

BRACKET

STRAP

DESICCANT

CARTRIDGE

LOWER

BRACKET

HOUSING

CHECK

VALVE

ASSEMBLY

¬

DISCHARGE

LINE

TURBO

CUTOFF

PISTON

EXHAUST

PURGE

VALVE

TURBO

CUTOFF

PISTON

B. Air usa e is exceptionally hi h and not normal for a

hi hway vehicle. This may be due to accessory air

demands or some unusual air requirement that does

not allow the compressor to load and unload (com-

pressin and non-compressin cycle) in a normal

fashion. Check for hi h air system leaka e.

C. The air dryer has been installed in a system that

has been previously used without an air dryer. This

type system will be saturated with moisture and

several weeks of operation may be required to dry it

out.

D. Location of the air dryer is too close to the air com-

pressor. Refer to Locating AD-9 On Vehicle section.

E. In areas where more than a 30 de ree ran e of tem-

perature occurs in one day, small amounts of water

can accumulate in the air brake system due to con-

densation. Under these conditions, the presence of

small amounts of moisture is normal and should not

be considered as an indication that the dryer is not

performin properly.

Note: A small amount of oil in the system may be normal

and should not, in itself, be considered a reason to

replace the desiccant; oil stained desiccant can function

adequately.

2. Check mountin bolts for ti htness. Retorque to 270-

385 inch pounds.

PURGE VALVE

HOUSING

ASSEMBLY

PURGE

VALVE

DISCHARGE

PORT

FIGURE 5 - AD-9 AIR DRYER SECTIONAL VIEW

DESICCANT

BED

OIL

SEPARATOR

CONTROL

PORT

SUPPLY

PORT

5

3. Perform the Operation & Leakage Tests listed in this

publication.

Every 10,800 hours; 300,000 miles or 36 months:

1. Rebuild the air dryer includin the desiccant cartrid e.

Note: The desiccant chan e interval may vary from vehicle

to vehicle. Althou h typical desiccant cartrid e life is three

years, many will perform adequately for a lon er period of

time. In order to take maximum advanta e of desiccant life

and assure that replacement occurs only when necessary,

it is important that Operation & Leakage Tests be performed.

WARN NG!

This air dryer is intended to remove moisture and other

contaminants normally found in the air brake system. Do

not inject alcohol, anti-freeze, or other de-icin substances

into or upstream of the air dryer. Alcohol is removed by the

dryer, but reduces the effectiveness of the device to dry air.

Use of other substances can dama e the air dryer and may

void the warranty.

OPERAT ON & LEAKAGE TESTS

1. Test the outlet port check valve assembly by buildin

the air system to overnor cut-out and observin a test

air au e installed in the #1 reservoir. A rapid loss of

pressure could indicate a failed outlet port check valve.

This can be confirmed by bleedin the system down,

removin the check valve assembly from the end cover,

subject air pressure to the unit and apply a soap solution

to the check valve side. Leaka e should not exceed a 1

inch bubble in 1 second.

2. Check for excessive leaka e around the pur e valve.

With the compressor in loaded mode (compressin air),

apply a soap solution to the pur e valve housin

assembly exhaust port and observe that leaka e does

not exceed a 1 inch bubble in 1 second. If the leaka e

exceeds the maximum specified, service the pur e valve

housin assembly.

3. Close all reservoir drain cocks. Build up system pressure

to overnor cut-out and note that AD-9 pur es with an

audible escape of air. Fan the service brakes to reduce

system air pressure to overnor cut-in. Note that the

system once a ain builds to full pressure and is followed

by an AD-9 pur e.

4. Check the operation of the safety valve by pullin the

exposed stem while the compressor is loaded

(compressin air). There must be an exhaust of air while

the stem is held and the valve should reseat when the

stem is released.

5. Check all lines and fittin s leadin to and from the air

dryer for leaka e and inte rity.

LOWER

MOUNTING

BRACKET

AD-9

AIR DRYER

AD-9

END COVER

FEMALE

CONNECTOR

MALE

CONNECTOR

LATCH MUST BE

INSERTED UNTIL

IT SNAPS OVER

TAB ON MATING

CONNECTOR

SIDE VIEW END VIEW

A two lead, 12 inch, wire harness with attached weather

resistant connector is supplied with all retrofit and

replacement AD-9 Air Dryers. Connect one of the two

leads of the wire harness to the en ine kill or i nition

switch. The remainin lead of the wire harness must

be connected to a ood vehicle round. A fuse should

be installed in the power carryin wire; install a 10 amp

fuse for 12 volt heaters and a 5 amp fuse for a 24 volt

heater.

Use 14 AWG wire if it is necessary to len then the wire

harness provided.

Make certain all wire splices are waterproofed.

Tie wrap or support all electrical wire leadin to the

AD-9.

FIGURE 6 - HEATER AND THERMOSTAT CONNECTOR

6. Check the operation of the end cover heater and

thermostat assembly durin cold weather operation as

follows:

A. Electric Power to the Dryer

With the i nition or en ine kill switch in the ON posi-

tion, check for volta e to the heater and thermostat

assembly usin a voltmeter or test li ht. Unplu the

electrical connector at the air dryer and place the

test leads on each of the pins of the male connector.

If there is no volta e, look for a blown fuse, broken

wires, or corrosion in the vehicle wirin harness.

Check to see if a ood round path exists.

B. Thermostat and Heater Operation

Turn off the i nition switch and cool the end cover

assembly to below 40 de rees Fahrenheit. Usin an

ohmmeter, check the resistance between the elec-

trical pins in the female connector. The resistance

should be 1.5 to 3.0 ohms for the 12 volt heater as-

sembly and 6.8 to 9.0 ohms for the 24 volt heater

6

assembly. Note: Some early models o the AD-9

will have resistance readings o 1.0 to 2.5 ohms or

the 12 volt heater assembly and 4.8 to 7.2 ohms or

the 24 volt heater assembly. I the resistance is higher

than the maximum stated, replace the purge valve

housing assembly, which includes the heater and

thermostat assembly.

Warm the end cover assembly to over 90 de rees

Fahrenheit and a ain check the resistance. The re-

sistance should exceed 1000 ohms. If the resistance

values obtained are within the stated limits, the ther-

mostat and heater assembly is operatin properly. If

the resistance values obtained are outside the stated

limits, replace the pur e valve housin assembly,

which includes the heater and thermostat assem-

bly.

REBUILDING THE AD-9 AIR DRYER

GENERAL

If, after completin the routine operation and leaka e tests,

it has been determined that one or more components of the

air dryer requires replacement or maintenance, refer to the

followin list to find the appropriate kit(s).

When rebuildin or replacin components of the air dryer

use only enuine Bendix parts. For ease in servicin the

AD-9 desiccant cartrid e assembly, it is recommended that

the air dryer be removed from the vehicle.

MA NTENANCE K TS AVA LABLE:

5005037Hard Seat Pur e Valve Housin Maintenance Kit

5005893Soft Seat Pur e Valve Housin Maintenance Kit

These kits contain the parts necessary to rebuild

the air portion of the pur e valve housin and do not

include the heater and thermostat.

107794 Desiccant Cartrid e Replacement Kit

This kit contains the parts necessary to chan e

the desiccant cartrid e only.

107796 Remanufactured Desiccant Cartrid e

Replacement Kit

This kit contains the parts necessary to chan e

the desiccant cartrid e only.

107799 End Cover Check Valve Assembly Replacement

3/4 inch thread size.

107800 End Cover Check Valve Assembly Replacement

1/2 inch thread size.

800405 Service New or Remanufactured Exchan e Pur e

Valve Housin Assembly - Soft Seat (w/heater

and thermo.) 12 volt system.

5004479Service New or Remanufactured Exchan e Pur e

Valve Housin Assembly - Hard Seat (w/heater

and thermo.) 12 volt system.

5004339Service New or Remanufactured Exchan e Pur e

Valve Housin Assembly - DLU (w/heater and

thermo.) 12 volt system.

5004338Service New or Remanufactured Exchan e Pur e

Valve Housin Assembly - Soft Seat (w/heater and

thermo.) 24 volt system.

5004480Service New or Remanufactured Exchan e Pur e

Valve Housin Assembly - Hard Seat (w/heater and

thermo.) 24 volt system.

5004340Service New or Remanufactured Exchan e Pur e

Valve Housin Assembly - DLU (w/heater and

thermo.) 24 volt system.

107695 Complete Mountin Bracket Kit

This kit contains the upper and lower brackets as

well as the necessary hardware items to mount

them.

IMPORTANT! PLEASE READ AND FOLLOW

THESE INSTRUCTIONS TO AVOID

PERSONAL INJURY OR DEATH:

When working on or around a vehicle, the following

general precautions should be observed at all times:

1. Park the vehicle on a level surface, apply the

parking brakes, and always block the wheels.

2. Stop the engine when working around the vehicle.

3. If the vehicle is equipped with air brakes, make

certain to drain the air pressure from all reservoirs

before beginning ANY work on the vehicle.

4. Following the vehicle manufacturers

recommended procedures, deactivate the electrical

system in a manner that removes all electrical

power from the vehicle.

. When working in the engine compartment the

engine should be shut off. Where circumstances

require that the engine be in operation, EXTREME

CAUTION should be used to prevent personal injury

resulting from contact with moving, rotating,

leaking, heated, or electrically charged

components.

6. Never connect or disconnect a hose or line

containing pressure; it may whip. Never remove a

component or plug unless you are certain all

system pressure has been depleted.

7. Never exceed recommended pressures and always

wear safety glasses.

8. Do not attempt to install, remove, disassemble or

assemble a component until you have read and

thoroughly understand the recommended

procedures. Use only the proper tools and observe

all precautions pertaining to use of those tools.

7

FIGURE 7 - AD-9 AIR DRYER ASSEMBLY

NOTE: NUMBERS 9 AND 12

NOT USED

7

1 O-RING

2 EXHAUST DIAPHRAGM

3 1 4" TAPPING SCREW

4 PURGE VALVE LOCK NUT

5 O-RING

6 O-RING

7 O-RING

8 PURGE VALVE ASSEMBLY

10 O-RING

11 PURGE VALVE

13 SPRING

14 O-RING

15 CHECK VALVE ASSEMBLY

16 3 8" CAP SCREW

17 3 8" SPECIAL WASHER

18 3 8" CAP SCREW (LONG)

19 LOCK NUT

20 LOWER MOUNTING BRACKET

21 O-RING

22 DESICCANT CARTRIDGE

COMPLETE

23 O-RING

24 HOUSING

25 5 16" X 4-1 2" UPPER BRACKET

CAP SCREW

26 UPPER BRACKET STRAP

27 UPPER MOUNTING BRACKET

28 5 16" LOCK WASHER

29 5 16" LOCK NUT

30 EXHAUST COVER

31 TORX HEAD BOLT

32 EXHAUST DIAPHRAGM WASHER

33 PURGE PISTON

4

32

3

30

13

33

14

10

11

2

18

31

5

15

17

20

17

1

6

16

SAFETY

VALVE

23

21

22

END

COVER

25

26

28

29

27

24

19

17

8

8

9. Use only genuine Bendix replacement parts,

components, and kits. Replacement hardware,

tubing, hose, fittings, etc. should be of equivalent

size, type, and strength as original equipment and

be designed specifically for such applications and

systems.

10. Components with stripped threads or damaged

parts should be replaced rather than repaired.

Repairs requiring machining or welding should not

be at tempted unless specifically approved and

stated by the vehicle or component manufacturer.

11. Prior to returning the vehicle to service, make

certain all components and systems are restored

to their proper operating condition.

AD-9 REMOVAL

1. Park the vehicle on a level surface and prevent movement

by means other than the brakes.

2. Drain all reservoirs to 0 p.s.i. (0 kPa). Caution:

Compressor dischar e line may still contain residual

pressure.

3. Identify and disconnect the three air lines from the end

cover and note the position of end cover ports relative to

the vehicle.

4. Unplu the vehicle wirin harness from the heater and

thermostat assembly connector on the pur e valve

housin assembly.

5. Loosen the 5/16" X 4-1/2" hex bolt securin the upper

mountin strap.

6. Remove, retain and mark the two 3/8" end cover cap

screws, lock nuts and four special washers that retain

the lower mountin bracket to the end cover, also mark

these two holes of the end cover. (These bolts are lon er

than the other 6 bolts.)

7. Remove the AD-9 air dryer from its mountin brackets

on the vehicle.

D SASSEMBLY

The followin disassembly and assembly procedure is

presented for reference purposes and presupposes that a

major rebuild of the AD-9 is bein undertaken. Several

replacement parts and maintenance kits are available which

do not require full disassembly. The instructions provided

with these parts and kits should be followed in lieu of the

instructions presented here. Refer to Fi ure 7 durin

disassembly.

Caution: While performin service on the AD-9 air dryer, it

is not recommended that a clampin device (vise, C-clamp,

etc.) be used to hold any die cast aluminum component as

dama e may result. To hold the end cover, install a pipe

nipple in the supply port and clamp the nipple into a vise.

1. Usin an adjustable wrench or an 1-3/4" socket, remove

the delivery, check valve assembly (15) and o-rin .

Remove the o-rin from the check valve assembly.

2. Remove the three 1/4" self tappin screws (3) that secure

the pur e valve housin assembly to the end cover

assembly. Pull the pur e valve housin assembly out of

the end cover assembly. Remove the three o-rin s (5,6 &

7) from the exterior of the pur e valve housin assembly.

Note: O-rin s 5 and 6 may be lod ed in the end cover

bores, if so, they must be removed

3. Pur e Valve Disassembly:

Note: In most cases a flat (non-extended) exhaust cover

(30) is used. This cover should be left intact while

servicin the pur e valve housin assembly. However, if

an extended type exhaust cover is in use to

accommodate the attachment of an exhaust hose, the

exhaust cover must be carefully peeled off the pur e

valve housin . Use a thin flat blade to pry the exhaust

cover off, taking care not to damage the potting

material (RTV sealant) under the cover. To remove

the piston from the pur e valve housin assembly requires

a special Torx head socket or a twelve point 1/4" socket

to hold the head of the pur e valve bolt (31).

A. Remove the 1/4" nut (4) from the bottom of the pur e

valve housin assembly usin a 9/16" socket wrench

and a Torx head socket to hold the head of the bolt

(31). Remove the diaphra m washer (32) (if present),

and the diaphra m (2) (if present), and the pur e

valve (11) from the pur e valve housin .

B. Remove the 1/4" Torx head bolt (31) from the oppo-

site end, then the pur e piston (33), the return sprin

(13) and two o-rin s (10 & 14); one on the O.D. and

the other in the inside of the pur e piston.

C. Heater and Thermostat Assembly Replacement.

Caution: Do not attempt to remove this assembly,

as it will be dama ed durin the removal process

and is not available as a service part. If the heater

and thermostat are defective, replace the entire pur e

valve housin assembly which includes these items.

4. Remove the remainin six 3/8" cap screws (16), lock

nuts (19) and twelve special washers (17) that secure

the end cover to the housin (24). Separate the end cover

and desiccant cartrid e (22) from the housin (24).

5. Remove the end cover to outer housin o-rin (23).

6. Do not remove the safety valve from the end cover unless

it has been proven defective. If replacement is required,

apply thread sealant or teflon tape on the threads of the

replacement valve and torque to 120-400 in. Ibs.

7. Place a strap or chain wrench around the desiccant

cartrid e (22) so that it is approximately 2-3 inches away

from the end cover. Rotate the cartrid e counterclockwise

until it completely separates from the end cover. Note:

A substantial torque (up to 50 lb. t.) may be required to

per orm this disassembly.

9

8. Remove the desiccant cartrid e o-rin (21) from the end

cover.

CLEAN NG & NSPECT ON

1. Usin mineral spirits or an equivalent solvent, clean and

thorou hly dry all metal parts.

2. Inspect the interior and exterior of all metal parts that

will be reused for severe corrosion, pittin and cracks.

Superficial corrosion and or pittin on the exterior portion

of the upper and lower body halves is acceptable.

3. Inspect the bores of both the end cover and the pur e

valve housin for deep scuffin or ou es.

4. Make certain that all pur e valve housin and end cover

passa es are open and free of obstructions.

5. Inspect the pipe threads in the end cover. Make certain

they are clean and free of thread sealant.

6. Inspect the pur e valve housin bore and seats for

excessive wear and scuffin .

7. Inspect the pur e valve piston seat for excessive wear.

8. Inspect all air line fittin s for corrosion. Clean all old

thread sealant from the pipe threads.

9. All o-rin s removed should be discarded and replaced

with new o-rin s provided in appropriate kit(s).

Any component exhibitin a condition described in step 1

to 8 should be replaced.

ASSEMBLY

Prior to assembly, coat all o-rin s, o-rin rooves, and bores

with a enerous amount of barium base lubricant. Refer to

Fi ure 7 durin assembly unless otherwise advised.

1. Pur e Valve Housin Assembly

A. Install the o-rin (14) in its roove on the O.D. of the

pur e piston. Place the return sprin (13) in the bore

of the pur e valve housin . Place the o-rin (10) into

its recess in the bore of the pur e piston. Install the

1/4" Torx head bolt (31) into the l.D. of the pur e

piston. Insert the pur e piston (33) into the l.D. of

the sprin (13). Usin a Torx head wrench, push the

pur e piston into the piston housin until it bottoms.

B. While depressin the pur e piston with the Torx head

wrench, install the followin parts over the pur e valve

bolt (31) from the opposite end of the pur e valve

housin ; the pur e valve (11) with its rubber side first,

followed by the diaphra m (2) (if present), the dia-

phra m washer (32) (if present) or the flat washer

and finally the 1/4" hex nut (4). Torque the pur e

valve nut and bolt (4 & 31) to between 60-80 in. Ibs.

C. Install the three o-rin s (5, 6 & 7) on the pur e valve

housin placin each in its appropriate location. If

the exhaust cover (30) was removed durin disas-

sembly, install it on the pur e valve housin assem-

bly makin certain the bubble portion is positioned

over the thermostat. Install the assembled pur e valve

housin in the end cover makin certain to orient

both parts such that the connector is approximately

10 de rees clockwise from the supply port, while

makin certain the pur e valve housin is fully seated

a ainst the end cover. Secure the pur e valve hous-

in to the end cover usin the three 1/4" self-tappin

screws (3). Start all three screws by hand then

torque to 50-80 in. Ibs.

2. Install the o-rin on the check valve assembly (15), then

install the assembly in the end cover.

3. Install the desiccant cartrid e o-rin (21) in its roove in

the end cover. Usin a li ht coat of barium rease,

lubricate the bottom of the desiccant cartrid e in the

area that will contact the o-rin (21) and end cover. Screw

the desiccant cartrid e into the end cover until contact

is made between it and the o-rin . Usin a strap or chain

wrench positioned 2-3" from the bottom of the cartrid e,

turn the desiccant cartrid e clockwise 180-225 de rees

beyond the position where initial contact was made

between the cartrid e and end cover o-rin . Torque should

not exceed 50 ft. Ibs.

4

FIGURE 8 - END COVER TO HOUSING TORQUE PATTERN

78

3

5

62

1&9

10

4. Install the end cover outer housin o-rin (23) on the

shoulder in the end cover. Place the housin (24) over

the desiccant cartrid e and ali n the holes. Install the

six 3/8" cap screws (16), lock nuts (19) and twelve special

washers (17) makin certain they are in the proper

position as marked durin disassembly. The two lon er

3/8" cap screws (18) will be used to secure the AD-9 to

its mountin bracket. Ti hten the six cap screws and

nuts in a star pattern in a fashion similar to Fi ure 8;

dependin on lower bracket location. Torque to 270-385

in. Ibs. (Refer to Fi . 8.) Note: The two remainin bolt

holes in the end cover and two 3/8" cap screws must be

the ones marked durin disassembly to assure proper

orientation of the ports and adequate len th of the cap

screws.

NSTALLAT ON

1. Install the assembled AD-9 air dryer back onto the vehicle

by slippin it into the upper mountin bracket. Ali n the

two unused holes in the end cover with the bottom

mountin bracket such that the bottom bracket supports

air dryer. The AD-9 end cover should rest on the bracket.

Usin the remainin two 3/8" cap screws (18), four special

washers (17), and two lock nuts (19), secure the air

dryer to the lower bracket. Ti hten, then torque the two

remainin cap screws to 270-385 in. Ibs.

2. Ti hten the 5/16" X 4-1/2" bolt and nut on the upper

mountin bracket. Torque to 80-120 in Ibs.

3. Reconnect the three airlines to the proper ports on the

end cover (identified durin disassembly).

4. Reconnect the vehicle wirin harness to the AD-9 heater

and thermostat assembly connector by plu in it into

the air dryer connector until its lock tab snaps in place.

5. Before placin vehicle back into service, perform the

Operation and Leakage Tests stated elsewhere in this

manual.

RETROFITTING THE AD-9 AIR DRYER

GENERAL

The followin retrofit instructions are presented for reference

purposes only since Bendix aftermarket retrofit and

replacement air dryers are packa ed with the most up-to-

date installation instructions. The instructions packa ed with

the AD-9 should be followed in lieu of those presented here.

The precedin portion of this manual deals with in-service

repair and or replacement of the AD-9 air dryer. The portion

of the manual that follows is concerned with installin an

AD-9 on a vehicle not previously equipped with one.

VEH CLE APPL CAT ON REQU REMENTS

The basic application requirements presented here apply to

a standard air dryer installation. The majority of hi hway

vehicles in use today will meet these basic requirements

however, some may not. Examples of vehicles that may not

meet the requirements include, bulk trailer unloadin

operations and other hi h air consumption/continuous flow

systems. While the AD-9 air dryer can be used on these

vehicles the standard installation procedure presented in

this manual may require modification to assure proper

operation and service life. Consult your local authorized

Bendix parts outlet or sales representative for additional

information.

1. Char e Cycle Time - The AD-9 air dryer is desi ned to

provide clean, dry air for the brake system. When a

vehicles air system is used to operate non-brake air

accessories it is necessary to determine that durin

normal, daily operation the compressor should recover

from overnor cut-in to overnor cut-out (usually 100

psi to 120 psi) in 90 seconds or less at en ine RPMs

commensurate with the vehicle vocation. If the recovery

time consistently exceeds this limit, it may be

necessary to bypass the air accessory responsible for

the hi h air usa e. Consult your local authorized Bendix

parts outlet or sales representative for additional

information.

2. Pur e Cycle Time - Durin normal vehicle operation, the

air compressor must remain unloaded for a minimum

of 20 seconds for the standard AD-9 Air Dryer or 30

seconds for the Extended Purge model. These

minimum pur e times are required to ensure complete

re eneration of the desiccant material. If the pur e time

is occasionally shorter than the times specified, no

permanent ill effect should be expected, however, if the

pur e time is consistently less than the minimum, an

accessory by-pass system must be installed.

3. European Air Brake Systems - Brake systems that

incorporate compressors without inte ral unloadin

mechanisms and/or utilize a compressor dischar e line

unloader valve have special AD-9 air dryer installation

requirements. Consult your local authorized Bendix parts

outlet or sales representative for additional information.

4. Air Compressor Size - Althou h the AD-9 air dryer can

be used in conjunction with lar er compressors, it was

desi ned primarily for units rated for up to 17 CFM. It is

recommended that when usin the AD-9 air dryer with a

compressor which has a rated displacement exceedin

17 CFM that an authorized Bendix parts outlet or Bendix

marketin representative be contacted for assistance.

5. Holset E or QE Type Air Compressors - In order for the

AD-9 to function properly when installed with the Holset

Type E or QE compressor, several specialized Holset

components are required. Consult your local authorized

Holset parts outlet or sales representative for additional

information.

6. Use of Standard or Extended Pur e AD-9 - Use the

followin uidelines:

11

5. When choosin the mountin location for the AD-9, note

the dischar e line len th requirements stated under the

headin Connecting the Air Lines, elsewhere in this

instruction sheet.

Important Note: Under normal operatin conditions, the

maximum inlet air temperature for the AD-9 air dryer is

150 de rees Fahrenheit.

MOUNT NG THE AD-9

1. To install the lower mountin bracket on the AD-9 air

dryer, it will be necessary to remove and discard two of

the end cover bolts and lock nuts. To determine which

end cover bolts to utilize to attach the lower bracket,

take into consideration the pipin connections required

to install the AD-9 air dryer and use those that will best

position the unit for ease of installation. Locate the

bracket such that it cradles the end cover as shown in

Fi ure 2. Utilizin the two 2-3/8" lon cap screws, lock

nuts and special washers provided with the AD-9 air dryer

retrofit unit, attach the lower mountin bracket and torque

to 270-385 in. lbs.

2. Assemble the mountin strap and upper mountin

bracket as illustrated in Fi ure 4, by utilizin the 5/16"

cap screw, 5/16" lockwasher and 5/16" nut provided.

3. Place the upper bracket assembly onto the shell of the

AD-9 air dryer and orient it so that it bears entirely on

the cylindrical surface and does not extend onto the

domed top. The slot spacin between the upper and

lower bracket should be a minimum of 5.5 inches apart.

Do not ti hten strap onto the shell at this time.

BRACKET

Total Vehicle Reservoir

Volume Requirement

Less than 9,000 cu. in. .................. Standard AD-9

9,000 - 12,500 cu. in. ........................... Extended Purge AD-9

Greater than 12,500 cu. in. ............ Contact Bendix Rep. or

Bendix ngineering

VEH CLE PREPARAT ON

1. Park the vehicle on a level surface and prevent movement

by means other than the brakes.

2. Drain all reservoirs to 0 p.s.i. (0 kPa).

LOCAT NG AD-9 ON VEH CLE

1. The AD-9 air dryer must be mounted vertically (pur e

exhaust toward road surface) outside the en ine

compartment in an area of air flow while the vehicle is in

motion. The AD-9 must not be exposed to direct wheel

splash (located behind axle mud flap is acceptable).

2. Locate the AD-9 air dryer as close to the first (supply)

reservoir as possible.

3. Do not locate the AD-9 air dryer near heat producin

components such as the vehicle exhaust and make

certain adequate clearance from movin components

(e. . drive shaft, suspension, pitman arm, etc.) is

provided.

2-1 8"

END

COVER

LOWER

BRACKET

EXTRA

LONG

BRACKET

CAP SCREW

¬

¬

SPECIAL

WASHER

FIGURE 9 - LOWER BRACKET INSTALLATION

4. Locate the AD-9 air dryer on vehicle so that a minimum

of 11 inches (28 CM) clearance below the end cover is

available to allow servicin . Alternatively, provide access

to the bracket bolts so the unit may be removed for

servicin . FIGURE 10 - UPPER MOUNTING BRACKET AND STRAP

5 16" CAP

SCREW

NUT

STRAP

LOCK WASHER

12

4. A universal mountin plate (Pc. No. 248478) is available

to facilitate the mountin of the AD-9 air dryer to the

vehicle. It can be obtained throu h an authorized Bendix

parts outlet.

5. Mount the AD-9 air dryer on the vehicle usin 3/8" bolts

( rade 5 min.) and washers. Torque to 25 ft. Ibs. (300

inch pounds.) After positionin and mountin the upper

bracket assembly accordin to the installation

requirements, torque the 5/16" nut to 80120 in. Ibs. to

ti hten strap onto the shell.

CONNECTING THE AIR LINES

PURGE CONTROL L NE

1. Install a Pur e Control air line havin a minimum inside

diameter of 3/16 inches between the AD-9 end cover

control port and an unused unloader port on the overnor.

The control line must be plumbed direct to the overnor

and not in series with automatic drain valves, lubrication

systems, etc.

2. The control line should slope downward to the end cover

without formin potential water traps.

D SCHARGE L NE

General:

Where minimum diameter are specified, lar er line diameters

enerally improve performance and life and reduce

temperatures, particularly in severe applications.

1. The dischar e line material should be wire braided Teflon

hose, copper tubin or a combination of both.

2. The dischar e line should slope downward from the

compressor dischar e port to the AD-9 air dryer supply

port without formin water traps, kinks or restrictions.

Cross-overs from one side of the frame rail to the other,

if required, should occur as close as possible to the

compressor.

3. Fittin extensions must not be installed at the AD-9

supply port.

4. Dischar e line len ths and inside diameter requirements

are dependent on the vehicle application and are as

follows:

FIGURE 2 - AD-9 CHARGE CYCLE

COMPRESSOR

10 AMP - 12V

5 AMP - 24V

SUP

CON

14 GA WIRE

TO IGNITION

& GROUND

SAFETY VALVE

DEL TO RESERVOIR

#2

RESERVOIR

#1

GOVERNOR

UNLOADER

PORT

DELIVERY

SUPPLY

CONTROL

(HIDDEN)

FUSE

13

Typical P&D, School Bus and Line Haul

The minimum discharge line length is 6 feet and the maximum is 16 feet.

LENGTH l.D. MIN. OTHER REQUIREMENTS

6.0 - 9.5 ft. ......... 1 2 in. ...........None

9.5 - 12 ft............ 1 2 in. ...........Last 3 feet including Supply Port fitting must

be insulated with 1 2 inch thick closed cell

polyethylene pipe insulation.

12 - 16 ft. ............ 5 8 in. ...........Last 3 feet including Supply Port fitting must

be insulated with 1 2 inch thick closed cell

polyethylene pipe insulation.

If the discharge line length ust be less than 6 feet or greater

than 16 feet, contact your local Bendix representative or

authorized parts outlet for further infor ation.

High Duty Cycle Vehicles

(City Transit Coaches, Refuse Haulers, etc.)

The minimum discharge line length is 10 feet and the maximum is 16 feet.

LENGTH l.D. MIN. OTHER REQUIREMENTS

10-16 ft. ........ 1 2 in. ........ None

If the discharge line length ust be less than 10 feet or greater

than 16 feet, contact your local Bendix representative or

authorized parts outlet for further infor ation.

DEL VERY L NE

1. Install an air line of the same approximate l.D. as the

dischar e line between the AD-9 air dryer delivery port

and the first (supply) reservoir. This line should also slope

downward to the reservoir, if possible.

EXHAUST L NE

1. If it is necessary to direct AD-9 air dryer dischar e

contaminants away from vehicle components it may be

necessary to purchase a special exhaust cover for the

AD-9 air dryer (Pc. No. 298924) to replace the standard

exhaust cover furnished with the unit. A 1 inch (25.4

mm) I.D. hose can be clamped on the special AD-9 air

dryer exhaust cover. Note: Use a thin flat blade to pry

the standard exhaust cover off.

W R NG THE HEATER/THERMOSTAT

1. Determine the vehicles electrical system volta e and

make certain that the AD-9 air dryer that is to be installed

contains the same volta e heater. Use the AD-9 air dryer

part number to confirm the proper volta e. The AD-9 air

dryer is available with either a 12 or 24 volt heater which

uses 75 watts of power.

2. A two lead, 12 inch, wire harness with attached weather

resistant connector is supplied with all retrofit and

replacement AD-9 air dryers. Connect one of the two

leads of the wire harness to the en ine kill or i nition

switch. The remainin lead of the wire harness must be

connected to a ood vehicle round (not to the air dryer

or its mountin bracket). A fuse should be installed in

the power carryin wire; install a 10 amp fuse for 12 volt

heaters and a 5 amp fuse for a 24 volt heater.

3. Use 14 GA wire if it is necessary to len then the wire

harness provided with the AD-9 air dryer. Make certain

all wire splices are waterproofed.

4. Tie wrap or support all electrical wire leadin to the AD-

9 air dryer at 6 - 8 inch intervals. Note: Wires should

have sufficient slack and not completely tau ht.

TEST NG THE AD-9

Before placin the vehicle in service, perform the followin

tests:

1. Close all reservoir drain cocks.

2. Build up system pressure to overnor cut-out and note

that the AD-9 air dryer pur es with an audible escape of

air.

3. Fan the service brakes to reduce system air pressure

to overnor cut-in. Note that the system once a ain builds

to full pressure and is followed by a pur e at the AD-9 air

dryer exhaust.

4. It is recommended that the followin items be tested for

leaka e to assure that the AD-9 air dryer will not cycle

excessively.

(A) Total air system leaka e (See Bendix publication

BW-5057 Air Brake Handbook).

(B) Compressor unloader mechanism.

(C) Governor.

(D) Drain cock and safety valve in first (supply) reservoir.

(E) All air connections leadin to and from the first

(supply) reservoir.

14

AD-9 AIR DRYER TROUBLESHOOTING CHART

SYMPTOMS

1. Dryer is constantly

cyclin or pur in .

A. Test for excessive system leaka e.

Allowable leaka e:

Pre-121 vehicles, sin le vehicles - 2 psi/

minute.

Tractor trailer - 3 psi/minute.

121 vehicles, sin le vehicle - 1 psi/minute per

service reservoir.

Tractor trailer - 3 psi/minute per service

reservoir.

B. Usin soap solution, test for leaka e at fittin s,

drain valve (if any) and safety valve in first

reservoir. Repair or replace as necessary.

C. Remove check valve assembly from end cover.

Subject air pressure to delivery side of valve.

Apply soap solution at opposite end and check

for leaka e. (Permissible leaka e - 1 inch bubble

in five seconds) If excessive leaka e, replace

check valve assembly.

D. Test overnor for proper cut-in and cut-out

pressures and excessive leaka e in both

positions.

E. With the supply port open to atmosphere, apply

120 psi at the control port. Apply a soap solution

to the supply port and exhaust port (pur e valve

seat area). Permissible leaka e - 1 inch bubble

in five seconds.

F. Remove air strainer or fittin from compressor

inlet cavity. With compressor unloaded, check

for unloader piston leaka e. Sli ht leaka e

permissible.

G. Test Air Dryer system usin Bendix Product

Bulletin PRO-08-19 entitled Troubleshootin The

Holset E compressor system With Bendix Air

Dryer.

H. With au e installed at RES port of overnor,

pressure should not drop below Cut-In pressure

at the onset of the compressor Unloaded

cycle. If pressure drops, check for kinks or

restrictions in line connected to RES port. Line

connected to RES port on overnor must be

same diameter, or preferably lar er than, lines

connected to UNL port(s) on overnor.

A. Excessive system

leaka e.

B. Excessive leaka e in

fittin , hoses and tubin

connected to the

compressor, air dryer

and first reservoir.

CAUSE REMEDY

C. Defective check valve

assembly in AD-9 air

dryer end cover.

D. Defective overnor.

E. Leakin pur e valve

housin assembly and/or

o-rin s in AD-9 air dryer

end cover.

F. Compressor unloader

mechanism leakin

excessively.

G. Holset E type

compressor.

H. Rapid cyclin of the

overnor due to air

starvation at the RES

port of the overnor.

15

AD-9 AIR DRYER TROUBLESHOOTING CHART (Continue )

SYMPTOMS

2. Water in vehicle

reservoir.

A. Desiccant requires

replacement - excessive

contaminants in

desiccant cartrid e

assembly.

B. Improper dischar e line

len th or improper line

material. Maximum air

dryer inlet temperature is

exceeded.

CAUSE REMEDY

E. Pur e (air exhaust) time

insufficient due to

excessive system

leaka e (see causes for

Symptom #1).

C. Air system char ed from

outside air source

(outside air not passin

throu h air dryer).

D. Air dryer not pur in

(see Symptom #5).

F. Excessive air usa e - Air

dryer/vehicle application

requires additional pur e

volume. Air dryer not

compatible with vehicle

air system requirement

(Improper air dryer/

vehicle application).

A. Replace desiccant cartrid e.

B. Refer to section entitled Connectin the Air

Lines and check Dischar e Line size and

len th.

C. If system must have outside air fill provision,

outside air should pass throu h air dryer. This

practice should be minimized.

D. See cause and remedy for Symptom #5.

E. Check causes and remedies for Symptom #1.

F. Char e Cycle Time - The AD-9 is desi ned to

provide clean, dry air for the brake system.

When a vehicles air system is used to operate

non-brake air accessories it is necessary to

determine that durin normal, daily operation

the compressor should recover from overnor

cut-in to overnor cut-out (usually 100 psi to

120 psi) in 90 seconds or less at en ine RPMs

commensurate with the vehicle vocation. If the

recovery time consistently exceeds this limit, it

may be necessary to bypass the air accessory

responsible for the hi h air usa e. An example

of where a by-pass system would be required is

when the compressor is used to pressurize a

tank trailer for purposes of off-loadin product.

Consult your local authorized Bendix parts

outlet or sales representative for additional

information.

Pur e Cycle Time - Durin normal vehicle

operation, the air compressor must remain

unloaded for a minimum of 20 seconds for

the standard AD-9 or 30 seconds for the

Extended Purge Model. These minimum

pur e times are required to ensure complete

re eneration of the desiccant material. If the

pur e time is consistently less than the

minimum, an accessory by-pass system must

16

AD-9 AIR DRYER TROUBLESHOOTING CHART (Continue )

SYMPTOMS

2. Water in vehicle

reservoir (continued).

be installed. Consult your local authorized

Bendix parts outlet or sales representative for

additional information.

European Air Brake Systems - Brake systems

that incorporate compressors without inte ral

unloadin mechanisms and/or utilize a

compressor dischar e line unloader valve have

special air dryer installation requirements.

Consult your local authorized Bendix parts

outlet or sales representative for additional

information.

Air Compressor Size - Althou h the AD-9 can

be used in conjunction with lar er

compressors, it was desi ned primarily for

units rated for up to 17 CFM. It is

recommended that when usin the AD-9 with a

compressor which has a rated displacement

exceedin 17 CFM that an authorized Bendix

parts outlet or Bendix marketin representative

be contacted for assistance.

G. Replace desiccant cartrid e/end cover/o-rin .

Check to make sure desiccant cartrid e

assembly is properly installed.

H. Replace desiccant cartrid e/end cover o-rin .

Check to make sure desiccant cartrid e

assembly is properly installed.

Replace desiccant cartrid e assembly.

A. Check compressor for excessive oil passin

and/or correct compressor installation. Repair

or replace as necessary. Rebuild or replace

cartrid e.

B. Test to determine if air is passin throu h

check valve. Repair or replace.

C. Check to determine if air is reachin first

reservoir. Inspect for kinked tubin or hose.

Check for undrilled or restricted hose or tubin

fittin s.

D. Increase volume in dischar e line. Added

len th or size of line, or add a pin tank.

E. Reduce system pressure or obtain a hi her

settin safety valve.

CAUSE REMEDY

G. Air by-passes desiccant

cartrid e assembly.

H. Pur e time is

si nificantly less than

minimum allowable.

3. Safety valve on air dryer

poppin off or

exhaustin air.

A. Desiccant cartrid e

plu ed.

B. Defective dischar e

check valve in end cover

of the AD-9.

C. Defective fittin s, hose or

tubin between air dryer

and first reservoir.

E. Safety valve settin lower

than the maximum

system pressure.

D. Excessive pressure

pulsations from

compressor. (Typical

sin le cylinder type).

17

AD-9 AIR DRYER TROUBLESHOOTING CHART (Continue )

SYMPTOMS

4. Constant exhaust of air

at air dryer pur e valve

exhaust or unable to

build system pressure.

(Char e mode.)

A. With compressor loaded, apply soap solution

on pur e valve exhaust, to test for excessive

leaka e. Repair pur e valve as necessary.

B. Check overnor for proper cut-in, cut-out

pressure and excessive leaka e in both

positions. Repair or replace as necessary.

C. Pur e control line must be connected to

unloader port of overnor.

D. Test heater and thermostat as described in

Step 7 of Preventative Maintenance Section.

E. Compressor dischar e to inlet port. Reconnect

lines properly.

F. Check to determine if air passes throu h

dischar e line. Check for kinks, bends,

excessive carbon deposits.

G. Dischar e line should be constantly slopin

from compressor to air dryer with as few bends

as possible.

H. See Symptom #1s Causes and Remedies.

I. Replace pur e valve housin assembly o-rin s.

A. Test to determine air flows throu h pur e

control line when compressor unloaded. Check

for undrilled fittin s. (See Symptom #4,

Remedy C.)

B. Refer to Remedies B, E, G for Symptom #4.

A. Air dryer pur e valve

leakin excessively.

CAUSE REMEDY

5. Air dryer does not pur e

or exhaust air.

B. Defective overnor.

C. Pur e control line

connected to reservoir or

exhaust port of overnor.

D. Pur e valve frozen open -

faulty heater and

thermostat, wirin , blown

fuse.

E. Inlet and outlet air

connections reversed.

F. Kinked or blocked

(plu ed) dischar e line.

G. Excessive bends in

dischar e line (water

collects and freezes).

H. Excessive system

leaka e.

I. Pur e valve stays open -

supply air leaks to

control side.

A. Broken, kinked, frozen,

plu ed or disconnected

pur e control line.

B. See Causes B, E, G for

Symptom #4.

6. Desiccant material

bein expelled from air

dryer pur e valve

exhaust (may look like

whitish liquid or paste

or small beads.)

- OR -

Unsatisfactory

desiccant life.

A. This symptom is almost

always accompanied by

one or more of

Symptoms 1, 2, 3, 4 and

5. See related causes

for these Symptoms

above.

B. Air dryer not securely

mounted. (Excessive

vibration.)

A. See Causes and Remedies for Symptoms 1, 2,

3, 4 and 5.

B. Vibration should be held to minimum. Add

bracket supports or chan e air dryer mountin

location if necessary.

C. Replace desiccant cartrid e assembly.

C. Defective cloth covered

perforated plate in air

dryer.

18

AD-9 AIR DRYER TROUBLESHOOTING CHART (Continue )

SYMPTOMS

6. (Continued.) D. Check for proper compressor installation; if

symptoms persist, replace compressor.

E. Check the torque on the desiccant cartrid e to

end cover attachment. Refer to assembly

section of this data sheet.

A. A sli ht pin in sound may be heard durin

system build up when a sin le cylinder

compressor is used. If this sound is deemed

objectionable, it can be reduced substantially

by increasin the dischar e line volume.

This can be accomplished by addin an

additional four feet of dischar e line or addin

a 90 cubic inch reservoir between the

compressor and the AD-9 air dryer.

A. Some leaka e of pressure past the metal seat

of the turbo cutoff feature of the AD-9 is to be

expected also may be audible. This sli ht loss

of air will not effect the en ine or turbo

performance.

B. Refer to Remedy C, Symptom #1.

A. Faulty overnor installation; no air line from

overnor to compressor or line is kinked or

restricted. Install or repair air line.

D. Compressor passin

excessive oil.

CAUSE REMEDY

7. Pin in noise

excessive durin

compressor loaded

cycle.

E. Desiccant cartrid e not

assembled properly to

end cover. (Loose

attachment)

A. Sin le cylinder

compressor with hi h

pulse cycles.

A. Inlet of air compressor

pressurized by

turbochar er from

en ine.

8. Constant seepa e of air

at air dryer pur e valve

exhaust (non-char in

mode.)

B. Defective check valve

assembly in AD-9 air

dryer end cover.

A. Compressor fails to

unload.

9. The air dryer pur e

piston cycles rapidly in

the compressor

unloaded

(noncompressin )

mode.

19

20 BW1627 © 2002 Bendix Commercial Vehicle Systems LLC All rights reserved 3/2002 Printed in U S A

Other manuals for AD-9

1

Table of contents

Other BENDIX Dehumidifier manuals

BENDIX

BENDIX AD-IS - Mounting instructions

BENDIX

BENDIX AD-1 AIR DRYER User manual

BENDIX

BENDIX AD-IP INTEGRAL PURGE AIR DRYER User manual

BENDIX

BENDIX AD-1 Mounting instructions

BENDIX

BENDIX AD-9 AIR DRYER User manual

BENDIX

BENDIX SD-08-2418 User manual

BENDIX

BENDIX TRAILER SYSTEM GUARD AIR DRYER User manual

BENDIX

BENDIX AD-IS - User manual

BENDIX

BENDIX AD-9si Mounting instructions

BENDIX

BENDIX AD-SP SYSTEM PURGE AIR DRYER User manual