2

PREVENTIVE MAINTENANCE

Important: Review the Bendix Warranty Policy before

performinganyintrusivemaintenanceprocedures.Awarranty

maybevoidedifintrusivemaintenanceisperformedduring

thewarrantyperiod.

No two vehicles operate under identical conditions; as a

result, maintenance intervals may vary. Experience is a

valuableguide in determining thebestmaintenanceinterval

for air brake system components.At a minimum, the TE-1™

valveshouldbeinspectedevery 6monthsor 1500operating

hours, whichever comes first, for proper operation and

electrical connections. Should the TE-1™valve not meet

theelements oftheoperational testsnotedinthis document,

furtherinvestigationandserviceofthevalvemayberequired.

TESTING FOR SERVICEABILITY

A. OperatingTest

1. With ignition switch on and system fully charged,

makeandhold a foot valve application and notethat

stop lights on tractor and trailer are functioning

properly.

2. Place tractor protection control valve in the

emergency position and note that the trailer stop

lightsare functioningproperly.

3. Place tractor protection control valve in normal

positionandreduceairpressureinsystembymaking

severalfootvalve applications or by slowlydraining

reservoirsandobservingdashgauge;notethattrailer

stop lights function at approximately 60* psi.

B. LeakageTest

Coat the entire switch with soap solution and check for

leaks;no leakage permitted.

If the trailer emergency stop light switch does not function

as described or if leakage is present, it is recommended

that the switch be replaced with a new switch available at

thenearest Bendix authorizeddistributor.

Noattempt shouldbemade todisassembleandrepair faulty

switch.

REMOVING

A. Place tractor protection control valve in emergency

position.

B. Disconnect electrical connections at switch.

C. Removeswitch.

INSTALLING

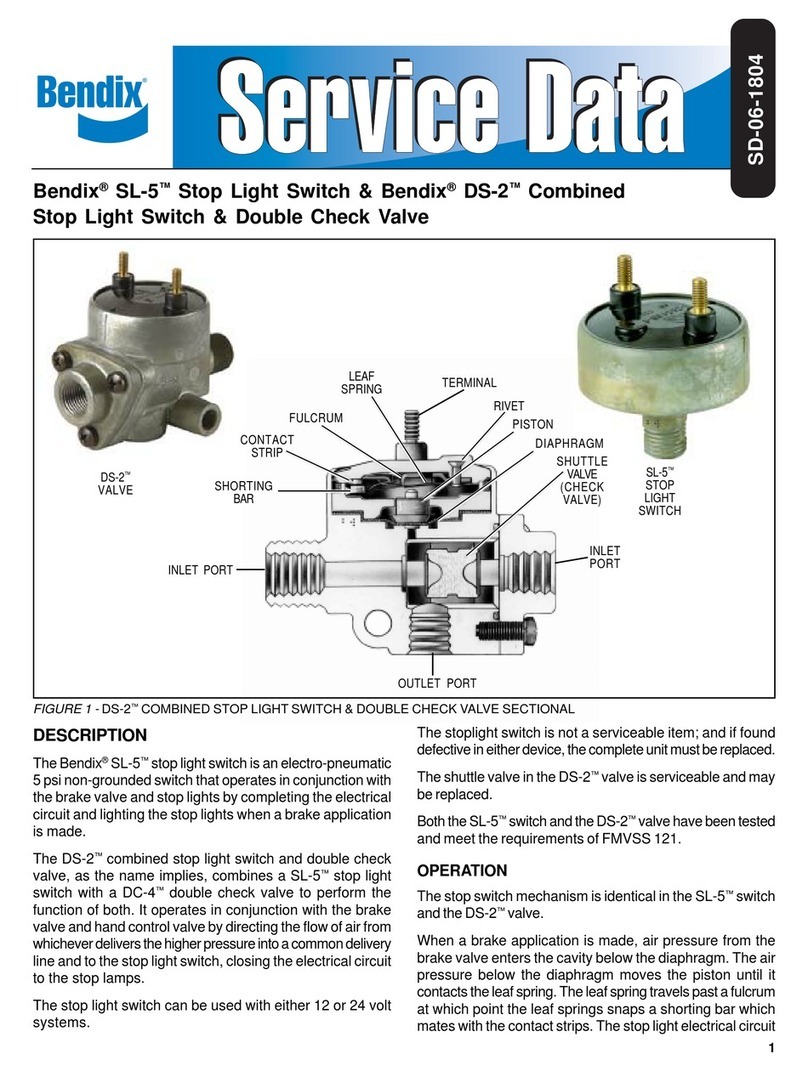

(Referto piping diagrams- Figure 2 andFigure 3.)

A. Installindelivery port of tractorprotection control valve

or in control line between control valve and tractor

protectionvalve.Alternateinstallation can be made with

ateeconnectionoffthe emergency line after the tractor

protectionvalve.

B. Wireasperwiring diagram (Figure 4).

WARNING! PLEASE READ AND FOLLOW

THESE INSTRUCTIONS TO AVOID

PERSONAL INJURYOR DEATH:

When working on or around a vehicle, the following

general precautions should be observed at all times.

1. Park the vehicle on a level surface, apply the

parking brakes, and always block the wheels.

Always wear safety glasses.

2. Stop the engine and remove ignition key when

working under or around the vehicle. When

working in the engine compartment, the engine

should be shut off and the ignition key should be

removed. Where circumstances require that the

enginebe in operation, EXTREMECAUTION should

be used to prevent personal injury resulting from

contact with moving, rotating, leaking, heated or

electrically charged components.

3. Do not attempt to install, remove, disassemble or

assemble a component until you have read and

thoroughly understand the recommended

procedures. Useonly the proper tools and observe

all precautions pertaining to use of those tools.

FIGURE 4

TE-1™TRAILER EMERGENCY STOP LIGHT SWITCH WIRING DIAGRAM

ACCESSORY POLE, IGNITION

SWITCH, ETC., THAT IS OFF

WHEN ENGINE IS OFF

BATTERY

TRACTOR STOP

LIGHT SWITCH TRACTOR STOP LIGHTS

ELECTRICAL

COUPLING

TE-1™TRAILER

EMERGENCY STOP

LIGHT SWITCH TRAILER STOP LIGHTS

IGN

TLR TTR

*Older switches were set at 55 psi.