2

TESTING FOR SERVICEABILITY

OPERATING TEST

1. Apply the brake valve and note that the stop light lights

before the delivery pressure reaches 7 psi.

2. Releasethebrakevalveandnotethat thestoplightgoes

“off”.

LEAKAGETEST

1. Withthebrakesfullyapplied,noleakageispermittedat

the stop light switch. If the stop light switch does not

function as described or if leakage is excessive, it is

recommended that it be replaced with a new unit or

repairedwithgenuineBendixpartsavailableatauthorized

Bendix parts outlets.

REMOVING

1. Disconnectelectricalconnectionsatthestop lightswitch.

2. Disconnect air line to the stop light switch.

3. Remove the stop light switch.

INSTALLING

1. Installinaconvenientlocationforservicing.

2. Install with pipe tap pointing to the ground and keep it

high for adequate drainage.

3. Connect the stop light switch in series in the stop light

circuit.

4. Keep the stop light switch terminals away from frame

memberstoavoidgrounding.

5. Connect the pipe tap to the brake chamber supply line

so that the stop light switch will operate whether the

footor hand valve is applied.

DISASSEMBLY

(SL-3™SWITCH)

1. Place hex portion of body in a vise.

2. Using a large end wrench on cover flats, turn cover (1)

in a counterclockwise direction and remove from body.

3. Remove terminal nuts, terminals (2) and terminal

connector (7) from cover.

4. Remove spring (3), plunger (4), washer (5) and

diaphragm(6) from body.

(SL-4™SWITCH)

1. Removetwo machine screws (7)andremovecover (8).

2. Removeterminalnutsandterminals(9)fromcover.

3. Removethevent plug(10)from cover.

4. Remove spring (11), contact strip (12), piston (13) and

o-ringdiaphragm (14) frombody.

CLEANING AND INSPECTION

Cleanallmetalpartsincleaningsolvent.Wiperubberparts

dry with cloth.

Inspect contact points for pits or wear. If pitting is not too

severe, the points may be reconditioned by filing with a

distributorpointfile. If points cannot be reconditioned,they

should be replaced. The contact strip in the SL-4™switch

may be turned over to use the other side of the contacts.

Check the spring for signs of deterioration; Replace if

discolored.ThespringintheSL-3™switchcarries thecurrent

ofthe electrical circuitinvolved;consequently, inthecaseof

excessivecurrent, asmightbe caused byashort, thespring

willbe overheatedandruined.

Inspect cover and body. If cracked or damaged, replace.

Only genuine Bendix service parts should be used for

replacement.

ASSEMBLY

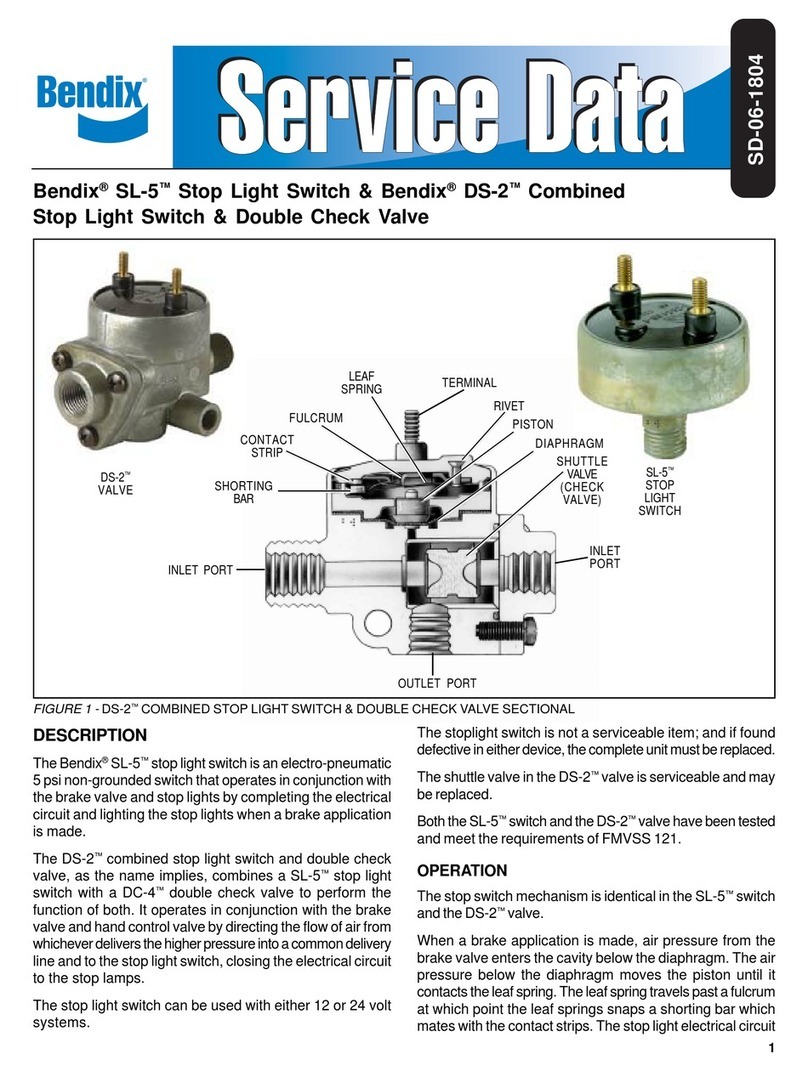

(SL-3™Switch) (Figure 1)

1. Insert terminal screws (2) in cover (1), making sure the

terminal connector (7) is properly positioned.

2. Secure terminal screws with washers and nuts, or

terminal clips, as the case may be.

3. Placediaphragm(6)in body.

4. Position contact plunger (4) on diaphragm.

5. Position spring (3) on plunger.

6. Place washer (5) on diaphragm and screw cover (1)

into body. Torque to 30 foot pounds. Make certain the

ventholein the cover is open.

(SL-4™Switch) (Figure 2)

1. Positionterminals(9)incover(8)andsecurewithwashers

andnutsor terminal clips.Placeventplug(10) in cover.

2. Place o-ring diaphragm (14) and piston (13) in body.

O-ring diaphragm should be installed with its flat side

adjacent to the piston.

3. Place gasket (15) in place on body and contact strip

(12) on piston(13).

4. Position cover assembly on gasket and secure with

machine screws. Torque to 20 inch pounds.

TEST OF REBUILT STOP LIGHT SWITCH

Bothoperatingandleakagetests,asindicatedundersection

headed “Testing for Serviceability”, must be made after

rebuildingor repairing thestoplightswitch. The switchmust

meetthefollowingspecifications;

1. No leakage is permissible at the stop light switch with

thebrakesapplied.

2. Thestop light switch contact should closewithnotmore

than7pounds of air pressure.