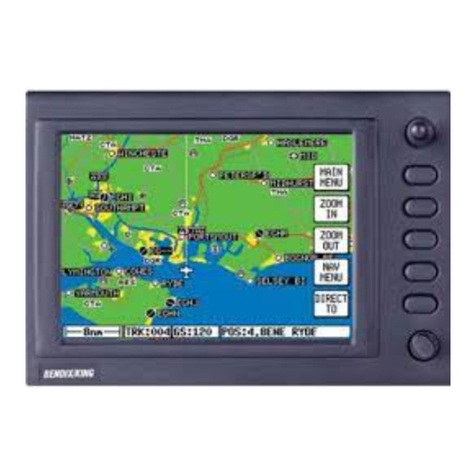

BENDIXKing Skymap IIIC Manual

Pilot’s

Guide

KFC

400

Flight Control System

This Pilot’s Guideprovides a general description

of

the vario

rational characteristics

of

the

KFC

400

Flight Control System.

ver, operation

of

the system should not be attempted without

Introduction

The KFC

400

Flight ControlSys-

tem combinescomplete autopilot and

flightdirector computationfunctions in

asingle computer.

Its

digitalflight

computer and integratedarchitecture

enable the KFC

400

to determine air-

craftcontrolrequirementssooner, and

to executethem with greater smooth-

ness and accuracy than previous au-

topilotsystems.

Due primarily to itsdualchannel

flight computer design, the KFC

400

can more positively control the air-

craft while providing a level

of

safety

monitoring unavailablewith single

channel systems. Digital, solid-state

design throughout the Flight Control

System provides maximumreliability

while economizingonsystem weight

and required installation space.

The KFC

400

is designedto opti-

mize passenger andflightcrewcom-

fort, white stillprovidingaccuratecon-

trol responsein any flight situation.

Wherever possible, autopilot-induced

aircraft motionsborder on the lower

limitsof human perceptibility, ensuring

exceptionally smooth flight. Many of

the Flight Control System's maximum

commandablevalues, however, are

determinedfor each individual aircraft

during the Flight ControlSystem

certificationprocess. Consult the

KFC

400

Flight ManualSupplement

foryour aircraft for particular values.

and vertical flightdirector modesthe

KFC

400

provides automatic, three-

dimensionalflight controlwhen inter-

facedwith the

KNS

660

Flight Man-

agement System. With eachway-

point in aflight plan assigned an alti-

tude, the KFC

400

can command

climbs

or

descents for perfect altitude

operation.

Inaddition to afull rangeof lateral

1

Internalsafety monitorsand auto-

matic self-test functions keepconstant

track of the KFC

400's

status, and

providesignals for automatic shut-

down of impairedcontrolaxes or flight

director functions. When the

KFC

400

decouples an autopilot axis it both

disengagesthe affected servo clutch

and shuts off motor drivepower, pro-

viding dual layers of protection

against servo overcontrol.

Inaddition to reliability and light

weight, the KFC

400

isdesigned to be

easy to maintain inthe field. Self-con-

taineddiagnostic tests assisttrouble-

shooting done by maintenanceper-

sonnelat BendixMing factory-ap-

proved service centers. The test func-

tions enable a technician to trace a

fault

to

the individual circuit board, or

externalsensor concerned. Circuit

boards inside remote-mounted

components areinstalledvertically, to

prevent condensation pooling.

Circuitry with the highest heat dissi-

pationrequirements are located near-

est the walls of each component

enclosureto optimize thermalman-

agement and serviceability. Qualified

Bendix/King service centersaround

the world are ready to provide assis-

tance whenever necessary.

The KFC

400

can interfacewith

electromechanical flight instruments

or the latest electronic displays, as

wellas navigation systems, radar al-

timetersand other peripheralcompo-

nents. All of the KFC

400's

digital

interfaces are based on ARlNC

429

specifications, and analog/digital con-

verters are supplied wherever neces-

sary to providethe greatest interface

versatility.

Table

of

Contents

introduction

.........................................................................................

1

System

Components

.........................................................................

4

Operational

Specifications

..............................................................

6

Operational

Capabilities

..................................................................

8

Component

Descriptions

Cockplt

Components

KMS

446

Flight DirectorMode Selector

.................................

10

KMC

440

Autopilot ModeController

.......................................

14

KHC

441

Heading and CourseController

..............................

16

KHC

442

Heading and CourseController

..............................

17

ControlWheel Switch Assembly

............................................

18

Go-Around Pushbutton

...........................................................

19

KAP

419

Annunciator Panel

...................................................

19

Electromechanical Display Units

............................................

20

EFS

10

Display Units

.............................................................

25

KAV

485

AltitudeNerticalSpeed Indicator

.............................

26

KST

488

SpeedflemperatureIndicator

..................................

29

Remote-Mounted

Units

KCP

420

FlightComputer

......................................................

30

KDA

430

GyroAdapter

...........................................................

30

KAM

432

Autopilot Monitor

.....................................................

30

KSA

470

Servo Actuator

........................................................

31

KDC

481

CentralAir Data Computer

.....................................

31

Preflight

TesVStartup

Procedures

...............................................

32

Flight Director Operations

RollAttitude HoldpitchAttitude Hold

............................................

35

Control

Wheel

Steering

.................................................................

35

Heading

.........................................................................................

35

Nav

...............................................................................................

35

Approach

.......................................................................................

36

Flight Director

................................................................................

36

Mach

..............................................................................................

36

VNAV

.............................................................................................

37

Altitude Hold

..................................................................................

37

Altitude Select

................................................................................

38

Climb

.............................................................................................

38

Descent

.........................................................................................

38

IndicatedAirspeed Hold

................................................................

39

Vertical Speed

...............................................................................

39

Go-Around

.....................................................................................

39

Autopilot Operations

Autopilot

.........................................................................................

40

Yaw Damper

..................................................................................

41

Half Bank

.......................................................................................

41

Soft

Ride

........................................................................................

41

RollAttitude Control

.......................................................................

41

Vertical Trim

..................................................................................

42

Operational Examples

Takeoff and Climb

.........................................................................

44

VNAV Descent

...............................................................................

46

Outboundon Front Course

............................................................

48

Front Course ILS

...........................................................................

50

Abnormal Procedures

.....................................................................

52

Emergency Procedures

..................................................................

54

3

The KFC400 Flight ControlSys-

tem is designed

to

locateall mode

andfunctioncontrolswithin conven-

ient reach

of

the pilot and to provide

clear, easily interpretedinformation

displays. Thefollowing components

are included inthe FlightControl

System.

Cockpit

Units

1

KMS446 Flight Director Mode

KMC440 Autopilot ModeController

m

488

Selector

KHC441 or KHC

442

Course/

HeadingController (electro-

mechanicalor electronicflight

instrument installations)

ControlWheel SwitchAssembly

Power LeverGo-AroundPushbutton

KAP41

9

Annunciator Panel

(electromechanicalflight instrument

installationsonly)

ElectromechanicalDisplay Units

EFS

10

Display Units

KAV 485 AltitudeNerticalSpeed

KST488 Speedmemperature

Indicator

Indicator (optional)

Remote-Mounted Units

KCP 420 FlightComputer

KDA 430 Gyro Adapter

KAM432 Autopilot Monitor

KSA 470 Servo Actuators

KDC481 CentralAir DataComputer

KAY

485

T

I

4

Dual

KFC

400

System

Diagram

I

ED

102

ED

loZ

I

1

KAV

485

5

Operational Specifications

ControllersC52a, C9c Panel

Units

Remote Units C52a, C9c

Servos

C9c

KAP 419 KAV 485 KCP420 KSA 470

KMS446 (C~C,ClOb) KDA 430

(plus

C87,

KMC440 C41c, C~C,

C4c)

KHC

441

KST488 (C43a) KAM432

KHC442 KDC481 (C~C,C8c,

ClOb, C43a,

C46a,

C88a, C95)

Environmental

Cate

Controllers Pane

Altitude

55,000

ft.

55,000

ft.

Temperature

-20' to +70°C -20' to +70°C

Temperature Variation

6

C

Humidity

A

Vibration

KPS KPS

Explosion Proof

X

X

A

55,000

ft.

55,000

ft.

-55'

to +7OoC

65'

to +7OoC

B

A

MNO

El

B

A

JLY

El

6

Unit Weight Dimensions

(H

x

W

x

L)

(Ibs)

KGs)

(IN)

(CM)

KAP 419

KCP 420

KDA

430

KAM 432

KMC 440

KHC

441

KHC 442

KMS

446

KSA 470

KSM 475

KDC

481

KAV

405

KST

488

KCI

310

KRG 332

.3

8.0

2.6

2.4

1.3

1.7

.6

1.2

3.0

1.4

3.7

3.6

.a

5.0

4.2

6.0

6.8

.a

4.8

.3

.2

.14

3.63

1.2

1.07

.6

.77

.27

.54

1.36

.63

1.68

1.63

.37

2.27

1.93

2.72

3.1

.34

2.18

.14

.1

1.1

x

4.3

x

4.5

5.3 x

5.5

x

13.7

5.3

x

2.0

x

12.8

5.3

x

2.0

x

12.8

1.9 x

5.8

x

7.3

1.9

x

5.8

x

7.3

1.5

x

5.8

x

3.9

1.9

x

5.8

x

7.3

3.5

x

4.2

x

3.7

3.9

x

4.2 x 2.2

5.3

x

3.1 x 13.6

6.2 x 3.4

x

9.1

1.7

x

3.4

x

7.3

4.3

x

4.3

x

9.4

4.3

x

4.3

x

10.4

4.3

x

4.3 x 9.1

5.4

x

5.5

x

9.92

2.1

x

2.2

x

5.0

5.4

x

7.8

x

4.3

3.4

dia

x

1.a1

1.2

x

2.1

x

3.0

2.8

x

10.8

x

i

1.4

13.5

x

14.0

x

34.8

13.5

x

5.1

x

32.5

13.5 x 5.1 x 32.5

4.8~14.7~18.5

4.8

x

14.7

x

18.5

3.8

x

13.6

x

9.9

4.8

x

14.7

x

18.5

7.7

x

10.7

x

9.4

9.9

x

10.7 x 5.6

13.5

x

7.9

x

34.5

15.7

x

8.6

x

23.1

4.3

x

8.6

x

18.5

10.8

x

10.8

x

21.2

10.8

x

10.8

x

26.3

10.8

x

10.8

x

23.2

13.7

x

14.0

x

20.1

5.4

x

5.6

x

12.7

13.6

x

19.8

x

10.9

8.5

dia

x 4.6

3.0

x

5.4

x

7.6

7

Operational Capabilities

Mode Parameter

KFC

400

Value

Attitude Hold

Heading Hold

NAV

(VOR Capt)

(VOR Track)

(Over Station)

PitchCommand Limit

PitchCommandAccel Limit

PitchHoldAccuracy

RollAngle Limit

RollCommand RateLimit

Roll

Command Accel Limit

RollHold Accuracy

RollAngle Limit

RollCommand RateLimit

RollCommandAccel Limit

Accuracy

Beam Intercept Angle

Capture Point

RollAngle Limit

RollCommand RateLimit

Roll

CommandAccel Limit

RollAngle Limit

Crosswind Correction

CourseChange

RollAngle Limit

+25 Deg, -15 Deg

.05g

f

.3

Deg SmoothAir

25 Deg

3

DegISec

1.6

DegiSecondISecond

f

1Deg SmoothAir

25 Deg

3

DegISecond

1.6

DegISecondiSecond

f

1 Deg Smooth Air

AllAngle

Function

of

DME, Deviation, Dev

Rate

&

Course Error

25 Deg

3

DegiSecond

1.6 DegiSecondiSecond

25 Deg

UpTo

30

Deg

UpTo

90

Deg

25 Deg

Approach

Beam Intercept Angle Upto 105 Deg Front Course

(LOC Capture) RollAngle Limit 25 Deg

(LOCTrack)

GS

Roll

Command RateLimit

Roll

Command Accel Limit

Capture Point

RollAngle Limit

Cross Wind Correction

Gain Programming

PitchCommand Limit

Capture Point

GS Damping

PitchRate Limit

Gain Programming

6 DegISecond

4

DegISecondiSecond

Function

of

Deviation, Dev Rate

&

Course Error

10 Deg

UpTo

30

Deg

Function

of

RadAlt or

(time, TAS)

+25 Deg, -15 Deg

Function

of

Deviation, Dev Rate

PitchAtt

&

TAS

Max 2 DegiSecondor .15G

Function

of

Rad Alt or

(time, TAS)

8

Mode Parameter

KFC

400

Value

Go-Around

PitchUpCommand

Engage Range

PitchLimit

Engage Vert

Spd

Limit

Max "g"DuringCapture

Engage Range

Engage Vert

Spd

Limit

Accuracy

PitchCommand Limit

PitchRate Limit

IAS

Hold

Engage Range

Accuracy

PitchCommand Limit

PitchRate Limit

Engage Range

Accuracy

Select Range

PitchCommand Limit

PitchRate Limit

Engage Range

PitchCommand Limit

Accuracy

Profile

Engage Range

PitchCommandLimit

Accuracy

Vert

Spd

Command

Engage Range

O)

PitchCommand Limit

(When

Installed

Station Elevation

Bias Range

Accuracy

Altitude Range

PitchRate Limit

Engage Range

PitchCommandLimit

Below

9,000

Ft. MSL

9

Selectable

0

to

55,000

Ft.

+

25 Deg,

-15

Deg

f

6,000

FVMin

f

.07g

-1,000

to

55,000

Ft.

f

2,000

FVMin

f

20

Ft, Smooth Air*

+25

Deg, -15 Deg

.l

g Vert Accel

60 Ktsto V,

f

2

Kts, Smooth Air

+

25

Deg,

-15

Deg

.15g Vert Accel

f

6,000

FVMin

f

50

Ft/Min*

f

6,000 FVMin

+

25

Deg,

-15

Deg

.lG

Vert Accel

60 Ktsto

V,

+

25

Deg,

-15

Deg

f

2 Kts

Selectable

f

6,000 Ft.

+25

Deg,

-15

Deg

f

50

FVMin*

Selectable

f

6 DegVTA Max (Certification)

Stored in660 Memory

+25

Deg,

-15

Deg

f

99.9

Mi

f20

Ft

0

to

55,000

Ft.

.lG

Vert Accel

UP

to Mmo

f

.005

MACH, Smooth Air

f

25

Deg,

-15

Deg

Component Descriptions

KMS

446

Flight

Director Mode Selector

16

17

18

19 20 21

I

I I

I I

I

I

22

I

23

I

24

I

25

I

26

I

27

10

11

12

13

14 15

16

17

18

19 20 21

I

112345161

7189)

unuuuu

'1

10

11

12

13

14 15

10

The

KMS

446

modeselector pro-

vides

control

and annunciationof the

KFC

400's

Flight Director modes. Illu-

minationof the annunciations is ad-

justed automatically by a photocell

locatedontheface of the unit.

Display

Features

Mode

Annunciations

1.

HDG

(headingselect)

-

Illumin-

ates when headingselect mode is

engaged bythe headingpushbutton.

Flashing indicates

loss

of a sensor

requiredto hold selected

HDG

(e.9.

invalidmagnetic heading, invalid

se-

lected heading) and continues untila

second pushof the

HDG

pushbutton

to acknowledgeautomatic disengage-

ment of the mode.

2.

NAV

(capture and track selected

navigation sensor)

-

Illuminates

when

NAV

capture or

NAV

track

mode is engaged by the

NAV

push-

button and normally sequenced

through

NAV ARM.

Flashing indi-

cates lossof a sensor requiredto cap-

tureor track the selected nav (e.g.

invalid

NAV,

invalidselected course)

and continues untila second push of

the

NAV

pushbutton acknowledges

automatic disengagementof the

mode.

3.

NAV ARM

(preengagecondition of

NAV)

-

Illuminateswhen

NAV

mode

iscalledfor by the

NAV

pushbutton.

It

allows acompatible lateralmodeto

beusedto interceptthe desired

course or track. Inthe event of a sus-

tained

NAV

invalid,

NAV ARM

willdis-

engage leavingthe current engaged

mode active and allowing later rearm-

ing

of

the

NAV

mode.

4.

APR

(capture andtrack selected

navigationsensor with approach

accuracy)

-

Illuminateswhen ap-

proach capture or approachtrack

mode is engaged by the

APR

push-

button and normally sequenced

through

APR ARM.

Flashing indi-

cates loss of a sensor requiredto cap-

ture or track the selected nav (e.g.

invalid

NAV,

invalidselected course)

and continues untila second push of

the

APR

pushbuttonacknowledges

automaticdisengagementof the

mode.

5.

APR ARM

(preengagecondition

of

APR)

-

Illuminateswhen

APR

mode iscalledfor by the

APR

push-

button.

It

allows acompatible lateral

mode to be used to intercept the de-

sired course. Inthe event of asus-

tained

NAV

invalid,

APR ARM

will

dis-

engage leavingthe current engaged

mode active and allowing rearmingof

the

APR

mode later.

6.

FD (flight director

)

-

Illuminates

when FD or

AP

buttonis pushedor

any flightdirector mode is engaged.

7.

MACH

(Holdcurrent

MACH

refer-

ence speed)

-

Illuminates when the

MACH

hold mode is engaged by the

MACH

pushbutton. Flashing indi-

cates

loss

of a sensor requiredto hold

current reference

MACH

airspeed

(e.g. invalidindicated airspeed) and

continues untilasecond pushof the

MACH

pushbutton acknowledges

automatic disengagement of the

mode.

8.

VNAV

(fly selected vertical track

angle)

-

Illuminates when vertical

navigation mode is engaged by the

VNAV

pushbutton. Flashing indicates

11

loss

of asensor requiredto fly the ver-

ticaltrack angleor achange inthe

VNAV

parameters requiring disen-

gagement (e.g. invalid

VNAV

devia-

tion) and continues untilthe

VNAV

pushbuttonis pushedto acknowledge

automatic disengagement.

9.

VNAV ARM

(preengage condition

of

VNAV)

-

Illuminates when vertical

navigationmode is calledfor by the

VNAV

pushbutton but the aircraft has

not yet reachedthe selected vertical

track angle

(VTA).

It

allows a

compatible vertical mode to be used

to interceptthe desired

VTA.

Inthe

event of invalid altitude or

VNAV

in-

puts,

VNAV ARM

will

disengage, leav-

ingthe current engaged mode active

and allowing rearming

of

the

VNAV

mode later.

10.

ALT

(hold current reference alti-

tude)

-

Illuminateswhen the

ALT

mode is engaged by the

ALT

push-

button

or

by automaticsequencing

through altitude arm and altitude cap-

ture. Flashing indicates

loss

of asen-

sor requiredto holdcurrent reference

altitude (e.g. invalid altitude) andcon-

tinues untila pushof the

ALT

push-

button acknowledges automaticdisen-

gagement of the mode.

11.

(ALT)ARM

(automaticcaptureof

selected altitude)

-

Illuminateswhen

the

ALT SEL

mode isengaged by the

ALT SEL

pushbuttonor Climb,

Descent or

VNAV

modes. Itallows a

compatible vertical mode to be used

to approach the selected altitude. In

the event of sustained invalidaltitude,

ALT ARM

modewill disengage leaving

the current engaged mode active and

allowing rearmingof the

ALT ARM

mode later.

12.

CLB

(climbat specified profile)

-

Illuminateswhen climb mode isen-

gaged by the

CLIMB

pushbutton.

Flashing indicates

loss

of asensor

requiredto fly the stored profile(e.g.

invalidaltitude, invalidindicated air-

speed) and continues until

a

second

push

of

the Climb pushbutton ac-

knowledges automatic disengage-

mentof the mode.

13.

DES(descend at specified verti-

cal

speed)

-

Illuminateswhen

descent mode isengaged

by

the

DESCpushbutton. Flashingindicates

loss

of

a sensor requiredfor descent

mode(e.g. invalidvertical speed) and

continues untila second push of the

DESC

pushbutton acknowledges

automatic disengagementof the

mode.

14.

IAS

(holdcurrent referenceair-

speed)

-

Illuminateswhen the air-

speed hold mode is engaged by the

IAS

pushbutton. Flashing indicates

loss

of

a sensor requiredto hold cur-

rent reference airspeed (e.g. invalid

indicated airspeed) and continues un-

til

a

second pushof the

IAS

pushbut-

ton acknowledges automatic disen-

gagement of the mode.

15.

VS

(holdcurrentor selectedverti-

calspeed)

-

Illuminateswhen the

verticalspeed hold mode is engaged

bythe

VS

pushbutton or by transition

from

DES

mode. Flashing indicates

loss of a sensor requiredto hold se-

lectedverticalspeed (e.g. invalidverti-

cal

speed) and continues untilthe

VS

pushbutton is pushedto acknowledge

automaticdisengagementof the

mode.

12

Control Features

ModeSelect Pushbuttons

16.

HDG (headingselect)

-

Alter-

natelyengages and disengageshead-

ingselect mode.

17.

NAV(capture andtrack selected

navigationsensor)

-

Alternately en-

gages and disengagesthe navigation

mode.

18.

APR (captureandtrack selected

navigationsensor with approach ac-

curacy)

-

Alternately engagesand

disengagesthe approach mode.

19.

FD(flight director)

-

Engages

FlightDirector inpitch attitude hold

andwings levelmode. PressingFD

whenflight director is engagedwill

disengage allflight director modes

if

autopilot is not engaged.

20.

MACH (holdcurrent MACH refer-

ence airspeed)

-

Alternately en-

gages and disengages MACH hold

mode.

21.

VNAV (fly selected vertical track

angle)

-

Alternately engagesand

disengagesVNAV mode.

22.

ALT (holdcurrent referencealti-

tude)

-

Alternately engagesand dis-

engagesaltitude holdmode.

23.

ALT SEL (automaticcaptureof

selectedaltitude) -Alternately en-

gages anddisengagesaltitude arm

mode.

24.

CLIMB

(

climbat specified profile)

-

Alternately engagesand disen-

gages climbmode.

25.

DESC(descendat specified ver-

ticalspeed)-Alternately engages

and disengagesdescent mode.

26.

IAS (holdcurrent referenceair-

speed)

-

Alternately engages and

disengagesairspeed hold mode.

27.

VS (holdcurrent or selectedverti-

calspeed)-Alternately engages

anddisengagesvertical speed mode.

1’

KMC 448

Autopilot Controller

7

8

4

7

5

a

9

I

lo

4

13

I

5

14

The KMC

440

allows engagement

of autopilot modesas well as vertical

trim and rollratecommands. Axis fail-

ure lights are locatedonthe face to

annunciateindividualaxis failures.

Inadualsystem a second column

of

failurelights are provided as well as

an autopilot transfer button and

annunciation.

Display Features

8.

HALFBANK (half bank angle)

-

Alternately engages and disengages

half bank mode.

9.

AP XFER (dualsystems only)

(autopilot transfer)

-

Alternately

selects autopilot control from left

or

rightsides.

10.

YD (yaw damper)

-

Alternately

engages and disengages yaw

damper.

Mode

Annunciations

1.

AP (autopilot)

-

Illuminateswhen

the autopilot is engaged by the AP

pushbutton.

2.

HB (half bank angle)

-

Illuminates

when half bank mode is engaged by

the Half Bank pushbutton.

3.

>

(Dual Systemsonly)

(autopilotcouple IefUright)

-

Illumi-

natespointing left or right alternately

when AP XFER ispushed.

4. YD (yaw damper)

-

Illuminates

when yaw damp isengaged.

5.

SR

(soft

ride)

-

Illuminateswhen

soft ride mode is engaged bythe

SOFT

RIDEpushbutton.

6.

Axis failure lightsilluminate when

the internal monitordetectsafailure in

one of the controlaxes.

Control Features

Mode

Select pushbutton

11.

SOFT

RIDE

(soft

ride) -Alter-

nately engages and disengagessoft

ride mode.

Other Controls

12. Rollrate command knobwhen

turnedfrom its center detent position

cancels existing lateral mode and

engages rollattitude hold. The farther

from center the knobis held, the

faster the autopilot increasesthe

aircraft's bank angle. When released,

the rollattitude stabilizes and the

autopilot holds rollattitude.

13. Vertical Trim allows modification

of certainvertical modes (e.g. altitude,

pitchattitude, MACH, IAS, VS). It

will

cancelvertical modeswhich utilizea

verticaltrack or stored vertical profile

(e.g. Glideslope, VNAV, Climb,

GoAround) and revertto pitchattitude

hold.

Action is either by discrete pushes

to modify a reference by a set amount

or continuous by holdingthe controlin

one position and slewing the refer-

ence.

7.

AP (autopilot)

-

Alternately

engages and disengagesthe autopi-

lot. Also engages Yaw Damper when

the autopilot is engaged.

15

KHC

441

Heading and Course Controller

(Mechanical Instruments Only)

2

\

4

\

/

1

3

Control Features

3.

Heading knob when rotated

1.

Course knobwhen rotated

repositionsthe course arrow on the

KPI

5538.

2.

Center pushbutton(pushdirect)

when pushedrotates course arrow

on

KPI

5538

to obtain acentered

deviation bar.

repositionsthe heading bugonthe

KPI

5538.

4.

Center pushbutton (push sync)

when pushed repositions the heading

bug on the KPI

5538

to under the

lubber line.

16

KHC

442

Heading and Course Controller

(EFS

10

Installations Only)

w

PULL

DIRECT

-

PULL

ON

0

I

PULL

SYNC

I

2

Control Features

1.

Course knobwhen rotatedreposi-

tions the course arrow on the EHSI.

2.

“Pull Direct”

-

When the course

knobis pulledrotatesthe course

arrow onthe EHSIto obtain a

centered deviation bar.

3.

Headingknobwhen rotatedreposi-

tions the heading bug onthe EHSI.

I

I

6

4

4. “Pull Sync”

-

When the heading

knob ispulled repositions the heading

bug on the EHSlto under the lubber

line.

5.

DHset knobwhen pulled out and

rotated sets the radar altitude at

which the DHwarning willoccur.

6.

TEST

when pushed enablesthe

radar altimeter self test.

17

Control Wheel Switch

Assembly

CONTROLWHEEL STEERING

MANUAL

ELECTRIC

TRIM

AP

DISCJTRIM

INTERRUPT

Mountedonthe aircraft control

wheel(s), the ControlWheel Switch

Assembly providespushbuttoncon-

trolsfor the ControlWheel Steering

function(flight director synchroniza-

tion) andAutopilot Disconnemrim

Interrupt. The manualelectrictrim

split rockerswitchesare also located

onthe control wheel switch assembly.

1.

ControlWheel Steering Push-

button

-

Pressingthe CWS Push-

buttondecouplesautopilot

servo

clutches, if engaged, and synchroniz-

es

the flight director commandbars

withthe current vertical and lateral

modes. SelectingControl Wheel

Steeringalso illuminatesa “CWS”

annunciatoronthe KAP

41

9

annun-

ciator panelor the EFS

10

EADI.

Uponrelease of the pushbutton, the

autopilot

servo

clutchesreengage

andthe flight directorcommands atti-

tudesto maintainthe current values

set inthe engaged modes.

If

the flight director is not en-

gaged, pressingthe CWS Pushbutton

activates it in PitchAttitude Holdand

Roll

Attitude Hold. The flight director

commandbar will synchronizeto the

attitudepresent upon pushbutton

re-

lease.

2.

AutopilotDisconnectrrrim Interrupt

Pushbutton-When pressed

momentarily,disengagesthe autopilot

andcancels alloperatingflight direc-

tor modes. A tone willsound upon

autopilot disconnectwhenthe push-

button isreleased.

pilot Disconnectnrim InterruptPush-

buttondisengagesthe autopilot,yaw

damper, suppressesthe autopilotdis-

connecttone, and may insome instal-

lationsdisengagethe flight director

and/or interruptelectrictrim power.

When pressedand held, the Auto-

3.

ManualElectricTrim Control

-A

splirocker switchcontrols manual

electricpitchtrim and disengagesthe

autopilot. Movingthe switchtothe

forward position activatesnosedown

trim, while movingit rearward acti-

vates nose-uptrim.

Note:

Certaininstallationsmay utilize

the originalmanufacturers electric

pitch trim control.

18

Other manuals for Skymap IIIC

7

Table of contents

Other BENDIXKing Control System manuals

Popular Control System manuals by other brands

Pentair

Pentair EASYTOUCH PL4 installation guide

Actility

Actility Click&Go Quick starter guide

m-Dimension

m-Dimension D4006 user guide

Centroid

Centroid Acorn CNC installation manual

Taylor Made Environmental

Taylor Made Environmental Cruisair SMX II Installation & operation

Airzone

Airzone UNO PACK installation manual