GCS CYSCAN Product manual

GC S

GC S

GUIDANCE

GUIDANCE

LIMITED

CONTROL

CONTROL

SYSTEMS

SYSTEMS

LIMITED

CyScan

Positioning

System

Installation and

Maintenance Guide

GC S

GC S

Copyright © 2003 Guidance Control Systems Limited. All Rights Reserved.

Copyright in the whole and every part of this manual belongs to Guidance Control

Systems Limited (the “Owner”) and may not be used, sold, transferred, copied or repro-

duced in whole or in part in any manner or form or in or on any media to any person

other than in accordance with the terms of the Owner’s Agreement or otherwise without

the prior written consent of the Owner.

Windows is a trademark of Microsoft Corporation.

All other brand or product names are trademarks or registered trademarks of their

respective companies or organisations.

Release: 1.1

Date: 17/3/03

Document No: 94-0003-1

Previous issue: Installation and Maintenance Guide v1.0

Date: 9/1/03

Changes: Various changes and additions

Guidance Control Systems Limited

4 Dominus Way • Meridian Business Park

Leicester • LE19 1RP • United Kingdom

Tel: +44 (0)116 229 2600

Fax: +44 (0)116 229 2604

Email: [email protected]

Website: http://www.gcsltd.co.uk

Printed in the UK

1CyScan Positioning System • Installation and Maintenance Guide r1.1

GC S

GC S

Contents

Introduction .................................................... 3

CyScan Installation ....................................... 4

Unpacking the CyScan System .................................................................. 4

Mounting the System Components ........................................................... 6

When mounting two CyScan sensors on the same vessel....... 6

Wiring the CyScan System......................................................................... 8

Power Supply Unit (PSU) ................................................................. 8

The Data Converter....................................................................... 10

Notebook computer ...................................................................... 10

Connecting the CyScan Sensor ................................................................ 11

CyScan LED Indicators ............................................................................. 12

Correct startup indication.............................................................. 12

Error states and possible causes ..................................................... 12

Shutdown/suspend ....................................................................... 12

CyScan Removal .......................................... 13

Switching off the CyScan Console System ............................................... 13

Disconnecting the CyScan Sensor ............................................................ 14

Un-mounting the CyScan Sensor ............................................................. 14

Packing the CyScan System ..................................................................... 15

Maintenance and Servicing ....................... 17

Removing and fitting key components ..................................................... 17

Stage 1 - The Rotor Heatshield ...................................................... 17

Stage 2 - The Rotor ....................................................................... 18

Stage 3 - The Body Cover .............................................................. 19

Stage 4 - The Motor Gearbox ........................................................ 20

Stage 5 - The CPU Module ............................................................ 21

Stage 6 - The Controller Board ...................................................... 22

Stage 7 - The Yaw Gyro ................................................................ 23

Stage 8 - The Vertical Reference Unit (VRU) ................................... 24

Stage 9 - The Actuators ................................................................ 25

Cleaning the CyScan Sensor .................................................................... 27

To clean the casing and bellows: ................................................... 27

To clean the optical window: ......................................................... 27

To clean the targets: ...................................................................... 27

Greasing the Gearbox ............................................................................. 27

2CyScan Positioning System • Installation and Maintenance Guide r1.1

GC S

GC S

Troubleshooting .......................................... 2

For further assistance .............................................................................. 28

No communication between CyScan Console and the Sensor ........ 28

Sensor head does not rotate ......................................................... 28

Sensor rotates slowly..................................................................... 29

System appears to be operational, however, the sensor

head is not levelling or rotating ..................................................... 29

System appears to be operational, however, no reflections

are displayed within CyScan Console ............................................. 29

System is operational but is not navigating .................................... 29

System navigating but no data is received at the DP system ........... 29

System appears to be operational, however, it is exhibiting

erratic behaviour with communications locking up occasionally ..... 29

System operates correctly but in cold weather loses targets. .......... 29

Alarm Codes ........................................................................................... 30

Fatal alarms - codes 2xxx ............................................................... 30

Errors - codes 3xxx ........................................................................ 30

Warnings - codes 4xxx .................................................................. 30

Information - codes 5xxx ............................................................... 30

CyScan Fuse Information ......................................................................... 31

Power Supply Unit Fuse ................................................................. 31

Controller Board Fuse.................................................................... 31

Appendices ................................................... 32

Appendix 1 - CyScan Sensor Connector Pin-outs ..................................... 32

Appendix 2 - CyScan Sensor Mounting Template ..................................... 33

Appendix 3 - CyScan PSU Mounting Template ......................................... 34

Appendix 4 - CyScan RS485 Data Converter Mounting Template ............. 35

Appendix 5 - Recommended Spares List .................................................. 36

Appendix 6 - Using CyScan Admin Console ............................................. 37

To start CyScan Admin Console ..................................................... 37

To exit CyScan Admin Console ...................................................... 37

CyScan Admin Console Quick Start ............................................... 38

Setting up the User Console Vessel Orientation ................... 39

Checking the Comms Port Settings ..................................... 40

Reinitialise the communications link .................................... 41

Enable Sensor Components ................................................ 42

Check Scanner Enabled....................................................... 43

Check system supply voltages ............................................. 44

Mooring Point Reflectors - Installation and Definition............................... 45

Reflector types .............................................................................. 45

Reflector Installation ..................................................................... 46

Defining Reflector Positions ........................................................... 47

Reflector Positioning Examples ...................................................... 48

3CyScan Positioning System • Installation and Maintenance Guide r1.1

GC S

GC S

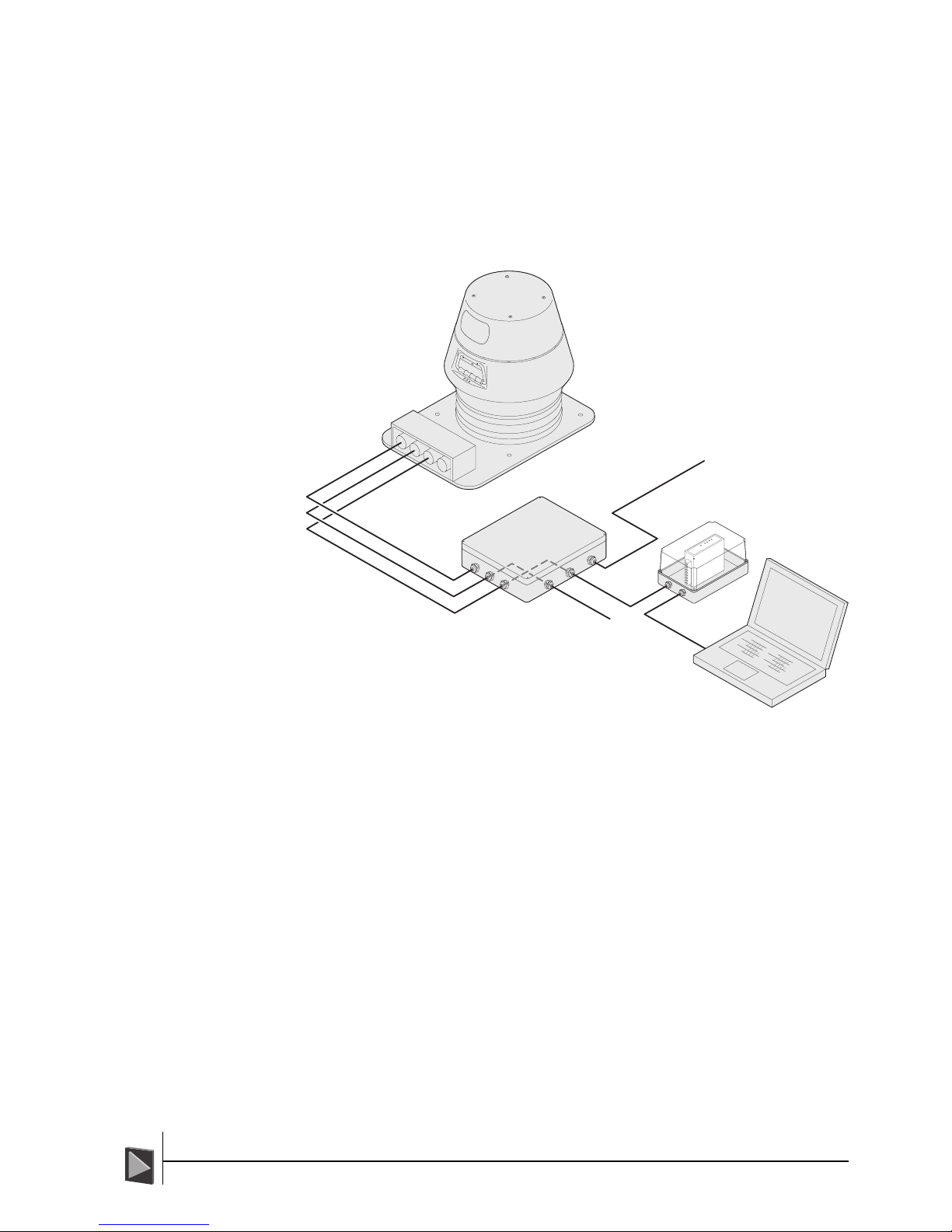

Introduction

Welcome to the CyScan positioning system. CyScan uses high accuracy laser navigation

to provide automated approach and/or station keeping relative to one or more desig-

nated mooring points. The mooring points can be fixed structures or other vessels.

CyScan is designed to be semi-portable and straightforward to operate. In use, the

CyScan system consists of several key elements, these being:

• The CyScan Sensor, which is mounted on

deck as required.

• The CyScan Console. A monitoring

application running within MS Windows

on a notebook computer. It provides the

DP operator with full information and

control over the data stream being fed to

the DP system.

• The Power Supply Unit (PSU). It is

contained within a watertight enclosure

and is mounted near to the CyScan

sensor. The Console and DP System cables

are fed via the PSU.

• The Data Converter. Situated near to the

DP System, this sealed enclosure translates

between the RS485 signals used by the

CyScan Sensor and DP Systems, and the RS232 signals used by the CyScan

Console Notebook computer.

The remaining requirements for the CyScan system are the Targets that must be

mounted on the designated mooring point(s). The Targets consist of specialist reflective

strips or cylinders placed in certain positions along the side of the mooring point structure

or vessel. The coordinates of the targets are then declared to (or discovered by) the

CyScan Console, and using this data the system is able to determine the exact position of

the vessel relative to the mooring point.

DP

System

CyScan

Console

PSU

Power

CyScan

Sensor

Data

Converter

The key elements of the CyScan system

CyScan

equipped

Vessel

Mooring Point/Vessel

Reflective Targets

Positional information is gained by using highly reflective target strips in fixed locations

4CyScan Positioning System • Installation and Maintenance Guide r1.1

GC S

GC S

CyScan Installation

The CyScan Sensor is designed to be semi-portable. This allows it to be mounted in

different positions on the vessel to present the best view of the mooring point targets.

Commissioning the CyScan system ready for operation involves four basic stages:

• Unpacking the CyScan System

• Mounting the CyScan Sensor

• Wiring the CyScan System

• Connecting the CyScan Sensor

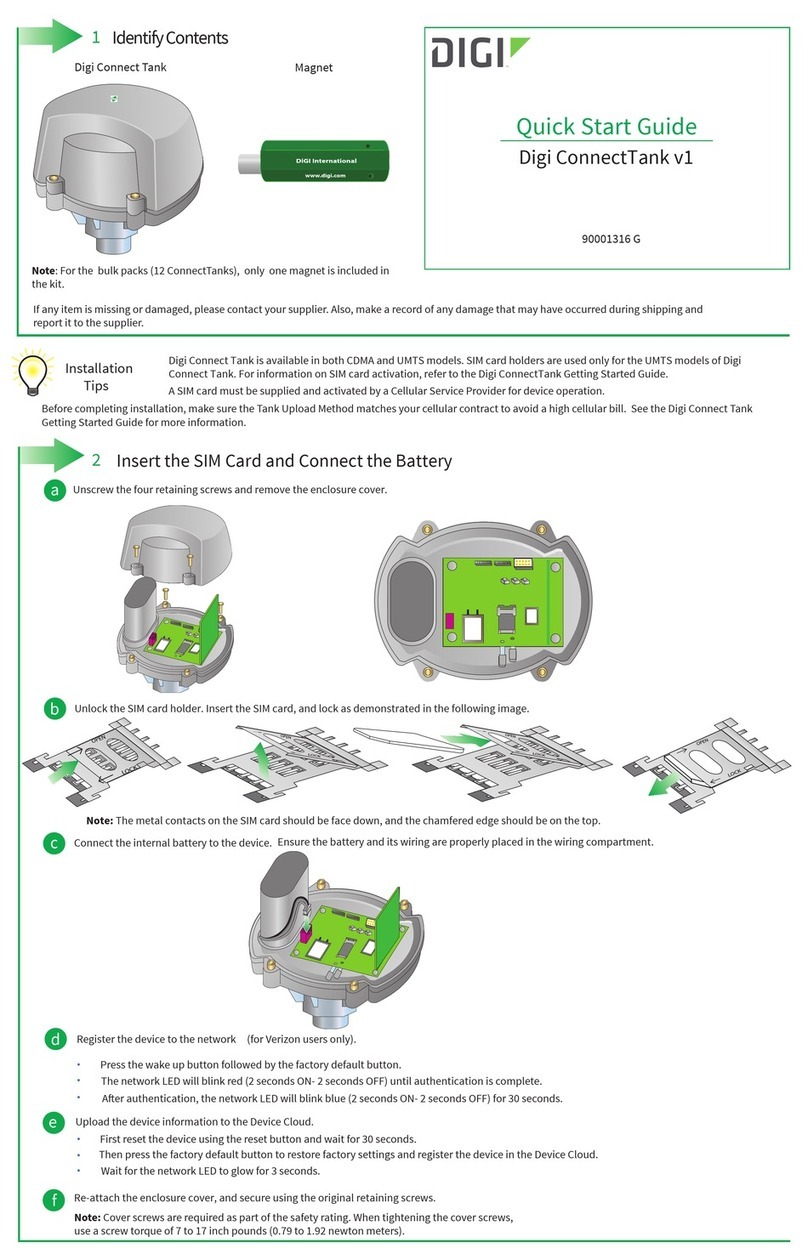

Unpacking the CyScan System

The whole CyScan system (comprising: main sensor unit, power supply and data con-

verter) are supplied and shipped in a custom-built flight case. Use the following proce-

dure to unpack and prepare the system elements ready for installation.

To unpack the CyScan system:

1 Position the CyScan flight case on a level surface, close to the area where the

sensor will be installed.

!Warning: The CyScan Sensor and peripheral items weigh in excess of 30kg. Two

people, should perform all lifting and carrying of the unit.

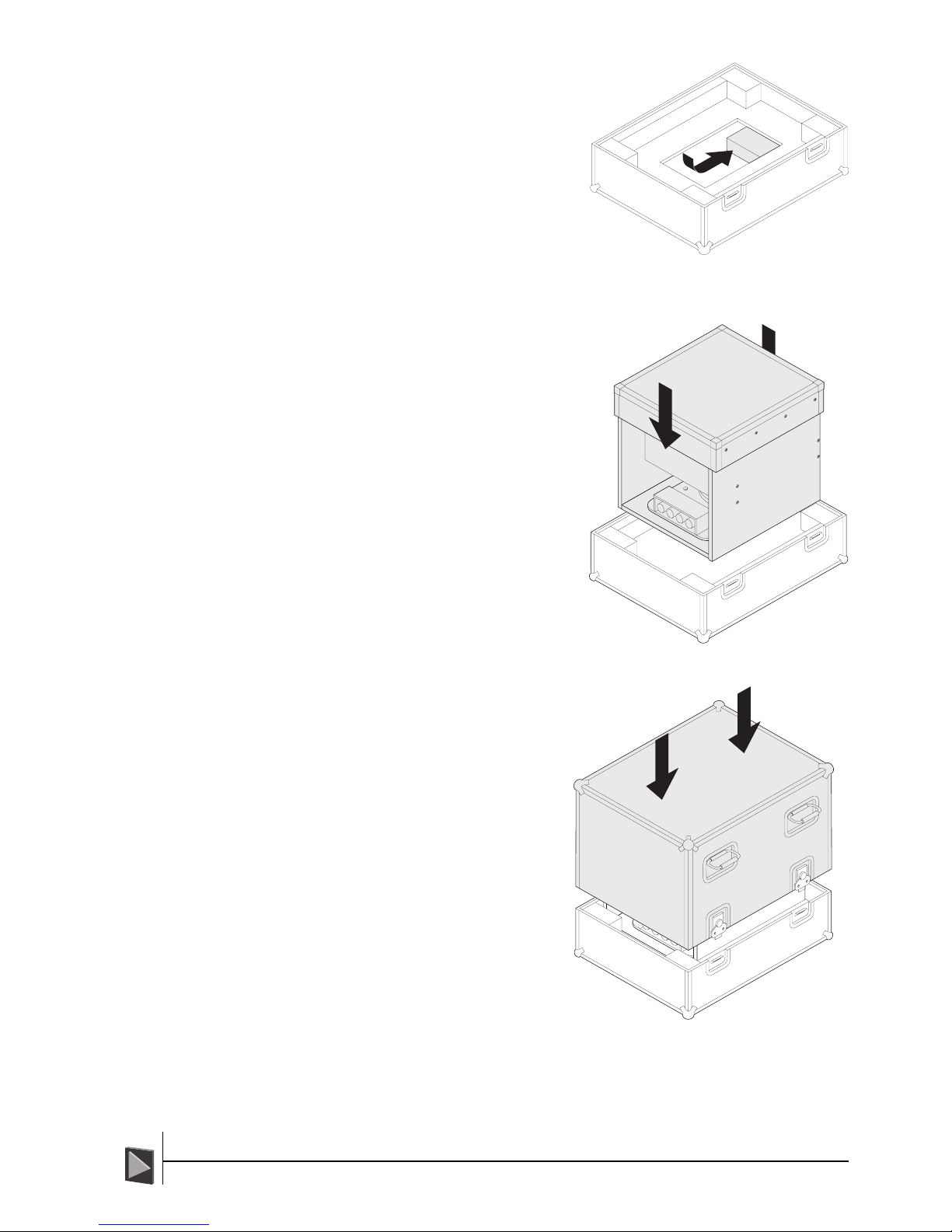

2 Release the four locking

catches by rotating the

butterfly-wing tabs anti-

clockwise. Swing the

catches outwards until they

lock out, away from the

lower lip.

3 With the assistance of

another person, lift and

remove the upper lid of the

flight case.

4 You will now be left with

the base of the flight case and an inner box

containing the sensor. Check that the eight

screws attaching the lid of the inner box are

intact. With the assistance of another person,

hold the open sides of the lid and lift the inner

box out of the flight case base. You can then

place the inner box onto the ground or, if space

is limited, rotate it horizontally by 45 degrees

and place it onto the lip

of the flight case.

5 Using a crosshead

screwdriver, remove the

eight screws securing

the lid onto the inner

box and remove the lid.

ïRemove the flight case lid

òLift out the inner box

ïRemove the inner box lid

5CyScan Positioning System • Installation and Maintenance Guide r1.1

GC S

GC S

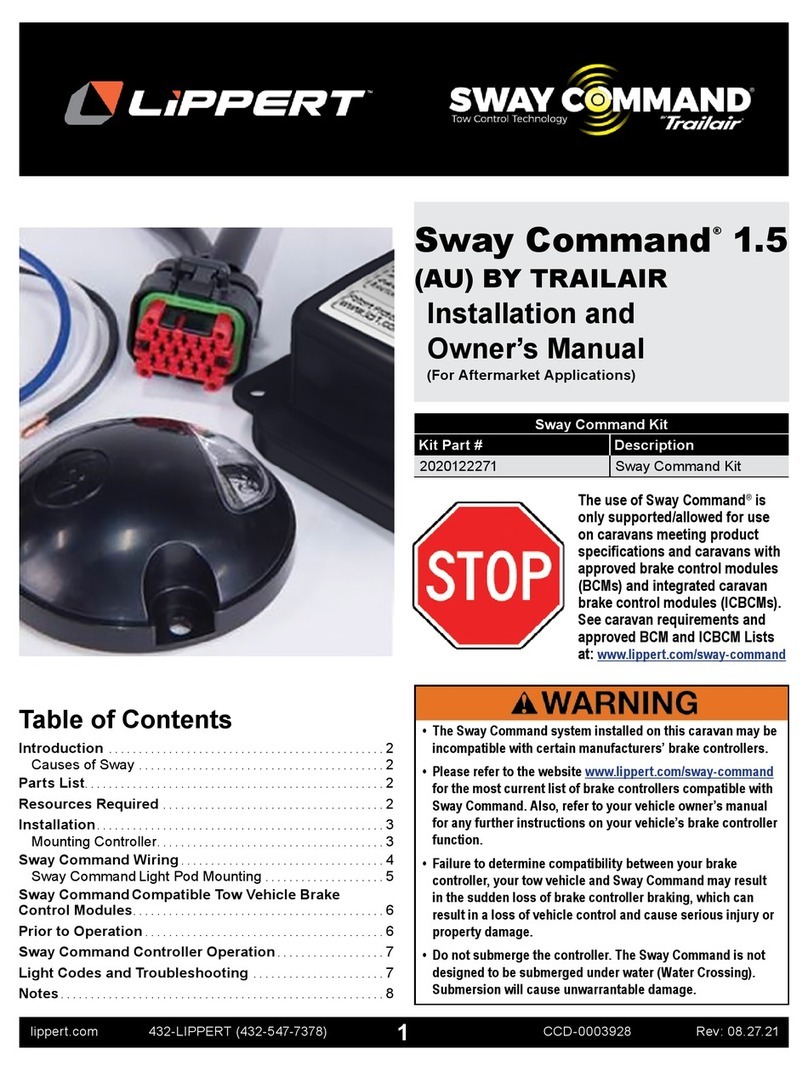

6 Using a crosshead

screwdriver,

remove the eight

screws securing

the two end

bumper boards

and remove.

7 Using a 13mm socket and ratchet,

remove the four bolts that secure the

CyScan sensor to the base of the inner

box.

8 With the assistance of

another person, lift the

sensor from the inner

box using the two

carrying handles. Place

the sensor next to the

pre-installed mounting

plate on deck.

9 From the access hole in

the base of the flight

case, remove the

power supply and data

converter boxes plus

their accompanying

cables.

The system is now ready for

installation.

ïRemove the bumper

boards

ñRemove the bolts

ïLift out the sensor

ïRemove the

peripheral items

6CyScan Positioning System • Installation and Maintenance Guide r1.1

GC S

GC S

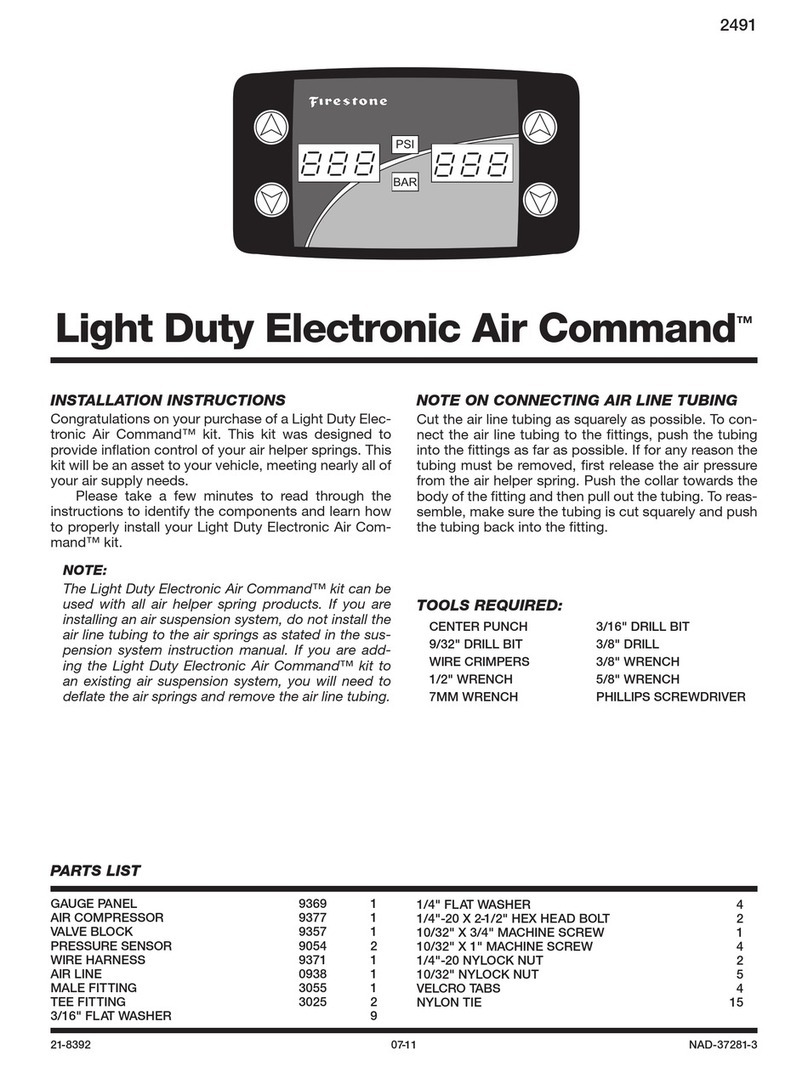

Mounting the System Components

The sensor can be mounted on the vessel using four bolts. The bolts secure the sensor

unit through the holes in the base.

!Warning: The CyScan Sensor weighs approximately 30kg. Two people, using the

integral handles on either side, should perform all lifting and carrying of the

unit.

To mount the CyScan Sensor:

1 With the assistance of another person,

use the two lifting handles to lift the

CyScan Sensor onto the required

mounting plate.

2 Orient the CyScan Sensor so that its

four connectors face the Stern of the

vessel.

3 Carefully lower the CyScan Sensor onto

the mounting position so that its four

mounting holes lineup with those of the

pre-drilled mounting plate. Refer to

Appendix 2 for mounting details.

4 Insert four M8 x 25 stainless steel bolts

and tighten them evenly using a 13mm

socket and ratchet.

STERN

Refer to Appendix 2 for

CyScan Sensor mounting

template details.

5 Remove each of the four locking pins

from the sensor. Ensuring that the white

bellows are not damaged, rotate the

larger barrel of each locking pin clockwise

until it becomes short enough to remove.

Keep the locking pins with the flight case

for future shipping. Avoid using tools for

this job to minimise the chance of inad-

vertently tightening the locking pins and

damaging the CyScan Sensor.

!Important: Ensure that the CyScan Sensor has a clear view in the intended

direction of the mooring point targets. Also, there should be no object within

300mm of the rotating head in any direction as the head requires sufficient space

to tilt in response to pitch and roll vessel movements.

When mounting two CyScan sensors on the same vessel

In situations where two separate CyScan sensors are to be used on the same vessel, the

following criteria should be met:

• The two CyScan sensors must be mounted at least 20m apart.

• An opaque screen should be mounted between the two sensors to avoid crossover

of laser beams.

• The blanking zones of both units should be set so that the alternate sensor is

excluded from the zone of operation.

7CyScan Positioning System • Installation and Maintenance Guide r1.1

GC S

GC S

To mount the CyScan PSU:

The CyScan PSU must be securely mounted within

one metre of the CyScan Sensor position.

1 Prepare a suitable site for the PSU and

pre-drill pilot holes for the mounting screws

according to the template provided in

Appendix 3.

2 Remove the PSU lid and insert four M6 x

30 stainless steel cap head screws through

the mounting holes at the four corners of

the PSU enclosure.

To mount the CyScan Data Converter

The CyScan Data Converter must be securely mounted in the vicinity of the CyScan

notebook computer.

1 Prepare a suitable site for the Data Converter and pre-drill pilot holes for the

mounting screws according to the template provided in Appendix 4.

2 Remove the Data Converter lid and insert four M4 x 20 stainless steel cap head

screws through the mounting holes at the four corners of the Data Converter

enclosure.

8CyScan Positioning System • Installation and Maintenance Guide r1.1

GC S

GC S

Wiring the CyScan System

The CyScan system introduces four main items to the vessel, these are:

• CyScan Sensor

• Power Supply Unit

• Data Converter

• CyScan Console Notebook Computer

The diagram below indicates the connections between the four items.

1

2

3

4

5

6

7

8

9

10

11

12

3

13

14

15

16

17

18

19

20

21

3

22

22

22

22

23

23

23

23

3

Console

DP

Power

2TX

2RX

1TX

1RX

PWR

Power

CyScan

Sensor

Power

Supply

Unit Data

Converter

DP Feed

Console Feed

To

DP Unit

Main

Power In

CyScan

Console

notebook

computer

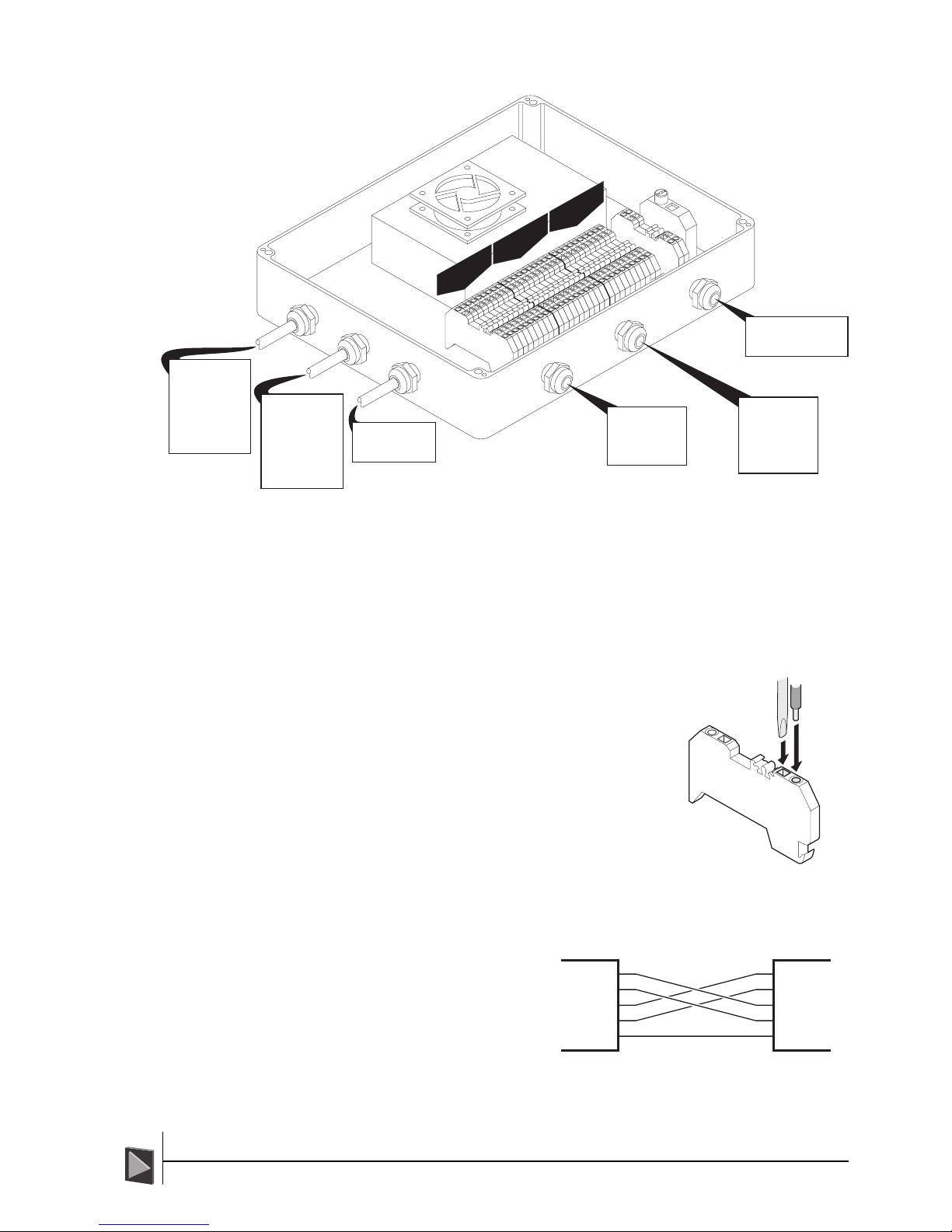

Power Supply Unit (PSU)

The PSU is supplied with three flying leads, all of which attach to the connectors at the

Stern end of the sensor. Three M20 x 1.5 threaded holes (fitted with stopping plugs) are

provided to accommodate cable glands leading to/from:

• The vessel’s DP system

• The CyScan notebook computer (via the Data Converter)

• A suitable AC power feed

Inside, the PSU contains a row of industrial connectors to make the wiring process as

quick and flexible as possible. Each connector is numbered and the relevant signal con-

nections (with their connector number) are shown on the diagram (overleaf). The PSU

requires a supply of 90-264VAC at 5A.

9CyScan Positioning System • Installation and Maintenance Guide r1.1

GC S

GC S

Power Supply Unit (continued)

!IMPORTANT: 0V is not the same as GND. 0V is the power supply return whereas

GND is a digital ground connection for the communication ports. If 0V and GND

are crossed or joined, the system will not function correctly.

!IMPORTANT: When replacing the lid on the PSU, ensure that the rubber seal is

smeared with silicone grease (Dow Corning® DC4) to maintain a watertight fit.

To insert wires:

!WARNING: Ensure all power is removed from the

system before altering any wiring.

1 Push a small flatblade screwdriver into the square

vertical hole at the front of the connector block

and press down on the lever inside.

2 While pressure is applied to the screwdriver, insert

the required wire(s) into the round hole adjacent to

the square hole.

3 Remove the screwdriver. Check that the cable is

securely held in place.

DP Signal Crossover

The RS485 connection between the

CyScan PSU and the vessel’s DP

system requires a crossover in order

that transmit and receive signals are

correctly routed. Ensure that the

crossover is correctly performed as

the cable from the DP system is

wired into the PSU.

1

2

3

4

5

6

7

8

9

10

11

12

3

19 18 17 16 15 14 13

20

21

3

23 23 23 22 22 22 22

23

3

Console

DP

Power

Power Input

90-264VAC 47-63Hz

0V AC

Earth

Conn.

1

2

3

Signal

RXA

TXB

TXA

RXB

GND

Connector

20

19

18

17

14

DP

OV

RXD+

TXD-

TXD+

RXD-

24V

Link GJ

GND

Link GJ

Cable Socket

A

B

C

D

E

F

G

H

J

Console

OV

RXD+

TXD-

TXD+

RXD-

24V

Link GJ

GND

Link GJ

Cable Plug

A

B

C

D

E

F

G

H

J

Power

Earth

24VDC

GND

Cable Socket

C

A

B

Signal

0V

24VDC

GND

RXA

TXB

TXA

RXB

Connector

23

22

11

10

9

8

5

Console Signals

(To Data Converter)

DP Connection

Main AC Power Input

3

RXA

TXB

TXA

RXB

GND

RXA

TXB

TXA

RXB

GND

CyScan

PSU

Vessel

DP System

10CyScan Positioning System • Installation and Maintenance Guide r1.1

GC S

GC S

The Data Converter

The Data Converter is necessary to translate between the RS485 signals used by the

CyScan sensor (and the DP system) and the RS232 signals used by the notebook compu-

ter. The Data Converter is contained within a watertight enclosure, however, it is usually

mounted on the bridge near to the CyScan notebook (refer to mounting template in

Appendix 4). The Data Converter requires a DC power supply between 7 and 35V – this

can be derived either from the CyScan Power Supply Unit or from the vessel’s bridge, as

required.

2TX

2RX

1TX

1RX

PWR

Signal

TX

NC

RX

NC

RTS

GND

7-35VDC

OV

Connector

1

2

3

4

5

6

7

8

Signal

GND

NC

RXB

RXA

TXB

TXA

Connector

6

5

4

3

2

1

DIP Switch

1

2

3

4

Position

OFF

OFF

ON

OFF

CyScan Notebook &

Power Connections

Console Signals

from PSU Unit

Data Converter Signal Crossover

The RS485 connection

between the CyScan PSU

and the Data Converter

requires a crossover in order

that transmit and receive

signals are correctly routed.

Ensure that the crossover is

correctly performed as the

cable from the Data Con-

verter is wired into the PSU.

RXA

TXB

TXA

RXB

GND

RXA

TXB

TXA

RXB

GND

CyScan

PSU

Data

Converter

The Data Converter is supplied with a single cable 2 metres in length that has a 9 pin

female D-Type connector for attachment to the CyScan notebook computer’s serial port.

A second cable gland allows entry for a cable to connect with the CyScan Power Supply

Unit.

otebook computer

The CyScan notebook computer is supplied with a battery charger and mains plug. This

should be connected when in use. A footprint of 400 x 400 mm should be allowed for

the console notebook computer. The notebook charger is typically 200 x 70 x 50mm and

will require mounting close to a mains supply.

11CyScan Positioning System • Installation and Maintenance Guide r1.1

GC S

GC S

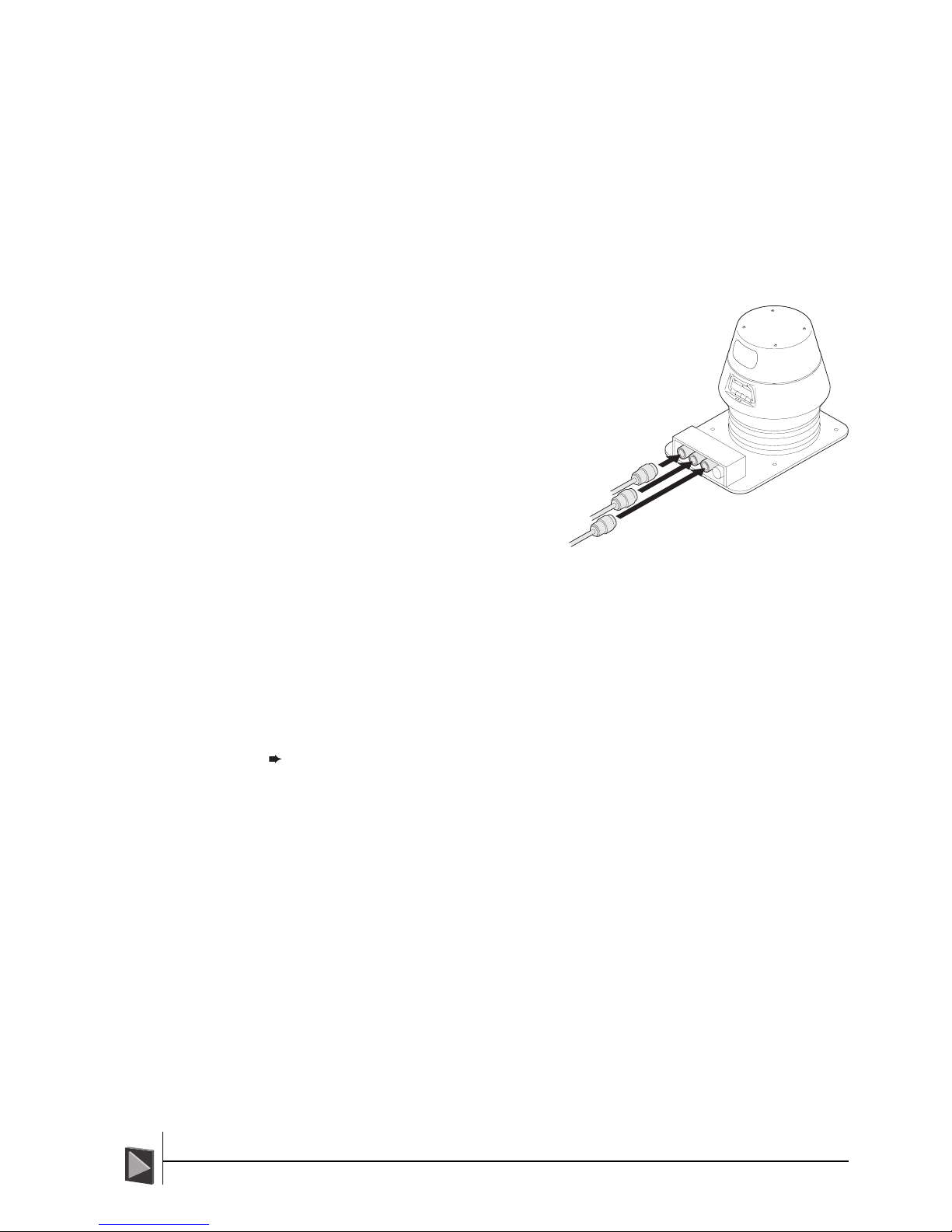

Connecting the CyScan Sensor

With the CyScan Sensor in position, the necessary electrical connections can be made.

!Important: The Console application must be closed whilst the Sensor is being

connected or disconnected.

To connect the CyScan Sensor:

1 Remove the protective dust caps from the Power, DP and Console sockets at the

Stern end of the CyScan Sensor. Do not remove the protective cap from the fourth

sensor connector.

The cable connectors and corresponding sockets are similarly labelled. Also, the

sockets and connectors are not interchangeable.

!Warning: The scanning head will begin to spin

within 30 seconds after power is applied.

Ensure that it is not obstructed before attach-

ing the power connector. Keep all objects at

least 300mm away from the scanning head

in all directions.

2 Attach each of the three cable

connectors, in the order that

follows, to the appropriate

sockets on the CyScan

sensor:

1 First, attach the

Power connector.

2 Next, attach the DP

Feed and Console connectors.

For each connection:

• Match the orientation of the cable connector to the socket (position 1 on

the connector should be facing upwards) and push it into the socket until

resistance is detected.

• Next, push the outer ring of the cable connector until it locks in place.

3 Double check that each connection is secure.

Note: For pin-outs of all sensor connectors, refer to Appendix 1.

DP Feed

Console

Power

12CyScan Positioning System • Installation and Maintenance Guide r1.1

GC S

GC S

Red

Yellow

Green

Leveller diagnostic

Embedded PC status

Main heartbeat

CyScan LED Indicators

To provide instant status information, the CyScan sensor features three LED indicators

mounted beneath the carrying handle at the Stern side. Each indicator displays the

current status of three key elements of the sensor circuitry:

Correct startup indication

As the CyScan sensor initialises itself, the following sequence should be seen:

Red Flashes once briefly when power is applied and should then be off for as

long as the yellow LED is on. As soon as the yellow LED has turned off, it

will toggle at one second intervals as the leveller circuitry initialises for about

30 seconds. After the initialisation period, the Red indicator should switch

off and stay off. If at any point it stays on permanently then a hardware

fault has been detected.

Yellow On continuously after power has been applied while the embedded PC

circuitry initialises. After the initialisation period, the Yellow indicator should

switch off and stay off. It will come on again once the system has been

shutdown or in case of an embedded PC failure.

Green Toggles twice a second after power is applied and while the yellow led is on. As

soon as the yellow led switches off and the leveller initialises (RED led toggles),

the green led will begin to flash at 10 Hz intervals giving the main system

heartbeat. When the system is suspended it flashes briefly once a second.

Error states and possible causes

Red Permanently on at any point - Electronic hardware failure within the leveller

or sensor circuitry. Can also come on when a hardware failure is detected

during operation.

Yellow On after the initialisation period is complete - Embedded PC failure or unit is

shut down. Communication with the sensor is not possible. Recycle power

to the CyScan system.

Green Permanently on or off - No heartbeat to the system. No operation is possi-

ble. Recycle power to the CyScan system.

Blinking slowly - unit suspended or shutdown (see YELLLOW and RED leds).

Toggling twice a second - after power has been applied, waiting for the PC

to initialise and the yellow LED to turn off.

Shutdown/suspend

Red Off unless there is a hardware failure.

Yellow On for shutdown, Off for suspend.

Green Flashes briefly once a second.

13CyScan Positioning System • Installation and Maintenance Guide r1.1

GC S

GC S

CyScan Removal

Decommissioning the CyScan system ready for stowage involves three basic stages:

• Switching off the CyScan Console System,

• Disconnecting the CyScan Sensor, and

• Un-mounting the CyScan Sensor

Switching off the CyScan Console System

!Important: The system running the CyScan Console application MUST be

switched OFF before the CyScan Sensor is disconnected.

To exit CyScan Console and shutdown the system

1 Click the ‘CyScan’ button in the lower left corner of the screen (this button is

unavailable while navigating). The control dialog will be displayed:

2 Click the down-arrow to reveal the three options. Select ‘Shut down’ and click the

OK button.

3 Click ‘Yes’ to confirm your selection in the subsequent pop-up message. The

application will send shut down commands to the CyScan sensor and then close

itself down.

4 In the lower left hand corner of the Windows screen, click the Start button.

5 Select the Shut Down option.

6 In the subsequent Shut Down Windows dialog, ensure that Shut Down option is

selected and click OK.

7 When the system reports that it is ‘safe to switch off your computer’, turn off the

notebook computer.

You can now proceed to disconnect and un-mount the CyScan Sensor (if required).

The status LEDs on the sensor unit should show the yellow LED on and the green LED

flashing briefly once a second.

Note: The Console application should always be running when the Sensor is in

operation.

14CyScan Positioning System • Installation and Maintenance Guide r1.1

GC S

GC S

Disconnecting the CyScan Sensor

!Important: The system running the CyScan Console application MUST be

switched OFF before the CyScan sensor is disconnected.

!Important: Do not disconnect the sensor if the scanning head is still spinning.

To disconnect the CyScan Sensor:

1 Begin by disconnecting the DP Feed and Console connectors.

For each connection:

• Pull the outer ring of the cable connector until it disengages from the socket.

• Next, gently pull the cable connector from the socket.

2 Now disconnect the Input Power connector.

3IMPORTANT: Replace the protective dust caps onto the three sockets on the

CyScan Sensor and also on the three cable connectors.

Un-mounting the CyScan Sensor

!Warning: The CyScan Sensor weighs approximately 30kg. Two people, using the

integral handles on either side, should perform all lifting and carrying of the unit.

To un-mount the CyScan Sensor:

1 Locking pin installation:

a Locate the four anodised locking pins that

were supplied with the CyScan sensor.

b Rotate the larger barrel of each locking pin

clockwise so that they become short

enough to be inserted between the base

plate and the middle body of the sensor.

c Ensure that the scanner head is parallel with

the Sensor baseplate. Locate the four locking pin holes in the sensor base

plate holes which are adjacent to each of the four larger mounting holes.

d For each of the four locking pins, insert the point of the thinner barrel into

the locking pin hole of the base plate. Then, push the larger barrel towards

the white bellows and gently rotate the larger barrel anti-clockwise so that

the pin extends.

Important: Ensure that the white bellows are not damaged by the locking

pin rotation.

e Continue rotating the larger barrel and guide the point of the locking pin

into the corresponding hole in the underside of the sensor body (the hole

will be directly above the one on the base plate).

f Do not tighten fully until all four locking pins are in place, and then tighten

them evenly by hand so that the sensor body is fixed in a level position.

IMPORTANT: Do not use tools to tighten the locking pins.

2 Using a 13mm socket and ratchet, remove the four

mounting bolts.

3 With the assistance of another person, use the two

lifting handles to lift the sensor away from the mount-

ing plate.

4 If necessary, place the sensor in its storage case

(covered next).

15CyScan Positioning System • Installation and Maintenance Guide r1.1

GC S

GC S

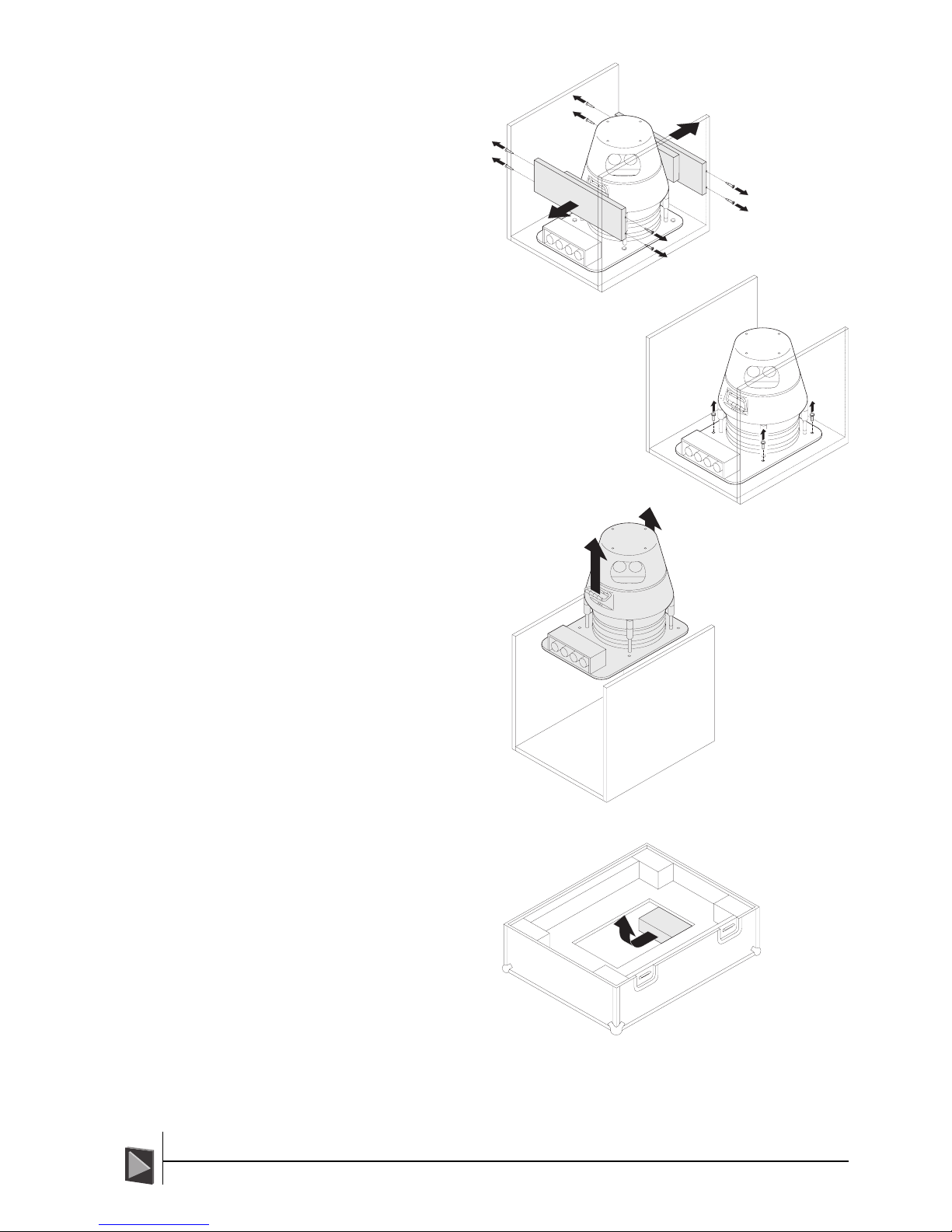

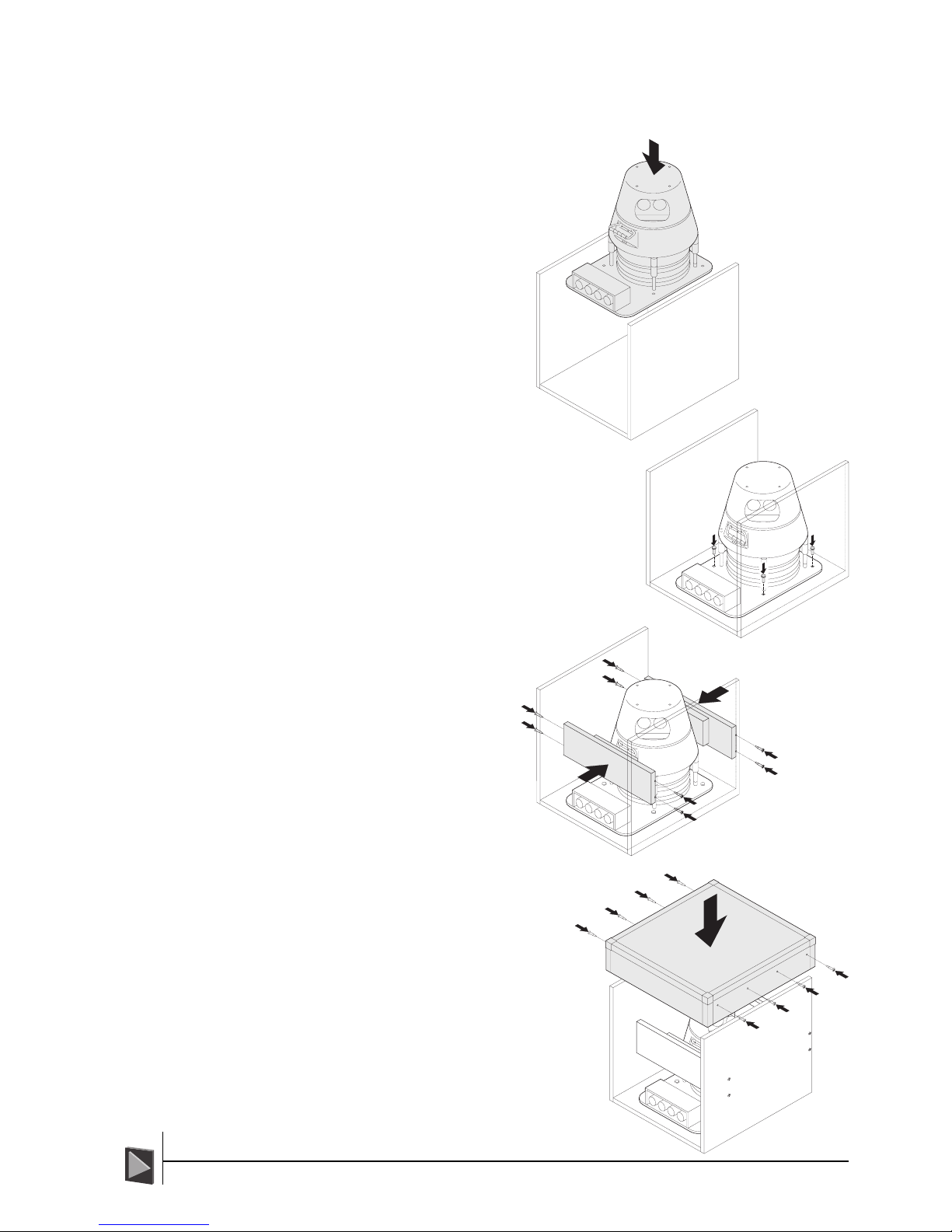

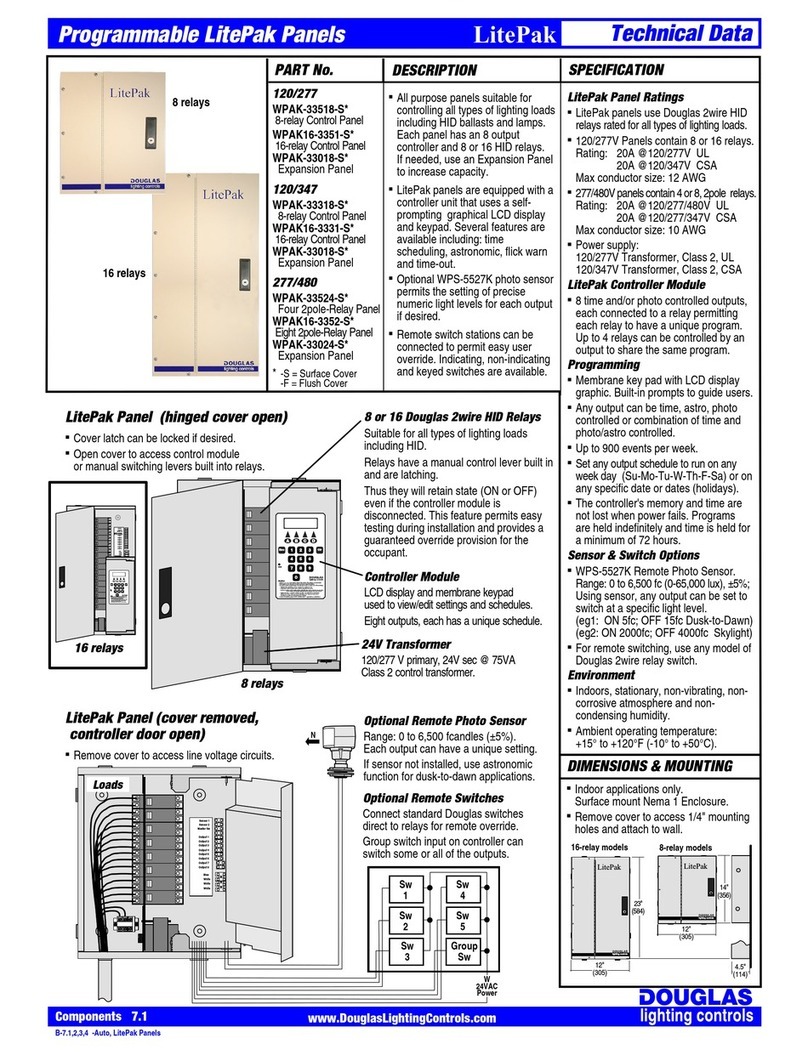

acking the CyScan System

With sensor disconnected and removed from its mounting plate, you can now begin to

pack it ready for shipping.

1 Locate the base and sides of

the wooden inner box in

which the CyScan sensor

was supplied. With the

assistance of another

person, lift the sensor into

the base of the inner box so

that the mounting holes of

the sensor base plate

correspond to the four

threaded inserts in the base

of the box.

2 Insert the four locking bolts. Using a 13mm

socket and ratchet, tighten the four bolts so

that the sensor is secure.

3 Locate the two end

bumper boards and

place them either side of

the sensor so that they

line up with correspond-

ing holes in the sides of

the box. The foam pads

on each of the bumper

boards should face

towards the sensor.

Insert the four screws

that secure each board

through the sides of the

inner box and tighten

with a crosshead screwdriver.

4 Place the lid of the inner box onto

base and sides and insert the

eight securing screws. Tighten the

eight screws using a crosshead

screwdriver.

16CyScan Positioning System • Installation and Maintenance Guide r1.1

GC S

GC S

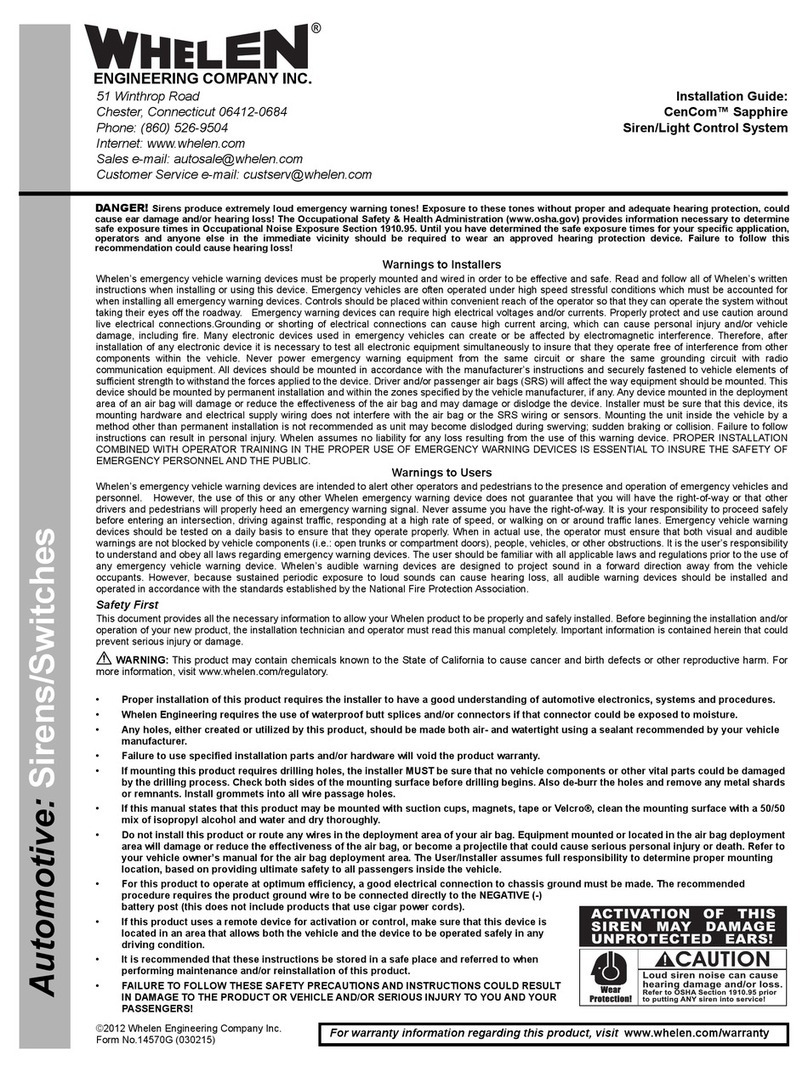

5 Locate the base of the CyScan flight

case. If the power supply and data

converter boxes are also to be

shipped, places these and their cables,

if necessary, into the lower recess of

the flight case base.

6 With the assistance of another person,

hold the open sides of the inner box

lid and lift the whole assembly into

the flight case base. Ensure that the

inner box is properly seated within the

foam guides of the flight case base.

7 With the assistance of another

person, place the lid of the flight

case onto the base so that it seats

correctly.

8 Engage the four locking catches

with the locking lips of the base

and secure each of the locking

catches by rotating the butterfly-

wing tabs clockwise.

The CyScan system is now ready for shipping.

17CyScan Positioning System • Installation and Maintenance Guide r1.1

GC S

GC S

Maintenance and Servicing

The CyScan sensor is constructed from distinct modules that can be removed and re-

placed as required. This section covers the removal, replacement, upgrading and servicing

of the CyScan sensor system. A list of recommended spare parts is listed in Appendix 5.

Removing and fitting key components

There are nine key stages of disassembly/assembly for all CyScan sensor modules, these

are:

Stage Previous stages required

1The Rotor Heatshield

2The Rotor 1

3The Body Cover 1

4The Motor Gearbox 1,2,3

5The CPU Module 1,3

6The Controller Board 1,3,5

7The Yaw Gyro 1,2,3,4,5,6

8The Vertical Reference Unit (VRU) 1,2,3,4

9The Pitch and Roll Actuators 1,2,3,4

The figures shown to the right of each stage are the other previous stages that you must

complete before access can be gained to the necessary components.

!WARNING: Ensure Static Safe Handling procedures are observed when removing/

fitting circuit board assemblies, e.g. CPU & Controller PCB, VRU, Yaw gyro, etc.

Stage 1 - The Rotor Heatshield

To remove the Rotor Heatshield:

1 Using a flat blade screwdriver, remove the

four screws on top of the rotor heatshield.

2 Lift the rotor heatshield up away from the

sensor.

To fit the Rotor Heatshield:

1 Place the rotor heatshield onto the rotor so

that the aperture aligns with the two rotor

lenses. Also the four mounting holes must

correspond to the four pillars on top of the

rotor.

2 Insert M5 x 12 slotted screws and bonded

seals into the four mounting holes and

using a flat blade screwdriver, tighten the

four screws in a staged and even manner

until all are tight.

18CyScan Positioning System • Installation and Maintenance Guide r1.1

GC S

GC S

Stage 2 - The Rotor

To remove the Rotor:

1 Using a flat blade screwdriver, loosen the two

screws on top of the rotor in an even manner

until they are both loose. Fully undo the two

screws and retract them from the rotor.

!IMPORTANT: Both screws have special

waterproof ‘bonded seal’ washers. Be

sure to keep the washers safe with the

screws. Standard washers must not be

used in replacement, as a watertight seal

will not be achieved.

2 Lift the rotor vertically upwards away from the

sensor gearbox.

To fit the Rotor:

1 Ensure the ‘O’ ring is present on the top of the gearbox shaft. Smear silicone

grease lightly over the ‘O’ ring but ensure none gets on the contacts of the ex-

posed connector.

2 Orient the rotor above the sensor with its main connector facing down to the

sensor and the face with the large

connector pointing in the same

direction as the small key screw

on the shaft. This ensures that the

keyway in the rotor connector

aligns with the key screw of the

shaft.

3 Place the rotor onto the shaft and

slide it down into position. It may

be necessary to rock the rotor

slightly to get it to fully mate with

the shaft.

4 Insert the two long M5 x 100

screws each with a specialist

waterproof sealing washer intact.

Smear silicone grease onto the

sealing washers for better water

protection. These bonded seal washers are essential to form a watertight seal -

normal washers must not be used in replacement.

!IMPORTANT: It is essential that the two screws in the next step are tight-

ened evenly.

5 Using a flat blade screwdriver, tighten the two screws alternately to take up the

slack. Now tighten the two screws alternately in decreasing steps of rotation, i.e.

one turn each, then three quarters each, then half each, etc. Continue in small

increments of rotation until both are brought to even tightness. Finally, apply a

coating of silicone grease around the screw heads and sealing washers to minimise

the chance of water ingress at this point.

6 Ensure that the rotor can rotate freely without touching any part of the sensor

gearbox.

Table of contents

Popular Control System manuals by other brands

Lipper

Lipper Sway Command 1.5 Installation and owner's manual

VIPA

VIPA System 200V CP 240 manual

Douglas Lighting Controls

Douglas Lighting Controls LitePak WPAK-33518-S Technical data

auer

auer Thorix EVOLUTION 2C Installation and operating instructions

Digitrax

Digitrax DS78V instructions

Eurotherm

Eurotherm PC300 Installation manual and user's guide

Whelen Engineering Company

Whelen Engineering Company CenCom Sapphire installation guide

Carel

Carel infrared IR32CE Series user manual

Intellitec

Intellitec iConnex user manual

Triple Plus

Triple Plus CLM-COAMAP-1-02 quick start guide

YASKAWA

YASKAWA VIPA System 300S manual

Lutron Electronics

Lutron Electronics VISEO GRAFIK5000 Operation manual