BENDIXKing Skymap IIIC Manual

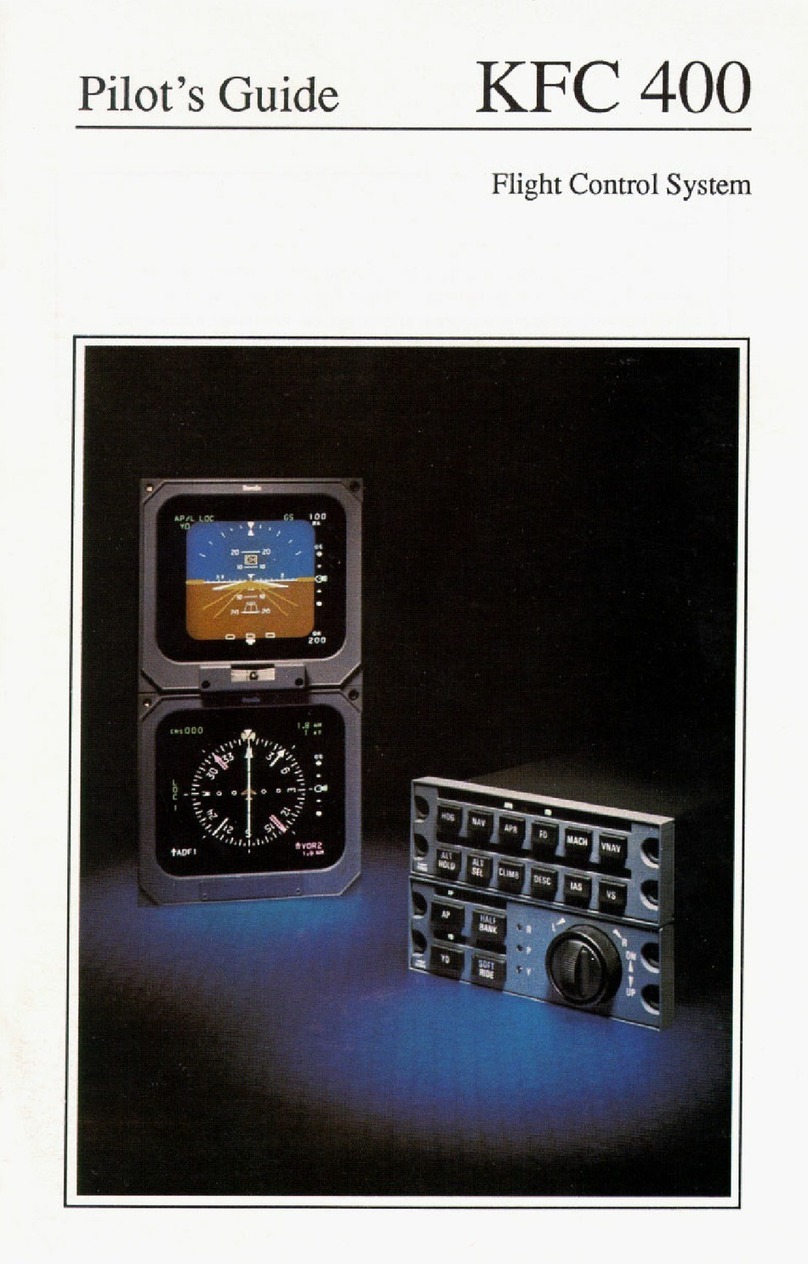

KFC 500

Pilot’s Guide

Bendix/King®

Flight Control System

Honeywell International Inc.

One Technology Center

23500 W. 105th Street

Olathe, Kansas 66061

FAX 913-791-1302

Telephone: (913) 712-0400

Copyright ©1993 Honeywell International Inc.

All rights reserved.

006-08750-0000

Rev. 0 Sept/93 N

006-08750-0000 September 1993

1

Introduction

The KFC 500 Automatic Flight

Control System combines complete

autopilot and flight director computa-

tion functions in a single computer.

Its digital flight computer and inte-

grated architecture enable the KFC

500 to determine helicopter control

requirements sooner, and to execute

them with greater smoothness and

accuracy than previous autopilot sys-

tems.

Due primarily to its dual channel

flight computer design, the KFC 500

can more positively control the air-

craft while providing a level of safety

monitoring unavailable with single

channel systems. Digital, solid-state

design throughout the Flight Control

System provides maximum reliability

while economizing on system weight

and required installation space.

The KFC 500 is designed to

optimize passenger and flight crew

comfort, while still providing accurate

control response in any flight situa-

tion. Wherever possible, autopilot-

induced aircraft motions border on

the lower limits of human perceptibil-

ity, ensuring exceptionally smooth

flight. Many of the Flight Control

System’s maximum commandable

values were determined for the Bell

Model 230 during the aircraft certifi-

cation process.

The KFC 500 is integrated with

KAD 480 Central Air Data System

and the EFS 40/50 Electronic Flight

Instrument System to enhance user-

friendliness as well as system

annunciation.

Internal safety monitors and

automatic self-test functions keep

constant track of the KFC 500’s sta-

tus, and provide signals for auto-

matic shutdown of impaired control

axes or flight director functions.

When the KFC 500 decouples an

autopilot axis it both releases the

affected servo brake and shuts off

motor drive power, providing dual

layers of protection against servo

overcontrol.

In addition to reliability and light

weight, the KFC 500 is designed to

be easy to maintain in the field. Self-

contained diagnostic tests assist

troubleshooting done by mainte-

nance personnel at Bendix/King®

factory-approved service centers.

The EFIS interface provides addi-

tional trouble-shooting access via the

cockpit display units. The Built-In-

Test functions enable a technician to

trace a fault to the individual circuit

board, or external sensor con-

cerned. Circuit boards inside remote-

mounted components are installed

vertically, to prevent condensation

pooling. Qualified Bendix/King®ser-

vice centers around the world are

ready to provide assistance when-

ever necessary.

The KFC 500 is integrated to the

EFS 40/50 Electronic Flight

Instrument System allowing a very

flexible navigation system interface.

All of the KFC 500’s digital interfaces

are based on ARINC 429 specifica-

tions, and analog/digital converters

are supplied wherever necessary to

provide the greatest interface versa-

tility.

2

Important:

This Pilot's Guide provides a general description of the

various operational characteristics of the KFC 500 Flight Control

System. However, operation of the system should not be

attempted without first reviewing the applicable FAA Approved

Rotorcraft Flight Manual Supplement for complete system

familiarization and operating limitations.

3

Introduction............................................................................................1

System Components.............................................................................5

System Description

Normal Flight Control Operations

KMS 540 Flight Director Mode Select Panel ....................................8

Basic Flight Director Mode ...............................................................8

Pitch Attitude Hold/Roll Attitude/Heading Hold.................................9

Lateral Command Control ................................................................9

Vertical Command Control .............................................................10

Force Trim Release........................................................................11

Navigation Standby ........................................................................11

Go-Around......................................................................................11

Yaw Force Trim Release................................................................12

Yaw Trim .......................................................................................12

KMS 540 Lateral Mode Selection

Heading (HDG)...............................................................................13

Bank Angle Limit (BL).....................................................................13

Navigation (NAV)............................................................................14

Approach (APR) .............................................................................14

KMS 540 Vertical Mode Selection

Altitude Select (ALT SEL)...............................................................16

Altitude Hold (ALT HOLD) ..............................................................16

Indicated Airspeed (IAS) ................................................................17

Vertical Speed (VS)........................................................................17

KMS 540 Autopilot and Yaw Damper Mode Selection

Yaw Damper (YD) ..........................................................................19

Autopilot (AP) .................................................................................19

KFC 500 Equipment Descriptions

KSA 572 Trim Actuator...................................................................20

KLA 570 Linear Actuator ................................................................20

KVG 350 Attitude Gyro...................................................................20

KCS 305 Slaved Compass System................................................21

KRG 332 Yaw Rate Gyro ...............................................................21

KAB 330 Triaxial Accelerometer ....................................................21

Control Position Transducer...........................................................21

Autopilot/EFIS Switches Descriptions

KCP 520 Flight Computer ..............................................................22

Autopilot/EFIS Master ....................................................................22

CMPST...........................................................................................22

VG SEL 1-2 ....................................................................................23

Table of Contents

4

DG SEL 1-2 ....................................................................................23

DME HOLD ....................................................................................23

VG FAST ERECT...........................................................................23

Cyclic Grip Switch Assembly..........................................................24

Collective Switch Assembly............................................................25

Basic EFS 40 Description

ED 461 EFIS Display......................................................................26

EFS 40 Display Units .....................................................................27

KAD 480 Air Data System

KDC 481T Central Air Data Computer ...........................................32

KAV 485 Altitude/Vertical Speed Indicator .....................................34

Emergency Procedures ......................................................................39

Preflight Procedures ...........................................................................43

Operational Examples

Attitude Hold...................................................................................48

Navigation Standby ........................................................................48

Force Trim Release........................................................................48

Heading Select ...............................................................................49

Go-Around Mode............................................................................50

Navigation Coupling .......................................................................50

Yaw Force Trim Release................................................................51

Yaw Trim ........................................................................................51

Takeoff and Climb ..........................................................................52

Front Course ILS Approach ...........................................................54

Go-Around from an ILS Approach..................................................56

Localizer Back Course Approach ...................................................58

Performance Specifications ...............................................................62

5

ı

2020

10 10

2020

10 10

33 N 3

GS

AZ GS 500

RA

DH

200

F

S

KDM 706A

ı

1

KDC 481

ı

2020

10 10

2020

10 10

33 N 3

GS

AZ GS 500

RA

DH

200

F

S

0

2

3

4

5

6

7

8

9ALT

VS ALT

1000 FT/MIN

VS

2

4

6

6

4

21

1

.5

.5

0

UP

DN

IN HG MB DEN ALT

SEL

ALERT

ALT

VS

1,160

30.08 1,690

1

1

ENG SEL

BARO

U

P

S

H

E

T

S

T

SEL

U

P

L

L

V

S

KCP 520

ı

KAV 485

KVG 350

KRG 332

YAW RATE GYRO

KCP 520

FD/AP

COMPUTER

SG 465

KMS 540

AP/FD

MODE SELECTOR

KDC 481T

AIR DATA

COMPUTER

SG 465

ı

ı

KRG332

RATEGYRO

ED 462

ED 461

ı

HDG NAV APR BL

ALT VS IAS

FD

AP YD

KSG 105

KSG 105

1

KSA 572

KLA 570

VG

FAST

ERECT

VG SEL

1 2

DME

HOLD

DG SEL

1 2

CMPST

TST

BRT

1

2

1

SYNC

REF

DIR

N

A

V

A

R

C

H

S

I

ADF 2

M

L

S

1

23

AZ

359

12.

6

NM

N

33

30

W

24

2

1

S

1

5

1

2

E

6

3

11.

5

11.

5

G

S

VG #2

DG #2

CRSR

NAV

FPL

MODE

TRIP

CALC

STAT

SETUP

OTHER

NAV

D/T

ACTV

REF

CTR

APT

VOR

NDB

INT

SUPL

ALT CLR ENT

KLN 90

ıEMP =TOP |PRESENT POS

dddddid‹ddd|

DIS 89.4nm|BUM 300^FR

GS 180kt| 37.4NM

ETE :29| N 38^01.4'

BRG 026^| W 95^32.6'

NAV 1|enr-leg |NAV 2

GPS

BRT

D

MSG

CRSR

KLN 90/90A

SG 465

SYMBOL

GENERATOR

ED 462

ED 461

SG 465

ı

KVG 350

KSG 105

KSG 105

1

TST

BRT

1

2

1

SYNC

REF

DIR

N

A

V

A

R

C

H

S

I

ADF 2

M

L

S

1

23

AZ

359

12.

6

NM

N

33

30

W

24

2

1

S

1

5

1

2

E

6

3

11.

5

11.

5

G

S

VG #1

DG #1

KNR 634

ı

KNR 634

ı

KDM 706A DME KNR 634

VOR/ILS/MB

KSA 572

KLA 570

KSA 572

KLA 570

POSITION

SYNCHRO

POSITION

SYNCHRO

POSITION

SYNCHRO

COLLECTIVE POSITION

SYNCHRO

CYCLIC

SWITCHES

VG

FAST

ERECT

VG SEL

1 2

DG SEL

1 2

CMPST

AP FAIL

TRM FAIL

DIRECTION

OFFLIGHT

KAB 330

ACCELEROMETER

PITCH

ROLL

YAW

KFC 500 SYSTEM BLOCK DIAGRAM

FOUR TUBE EFS 40 SYSTEM

6

7

KFC 500

Normal Operation

8

KMS 540 Flight Director Mode Select Panel

a new altitude in Altitude Select,

does not affect active tracking modes

such as Heading or Vertical Speed

Hold. It is often useful to engage a

separate mode to provide flight guid-

ance to the capture point for a

course or altitude selected in an Arm

mode. The Flight Control System

will transition automatically to capture

the armed mode, cancelling the pre-

vious selection. Examples of this

operation are described in the

Operational Examples section of this

guide.

To cancel a flight director mode

engaged in either capture or tracking

operations, either select an alternate

tracking mode or press the engaged

mode’s pushbutton on the mode

select panel. The latter method also

cancels modes while in their Arm

phases. Go-Around is an exception.

The collective-mounted pushbutton

provides the engage function only.

When the flight director is operat-

ing with no horizontal or vertical

mode selected, the KFC 500 auto-

matically engages in Heading Hold

and Pitch Attitude Hold. These

default modes provide basic flight

stability and serve as safety backups

in the event that the flight computer

cancels an active mode due to loss

of required navigation signal or sys-

tem malfunction. Engaging the

KFC 500 in any tracking mode auto-

matically cancels the corresponding

default mode for that particular axis.

Basic Flight Director Mode

Depressing the FD button on the

Mode Select Panel will activate the

basic Flight Director. Pitch Attitude

Modes of Operation

The KMS 540 Mode Select Panel

provides control and annunciation of

the KFC 500’s Flight Director,

Autopilot, and Yaw Damper modes.

Illumination of the annunciator lamps

on the mode controller is adjusted

automatically by a photocell located

on the face of the unit. To activate

flight director or autopilot modes

using the Mode Select Panel, press

the desired pushbutton. The corre-

sponding mode lamp above the

pushbutton will illuminate and the

mode annunciation on the Electronic

Attitude Director Indicator, EADI, will

appear. Alternatively, to deactivate a

flight director or autopilot mode when

activated, depress the respective

pushbutton.

The KFC 500 will engage in only

one horizontal and one vertical track-

ing mode at a time. Flight director

modes engaged in initial, arming

sequences, however, do not conflict

with tracking operations in other

modes. For example, selecting a

new course in the Nav Arm mode, or

ı

APRHDG

ALT

BL

IAS

AP FD

NAV

VS

SCAS

Normal Operation

9

Hold and Roll Attitude/Heading Hold

automatically engage unless other

tracking modes are selected. Pitch

Attitude Hold and Roll

Attitude/Heading Hold are annunci-

ated on the EADI as PIT and ROL,

respectively.

Pitch Attitude Hold

Roll Attitude/Heading Hold

In the absence of any other

selected Flight Director Modes, the

Flight Director will provide com-

mands to maintain current pitch atti-

tude and establish a level roll atti-

tude. When roll attitude approaches

six degrees or less bank angle, the

flight director will provide commands

to maintain constant heading.

Target roll and pitch attitudes

may be selected by several methods.

Adjusting the helicopter’s attitude

manually may be accomplished by

pressing the Force Trim Release

(FTR) Switch to the first detent while

moving the cyclic (and the helicopter)

to the desired attitude. Upon release

of the FTR switch, the Flight Director

will provide commands to maintain

the target Pitch and Roll attitude.

Alternatively, Attitude Hold com-

mands may be modified by moving

the Cyclic mounted Beep Trim(CBT)

switch in the appropriate directions.

If a target roll attitude of six

degrees or less is selected, the Flight

Director will provide commands to

maintain the helicopter's current

heading. Heading information from

the KSG 305 Compass System's

Directional Gyro provides heading

informantion to the Flight

Director/Autopilot.

Selecting any horizontal or verti-

cal tracking mode cancels Roll

Attitude Hold or Pitch Attitude Hold,

respectively. Either mode may be

used in conjunction with any Arm

mode to provide flight guidance for

course or altitude intercepts.

Lateral Command Control

Activated by the Cyclic Beep

Trim (CBT) switch when the Flight

Director or Autopilot is on, Lateral

Command Control modifies the

AFCS’s reference attitude during

operations in Roll Attitude Hold.

Moving the four-way switch either

right or left cancels any selected

flight director horizontal mode and

engages Roll Attitude Hold.

Operating Lateral Command Control

does not affect Arm operations in

Nav or Approach modes, nor does it

affect flight director vertical modes,

with the exception of Glideslope,

which it cancels along with

Approach. When Lateral Command

Control is used, the aircraft will be

commanded to follow the pilot’s input

to roll left or right with a constant roll

rate until the beep trim switch is

released.

Upon release of the CBT switch,

the flight director will command the

aircraft to maintain the existing roll

FD

FTR

CBT

Cyclic Grip

Switches

10

attitude. Roll attitudes of less than six

degrees of bank will cause the Flight

Director to revert to commands for

roll-level flight with heading hold.

Activating Discrete or Continuous

Lateral Command has the following

effect upon command values in flight

director operations:

Flight Director Lateral Command Values

Discrete Command System Response

Roll Attitude Hold First Click=6°, Subsequent=1° per click

Heading Select 1° Heading Bug Movement per click

Continuous Command

Roll Attitude Hold Constant Roll Rate

Heading Select 15° Heading Bug Movement per second

Vertical Command Control

Using the same cyclic switch as

mentioned in the previous para-

graph, vertical commands can be

modified by moving the vertical com-

mand switch fore and aft. Operation

of the Vertical Command Control

depends on the flight director or

autopilot mode engaged. Moving

the switch forward adjusts the heli-

copter’s pitch attitude downward,

while moving it rearward adjusts the

attitude upward.

Activating Vertical Command

cancels certain flight director vertical

tracking modes, but has no effect on

modes engaged in the Arm phase.

The flight director will revert to Pitch

Attitude Hold if it was coupled in

Glideslope, Altitude Capture or Go-

Around at the moment of command

activation. Attitude Hold, Altitude

Hold, Indicated Airspeed Hold and

Vertical Speed Hold will remain cou-

pled throughout Vertical Command

operation.

Activating Discrete or Continuous

CBT

Flight Director Vertical Command Values

Discrete Command System Response

Pitch Attitude Hold 0.5° per click

Altitude Hold 10 feet per click

Indicated Airspeed Hold 1 knot per click

Vertical Speed Hold 100 fpm per click

Continuous Command

Pitch Attitude Hold Maintains const. acc. profile until release

Altitude Hold 50 feet per second

Indicated Airspeed Hold Five knots per second until release

Vertical Speed Hold 300 fpm per second until release

11

Vertical Command has the effect

upon command values in flight direc-

tor operations shown in the preced-

ing table.

Force Trim Release (FTR)

When the Flight Director is

active, the Force Trim Release

switch allows the crew to synchro-

nize flight director commands in pitch

and roll to the actual helicopter posi-

tion. When the selected mode for

flight director is pitch attitude hold,

altitude hold, airspeed hold, roll level

or roll attitude hold, FTR will cause a

new flight director reference to be

established upon release of the

switch. All commands will then be

directed to hold this new reference.

When the autopilot is in Attitude Hold

mode with no flight director, the

AFCS synchronizes attitude with the

present helicopter attitude when

released.

When the FTR switch is

depressed, the trim servo magnetic

brakes release, eliminating the artifi-

cial feel system, allowing the pilot

free movement of the cyclic. When

the switch is released the trim brake

re-engages. The FTR switch is dou-

ble detent. Actuation to the first

detent allows the pitch and roll

brakes to release for free cyclic

movement. Depressing through the

second detent releases the yaw

brake in addition to the pitch and roll,

allowing free cyclic and pedal move-

ment. The Force Trim System must

be “ON” for the AFCS to operate.

Navigation Standby

When the Navigation Standby

Switch on the cyclic is momentarily

depressed, the flight director deacti-

vates and the flight computer com-

mands attitude retention.

Subsequent activation of the flight

director modes may be accom-

plished by depressing the appropri-

ate Mode Select Panel pushbuttons

or by arming an altitude on the

Altitude/Vertical Speed Indicator.

Go-Around

Pressing the Go-Around

Pushbutton on the collective switch

box activates the Go-Around mode in

which the flight director commands a

750 feet per minute climb in a roll-

level attitude. Any horizontal tracking

mode may be subsequently reen-

gaged without cancelling the Go-

Around climb.

NAV

Standby

Go-

Around

FTR

Yaw Force Trim Release

A Collective mounted Yaw Force

Trim Release is provided.

Depressing this switch releases the

Yaw brake, allowing free pedal

movement when the autopilot or Yaw

Damper is engaged. Upon release of

the switch, the Autopilot/Yaw

Damper will command ball centered

flight.

12

Yaw Trim

A Collective mounted Yaw Trim

Switch is provided. Holding the

switch to the right or left moves the

Yaw Axis in the corresponding direc-

tion at a constant rate. Yaw Damper

must be operational and active for

Yaw Trim to function.

Yaw

Force

Trim

Release

Yaw

Trim

Bank Angle Limit Presentation

13

HDG (heading select)

Depressing the HDG pushbutton

on the mode select panel activates

Heading Select mode. The Heading

mode will provide flight director com-

mands to track the heading bug on

the EHSI. The heading lamp on the

mode select panel illuminates and

“HDG” is displayed on the EADI

when the heading select mode is

activated. Activating Heading Select

cancels any other lateral tracking

mode. If the Heading Select mode is

active, depressing the HDG pushbut-

ton will deactivate the the Heading

Select mode and revert the flight

director commands to maintain a roll-

level attitude that maintains the heli-

copter's present heading, the default

mode. Flashing of the annunciator

lamp indicates loss of a sensor

required to hold the selected heading

(e.g. invalid magnetic heading,

invalid selected heading). The lamp

continues flashing until a second

push of the HDG pushbutton (pilot

acknowledgement of mode loss) or

until another lateral mode is acti-

vated.

BL (bank angle limit)

This pushbutton allows the pilot to

select the maximum commanded

bank angle to be used during the

non-approach phases of flight. The

Bank Angle Limit mode allows the

maximum commanded bank angle to

be 25°, 20°, 15°, or 10°. The value

for the Bank Angle Limit is achieved

by cycling the pushbutton until the

desired value is displayed on the

EADI. If the default value, 20°, is

selected, the selected value declut-

ters on the EADI. The default value,

20°, is obtained at power-up if no

action is taken by the pilot to select

another value.

In the coupled approach phases

of flight, bank angle limiting is dis-

abled to provide optimum flight per-

formance. When coupled with the

Approach mode Armed, all captures

are made with a maximum bank

angle of 20°. If lesser bank angles

are required, the pilot may use the

heading select mode (move the

heading bug slowly) to capture the

KMS 540 Lateral Mode Selection

HDG

TST

BRT

1

2

1

SYNC

REF

DIR

N

A

V

A

R

C

H

S

I

ADF 2

L

O

C

1

CRS

359

12.6 NM

11.

5

11.

5

G

S

N

33

30

W

24

21

S

15

12

E

6

3

360°

BL

NAVHB

BL10

HDGAP

YD

Heading Select Bug

Heading Select Knob

14

localizer and then depress the APR

pushbutton to activate Approach

Mode when tracking inbound on the

appropriate course.

When the KFC 500 is coupled to

a flight management system (FMS)

that has a composite steering com-

mand to drive the flight director (ie.

KLN 90, KNS 660), the flight man-

agement system has complete con-

trol of bank angles up to 25°. Bank

limiting when coupled to a FMS is

inhibited in this situation to prevent

poor tracking performance.

Bank Angle Limit may be

engaged in conjunction with any

flight director tracking mode.

However, it’s operation will be inhib-

ited in the Approach mode and when

coupled to a FMS.

NAV (capture and track selected

navigation sensor)

The nav lamp illuminates and “NAV”

is displayed in the lateral mode win-

dow of the EADI when the NAV or

NAV ARM mode is activated by

depressing the NAV pushbutton on

the KMS 540 Mode Select Panel.

When the NAV mode is selected by

the NAV pushbutton and course nee-

dle deflection exceeds the capture

requirements of NAV mode (greater

than 50% full scale needle devia-

tion), the NAV ARM mode is acti-

vated and allows a compatible lateral

mode to be used to intercept the

desired course or track. If the air-

craft’s deviation from the selected

course centerline is sufficiently small

(less than 50% full scale needle devi-

ation), or if the rate of closure with

the new course is sufficiently high,

the flight director initiates the NAV

Capture sequence immediately.

A flashing NAV lamp indicates

loss of a sensor required to capture

or track the selected nav (e.g. invalid

NAV, invalid selected course) and

continues until a second push of the

NAV pushbutton (pilot acknowledge-

ment of mode loss). In the event of a

sustained NAV invalid during NAV

ARM, the current lateral mode will

remain active until another mode is

selected. The NAV pushbutton may

also be used to deactivate the NAV

mode.

APR (capture and track selected

sensor with approach authority)

The approach lamp on the mode

select panel illuminates when the

approach or approach ARM mode is

activated by depressing the APR

pushbutton. Upon initial selection,

APR

TST

BRT

1

2

1

SYNC

REF

DIR

N

A

V

A

R

C

H

S

I

V

O

R

1

CRS

090

7.5 NM

010°

KT140

N

33

30

W

24

21

S

15

12

E

6

3

NAV

Selected Course Course Pointer

Course Select Knob

engages Glideslope Arm (GS ARM),

Capture and Track (GS) sequences

during ILS front course approaches.

The localizer must be captured in

order for glideslope to ARM or cou-

ple. Glideslope coupling is inhibited

during back course procedures.

Any horizontal tracking mode

may be employed during Approach

Arm phases and will cancel automat-

ically upon initiation of Approach

Capture and Track. Any vertical

mode may be used prior to glides-

lope capture or track and will auto-

matically cancel upon initiation of

glideslope capture. Activation of

Approach Capture will automatically

incorporate the default maximum

commanded bank angle, 20°, for

optimum comfort and performance.

A flashing APR lamp indicates

the loss of a sensor required to cap-

ture or track the selected nav (e.g.

invalid NAV, invalid selected course)

and continues until a second push of

the APR pushbutton (pilot acknowl-

edgement of mode loss). The APR

pushbutton also deactivates the

approach and approach arm modes.

When flying inbound on a

Backcourse Approach, the selected

course should be in the opposite

direction of the helicopter's heading.

15

the Approach mode engages in

either Approach Arm or Capture,

depending on the aircraft’s closure

rate and proximity to the selected

course. The flight director may initi-

ate turn commands before the

course deviation indicator displays

movement. Selecting the Approach

mode after the aircraft has already

passed the point at which Approach

Capture normally would begin may

result initially in course overshoot

due to the flight director’s roll com-

mand limits. If APR mode is called

for by the APR pushbutton and

course needle deflection exceeds the

capture requirements of the

approach mode (greater than 50%

full scale needle deviation),

Approach ARM is activated and a

compatible lateral mode may be

used to intercept the desired course.

The KFC 500 discriminates auto-

matically between front course and

back course approaches, and VOR,

LNAV, and MLS procedures. While

the KFC 500 uses this information to

determine the type of navaid

involved, front course/back course

selections are determined by the rel-

ative angle between the aircraft’s

heading and the course selected on

the EHSI. Intercept angles between

0° and 105° cause the KFC 500 to

select the ILS front course. Angles

between 106° and 180° cause the

flight director to command back

course interception and tracking.

It is essential that the course

selector arrow on the navigation dis-

play always be aligned with the ILS

front course. Failure to align the

course arrow properly may result in

erroneous front course/back course

selection by the KFC 500.

The flight director automatically

TST

BRT

1

2

1

SYNC

REF

DIR

N

A

V

A

R

C

H

S

I

ADF 2

L

O

C

1

CRS

179

12.6 NM

N

33

30

W

24

21

S

15

12

E

6

3

360°

16

ALT SEL (automatic capture of

selected altitude)

“ALT” is annunciated in white on

the EADI when the Altitude Select

mode is armed by depressing the

SEL pushbutton on the KAV 485

Altimeter/Vertical Speed Indicator.

The selected altitude is displayed in

the KAV 485’s altitude preselect win-

dow. Altitude Select will automati-

cally Arm after a change in the alti-

tude select value. The Altitude

Select mode provides a method for

selecting, capturing, and tracking

another altitude. ALT SEL requires a

compatible vertical mode to be used

to acquire the selected altitude.

Upon reaching the altitude capture

point, the selected vertical mode will

cancel and the flight director will

engage Altitude Capture and then

Altitude Hold. Altitude Select must be

deactivated to inhibit capture and

tracking of the preselected altitude.

If the value of selected altitude is

changed while in altitude capture, the

system reverts to pitch attitude hold

mode. In the event of sustained

invalid altitude, ALT SEL mode will

deactivate. To disengage Altitude

Select, press the SEL mode push-

button on the KAV 485. Detailed

operation of the KAV 485 is

described on page 34.

ALT HOLD (hold current reference

altitude)

The light above the ALT pushbut-

ton illuminates and “ALT” is dis-

played on the EADI in green when

the Altitude Hold mode is activated

by depressing the ALT pushbutton or

by automatic sequencing through

Altitude Arm and Altitude Capture.

In the Altitude Hold mode, the flight

director commands pitch attitudes for

tracking of the helicopter altitude at

the moment of mode selection. The

system normally uses barometrically

corrected altitude, but can use pres-

sure altitude in the event barometric

altitude is not available. Altitude Hold

can be entered directly or in conjunc-

tion with the Altitude Select mode.

Engaging Altitude Hold directly dur-

ing a climb or descent will cause the

aircraft to fly through the desired alti-

tude and then return to the desired

altitude from the other side. For this

reason, the vertical speed should be

limited to 500 fpm when this method

KMS 540 Vertical Mode Selection

0

2

3

4

5

6

7

8

9ALT

1,160

30.08 1,700

1

ı

ALT

ALERT

ALT

SEL

SEL

U

P

L

L

V

S

KAV 485 Altitude Select

ALT

Selected

Altitude

Display

17

of Attitude Hold engagement is used.

Selecting Altitude Hold after the

Altitude Select mode has been

engaged cancels Altitude Select

(white “ALT” on EADI). The flight

director will command the aircraft to

hold the altitude present at the

moment of mode selection.

Altitude Hold commands may be

modified by moving the CBT switch

forward (decrease reference altitude)

or rearward (increase reference alti-

tude).

A flashing lamp above the ALT

pushbutton indicates loss of a sensor

required to hold current reference

altitude (e.g. invalid altitude). The

flashing continues until a push of

the ALT pushbutton acknowledges

automatic deactivation of the mode.

The ALT pushbutton may also be

used to deactivate the altitude hold

mode.

IAS (hold current reference air-

speed)

The lamp above the IAS pushbutton

illuminates when the airspeed hold

mode is activated by depressing the

IAS pushbutton. Engaging the

Indicated Airspeed Hold Mode

causes the flight director to com-

mand pitch attitudes to maintain the

indicated airspeed current upon

selection. Airspeed commands may

be altered through use of the flight

director CBT switch.

OVERSPEED PROTECTION

A flashing IAS lamp indicates

loss of a sensor required to hold the

current reference airspeed (e.g.

invalid indicated airspeed). Flashing

continues until a second push of the

IAS pushbutton (pilot acknowledge-

ment of mode loss). The IAS push-

button may also be used to deacti-

vate the IAS hold mode. The

airspeed reference is provided by the

KDC 481T central air data computer.

As a safety feature, the flight

director automatically reverts to

Indicated Airspeed Hold and flashes

the IAS annunciator lamp (amber

“IAS” on EADI) whenever the heli-

copter exceeds a stored maximum

speed. Except in Altitude Hold and

altitude capture modes, the flight

director will command pitch attitudes

to reduce indicated airspeed to VNE

and then resume the previous pitch

mode.

VS (hold current or selected vertical

speed)

Depressing the ENG pushbutton on

the KAV 485 Altimeter/Vertical

Speed Indicator or on the KMS 540

Mode Select Panel activates the

flight director in Vertical Speed

mode. In Vertical Speed mode, the

flight director commands pitch atti-

tudes to maintain the vertical speed

selection displayed by the KAV 485

Altitude/Vertical Speed Indicator. In

IAS

VS

18

the absence of a preselected vertical

speed, engaging the mode will cause

the flight director to command a

climb or descent at the current heli-

copter vertical speed. In addition,

vertical speed commands may be

modified through use of the autopilot

CBT switch. The vertical speed

select (VS SEL) knob on the

Altimeter/Vertical Speed Indicator

changes selected vertical speed. The

small knob changes the vertical

speed 100 fpm per click and the

large knob 1000 fpm per click.

When VS mode is engaged or

the preselect function of the

Altimeter/Vertical Speed Indicator is

activated, an orange bug appears on

the vertical speed scale. The vertical

command switch or the VS SEL

knob on the KAV 485 repositions the

bug for reference for the pilot and

autopilot (the small knob must be

pulled out). A flashing VS Lamp on

the mode select panel above VS

indicates loss of a sensor required to

hold selected vertical speed (e.g.

invalid vertical speed). Flashing con-

tinues until the VS pushbutton is

pushed (pilot acknowledgement of

mode loss). The VS pushbutton may

also be used to deactivate the verti-

cal speed mode.

Note:

A flashing lamp may also be

extinguished by selecting another

mode of the same axis. Depressing

the pushbutton under the flashing

annunciation verifies the acceptance

of the default mode either wings level

or pitch attitude hold.

VS ALT

1000 FT/MIN

VS

2

3

21

1

.5

.5

0

UP

DN

IN HG HPa DEN ALT

SEL

VS

. ,

ENG SEL

BARO

U

P

S

H

E

T

S

T

SEL

U

P

L

L

V

S

3

KAV 485

Vertical Speed Select

Vertical Speed Bug

19

YD (yaw damper)

The lamp above the YD pushbutton

illuminates and a green “YD”

appears on the EADI when yaw

damp is engaged. The YD pushbut-

ton alternately engages and disen-

gages yaw damper functions inde-

pendently of autopilot operation. The

yaw damper will automatically

engage when the autopilot is

engaged. Autopilot disengagement

will NOT, however, disengage the

yaw damper. Yaw damper disen-

gagement is annunciated by a flash-

ing red “YD” on the EADI.

The yaw damper augments rotor-

craft stability by opposing uncom-

manded yaw motion, while also offer-

ing turn coordination and ball

centering. In case of hydraulic power

loss, consult the Rotorcraft Flight

Manual Supplement for the proce-

dures specified for yaw damper oper-

ation. Loss of #1 hydraulic system

automatically disconnects the YD.

AP (autopilot)

The lamp above the AP pushbutton

illuminates when the autopilot is

engaged. The AP pushbutton alter-

nately engages and disengages the

autopilot. Pressing the Autopilot

pushbutton initiates autopilot control

of the pitch, roll and yaw axes. The

yaw damper, if not previously

engaged, engages automatically

upon autopilot activation. In the

absence of any selected flight direc-

tor modes, the autopilot will follow

basic Roll Attitude Hold and Pitch

Attitude Hold commands synchro-

nized to the aircraft attitude current

upon activation.

KMS 540 Autopilot and Yaw Damper Mode Selection

AP

Autopilot pushbutton engages all

three axes with trim; pitch, roll, and

yaw.

Other manuals for Skymap IIIC

7

Table of contents

Other BENDIXKing Control System manuals

Popular Control System manuals by other brands

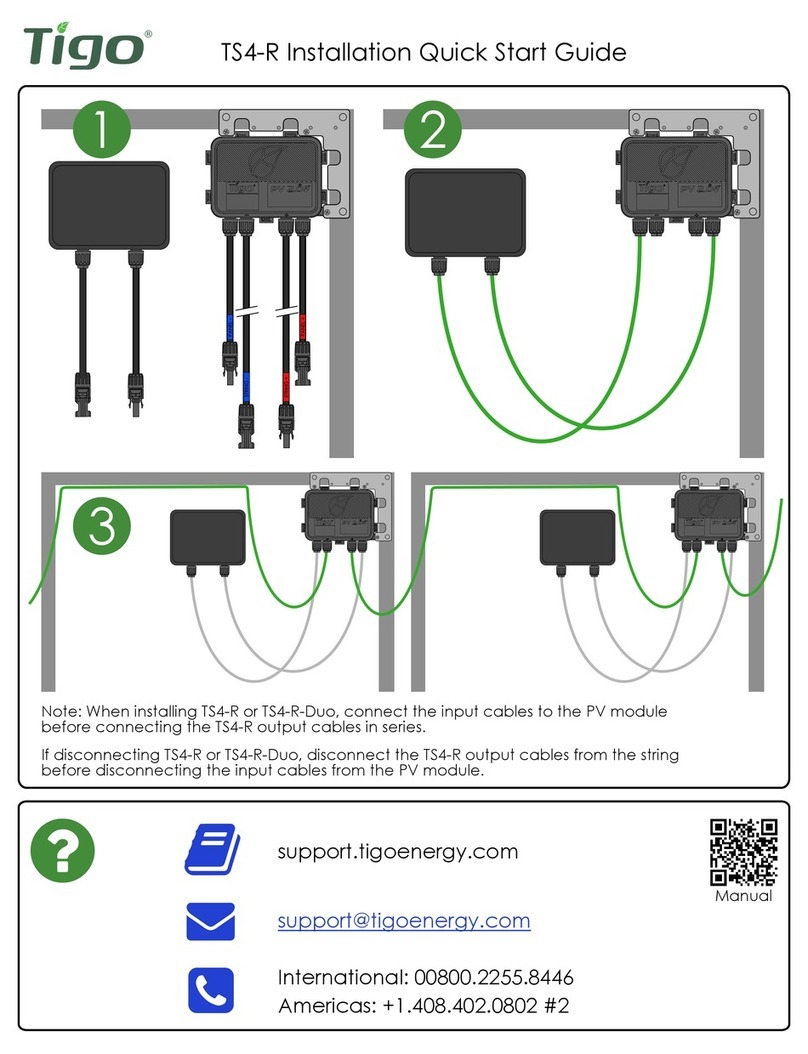

Tigo

Tigo TS4-R Installation & quick start guide

ero electronic

ero electronic ESR user manual

LEGRAND

LEGRAND Pass & Seymour Harmony De-Hummer installation instructions

Colorbeam

Colorbeam T021 user guide

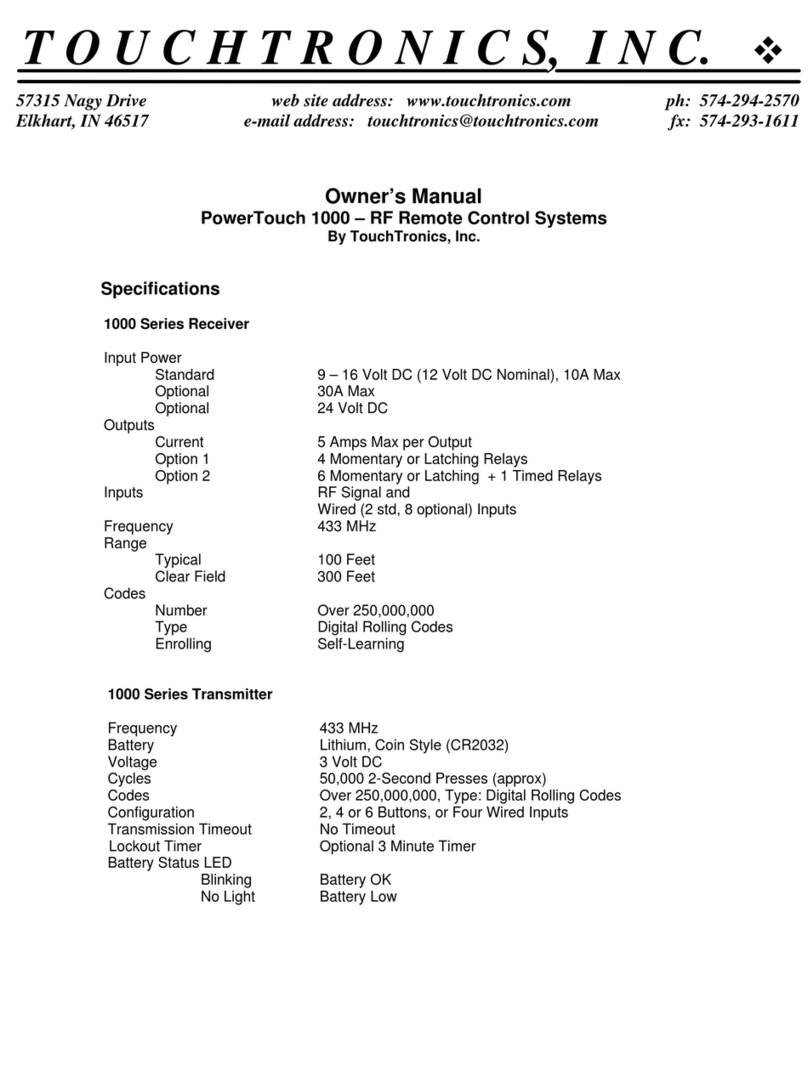

TouchTronics

TouchTronics PowerTouch 1000 owner's manual

Phason

Phason AutoSort Connect Installation and getting started guide