Î

isel- Ê«>VÌʵիiÌÊÊ*

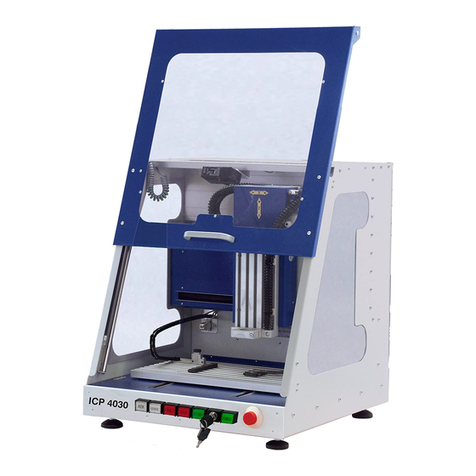

This manual includes the instructions for all machines of the ICP type.

The ICP is provided in three different system configurations. However, this listing also specifies

which part of the instructions is relevant for you. This applies also to the chapters.

£° /iÊ*Ê>ÃÊ>ÊV«iÌ]ÊÌÞ«iÊ£

The case is supplied including the driving axes, without electronics, without software,

without tooling machine. With this system configuration, you can employ and connect

your own controller electronics. A tooling machine is also freely selectable.

Ó° /iÊ*Ê>ÃÊ>Ê>Vi]ÊÌÞ«iÊÓ

In addition to type 1, this system configuration includes an Ãil controller for the linear

axes. It contains a safety circuit and some optional inputs/outputs (24 V and/or 230 V).

For this purpose, you receive the Ãil HPDOWN software and the I5DRV machine driver.

The tooling machine is freely selectable.

ΰ /iÊ*Ê>ÃÊ>ÊV«>VÌÊiµÕ«iÌ]ÊÌÞ«iÊÎ

The complete installation (mechanics, electronics, tooling machine and software

(ISY-CAM + REMOTE, I5DRV)) is immediately ready after commissioning.

At every expansion level, the ICP is a compact machine that offers an abundance of

possibilities for processing work pieces.

As a prerequisite for your work with the ICP and depending on the implementation, you

require basic knowledge in CNC engineering and PC application, a computer, a mains

socket, and some creativity.

*i>Ãi]ÊVÃ`iÀÊÌiÃiÊÃÀÌÊÃÌÀÕVÌÃÊÌ

• properly commission the equipment,

• fast, safely, and effectively work,

• keep away dangers of persons,

• and thus exploit the full potential.

To get acquainted to work with this machine, we recommend that you carry out the

processing example which is appended to these instructions (for the ICP with the HPDOWN,

REMOTE, and/or ISY software).

We wish you a lot of success. Enjoy your future working with the ICP.